Enotec ENSITU 7000 User manual

Doc.-ID: ENS_13062019-EN

Installation and Operation Manual

O

2

Transmitter Probe

ENSITU

®

7000

Version 04

Doc.-ID: ENS_13062019-EN

Preface

Dear Customer,

Thank you for selecting ENSITU®7000 as your InSitu flue gas oxygen analyzer.

Since 1980 our analyzer systems have been operating in numerous applications with tens of thousands

of units being produced and shipped worldwide. ENOTEC is committed to absolute quality and

performance and over time we have continuously enhanced our products to integrate various features

and functions.

ENOTEC probes include the zirconium oxide sensor which has a gas-tight seal made by using a special

process and technique developed by ENOTEC. This leads to a considerably increased service life

compared to "glued or cemented" sensors that have a tendency to leak or crack during operation.

All ENOTEC instruments are thoroughly tested in the factory and are subject to a strict ISO9001 Quality

Assurance Procedure. Therefore, with the correct installation, the operation of the ENSITU®7000 is very

straightforward and user friendly and will provide many years of trouble free operation with perfect

measuring results.

Symbols used in this Manual

Warning

Follow all instructions in the manual

Consider Information

Points out important information which

must be considered before execution

Warning hot surface

Warns of danger of burns which could

occur from hot system parts

Note

Contains further detailed information

Attention

Warns of risks by destroying the system

or its components or its functionality

Ground earth electrical protection

The contents of this manual are protected by copyright. Alterations and errors reserved.

Safety Instruction

After removal of terminal covers some parts of this system may be accessible which are under voltage.

Only well trained and authorized personnel are allowed to work on this system. The personnel must

know and understand all precautions, safety, installation and maintenance instructions of this manual.

The trouble free and safe operation of the ENSITU®7000 requires safe transportation, professional

storage, installation, operation and maintenance.

Furthermore all local safety and legal requirements at the point of installation and operation must be

considered.

The ENSITU®7000 may not be used to measure oxygen in combustible gases or in an environment

with combustible gases as the heated sensor may cause an explosion risk.

Installation and Operation Manual - ENSITU®7000 Table of Contents

Doc.-ID: ENS_13062019-EN 1

Table of Contents

1System Description 2

1.1System Overview ................................. 2

1.2Measuring Principle.............................. 4

1.3Intended use......................................... 4

1.4Safety Hazards..................................... 4

1.5Disruption of the Process ..................... 5

1.6Storage instructions.............................. 5

1.7Name Plates......................................... 5

2Installation 6

2.1Installation of the probe ........................ 6

2.2Adjusting the V-shield........................... 7

2.3Mounting of the Probe .......................... 7

2.4Connection of the probe plug for

detached electronics ............................ 8

2.5Access to the Terminals ....................... 8

2.6Wiring Diagram of the Electronic Unit .. 9

2.7Test gas connection / reference air ports

........................................................... 10

3Software and Analyzer Control 11

3.1Installation of the ENOTEC Remote App

........................................................... 11

3.2Establish a connection ....................... 12

3.2.1Search for available analyzers ........... 12

3.2.2Pair with the Analyzer......................... 12

3.2.3Connect with the ENSITU 7000®

Analyzer ............................................. 13

3.2.4Enter the Pin Code ............................. 14

3.3Screen Overview ................................ 14

3.4Change access level .......................... 15

3.5Save and Share System Protocols..... 15

3.6O2Sensor Calibration......................... 16

4Initial Operation 17

4.1Checklist before start-up of the Analyzer

........................................................... 17

4.2System power up................................ 17

4.3Display and LEDs............................... 17

5Service and Maintenance 18

5.1Preparation of the test gas tubing ...... 18

5.2Connect the test gas tube .................. 18

5.3Test air / test gas supply to the probe for

calibration ........................................... 18

5.3.1Test air supply with pump................... 18

5.3.2Test air supply with instrument air...... 19

5.3.3Test gas / Test air supply (certified test

gas) .................................................... 19

5.4Exchange fuses...................................19

5.5Exchange of the probe inner part........20

5.6Replacing the Filter .............................21

5.6.1Remove the old Filter ..........................21

5.6.2Cement in the new Filter .....................21

6Error Codes 22

7Troubleshooting 24

ATechnical Specifications 25

A.1Technical specifications - KES-700X .25

A.2Technical Specifications - Electronics

unit ......................................................26

A.3Technical Specifications - General.....26

A.4Technical Specifications......................27

BDimensional Drawings 28

B.1Dimensional drawings of the KES-700X

probes .................................................28

B.2Counter flange ADP-7000 ...................29

B.3KES-700X Probe inner parts...............30

CSpare Parts 31

C.1Probe components ..............................31

DWarranty 32

Index 33

System Description

Installation and Operation Manual - ENSITU®7000

2 Doc.-ID: ENS_13062019-EN

1 System Description

1.1 System Overview

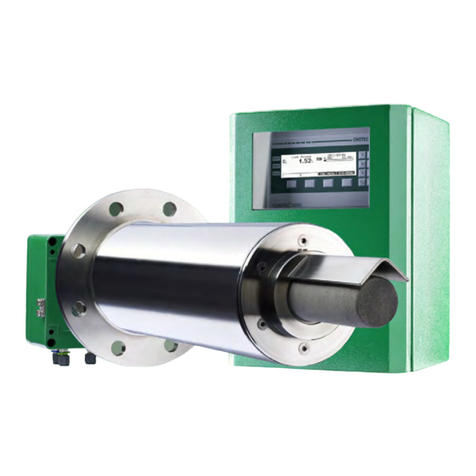

Figure 1 – ENSITU®7000 transmitter probe

Electronic unit Safe Area

Max. ambient temp.: -40 °C to +70 °C (-40 °F to +158 °F)

InSitu measuring probe Duct / combustion chamber

Probe flange Flue gas direction

Max. process gas temp: 600 °C (1112 °F)

Counter flange (Optional)

Isolation Customer supply

Manufacturer supply

Duct wall Customer supply

Power supply 48V DC , 5A max.-

Optional: Power adapter from ENOTEC

Max. cable length, 50 m

Input and output signals (analog and digital)

Test air / test gas in

Installation and Operation Manual - ENSITU®7000

System Description

Doc.-ID: ENS_13062019-EN 3

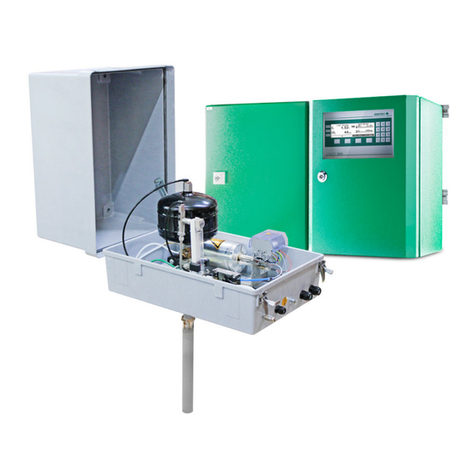

Figure 2 – ENSITU®7000 transmitter probe - electronics detached

Electronic unit - detached Safe Area

Max. ambient temp.: -40 °C to +70 °C (-40 °F to +158 °F)

InSitu measuring probe Safe Area

Max. ambient temp.: -40 °C to +80 °C (-40 °F to +176 °F)

Probe flange Duct / combustion chamber

Counter flange (Optional)

Isolation Customer supply

Flue gas direction

Max. process gas temp: 600 °C (1112 °F)

Duct wall Manufacturer supply

Cable with plug. Max. cable

length + = 50 m

Customer supply

Power supply 48V DC, 5A max.

Optional: Power adapter from ENOTEC

Max. cable length + = 50 m

Input and output signals (analog and digital)

Test air / test gas in

System Description

Installation and Operation Manual - ENSITU®7000

4 Doc.-ID: ENS_13062019-EN

1.2 Measuring Principle

The ENSITU®7000 O2probe is installed in a duct to measure O2in non-combustible process

gases and is coupled with an electronic unit for voltage and signal processing.

The oxygen sensor is at the tip of the probe and is regulated to 800 °C and works on the

zirconium oxide principle of measurement. Here, a mV signal between the reference gas side of

the sensor (inside, 20.95 % O2dry) and the measured gas side is measured, which depends

logarithmically on the ratio of oxygen partial pressures on both sides of the sensor.

The mV signal is converted according to the Nernst equation into oxygen partial pressure within

the process gas, whereby the O2concentration is determined in the process gas. Gas-tight

separation of reference air and process gas is of particular importance.

Should combustible components such as CO or H2be present in the sample gas, they will react

with oxygen at the sensor surface and can reduce the measured value.

1.3 Intended use

Info

The ENSITU®7000 analyzer system is a system for measuring the oxygen concentration in flue

gases and other non-combustible gases. For reasons of safety and the possibility of accidents,

unauthorized conversions and modifications of the system are prohibited.

Warning

The system cannot be used to determine the oxygen concentration of combustible gases or in a

location where combustible gases are present as the sensor temperature of 800 °C could

present an explosion hazard!

Info

The minimum concentration of O2 in flue gas should under normal process conditions, not be

less than 0.5 %.

Caution

Under no circumstance should the measuring probe be directly connected to the 230 V / 115 V

main power supply as this will immediately destroy the probe heater element!

1.4 Safety Hazards

Warning hot surface

During operation, the temperature of the probe filter head and of other parts exposed to flue gas

is up to 800 °C (1472 °F). Direct contact with the hot parts when dismantling or maintenance will

cause severe burns!

The probe may only be removed with heat-insulated gloves. Before removing the probe, always

switch off the supply voltage. After removal, store the probe in a safe, protected place and wait

until it has cooled down below 35° C (95° F).

Installation and Operation Manual - ENSITU®7000

System Description

Doc.-ID: ENS_13062019-EN 5

1.5 Disruption of the Process

The analyzer system has to be kept in operation also in the event of the process being

disrupted or if the plant is powered off temporarily (e.g. at night or during the weekend).

Frequently cooling down and heating up of the probe results in thermal stress of the hot probe

parts (heater, thermocouple and sensor) and reduces their product life. ENOTEC will not accept

any responsibility for resultant damage.

1.6 Storage instructions

ENOTEC equipment and spares are to be stored in a dry and ventilated environment. Paint

fumes, silicone sprays, etc. must be avoided in the storage environment.

1.7 Name Plates

The name plate contains information about the voltage, the nominated current, frequency,

protection class and serial number. The serial number refers to information which is detailed in

the system test report and supplied with the system.

Electronics name plate Probe name plate

Figure 3 – Position of the name plates

Installation

Installation and Operation Manual - ENSITU®7000

6 Doc.-ID: ENS_13062019-EN

2 Installation

Warning

The system is not equipped with an external power-off switch. The line voltage

switch/fuse/breaker must be installed and be in accordance with local technical standards and

should be near to the electronic unit and must be clearly marked as such. Before removal of the

electronic terminal cover the line voltage must be switched off. The line voltage to the electronic

unit must be switched on again after the cover is back in position. After installation power

conducting parts may not be accessible.

2.1 Installation of the probe

The flue gas temperature, pressure and all other process conditions must be in accordance with

the specification. Leave enough space for insertion/removal of the probe.

Before cutting a hole in the flue gas duct, make sure that the inside of the duct has enough

space for probe installation and that no fly ash is blown out nearby or any obstacles are in the

way.

ENOTEC recommends installing the probe horizontally (-3 ° to - 5 °) for fastest possible

response times.

Transmitter probe

Maintain ambient and process temperature

limits.

Probe with detached electronics

Maintain ambient and process temperature limits

Maintain the protection class

Avoid vibrations > 2g

Installation and Operation Manual - ENSITU®7000

Installation

Doc.-ID: ENS_13062019-EN 7

2.2 Adjusting the V-shield

The filter head is 360° rotatable and must be adjusted so that the filter abrasion shield faces the

oncoming flue gas.

Before installing the probe, the direction of flue gas flow must be determined and the filter

head assembly turned to such a position that the V-shield faces the oncoming flue gas. Loosen

the counter nut , loosen the screw and rotating the filter head / abrasion shield to the

required position, tighten the screw and counter nut.

Flue gas direction

Abrasion shield

Filter

Filter head

Screw

Counter nut

Flange

Test gas connection

Electronic unit

Figure 4 - Adjustment of the

abrasion shield

2.3 Mounting of the Probe

Insulation (customer supply)

Counter flange

(optional ENOTEC supply)

Flange gasket

Bolts

Electronic unit

Figure 5 - Mounting of the Probe – for dimensions, see chapter B.

Installation

Installation and Operation Manual - ENSITU®7000

8 Doc.-ID: ENS_13062019-EN

2.4 Connection of the probe plug for detached electronics

Contact Polarity Description

1, 2 + Probe heater

3

+ Probe data board

4

+ Thermocouple

5

+ O2sensor

6, 7

-

Probe heater

8

-

Probe data board

9

-

Thermocouple

10

-

O

2sensor

Figure 6 - Probe plug connection for detached electronics.

See Figure 2 for configuration and chapter 0 for cable specifications.

2.5 Access to the Terminals

Warning

Power supply lines are to be connected / disconnected only in a de-energized state as not to

risk a short circuit.

Remove the 2 clips at the sides of

the terminal box,

loosen the 4 captive screws ,

open the constrained terminal box lid

from the top .

Figure 7 - Access to the Terminals

Warning

Tighten the screws for the terminal box lid with a torque of 3 Nm.

Installation and Operation Manual - ENSITU®7000

Installation

Doc.-ID: ENS_13062019-EN 9

2.6 Wiring Diagram of the Electronic Unit

Figure 8 - Wiring diagram of the

ENSITU®7000

Electronic Unit

+

48 V DC 5A Power supply

-

1 + 4-20 mA Sink

O2analog output2

-

+ 4-20 mA Source

3 -

4 +

24V DC = Active O2zero point calibration

5 -

6 Shield

7 Reserved

8 Reserved

9 Reserved

10 Shield

Installation

Installation and Operation Manual - ENSITU®7000

10 Doc.-ID: ENS_13062019-EN

2.7 Test gas connection / reference air ports

Figure 9 - Overview of test gas connection / reference air ports

Test gas

connection

The test gas connection is equipped with a check valve with

1/4" parker connection for 1 or 2-point calibration purposes.

See chapter 3.6 for the calibration procedure.

If instrument air is available, it should be used for 1-point calibration

purposes:

Test air / test gas flow rate, 150 – 180 l/h

Reference air in /

Reference air out

The reference air ports allow for sufficient supply of ambient air as

reference air to the reference side of the sensor. The ports are

equipped with screw-in aeration membranes to prevent the ingress of

water or dust.

Alternatively, should the ambient air be contaminated with exhaust

fumes or have a high humidity which could influence the O2

measurement, one of the ports can be used for the connection of

instrument air (according to ISO 8573-1 class 2) as reference air (in

this case instrument air should also be used as test air).

The second unused port acts as reference air outlet.

The following must be noted in this case:

The screw-in aeration membrane must be removed from the

port where the instrument air is connected.

Instrument air flow rate, 15 - 20 l/h

Installation and Operation Manual - ENSITU®7000

Software and Analyzer Control

Doc.-ID: ENS_13062019-EN 11

3 Software and Analyzer Control

Info

ENSITU®7000 has no interface to interact with and can be controlled via smartphone or tablet

running the Android operating system over a Bluetooth connection using the ENOTEC Remote

app.

The interface language of the app will be the system language on the Android smart device.

Available languages are English, German and Spanish.

3.1 Installation of the ENOTEC Remote App

Download and install the ENOTEC Remote app, which is

available free of charge on the Google Play Store.

The app requires an Android smart device (Smartphone / Tablet)

with software version 4.1.2 or higher and Bluetooth.

Software and Analyzer Control

Installation and Operation Manual - ENSITU®7000

12 Doc.-ID: ENS_13062019-EN

3.2 Establish a connection

3.2.1 Search for available analyzers

In connection distance to the ENSITU analyzer, start the

ENOTEC Remote app and search for available

analyzers.

Figure 10 – Search for available analyzers

3.2.2 Pair with the Analyzer

The ENSITU®7000 analyzer will appear in the list of

Bluetooth enabled devices on your smart device. Tap on

the analyzer name.

The blue LED of the analyzer will now blink.

Tap the back arrow to return to the ENOTEC Remote

app.

Should the ENSITU®7000 analyzer not appear in the list,

check the following:

Is the analyzer switched on?

Are analyzer and smart device in connection distance

to eachother?

Figure 11 – Pair with the ENSITU 7000®

Installation and Operation Manual - ENSITU®7000

Software and Analyzer Control

Doc.-ID: ENS_13062019-EN 13

3.2.3 Connect with the ENSITU 7000®Analyzer

List of paired analyzers - tap to control this

analyzer.

FAQ and troubleshooting.

Cloud and other settings.

Cloud storage is not hosted by ENOTEC GmbH.

Users of the ENOTEC Remote app can find help

for the standalone setup of the cloud at

http://www.owncloud.org.

QR code reader to transfer sensor parameters to

the analyzer.

Search for Bluetooth enabled ENOTEC analyzers.

Lists the system protocols stored on the smart

device.

Figure 12 - Connect with the ENSITU®7000

The ENSITU®7000 analyzer is now paired with the smart device and will remain in the paired

analyzers list. Tap the analyzer which is to be controlled.

The analyzer name is freely changeable in the settings menu. It is recommended to give the

analyzer an individual name (e.g TAG Nr.).

Software and Analyzer Control

Installation and Operation Manual - ENSITU®7000

14 Doc.-ID: ENS_13062019-EN

3.2.4 Enter the Pin Code

Enter the pin code. Default at delivery is 0000 0000.

Once a connection has been established between the

smart device and ENSITU®7000 the blue REMOTE LED

will remain lit.

Should the pin be unknown, the mainboard serial number

can also be used as pin. Open the terminal box lid as

described in chapter 2.5 to reveal the mainboard serial

number.

For security reasons, the authentication pin must be

changed to a more secure pin in the analyzer settings.

Figure 13 – Enter the authentication pin code

3.3 Screen Overview

Figure 14 - Screen Overview

Displays the currently measured O2value.

Detailed measured values.

Current screen – overview of measured values.

Displays previous calibration results (last 20).

Swipe left or right to display individual calibrations.

Displays detailed analyzer information.

ENSITU®7000 settings.

Check the mA output using a current measuring

instrument such as a multimeter (System access).

Calibrate the O2sensor – see chapter 3.6.

Save all analyzer information on the smart device

or in a private cloud, send the file electronically.

Service menu (hidden in normal state, contact

ENOTEC).

Disconnect from the analyzer.

Appears when a warning occurs. Tap for details.

Appears when an error occurs. Tap for details.

Change access levels. See chapter 3.4.

Displays the connection quality to the analyzer.

The lower the value the better.

Installation and Operation Manual - ENSITU®7000

Software and Analyzer Control

Doc.-ID: ENS_13062019-EN 15

3.4 Change access level

To protect the analyzer from unauthorized usage,

certain functions are secured by access levels.

Tap the lock to choose the required access level

"Public" access level is set by default; no changes to

analyzer parameters are possible.

The default PIN code for “System” access level is 0000

which will allow access to all standard analyzer

functions such as configuration of the measuring range

or calibration.

Figure 15 – Change access level

3.5 Save and Share System Protocols

Info

The ENOTEC Remote app can save all relevant analyzer and process information to an HTML

file. This file can be saved locally or be sent to an ENOTEC service point for analysis.

Enter the „Archive“ menu.

Tap “CREATE SYSTEM PROTOCOL” and

choose to save the protocol locally or save and

send it electronically (internet connection

necessary).

Cloud storage is also possible, see chapter 3.2.3.

Storage location on smart device.

List of saved system protocols, tap to open.

Figure 16 – System protocols

Software and Analyzer Control

Installation and Operation Manual - ENSITU®7000

16 Doc.-ID: ENS_13062019-EN

3.6 O

2

Sensor Calibration

Info

To achieve a higher accuracy, a calibration can be carried out. An O2sensor calibration can be

started as soon as high gas (e.g. instrument air or ambient air, 20.95 vol. % O2) or low gas

(certified bottled test gas, e.g. 2.1 vol. % O2) is applied to the test gas port at a flow rate of 150 –

180 l/h. See chapter 5.3 for additional information.

The difference between high and low test gas O2concentration must be at least 5.00 %.

The minimum O2concentration of the low test gas is 0.20 %.

A 1-point calibration always takes place if the analyzer cannot determine a previous valid

calibration value as reference value. A 1-point calibration can be carried out with high or low test

air or test gas. The sensor offset is adjusted by a 1-point calibration and will adjust the

parameter "O2sensor offset".

A 2-point calibration is carried out when the complementary gas of the previous calibration is

applied and must take place within two hours to the previous calibration.

The 2-point calibration will adjust the parameters "O2sensor offset" and "O2sensor slope”.

Figure 17 – O2sensor calibration

Once test air / test gas has been applied to the probe test gas port, initiate the calibration by

tapping the Cal. button . Sensor signal stability must be reached before the calibration

can take place. The stability progression is depicted with the orange circle . Once the sensor

signal is stable, “ACCEPT MEASURED VALUE” will appear and must be confirmed.

The calibration progression bar becomes green as soon as sensor stability is reached.

Follow the onscreen instructions carefully to complete the calibration.

Installation and Operation Manual - ENSITU®7000

Initial Operation

Doc.-ID: ENS_13062019-EN 17

4 Initial Operation

4.1 Checklist before start-up of the Analyzer

Make sure that there are no leakages at the probe - e.g. is the counter flange welded gas tight

to the duct and are the flange bolts tightened sufficiently? Are new gaskets in use? Are the

cable glands tightened sufficiently

See section 2.3 - Mounting of the Probe.

Do the conditions at site match the specification in the data sheets?

See section A - Technical Data.

4.2 System power up

Switch on the power supply to the analyzer. The sensor heating phase will start immediately

which is followed by measuring mode.

4.3 Display and LEDs

Figure 18 – ENSITU®7000 display with LEDs

Display

Measured O2value

(or) sensor heating phase

(or) error code

Green

LED

Blinks during heating phase.

Lit when measurement is valid

Blue

LED

Lit when an ENOTEC Remote

connection is active

Red

LED

Lit when an error has occurred

and the error has not been

rectified

Blinks when an error has

occurred, has been rectified

but not acknowledged

Measuring mode showing the currently measured O2 value

Upper row/O2value (blinking alternately) – O2over range

Lower row/O2value (blinking alternately) – O2under range

Sensor heating phase (°C)

Error code – See chapter 6

Figure 19 – ENSITU®7000 display

Service and Maintenance

Installation and Operation Manual - ENSITU®7000

18 Doc.-ID: ENS_13062019-EN

5 Service and Maintenance

Warning Hot Surface

The probe may only be removed with heat-insulated gloves. Before removing the probe, always

switch off the supply voltage to the electronics. After removal, store the probe in a safe,

protected place and wait until it has cooled down below 35 °C/ 95 °F.

Info

After exchanging parts or servicing the ENSITU®7000 whereby the system was switched off, it

is recommended to carry out a 1-point calibration 24 hours after the system has been switched

back on.

5.1 Preparation of the test gas tubing

Test gas tube (customer) ¼'' or 6/4mm OD/ID

Nut (Manufacturer supply)

Seal (Manufacturer supply)

Support sleeve (Manufacturer supply)

Figure 20 – Preparation of the test gas port

5.2 Connect the test gas tube

Remove the sealing cap

Screw on the test gas tube

Figure 21 – Connect the test gas tube

5.3 Test air / test gas supply to the probe for calibration

5.3.1 Test air supply with pump

Pump

Flow meter (150 … 180 l/h)

Figure 22 - Test air supply with a

pump using ambient air

Table of contents

Other Enotec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Hanna Instruments

Hanna Instruments Chromium VI quick start guide

Leuze

Leuze AMS 307i Original operating instructions

Racal Instruments

Racal Instruments 9916 Workshop manual

Konica Minolta

Konica Minolta CHROMA METER CS-200 instruction manual

Keysight Technologies

Keysight Technologies FieldFox B Series user guide

Panasonic

Panasonic k-nl304k user manual