Enotec COMTEC 6000 ATEX GasEx User manual

Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual

Explosion-Proof O

2

/COe Analyzer System

COMTEC

®

6000 ATEX GasEx

Version: 19

for Software Version: 4.13

Doc.-ID: COMGAS_11022020_EN

Preface

Dear Customer,

Thank you for selecting COMTEC

®

6000 GasEx as your InSitu Flue Gas O

2

/ COe Analyzer System.

Since 1980 our analyzer systems have been operating in numerous applications with tens of thousands of units being produced

and shipped worldwide. ENOTEC is committed to absolute quality and performance and over time we have continuously

enhanced our products to integrate various features and functions.

In this package, the electronic unit uses the very latest Microprocessor Technology, making the SME5 electronic unit one of the

most advanced and up-to-date monitoring units, permitting you to reduce your maintenance & fuel costs and to achieve

increased measuring accuracy with operational reliability.

ENOTEC probes include the zirconium oxide sensor which has a gas-tight seal made by using a special process and technique

developed by ENOTEC. This leads to a considerably increased service life compared to "glued or cemented" sensors that have

a tendency to leak or crack during operation.

All ENOTEC instruments are thoroughly tested in the factory and are subject to a strict ISO 9001 and internal quality assurance

procedure. Therefore, with correct installation, the operation of the COMTEC

®

6000 GasEx InSitu analyzer system is

straightforward and user friendly and will provide you with many years of trouble free operation with perfect measuring results.

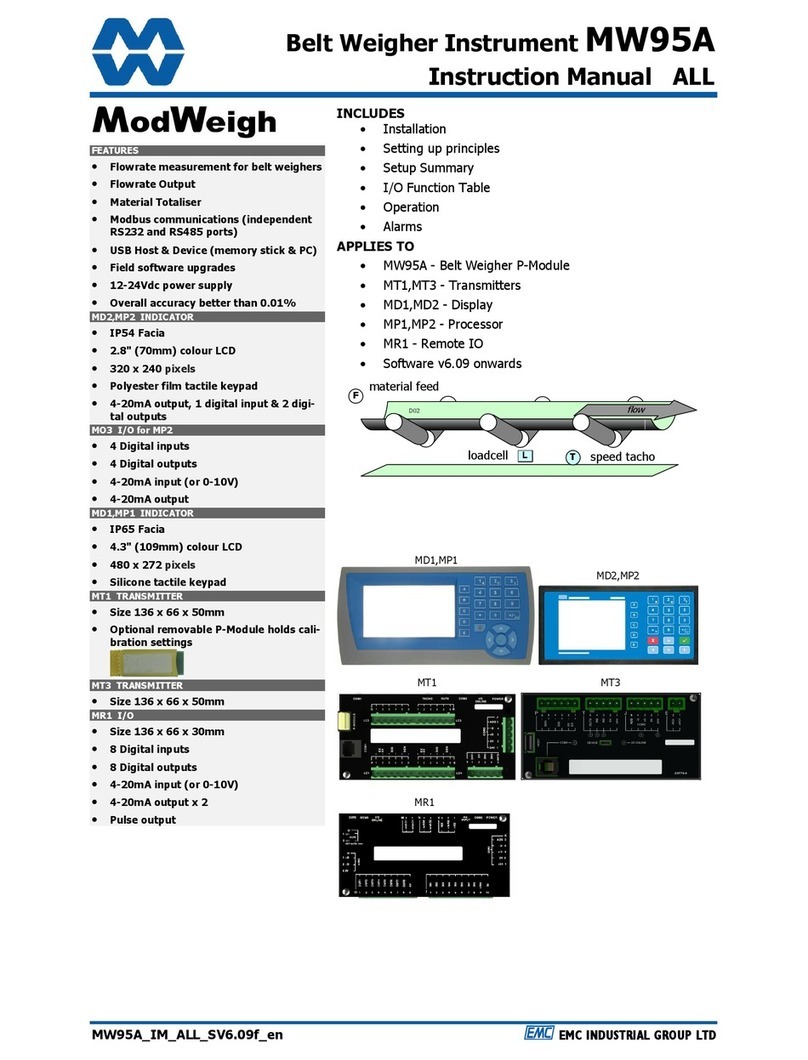

Symbols used in this Manual

All symbols listed beneath, attached to the analyzer or noted in this manual show important information as well as safety

instructions for installation, operation and maintenance, to protect the personnel and the equipment.

Warning

Follow all instructions in this manual

Consider Following Information

Points out important information which must be

noted before execution

Warning hot Surface

Warns of danger of burns which could occur from

hot system parts

Info

Contains further detailed information

Caution

Warns of risks by destroying the system or its

components or its functionality

Ground earth electrical protection

The content of this manual is protected by copyright. Alterations and errors reserved.

Safety Instruction

This system is operated with line voltage. If covers are removed during which line voltage is still connected, an electric shock

hazard will occur.

Only well trained and authorized personnel are allowed to conduct work on this system. Personnel have to understand all

precautions, safety instructions, installation and maintenance instructions in this manual. The trouble free and safe operation of

this system requires safe transportation, professional storage, installation, operation and maintenance. Furthermore, all local

safety requirements have to be considered.

This system may not be used in the vicinity of combustible gases as parts of the system may cause a risk of explosion.

The device may only be put into operation if the enclosed instructions have been fully understood.

This manual is also available in other languages on request

Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx Table of Contents

Doc.-ID: COMGAS_11022020_EN 3

Table of Contents

1System Description 4

System Overview......................................................4

1.1

Measuring Principles ................................................6

1.2

Explosion Protection.................................................6

1.3

Intended Use.............................................................6

1.4

Safety Hazards .........................................................6

1.5

Disruption of the Process..........................................6

1.6

Storage instructions..................................................6

1.7

Name Plates .............................................................7

1.8

ATEX Certification - Probe........................................7

1.9

ATEX Certification - Electronics .............................14

1.1

2Installation 31

Installation Requirements for electronic unit ..........31

2.1

Installation of probe signal cable FEP-0007/8........32

2.2

Access to the terminals...........................................33

2.3

Wiring diagrams of COMTEC 6000 GasEx (SME-5D

2.4

and EX probe).........................................................34

Ferrite Sleeves........................................................35

2.5

Terminal connections of the COMTEC 6000..........35

2.6

Installation of the probe ..........................................36

2.7

Mounting of the Counter Flange at the Duct ..........36

2.8

Adjustment of the Probe Filter Head V-Shield........37

2.9

Mounting the protection tube at the flange.............37

2.10

Insulation with cooling protection tube....................38

2.11

Electrical connections at the Probe ........................39

2.12

Pneumatic connections at the Probe......................39

2.13

Requirements for pneumatic cable FEP-0002 .......40

2.14

Preparation of the pneumatic cable........................40

2.15

Connection of the pneumatics................................40

2.16

3Initial Operation 42

Checklist before commissioning the system ..........42

3.1

System Power Up...................................................42

3.2

Display - Probe Heating Phase ..............................42

3.3

Display - Measuring Mode......................................43

3.4

Keypad and Display................................................43

3.5

Status LEDs............................................................43

3.6

Softkey Symbols.....................................................43

3.7

System Code ..........................................................43

3.8

4Menu Overview and Explanations 44

Menu Overview - SYS-MENU.................................44

4.1

Menu Explanations - SYS-MENU...........................48

4.2

4.2.1

O

2

Measuring Ranges (Scaling)........................48

4.2.2

Limit alarm settings...........................................48

4.2.3

O

2

Sensor calibration values.............................48

4.2.4

Measuring value averaging for (O

2

and COe)...48

4.2.5

mA output on system errors (O

2

and COe) .......48

4.2.6

COe Measuring Ranges (Scaling).....................49

4.2.7

COe Sensor Calibration values.........................49

4.2.8

Time per test gas apply.....................................49

4.2.9

Delay time to process........................................49

4.2.10

Pre-purge time ..................................................49

4.2.11

Automatic Calibration (ACAL) ...........................49

4.2.12

ENOTEC REMOTE...........................................50

4.2.13

Measuring units.................................................50

4.2.14

Language..........................................................50

4.2.15

Change system code ........................................51

4.2.16

Load factory settings.........................................51

4.2.17

Set COe measurement to off/on.......................51

4.2.18

Service (Factory Service Settings)....................51

Menu Overview - System Checks.......................... 52

4.3

Menu Overview - Calibration Menu........................ 53

4.4

4.4.1

Calibration Menu - Display Overview................53

4.4.2

1-point calibration (O

2

and/or COe) (manual) ...54

4.4.3

2-point calibration (O

2

and/or COe) (manual) ...54

5Service and Maintenance 55

Exchange fuses......................................................55

5.1

Pressure and Flow rates for Test Air and/or

5.2

Reference Air ......................................................... 55

Adjusting the Flow Rate - SME 53.........................56

5.3

Position of the adjustment valves (SME-53)..........57

5.4

Adjusting the Flow Rate at the Pneumatic Unit ..... 58

5.6

Replacing the Filter Head.......................................59

5.7

Replacing the Probe............................................... 59

5.8

Replacing the Probe Inner Part..............................60

5.9

Replacing the O

2

sensor........................................ 61

5.10

Replacing the COe Sensor ....................................62

5.11

5.11.1

Seal the COe sensor guide tube.......................63

Relay Outputs / Functions and Correlation............64

5.12

6Status Messages 65

Error Messages......................................................65

6.1

Alarm Messages ....................................................67

6.2

Service Messages.................................................. 67

6.3

Heater Control Unit ................................................68

6.4

7Troubleshooting 69

ATechnical data 71

A.1

Technical Specifications SME-5D..........................71

A.2

Technical Specifications SME-53 ..........................72

A.3

Technical Specifications - Probes..........................73

A.4

Requirements for the gas supply...........................74

A.5

Dimensional drawings of the Electronics...............75

A.6

Pneumatic Unit....................................................... 77

A.7

Gas plans............................................................... 77

A.8

Dimensional drawing of probes KEX600x..............79

A.9

Protection Tube Flanges........................................80

A.10

Counter flanges......................................................80

A.11

Probe components.................................................82

A.12

Probe inner part .....................................................83

A.13

Overview of the Mounting Plate in Ex Housing......84

A.14

Mounting Plates - Safe Area Housing.................... 85

A.15

19” Rack - SME-54................................................. 87

A.16

Display Board.........................................................88

BWarranty 89

CDeclaration of Conformity – Probe 90

DDeclaration of EC conformity - Electronics 91

Index 92

System Description Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx

4 Doc.-ID: COMGAS_11022020_EN

1 System Description

System Overview

1.1

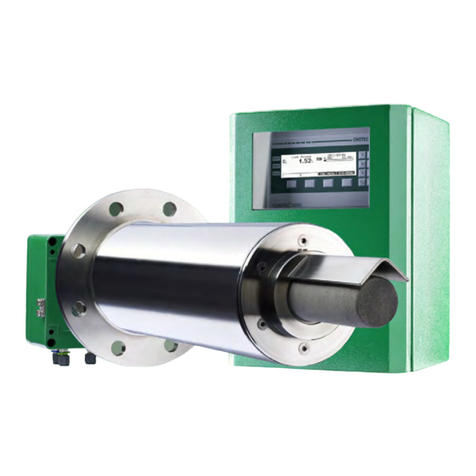

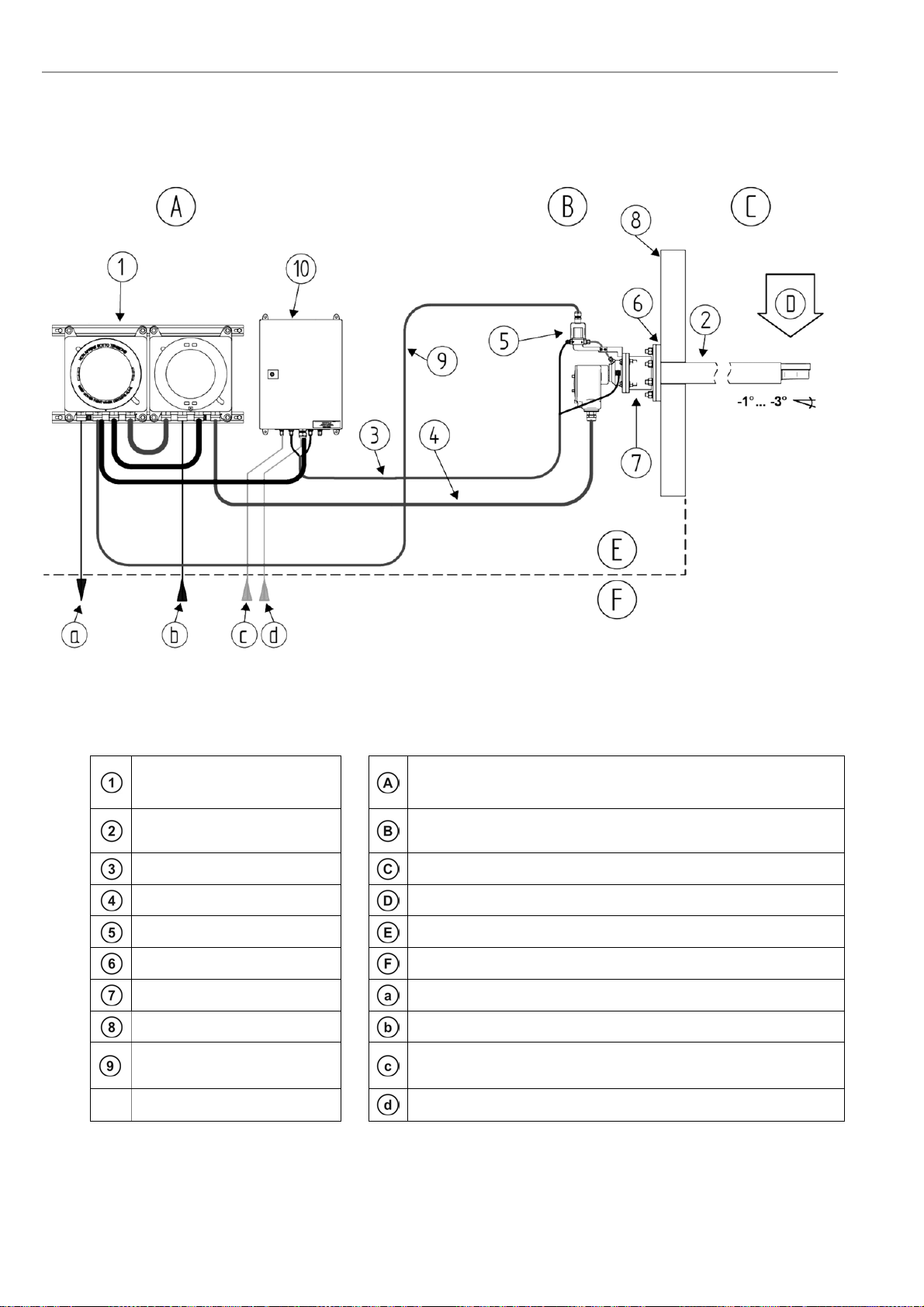

Figure 1 - System Overview with explosion proof housing and probe

Electronic unit / IP66 Hazardous Area-

Max. ambient temp.:-20°C to +55°C (-4°F to + 131°F)

In-situ measuring probe / IP66 Hazardous Area

Max. ambient temp.:-20°C to +70°C (-4°F to + 158°F)

Pneumatic cable Duct / combustion chamber

O

2

probe signal cable Flue gas direction – max. flue gas temperature 500 °C

Solenoid valve (Optional) Manufacturer supply

Counter flange (Optional) Customer supply

Isolation: Customer Output signals (analog and digital)

Duct wall Power supply

Solenoid valve control cable

(only with solenoid valve) Test gas in

Pneumatic unit / IP65 Instrument air in

Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 5

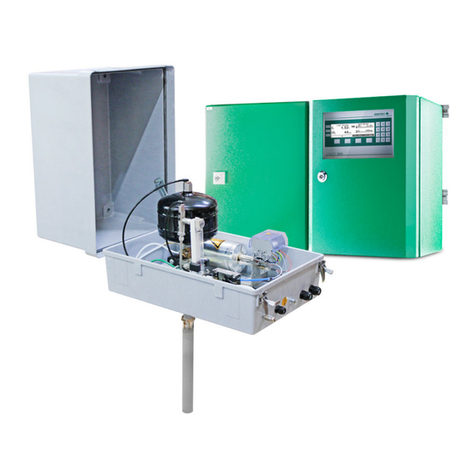

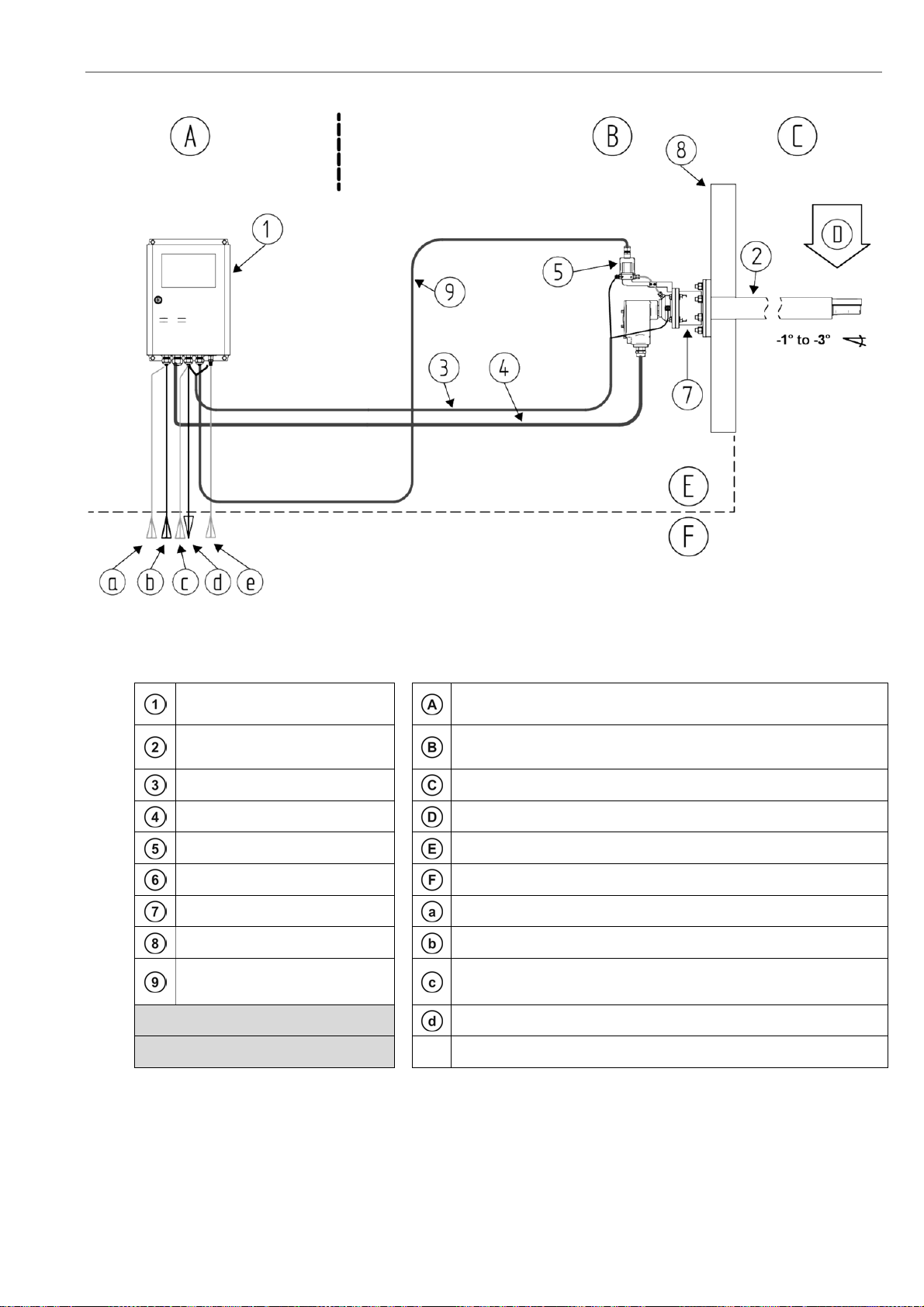

Figure 2 - System Overview with Safe Area housing

Electronic unit / IP66 Safe Area

Max. ambient temp.: -20°C to +55°C (-4°F to + 131°F)

In-situ measuring probe / IP66 Hazardous Area

Max. ambient temp.: -20°C to +70°C (-4°F to + 158°F)

Pneumatic cable Duct / combustion chamber

O

2

probe signal cable Flue gas direction – max. flue gas temperature 500 °C

Solenoid valve (Optional) Manufacturer supply

Counter flange (Optional) Customer supply

Isolation: Customer Test gas in

Duct wall Power supply

Solenoid valve control cable

(only with option solenoid valve) Instrument air in

Output signals (analog and digital)

Test air in (only with pump version of electronics)

System Description Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx

6 Doc.-ID: COMGAS_11022020_EN

Measuring Principles

1.2

The COMTEC

®

6000 O

2

/ CO

e

analyzer system consists of an in-situ probe which is installed in a duct to measure

non-combustible process gases and of an electronic unit for voltage and gas supply, as well as for signal processing.

The O

2

sensor of the COMTEC 6000 is at the tip of the probe and is regulated to 800 °C and works on the zirconium

oxide principle of measurement. Here, a mV signal between the reference gas side of the sensor (inside, instrument

air 20.95% O

2

) and the measured gas side is measured, which depends logarithmically on the ratio of oxygen partial

pressures on both sides of the sensor. The mV signal is converted according to the Nernst equation into oxygen

partial pressure within the process gas, whereby the O

2

concentration is determined in the process gas. Gas-tight

separation of reference air and process gas is of particular importance.

The CO

e

sensor at the tip of the COMTEC

®

6000 probe detects combustible, gaseous molecules whereby the

measured value corresponds to the CO equivalent (CO

e

= CO equivalent). This value can be used as an indication of

the combustion efficiency. A high COe value correlates with poor efficiency because a portion of the fuel is not

completely oxidized.

The InSitu sensor is in contact with the sample gas with both electrodes. These catalytically active electrodes cause

oxidation of the non-oxidized gas molecules, so that a voltage is generated between the electrodes, which depend on

the COe concentration. Thus CO, H2 and CxHy (Hydrocarbons) can be measured.

Explosion Protection

1.3

The electronic system of COMTEC

®

6000 GasEx Analyser Systems is certified for zone 1 – 2 installations and also

the probe can be installed in zone 1 - 2 areas.

Intended Use

1.4

The COMTEC

®

6000 GasEx InSitu Analyser System is a system for measuring the concentration of oxygen and COe

in flue gases and any other non-combustible gasses. For reasons of safety and the possible occurrence of accidents,

unauthorized conversions and modifications of the system are prohibited.

Info

The minimum concentration of O

2

in flue gas should under normal process conditions, not be less than 0,5%.

If the O

2

concentration is regularly below 0,5%, we recommend the option of CSP (Cell Surface Protection) to

protect the O

2

sensor

.

Caution

Under no circumstance should the measuring probe be directly connected to the 230V main power supply, as this will

immediately destroy the probe heater element!

Safety Hazards

1.5

Warning hot Surface

During operation, the temperature of the probe filter head and of all parts exposed to flue gas is 150°C – 500°C

(302°F - 932°F). Direct contact with the hot parts for dismantling or maintenance will cause severe burns!

The probe may only be removed with heat-insulated gloves. Before removing the probe, always switch off the

supply voltage to the electronic system.

Disruption of the Process

1.6

The analyser system has to be kept in operation also in the event of the process being disrupted or if the plant is

powered off temporarily (e.g. at night or during the weekend). Frequently cooling down and heating up of the probe

results in thermal stress of the hot probe parts (heater, thermocouple and sensor) and reduces their product life.

ENOTEC will not accept any responsibility for resultant damage.

Storage instructions

1.7

ENOTEC equipment and spares are to be stored in a dry and ventilated environment. Paint fumes, silicone sprays,

etc. must be avoided in the storage environment.

Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 7

Name Plates

1.8

The name plate of the probe contains year of manufacture, probe serial number, O

2

sensor number and system order

code. The system order code contains system information which details the system test report and is supplied with

the system

SME-5D

SME-53

Figure 3 - Name plate of the electronics

Probe connection box

Figure 4 - Name Plate of the Probe

ATEX Certification - Probe

1.9

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

8 Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 9

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

10 Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 11

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

12 Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 13

System Description Installation and Operation Manual - COMTEC

®

6000 ATEX GasEx

14 Doc.-ID: COMGAS_11022020_EN

ATEX Certification - Electronics

1.1

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 15

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

16 Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 17

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

18 Doc.-ID: COMGAS_11022020_EN

Installation and Operation Manual - COMTEC®6000 ATEX GasEx System Description

Doc.-ID: COMGAS_11022020_EN 19

System Description Installation and Operation Manual - COMTEC®6000 ATEX GasEx

20 Doc.-ID: COMGAS_11022020_EN

Table of contents

Other Enotec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sequoia

Sequoia LISST-VSF user manual

Keysight Technologies

Keysight Technologies N9340B Configuration guide

Honeywell

Honeywell UDA2182 Faq

Physio Control

Physio Control TrueCPR 80596-000001 Instructions for use

Stanford Research Systems

Stanford Research Systems SR785 Brochure & specs

PCB Piezotronics

PCB Piezotronics J357B34 Installation and operating manual