enmco PT16FM User manual

Operating Instruction

Self Powered Digital Tach / Maintenance / Hour Meter

Please read and understand the following notices carefully, and correctly install and operate the product before using.

①

①

③

Product Accessories List

----------------------------------------------------

----------------------------------------------------

----------------------------------------------------

----------------------------------------------------

----------------------------------------------------

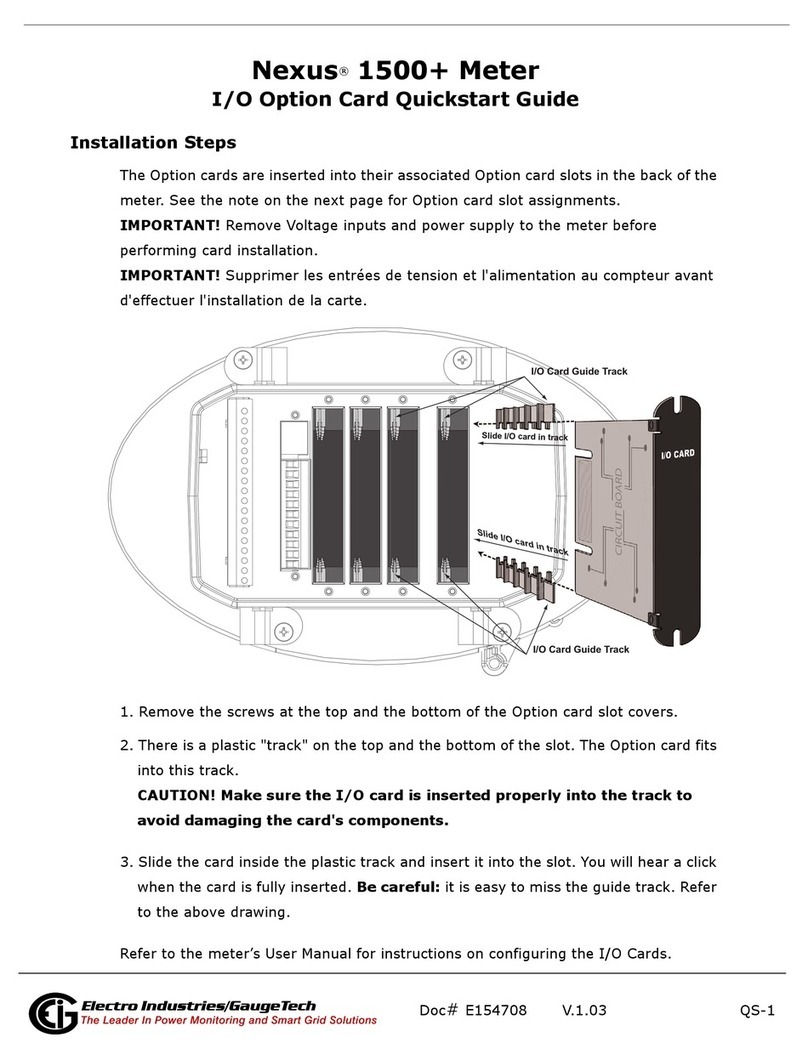

Product Installation

Product Operation

Specifications

Dimension

⑨

⑩

1. Please make sure to refer to the installation instructions in the

operating instructions to avoid damage caused by installation errors.

2. The product included the battery inside and can not be replaced,

do not disassemble or replace the battery by yourself.

3. Do not pull the wiring when using it to prevent falling off or poor

contact happened.

4. Please install the product in a proper location to avoid the

possibility of this product being hit and prevent damage to the

product.

5. The product has certain waterproof function, but can not be used in

deep water or soaked in rain for a long time.

6. Please use the product at the specified temperature, high

temperature environment may cause damage to the product.

This product can be directly installed with double-sided tape or screwed, the

installation method is as follows:

a) Clean properly the surfaces.

Note: Make sure the surface is flat and the oil

is clean enough.

b) Stick the double-sided tape on the back of

the product.

Note: Before pasting the double-sided tape,

please make sure the back of the product is

clean and tidy, without moisture or grease.

c) Remove protection from double-sided tape.

Note: When removing the double-sided tape

protector, make sure that the double-sided

tape is not exposed to water or oil on both

sides.

d) Fix the tach hour meter in a proper position.

Note: Before pasting the double-sided tape,

please confirm that the pasted place is clean

and tidy, no moisture or oil.

Product Accessories List

Product Installation

1. Double-sided tape installation:

Proper position requirement: No moisture, no grease, is a plane, no violent

vibration, and the temperature not exceed 125 F.

①

product*1

1double-sided tape*1

2paper card*1

3

user manual*1

4cable tie*2

5

The test after the connection: Start the engine, the LCD of the tach

hour meter displayed the RPM and timing, which means the connection is

correct. If the RPM is inaccurate, please refer to clause A to adjust the turns

of the winding, or set the type of the engine (more information will be provided

in the following instructions).

C

b) Choose a location where the pick-up wire (included) will reach the meter

to the spark plug.

c) Install with screws as the below diagram.

a) The design allows for either a flush panel mount or surface mount.

Red signal wire connection: Wrap the red signal wire around the spark

plug, wrap it 4 to 5 turns, and fasten it with a cable tie to ensure it is effectively

fixed and will not loosen. (If the connection is not strong, the tachometer will

get insufficient signal, then the RPM and hour values will be inaccurate.)

a) For traditional ignition modes, wrap red signal wire 4 to 5 turns tightly

around the engine spark plug wire.

b) For "pencil coil" ignition, wrap red signal wire around the plastic coil above the

spark plug.

c) The spark plug signal generated by different engine types has the difference of

strength and weakness. By adjusting the turns of winding, the appropriate adjustment

can be made to improve the accuracy of the RPM and timing data. This is a skill that

different degree spark plug signal that allows the induction wire to acquire.

2. Screw installation:

3. Signal wire installation.

Note: Proper position requirement: no moisture, no grease, is a plane, no

violent vibration, and the temperature not exceed 125 F. Do not drill into gas

tank, engine crankcase or oil reservoir frames.

Under normal condition, if the RPM is a little low, you can

increase the winding turns, if the RPM is a little high, you can

reduce the winding turns. For example, wrap 6-10 turns, if the

RPM is a little high, you can reduce the winding turns. For

example, wrap 2-4 turns, if the RPM is a little low, you can

increase the winding turns.

Connect the black shielded wire’s terminal to

the ground, the connection place can be the

metal casing, frame, ground or chassis of the

engine.

②

4 stroke installation, wrap pickup wire

around head of coil.

2 stroke installantion, wrap pickup wire

around spark plug lead.

panel mountsurface mount

A

Black signal wire connection: The black wire is the ground wire,

which helps the meter to obtain a stable RPM.

B

1. Product operating

system introduction

2. Selection of product system.

③

Product Operation

a) In order to meet the usage

habits of different users, the

program of this product has 2

sets of use systems (just like

after the WINDOWS system

can be used on the apple

computer, the user can switch

to use the WINDOWS system

and the IOS system),

respectively, DSP-1 and DSP-

2, the default system of the

product is DSP-1.

a) Push "MEUN" button continuously until display the "TOT" (interface).

b) Press and hold "SET" button continuously until display the "DSP-1"

or "DSP-2" icon, release the "SET" button, and it will automatic return to

"TOT" interface, and you have selected the system needed in this way.

(Note: "DSP-1" and "DSP-2" is cyclely selection.)

b) The difference between

DSP-1 and DSP-2 is that the

display mode is different. All

functions of DSP-1 are

directly displayed, while the

function of DSP-2

distinguishes between time

module and RPM module.

These two modules can be

called separately for display.

The functions of DSP-1 and DSP-2 are shown as the following diagram:

DSP-1 DSP-2

Press and hold

3. The function and operation under the DSP-1 system

④

Engine

firing

patterns

1P1R

1P2R

2P1R

3P1R

3P2R

4P1R

5P2R

6P1R

8P1R

4 stroke 2 cylinder

4 stroke 1 cylinder

4 stroke 4 cylinder

2 stroke 2 cylinder

4 stroke 6 cylinder

2 stroke 3 cylinder

4 stroke 3 cylinder

4 stroke 8 cylinder 4 spark per revolution

5 spark 2 revolution

8 spark per revolution

6 spark

per revolution

4 stroke 5 cylinder

4 stroke 12 cylinder

2 stroke 6 cylinder

4 stroke 16 cylinder

1 spark

per revolution

1 spark 2 revolution

2 spark

per revolution

3 spark

per revolution

3 spark 2 revolution

25000

25000

12500

8000

16000

6250

10000

4000

3125

2 stroke 1 cylinder

Engine type RPM

Capacity

Spark plug

firing and engine

rotate laps

RPM

---- Typical RPM display during operation of the engine

Programmable firing patterns

---- Determined the amount

of pluses(sparks) per engine revolution.

a) When the tach hour meter detect the engine spark plug signal for

more than 1s continuously, the LCD will display the current RPM of

the engine.

b) The RPM will be refreshed every 0.5s.

c) The RPM can be programmed for different pulses per revolution;

Different programming setting will get different RPM; Please follow

the instructions in section 2 below to programming setting for

accurate programming.

This product provides 9 programmable firing patterns, which can be

selected according to the corresponding relationship in the table below.

Note: Some 4 stroke 1 cylinder engine is 1P1R, the setting is the same

way as the 2 stroke 1 cylinder engine.

1

2

DSP-1 to DSP-2

Press and hold

⑤

a) Press the "MENU"button 5 times until display shows "1P1r"icon.

(The factory default setting is "1P1r", if it has been set before, the firing

pattern will be displayed the one that set before) a)

To view MAX RPM:

Press the "MENU"

button for 4 times until display shows the

"MAX RPM".

Programming alert RPM :

b)

To reset MAX RPM:

Press and hold the

"SET" button until display shows RPM

"000000" start flashing, MAX RPM is reset.

When the RPM of the engine during the operation exceeds the set

value, the meter will flash to remind.

b) Press and hold the "SET" button until display shows "1P1r" icon start

flashing, release and press "SET" button or "MENU" button to toggle

through all engine firing patterns setting.

a) Press the "MENU" button for 3 times until display shows "RPM" icon

and alert RPM numerical value.

c) Stop at correct firing pattern setting for your engine.

d) Wait for 10 seconds and display will return to "TOT" total hours.

(Tachometer is now ready to use)

Note:

If the obtained RPM is not accurate, for example, the RPM is half

of the actual RPM, you can adjust it by programming the firing patterns.

To set the tachometer. (Spark plug firing revolution) MAX RPM---- Display the maximum RPM recorded during the

last period of operation.

Alert RPM ---- The setting value of the warning reminder.

Press the button

5 times Press the button

4 times

Press and hold

the button for 2S

Press and hold

the button for 2S

3 4

5

⑥

TOT---- Total hours of operation.

JOB---- Hours of operation since the timer was reset.

b) Press and hold the "SET" button until

display shows "RPM" icon and alert RPM

numerical value starts flashing.

c) Press "SET" or "MENU" button until you

get desired alert RPM numerical value,

release the button, the LCD will flash for 10

seconds and return to "TOT" (total hours).

d) If the alert RPM numerical value is set to

OFF, which means that the alert RPM

function is closed.

a) This is always displayed when engine is off. (DSP-1 SYSTEM)

To view "JOB" time:

Press the "MENU"

button once.

To reset "JOB" time:

Press and hold the

"SET" button until display shows "0000:00"

starts flashing, then release the "SET" button,

the "JOB" display will reset to "0:00", and you

will begin to record the next job interval.

b) Total hours can not reset.

c) The total hours max value is 999999; When the total hours range is

0.0-9999hours59min, the timing accuracy is 1min; When the total hours

range is 9999hours59min-99999.9hours, the timing accuracy is 0.1H;

When the total hours exceeds 99999.9hours, the timing accuracy is 1H.

d) When the total hours exceeds 999999hours, the timing will restart from

0.

Press the button

3 times

Press the button

once

Press and hold

the button for 2S

Press and hold

the button for 2S

(1234Hours 56Minutes)

6

7

⑦

When the maintenance interval time is

reached, and the LCD display will flashing,

and press the "SET" or "MENU" button to

clear the status, the next maintenance

interval time starts timing.

a) Press the "MENU" button twice until display shows "SVC" icon and

maintenance interval time.

The selection of the hours mode and RPM mode.

b) At the hours mode interface, press and hold the "MENU" button until

display the icon "RPM" and "0" on the screen, which means enter into the

RPM mode; Similarly, at the RPM mode interface, press and hold the

"MENU" button to enter into the hours mode.

a) When entering the DSP-2 system, the first entry is the hours mode.

a) Hours mode contains TOT function, JOB function, SVC function

b) The use and settings of the TOT function, JOB function, and SVC

function are the same as described in DSP-1.

b) Press and hold the "SET" button until display shows "SVC" icon and

maintenance interval time starts flashing.

c) Press "SET" or "MENU" button until you get desired hours, release

the button, the LCD will flash for 10 seconds and return to "TOT" (total

hours).

d) When the maintenance interval time is reached 0, the "SVC" icon will

flash. The SVC time setting range is 0-2000H. If the SVC is set to OFF,

which means the SVC function is closed.

Programming SVC time:

SVC ---- Maintenance interval time. Note: Timing is countdown. 4. The function and operation under the DSP-2 system.

1

The function circulation of the hours mode.

2

Press the button

twice

Press and hold

the button for 2S

Press and hold

the button

8

⑧

a) Press the "MENU" button and the "SET" button at the same time until

the "OFF" icon displayed on the screen, then release the button and the

LCD display will shut down automatically.

b) Once detect the continuous engine signals within 8 seconds,or press

the "MENU" or "SET" button again, the LCD screen will be displayed.

c) When LCD screen is closed, the historical data will be retained and

will not be cleared.

5. Other

To shut down LCD display.

1

a) RPM mode contains RPM function, alert RPM function, MAX RPM

function, firing patterns choice.

b) The usage and setting of the RPM function, alert RPM function, MAX

RPM function, and firing patterns choice is the same way as described

in DSP-1.

The function circulation of the RPM mode.

3

+

Table of contents

Popular Measuring Instrument manuals by other brands

Dranetz

Dranetz ENCORE Series installation guide

Thermo Scientific

Thermo Scientific EUTECH INSTRUMENTS OAKTON 450 Series Operation instructions

ACD

ACD Cal 2000 instruction manual

Watanbe

Watanbe A5000 Series instruction manual

KVANT

KVANT Atom Series Operational manual

Argo-Hytos

Argo-Hytos OPCom operating manual

MEYTEC

MEYTEC GT-200S manual

Parker Pneumatic

Parker Pneumatic MPS-9 Series Installation & service instructions

Electro Industries/GaugeTech

Electro Industries/GaugeTech Shark 100T quick start guide

SIXTOL

SIXTOL SX3002 Instructions for use

ELKHART BRASS

ELKHART BRASS Scorpion RF 8294-07 Installation, operating, & maintenance instructions

Center

Center 321 instruction manual