enphase BRK-100A-2P-240V User manual

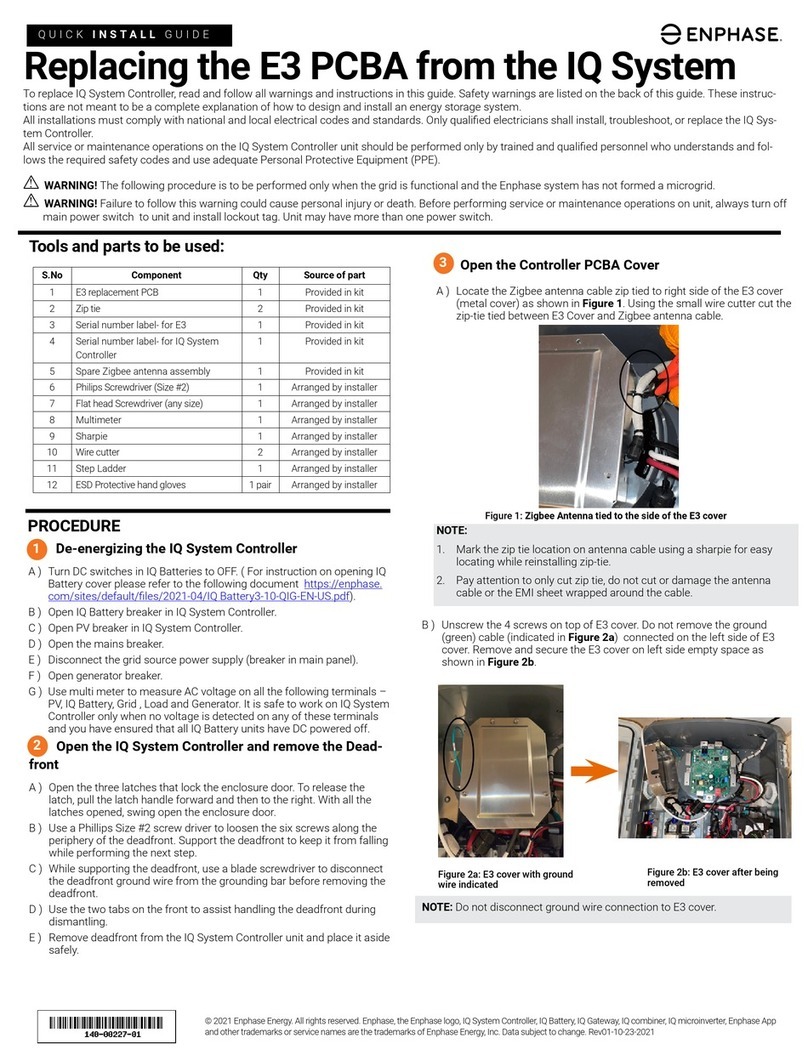

QUICK INSTALL GUIDE Model number: EP200G101-M240US01

Install the Enphase IQ System Controller 2

To install the Enphase IQ System Controller 2 and the Enphase IQ System Controller 2 wall-mount bracket, read and follow all warnings and instructions in this

guide and in the Enphase IQ System Controller 2 Installation and Operation Manual at enphase.com/support. Safety warnings are listed on the back of this

guide. These instructions are not meant to be a complete explanation of how to design and install an energy storage system. All installations must comply with

national and local electrical codes and standards. Only qualied electricians shall install, troubleshoot, or replace the IQ System Controller 2.

The Enphase Energy System includes the Enphase IQ System Controller 2 with Microgrid Interconnection Device (MID) capability, which

consolidates interconnection equipment into a single enclosure and streamlines grid-independent capabilities of PV and storage installations

by providing a consistent, pre-wired solution for residential applications. Along with MID functions, it includes PV, storage, and generator input

circuits.

©2021 Enphase Energy. All rights reserved. Enphase, the Enphase logo, IQ System Controller 2 , IQ Battery, IQ Gateway, IQ combiner, IQ microinverter, Enphase

App and other trademarks or service names are the trademarks of Enphase Energy, Inc. Data subject to change. Rev02-10-25-2021

S c e n a r i o 1 :

Whole home backup with IQ System

Controller as service entrance: This

is the preferred conguration for back

up of the entire main load panel. This

conguration supports up to an 80A

breaker each for the PV circuit, battery

storage and Generator(optional).

S c e n a r i o 2 :

Partial home backup with main load

panel as service entrance: This is

the preferred conguration for partial

home backup with subpanel with

PV and IQ Battery. Generator can be

integrated with IQ System Controller

based on the homeowner’s needs.

S c e n a r i o 3 :

Whole home backup with Solar

Only backup: This is the preferred

conguration for backup of the entire

main load panel using only IQ8 PV.

Generator can be integrated with

IQ System Controller based on the

homeowner’s needs.

(optional)

(optional)

(optional)

PREPARATION

A ) Inspect the packaging and the IQ System Controller 2 for damage. Do

not install or use the IQ System Controller 2 if it has been damaged in

any way.

B ) Ensure that you have the following:

• One Enphase IQ System Controller 2. The IQ System Controller 2 shipping

box contains an Enphase IQ System Controller 2, mounting bracket,

mounting hardware, and literature kit (bag with labels and accessories:

150-00148). Among the accessories are four-pin receptacles/dry contacts

that will be used for controlling external power relays.

* WARNING: The IQ System Controller 2 weighs 39.4 kg (87 lbs) and

will require two persons to lift the unit.

C ) Make sure you have the following required items:

• Enphase IQ Battery, which is required for off-grid applications.

• The Enphase IQ System Controller 2 requires a wireless connection

to an IQ Gateway, which requires an Internet connection. Failure to

maintain an Internet connection may have an impact on the warranty.

See enphase.com/warranty for full terms and services.

• Wireless USB Adapter (COMMS-KIT-01) to be installed at IQ Gateway

for communications with IQ Battery and IQ System Controller 2.

Includes USB cable for connection to IQ Gateway and allows wireless

communication with IQ Battery and IQ System Controller 2.

• Two current transformers (CT-200-SPLIT) for consumption monitoring

• One current transformer (CT-200-SOLID) for production metering

• IQ System Controller 2 lifting handles (EP200G-HNDL-R1).

• Eaton BR Series breakers, rated maximum 80A for IQ Battery and

Enphase IQ Combiner.

• If breakers are required at the input or output to IQ System Controller

2, use Eaton, Type CSR breakers rated 100 A, 125 A, 150 A, 175 A or

200 A.

• Tools: conduit (with ttings and tting tools), drill, 5/32 inch pilot bit

(or metric equivalent), screwdriver, socket, wrench, adjustable wrench,

torque wrench, level, 5/32 inch Allen key (or metric equivalent),

conductor stripper, electrician’s hole saw (2 inch) kit or punch set, and

stud nder, if installing on studs.

• Conduit ttings (hubs) are required for all installations, and NEMA

Type 3 conduit ttings (hubs) are needed when installing out of doors

(one for each used conduit opening).

• Conduit ground hub rings.

NOTE: Conduit entry is allowed only through the bottom or bottom sides

of the unit.

• Three #10, 1/4”, or 5/16” lag bolts or screws, 7.6cm (three inches) long

(depending on attachment wall), for each wall-mount bracket. Check with

a structural engineer and local standards for local requirements.

• Washers for use between fastener heads and wall-mount bracket.

• Conductors rated at 75°C. For sizes, refer to the table on the unit and

to local codes.

• Over current protection: maximum in accordance with local standards.

• The door sheet metal is not required to be grounded, since it is pro-

tected from live parts by other grounded metal and insulating plastic

materials, thus is considered unlikely to become energized.

INSTALLATION

Use the Enphase Installer App™ mobile app for iOS and Android devices. It

allows installers to congure the system while on site, eliminating the need

for a laptop and improving installation efciency.

NOTE: Only one IQ System Controller 2 can be commissioned in one

system. Multiple IQ System Controller 2s can exist on the same site but

they need to be in separate systems, i.e. separate Enphase App/Enphase

Installer App activations.

Plan a location for the IQ System Controller 2

The IQ System Controller 2 housing is NEMA type 3R and you can install it indoors

or outdoors.

* WARNING: Protection against lightning and resulting voltage surge

must be in accordance with local standards.

A ) Follow all local codes and standards when planning for and installing

the Enphase IQ System Controller 2.

B ) Choose a well-ventilated location where the ambient temperature

is within -40° C to 50° C (-40° F to 122° F), preferably out of direct

sunlight.

C ) Ensure that the mounting location can sustain the weight of the IQ

System Controller 2 and mounting bracket 39.4 kg (87 lbs). The wall

must include studs that can bear 39.4 kg (87 lbs) or can be of masonry

or other suitable structure that can bear the weight.

D ) Check the mounting location clearances:

• Indoors: at least 15cm (six inches) off the

ground, 15cm (six inches) from the ceiling,

and 15cm (six inches) on each

side.

• Outdoors: at least 91cm (three

feet) off the ground and 15cm

(six inches) on each side.

E ) Ensure that there are no pipes or

electrical conductors where you

plan to drill.

F ) Plan to maintain at least 90cm

(three feet) of clearance in front

of the IQ System Controller 2.

G ) Consider the dimensions of the

IQ System Controller 2, easy

access, unit height, conduit

entry, and length of cable when

selecting the location.

H ) Select a location where you can

interconnect to the site’s load

center using the Enphase IQ

System Controller 2.

1

width = 19.7 in.

36 in.

depth = 9.7 in.

IQ System Controller 2

dimensions

S c e n a r i o 4 :

Partial home backup with Solar

Only backup: This is the preferred

conguration for partial home

backup with subpanel using only IQ8

PV. Generator can be integrated with

IQ System Controller based on the

homeowner’s needs.

(optional)

Install the wall-mount bracket

A ) Mark a plumb line over the wall stud as a guide.

* WARNING! Multiple risks. Make sure not to drill or attach into

electric wiring or pipes that are in the wall!

B ) Remove the wall mount bracket only from the shipping box.

C ) Place the wall-mount bracket on the wall so that the mounting holes in

the middle of the bracket align with the center of the stud. Use a level

to keep the bottom of the wall-mount bracket level.

D ) Use the #10, 1/4”, or 5/16” wood screws (or masonry attachments

if installing in masonry) to attach the bracket using one screw and

washer for each slot. The slot size of the IQ System Controller 2

wall mount bracket is 8.5mm. Use an appropriately sized washer for

each of the screws, and check with a structural engineer and local

standards for local requirements.

E ) Verify that the wall-mount bracket is level, solidly attached to the wall,

and oriented for upright installation of the IQ System Controller 2.

* WARNING! Risk of injury and equipment damage. Do not mount

an IQ System Controller 2 on a bracket that is not properly attached to

a wall.

* WARNING! Risk of injury and equipment damage. Protect the IQ

System Controller 2 from impact damage and improper use.

2

D ) Repeat on the other side with the second handle.

* WARNING! Risk of injury and equipment damage. Two persons

are required to lift the IQ System Controller 2.

E ) Use the lifting handles, take the IQ System Controller 2 from the

packaging, making sure it is top side up (upright). IQ System Controller

2 is designed only for vertical installation without inclination (must be

level).

F ) Lift the IQ System Controller 2 slightly above the installed wall mount

bracket and allow it to slide down so that the bracket facing hooks set

into both the top and bottom shelves of the wall mount bracket.

G ) Allow the IQ System Controller 2 to slide down until the IQ System

Controller 2 is fully seated on the wall-mount bracket shelf.

* WARNING! Risk of injury and equipment damage. Do not release

the IQ System Controller 2 until you ensure that the IQ System Control-

ler 2 is fully seated in the wall-mount bracket shelf.

H ) For each handle, pull the plunger tabs

to release them and remove the lift

handles.

I ) Reserve the handles for the next

installation.

J ) On the bottom handle mounts, use the

two provided partial-threaded custom

M6 screws to secure each side of the IQ

System Controller 2 and tighten to 0.5

N•m (4.4 lb•in) or less.

The threaded portion of the screw

engages with the bracket, while the un-

threaded portion of the screw engages

with the hole in the bracket to prevent

vertical movement of the bracket.

* WARNING! Risk of injury and

equipment damage. Do not skip this

step. Without these screws in place,

the IQ System Controller 2 may fall and

cause injury or damage if bumped or

shaken.

K ) Use the four ller plates, provided in the lit kit, to cover the screws.

IQ System Controller 2

Wall Mount Bracket Align with stud

Bracket

shelf

8.5 mm mounting

slots

Bracket facing hooks

on back of the IQ System

Controller 2

3

Unbox and mount the IQ System Controller 2 on the

wall

* WARNING: Risk of injury. Take care when lifting. The IQ System

Controller 2 is heavy 38.5 kg (85 lbs).

* WARNING! Risk of injury and equipment damage. Avoid dropping

the IQ System Controller 2. Doing so may create a hazard, cause

serious injury, and/or damage the equipment.

A ) Remove the upper IQ System Controller 2 box, and locate the slots on

both sides of the IQ System

Controller 2 enclosure.

B ) Locate the lifting handles (sold

separately) and check that the

plungers are extended and

ready to engage into the IQ

System Controller 2 slots.

C ) Align one handle on one side of

the IQ System Controller 2 and

press the handle into the slots,

and slide the handle toward the

top of the IQ System Controller 2 enclosure until it clicks into place.

Check that the handle is secure.

Attach handles

Install breakers as needed

The IQ System Controller 2 includes one two-pole 40A circuit breaker

that feeds the neutral forming transformer (NFT). You can install addi-

tional breakers, if needed. You must follow all NEC and local electrical

codes.

Install breakers as needed for the AC grid, main load, Enphase IQ Combin-

er, Enphase IQ Batteries, and generator(optional). These breakers are not

included and must be ordered separately.

NOTE: You must install a backup loads breaker if required by local code.

* WARNING! Risk of injury and equipment damage. Use only the

breakers listed in this table.

List of allowed breakers and hold down kits:

Enphase Model No. Type and Eaton part no.

BRK-100A-2P-240V

BRK-125A-2P-240V

BRK-150A-2P-240V

BRK-175A-2P-240V

BRK-200A-2P-240V

BRK-20A-2P-240V-B

BRK-30A-2P-240V

BRK-40A-2P-240V

BRK-60A-2P-240V

BRK-80A-2P-240V

BRK-20A40A-4P-240V

EP200G-NA-HD-200A

• Main Breaker, 2 pole, 100A, 25kAIC, CSR2100

• Main Breaker, 2 pole, 125A, 25kAIC, CSR2125N

• Main Breaker, 2 pole, 150A, 25kAIC, CSR2150N

• Main Breaker, 2 pole, 175A, 25kAIC, CSR2175N

• Main Breaker, 2 pole, 200A, 25kAIC, CSR2200N

• Circuit Breaker, 2 pole, 20A, 10kAIC, BR220B

• Circuit Breaker, 2 pole, 30A, 10kAIC, BR230B

• Circuit Breaker, 2 pole, 40A, 10kAIC, BR240B

• Circuit Breaker, 2 pole, 60A, 10kAIC, BR260

• Circuit Breaker, 2 pole, 80A, 10kAIC, BR280

• Quad breaker, 4 pole, 20A/40A, 10kAIC, BQC220240

• Eaton type BR circuit breaker hold-down screw kit,

BRHDK125

4

Breaker installation positions are noted in the diagram:

A ) Ensure that the IQ System Controller 2 is completely de-energized.

B ) Open the three latches that lock the enclosure door. To release the

latch, pull the latch handle forward and then to the right. With all the

latches opened, swing open the enclosure door.

* WARNING: Risk of equipment damage. Do not remove the

pre-installed solar shield attached to the enclosure door.

C ) Use a Phillips screw driver to loosen the six screws along the

periphery of the deadfront. Support the deadfront to keep it from

falling while performing the next step.

D ) While supporting the deadfront, use a screwdriver to disconnect the

deadfront ground wire from the grounding bar before the deadfront is

removed.

E ) Use the two tabs on the front to assist handling the deadfront during

the removal. Keep the deadfront and screws handy as you will need

them later.

* WARNING: Risk of electric shock. To maintain the warranty, do

not modify the deadfront other than to remove or replace ller plates,

as needed.

F ) If you install a main breaker or load breaker, remove the standard lugs

before installing the Eaton CSR breaker. By default, lugs are provided in

the IQ System Controller 2 unit for connection to the mains and to the

load. In case of usage without breakers, the conductors are connected

directly to these lugs. When breakers are used, the lugs are replaced

with breakers during installation.

G ) Remove a ller plate from the deadfront for each breaker position

you will use. Refer to the breaker position diagram to the left. To

remove the ller plate, press the two snaps inward while gently

pushing the ller plate out.

H ) For the IQ Battery, AC Combiner or Generator (optional) connection,

snap the appropriately sized BR series two-pole Eaton breaker onto the

busbar, using only the breaker positions indicated in the diagram on the

door of the unit. The wires to be connected to each breaker are located

beside each breaker position. Remove the heatshrink cap on the wire

ends before inserting into the breaker.

I ) There are three ways of installing the IQ Gateway breaker:

Option 1: Unwire and remove the IQ Gateway breaker from the IQ Com-

biner, wire L1 and L2 from IQ Gateway terminals through the PV conduit

toIQ System Controller, insert IQ Gateway breaker onto the bottom right

position onIQ System Controllerbusbar (earlier reserved forgenerator),

wire IQ Gateway L1 and L2 to IQ Gateway breaker onIQ System Control-

lerbusbar.

Option 2: Unwire and remove IQ Gateway breaker inside IQ Combiner , wire

L1 and L2 from IQ Gateway terminals through the PV conduit throughIQ

System Controllerto backup panel ,insert IQ Gateway breaker onto an

available space on backup loads panel,wire IQ Gateway L1 and L2 to IQ

Gateway breaker on backed uploads panel.Generator breaker position is

free to be used with generator.

Option 3: Unwire and remove IQ Gateway breaker inside IQ Combiner,

unwire and remove NFT breaker insideIQ System Controllerand insert

quad breaker (BRK-20A40A-4P-240V) in the NFT position, wire L1 and L2

from IQ Gateway terminals

through the PV conduit toIQ

System Controller, wire IQ

Gateway L1 and L2 and

NFT L1 and L2 to the quad

breaker. Generator breaker

position is free to be used

with generator.

J) The bottom right breaker

position can be used for the

below purposes :

1. Power the IQ Gateway

2. Interconnect with the

Generator (optional)

3. Power the control

transformer to enable the

auxiliary contact load/PV

shedding feature

4. Connect the subpanel

backup load breaker for <100A load subpanel. You can connect the

main breaker of the subpanel to this position, since the load side lugs

in IQ System Controller do not support <100A breaker or <1AWG wires.

Ensure you stick the “GENERATOR” or “BACKUP LOADS” label, on top of

the “IQ Gateway” embossing, on the IQ System Controller deadfront per

the usage.

K ) Install each breaker by rocking it to the left, catching the clips that hold it in

place. Then rock the breaker to the right so it is fully seated and secure.

L ) For the main load breaker, use an appropriately sized CSR Eaton breaker.

Install at the location indicated in the diagram on the door of the unit.

M ) Remove the mains/load lugs by unscrewing the two nuts holding the lugs.

Re-use the same nuts to x the CSR breakers in the same position. Torque

to 4 N•m (35.4 lb•in).

N ) Use the 8-32 screw (from the lit kit marked 150-00148 that ships with the IQ

System Controller 2) to secure the mains breaker (not the load breaker). Use

a T20 drive to tighten the 8-32 screw to 1.5 N•m (13.3 lb•in). Do not use any

other screw.

O ) Check that all breakers are properly seated.

P ) Use the included stowed conductors, as labeled, to wire the circuit

breaker(s) for the IQ Batteries, IQ Combiner, and generator (optional), as

needed. The stowed conductors are provided with crimped-on ferrules

with end caps to prevent accidental contact. Remove the conductor end

caps as needed.

Q ) Torque the breaker connections as listed in the following and in the

conductor table on the unit.

R ) Purchase and install two circuit breaker hold-down screw kits (SKU:

EP200G-NA-HD-200A) to secure the IQ Battery and generator double-pole

circuit breakers.

Connections Wire size (AWG) Torque (N•m / lb•in)

Main lugs

Backup load lugs (use a 1/4” hex drive) Cu/AL: 300 KCMIL - 1 31.1 / 275

CSR breaker bottom wiring lugs Cu/AL: 300 KCMIL - 2 28.2 / 250

BR breakers (wire provided) 6 3.1 / 27

AC Combiner lugs,

IQ Battery lugs, and

Generator lugs

14 - 10

8

4 - 6

2 - 3

2.8 / 25

3.4 / 30

3.9 / 35

4.5 / 40

Neutral - large lugs (use a 3/8” hex drive) Cu/AL: 300 KCMIL - 6 31.1 / 275

Neutral and ground bars

Large holes (5/16-24 UNF) 1/0 - 3

4 - 6

8

10 -14

5.6 / 50

5.1 / 45

4.5 / 40

4.0 / 35

Small holes (10-32 UNF) 6 - 8

10 -14

2.8 / 25

1.7 / 15

Required practices when

torquing connections:

• Always follow NEC

2017 110.4 (D)

dictates.

• You must use a cali-

brated torque tool to

achieve the indicated

torque values.

• Use tamper-proof

torque mark/

paint after torquing

connections.

Load breaker

AC Combiner

breaker

IQ Battery

breaker

Generator

breaker

Mains breaker

Ground wire

Install 8-32

screw with 1.5

N•m torque

CSR breaker upper

lugs: 4 N•m torque

CSR breaker bottom

wiring lugs: 28.2 N•m

torque

I/O - 1

(24V, 1A)

I/O - 2

(24V, 1A)

Gen - I/O

(24V, 1A)

NO1 NO2 NC1 NC2 NO3

RSD

NC3 NC4

AC CombinerPV/Storage Generator

Control PCBA & cover

Breaker spaces for auto

transformer, generator,

AC Combiner and

Encharge circuits

Eaton breaker

CSR2100N/2150N/200N

Two general purpose

relay I/O

A: Up to 80A to PV Combiner

B: Up to 80A to Encharge

C: Up to 200A to backup load panel

D: Up to 80A to generator

A B C D From utility meter or

main load panel

AC power wire

Generator I/O

Ground

Neutral

Main service disconnect

Eaton breaker

CSR2100N/2150N/22000N

200A main MID relay

5

Conduit guidance -

bottom entry Conduit guidance -

side entry

Wire the eld connections and the rapid shutdown (RSD)

switch

+ DANGER! Risk of electric shock. Check that all circuits connecting to the IQ

System Controller 2 are de-energized before wiring.

* WARNING! Do not install consumption CTs on the conductors above the

common busbar or on the main conductors below the main breaker if the

main breaker is used as service entrance. If the main breaker is the service

entrance breaker, You must install the CTs on the conductors near the service

entrance of system controller.

A ) Drill conduit entry holes as needed, and install conduit grounding lugs for each

opening. Be sure to reseal unused conduit entry holes with sealing plugs.

NOTE: Main supply conductors may enter the IQ System Controller 2 from the

bottom or from the bottom-left side. Backup load conductors may enter the

IQ System Controller 2 from the bottom or bottom-right side. IQ Battery, IQ

Combiner and generator conductors may enter from the bottom, bottom-left or

bottom-right sides.

B ) Size the conductors (Line, Neutral and Ground) depending on the breaker or

fuse, proper ampacity, and voltage rise requirements according to local codes.

Refer to the conductor rating table on the door of the IQ System Controller 2.

C ) If the IQ System Controller 2 is not installed as service equipment1, you must

remove the main bonding jumper connected between the grounding bar and the

neutral assembly. Refer to the wiring diagram.

NOTE: Do not modify or rewire any of the other pre-installed wiring or bonding

connections in the IQ System Controller 2.

D ) If IQ System Controller 2 is installed as service equipment1:

• Connect a grounding electrode conductor to the grounding bar.

• From the lit kit, place the label “GROUNDING ELECTRODE TERMINAL” adjacent

to the grounding bar.

• From the lit kit, place the label “SUITABLE FOR USE AS SERVICE EQUIPMENT”

/ “MAIN SERVICE DISCONNECT” on the deadfront near the main breaker/

service disconnect.

• If IQ System Controller 2 is not used as service equipment, these labels should

not be used.

E ) Connect Lines, Neutral, and Ground. For details, refer to the conductor table on

the unit for sizes and refer to local codes.

* WARNING! Risk of equipment damage. Always connect to two Lines (ac-

tive), one neutral, and one ground.

F ) Connect the AC wires of Enphase IQ Combiner, IQ batteries, and generator into

the terminal lugs at the bottom of the IQ System Controller load center on the

left.

* WARNING! Do not connect the AC wires directly into the breakers. The AC

wires go into the terminal lugs as shown in the label.

G ) Rapid shutdown (RSD) switch connections

To conduct IQ8 PV rapid shutdown, a double pole single throw

lockable RSD switch is required. The RSD switch should be

placed in a readily accessible location outdoor and wired to IQ

System Controller. The maximum distance between the RSD

swtich and IQ System Controller is 200 feet. The RSD port in

IQ System Controller 2 accepts 28AWG to 16AWG wire sizes.

For RSD switch that supports only higher gauge wire sizes

(e.g. 12AWG), the cable assy header included in the IQ System

Controller 2 Lit Kit is required.

To connect the RSD switch with the IQ System Controller RSD

port, wire the L1 and L2 of one pole of the RSD switch to the

two terminals of NC3 in IQ System Controller, and wire the L1

and L2 of the other pole of the RSD switch to the two terminals

of NC4 in IQ System Controller.

To convert the RSD switch 12AWG wires to 16 AWG wires,

connect the RSD wires rst to the cable assy headers from the

IQ System Controller lit kit, and then connect the 16AWG wires

on the header to NC3 and NC4 in IQ System Controller.

H ) After all conductors are connected and secured, check that

there are no exposed conductors or stray wires.

I ) Gently arrange all the conductors and connectors inside the

cabinet.

+ DANGER! Risk of electric shock. The system is not ready

to be energized! Do not close any circuit breaker yet.

NOTE: The polarity of L1 and L2 is swapped inside Eaton CSR

series main breakers. Installers should follow L1 and L2 on the

following image when installing consumption CTs.

*The extra lug near the top right side of NFT (auto transformer) is a

manufacturing test terminal intentionally unpopulated with no end user

application.

Cable Header

Assembly

12 AWG wires

6

Device Supported SKU’s

1) PCS Controller(IQ

Gateway)

• IQ Gateway i.e., ENV-IQ-AM1-240

• Envoy S metered i.e., ENV-S-AM1-120*

• IQ Combiner boxes containing the IQ Gateway:

IQ Gateway is included in X-IQ-AM1-240-3C,

X-IQ-M1-240-3,

X-IQ-AM1-240-3-ES, X-IQ-AM1-240-3C-ES,

X-IQ-AM1-240-2, X-IQ-AM1-240-B, X-IQ-AM1-240-4,

X-IQ-AM1-240-4C

2) Current Transformers

• CT-200-SPLIT(needs 2 units)

• CT-200-SOLID(included with the IQ Gateway)

3) IQ System Controller 2 EP200G101-M240US01

4) IQ Battery • ENCHARGE-3-1P-NA, ENCHARGE-10-1P-NA,

• ENCHARGE-3T-1P-NA, ENCHARGE-10T-1P-NA

5) Microinverters • IQ6 series (IQ6, IQ6Plus), IQ7 series(IQ7, IQ7A, IQ7Plus, IQ7X,

IQ7PD)

• M215 and M250 series*

* Envoy S metered and M-series inverters do not support PV curtailment for MPU avoidance.

The National Electric Code(NEC) 2017 NEC 705.12(B)(2)(3)(b) allows

backfeed of current from solar/storage into the main panel subject to

the following limit

Backfeed allowed <= ((120% of busbar rating) – Ampacity of

the overcurrent protection device protecting the busbar )/

125%

Enphase, through its Enphase mobile app, also provides grid proles

that comply with PEL limits for various jurisdictions. In a situation

where both the PCS limit and a PEL prole are being used, the

maximum current backfed from the IQ System Controller 2 to the main

panel is always the lower of the PEL limit and the PCS limit.

NOTE: Import Only Mode for Energy Storage System is xed in

software and cannot be changed in the eld.

Conguring PCS In the Enphase Storage System

A ) Check that you have the following items. You must use the listed CTs

and Enphase IQ Gateway or the Envoy-S Metered with the IQ System

Controller 2 and IQ Battery for Power Control System functionality.

• Two current transformers (CT-200-SPLIT) for consumption/PCS

monitoring

• One current transformer (CT-200-SOLID) for production metering

(included with IQ Gateway)

• IQ Gateway (ENV-IQ-AM1-240) or Envoy-S Metered (ENV-S-AM1-120):

The IQ Gateway can be standalone or integrated in an IQ Combiner

box.

B ) Follow all instructions in the IQ Gateway or IQ Combiner Quick Install

Guide to ensure that CTs are installed and wired correctly with correct

polarity. Refer to the following diagram for the locations and polarity (arrow

on top of CT) on the CTs.

For whole home backup conguration, the CTs should be placed in the

same location (Production CT in IQ Combiner; PCS CT in IQ System

Controller 2) as shown in the diagram PCS CT installation within IQ System

Controller 2.

C ) When being used for PCS, you must install the CT-200-SPLIT current

transformer inside the system controller on the conductors near the

service entrance of the the system controller. The arrows on the Consump-

tion/PCS CT must point towards the loads, towards the busbar inside

the IQ System Controller 2. Refer to the image on the next page for the

Consumption/PCS CT location and wiring to the IQ Gateway.

D ) You must protect all PCS controlled busbars and/or conductors with

suitably rated overcurrent devices that are appropriately sized for the

busbar rating or conductor ampacity. Refer to the IQ Gateway/IQ Combiner

QIG to see wiring details for CTs.

E) You must indicate, with a label, the maximum current setting for back-

feed from IQ System Controller 2 that is controlled by PCS. Apply a label on

the IQ System Controller deadfront indicating the maximum current setting

for back-feed from IQ System Controller 2 that is controlled by PCS. An

example of the required label is shown as follows. Record the maximum

operating amps value on the label.

THE MAXIMUM CURRENT BACKFED BY THIS SYSTEM TO THE MAIN

PANEL MAY BE CONTROLLED ELECTRONICALLY. REFER TO MANU-

FACTURER’S INSTRUCTIONS FOR MORE INFORMATION

PCS CONTROLLED CURRENT SETTING: ___________ AMPS

Set Up the Power Control System

The IQ System Controller 2 device, when used with IQ Gateway and Produc-

tion as well as Consumption/PCS CTs, enables the Power Control System

(PCS) functionality in the Enphase Storage System.

The Enphase Storage System supports 2 PCS use cases:

• Import Only mode for Energy Storage System (ESS): Enphase Storage

System can import power from the Area Electric Power System (EPS)

for charging purposes but does not export active power from the ESS

to the Area EPS. The ESS mode of Import Only applies irrespective

of the congured battery smart prole, i.e., Self-Consumption, Full

Backup, or Savings (Time of Use) with optimization.

• Main Panel Upgrade (MPU) avoidance: In the partial home backup

scenario, the PCS limit the currents backfed into the main panel as

allowed by 2020 NEC article 705.13. This ensures that the main panel

complies with the NEC article 705.12.

NOTE: This use case is only supported with IQ Gateway and

IQ6/7/8 series inverters.

This mode is applicable when the system is congured as in

Scenario 2 as described on page 1 of this QIG.

IQ Battery/PV

01 ECO-004882 INITIAL RELEASE AKC 05OCT20

Wiring Diagram Label,

Enpower 200G-R2

780-00470 02

HENRY W

HENRY W 05OCT20

05OCT20

02 ECO-005166 - MODIFY LABEL MN 12MAR21

NFT/IQ Gateway*

AC Combiner Generator/IQ Gateway*

80

80

IQ Battery/PV AC Combiner Generator

780-00470-02

Remote Rapid

Shutdown

Switch

RSD Gen I/O

*IQ Gateway can only be put on

one of these two breaker

positions. Refer to the QIG for

instructions.

Grounding Electrode conductor.

Connected to earth when used

as service equipment.

Connected to main service when

not used as service equipment.

IQ Battery

PCS CT installation within IQ System Controller 2

IQ Gateway Terminal Block

Relay contacts

(if needed)

white

blue

Not used

white

blue

Consumption CTs

The arrows must point

toward the load, away

from the grid.

P1 C1 C2

1 2 3 4 NO

Ref

Common

C

Digital Input Relay

PD, B300

OVC II

L1 L2

N

CU, 75C, 14AWG MIN

MEAS CAT III

OVC III Production | Consumption

Set Up the Power Control System (continued)

6

F ) For Production as well as Consumption/PCS CTs, you must apply the

following label to each CT when the system is congured to use PCS-based

current limiting.

The available space on the CTs for labeling is as follows.

Consumption/PCS CT (CT-200-SPLIT):

• Left side: 20mm(vertical) x 14mm(Horizontal)

• Back side: 20mm (vertical) x 20mm(Horizontal)

Production CT (CT-200-SOLID):

• 9mm(vertical) x 30mm(horizontal)

This sensor is part of a Power Control System. Do not re-

move or disable. Replace with same type and rating.

NOTE: The maximum operating currents in controlled busbars or

conductors are limited by the settings of the Power Control System

(PCS) and may be lower than the sum of the currents of the connected

controlled power sources. The settings of the PCS controlled currents

may be used for calculation of the design currents used in the relevant

sections of NEC Article 690 and 705.

* WARNING! Risk of electric shock and re. Only qualied personnel

are permitted to set or change the setting of the maximum operating

current of the PCS. The maximum PCS operating current setting shall

not exceed the busbar rating or conductor ampacity of any PCS con-

trolled busbar or conductor.

G) PCS Export Limiting via Enphase Installer App

PCS that ensures the Import Only mode for ESS is always running in the

system and the import only mode is not changeable. Energy storage

never exports to grid and therefore never backfeeds the main panel in a

partial backup scenario if consumption/PCS CTs are placed as outlined

in section 6.

This section outlines how to congure current export limiting to limit PV

current when PV current exceeds the allowed backfeed/export.

The MPU avoidance use case of PCS can be enabled via Enphase

Installer App during installation at Step 2 b) Site Conguration as shown

in the gure below:

NOTE: The MPU avoidance use case requires conguration using the

Enphase Installer App version v3.0.8 or higher and IQ Gateway software

version 6.1.32 or higher.

In the site conguration menu, the user can see 2 options:

• Select Backup Type

• PCS Export Limiting

As the MPU avoidance conguration can only be enabled in the partial

home backup mode, the installer has to rst select the ‘Partial Home

Backup’ conguration under ‘Select Backup Type’.

Then, in the ‘PCS Export Limiting’ section, the installer is required to

enter the type of micro-inverters(IQ8, IQ7, IQ6) & the number of micro-in-

verters of each type. Along with this, the installer adds information on

the rating of the main load panel busbar, the main service breaker rating

& can also set the PCS Controlled Export Current Limit. If this value is

not set, the system auto-calculates the export current limit based on the

Auxiliary Contact Connections

IQ System Controller 2 has three I/O ports and one Rapid Shutdown Switch

(RSD) port.

- I/O-1, I/O-2 are for load and excess PV control:

- I/O-1 has two normally open auxiliary contacts (NO1, NO2), and each

auxiliary contact has two terminals

I/O-2 has two normally close auxiliary contacts (NC1, NC2), and each auxil-

iary contact has two terminals

The RSD port is for connecting with a remote RSD switch. It has two normal-

ly close auxiliary contacts (NC3, NC4), and each auxiliary contact has two

terminals.

Gen-I/O has one normally open auxiliary contact (NO3) for generator control,

and this contact has three terminals.

All the auxiliary contact relays are rated for pilot duty at 24Vac/Vdc (nomi-

nal) and 1 Amp.

A. Auxiliary Contact connections for shedding excess PV and load

For making the connections you would need the following components: a

denite purpose contactor, control transformer, and fuse.

For recommendations please refer the tech brief

https://support.enphase.com/s/article/Load-and-Solar-Circuit-Control-using-Enpower-Auxiliary-Contacts

Steps for connecting auxiliary contact for shedding excess PV or load:

1. Use wires sized per local code requirements taking into consideration

the voltage drop/rise and upstream breaker or fuse.

2. Connect one of the primaries of the control transformer to 120V

breaker, and the other wire to the neutral bus in the backup load panel

via an OCPD such as an inline fuse.

3. Connect one wire of the secondary of the control transformer to one of

the terminals of either NO/NC auxiliary contact from I/O-1 or I/O-2 on

IQ System Controller 2.

4. Connect the other terminal of the auxiliary contact to the 24Vac coil

terminal (usually named A1) of the denite purpose contactor.

5. Connect the other terminal of the contactor coil (usually named A2) to

the other wire of the secondary of the control transformer.

6. For shedding excess load:

a. Connect the L1 (and L2 if 240V) terminal of the denite purpose

contactor to the backup load panel protected by a breaker.

b. Connect the T1 (and T2 if 240V) terminal of the contactor to the

excess load circuit that needs to be shed.

7. For shedding excess PV:

a. Connect the L1 and L2 terminals of the denite purpose contactor to

the OCPD (e.g., breaker in the AC combiner) protecting the inverter

output circuit of the excess PV to be shed.

b. Connect the T1 and T2 terminals of the denite purpose contactor to

the inverter output circuit of excess PV that needs to be shed.

7

I/O - 1

(24V, 1A)

I/O - 2

(24V, 1A)

Gen - I/O

(24V, 1A)

NO1 NO2 NC1 NC2 NO3

RSD

NC3 NC4

AC CombinerPV/Storage Generator

Line diagram for auxiliary contact connections image shows NO1 is used

to shed excess loads and NO2 is used to shed excess PV. See our technical

brief, Load and Solar Circuit Control using IQ System Controller Auxiliary

Contacts (https://support.enphase.com/s/article/Load-and-Solar-Circuit-Control-using-Enpower-Auxil-

iary-Contacts), for detailed line diagram and other details.

B. Securing Auxiliary Contact to IQ System Controller 2

IQ System Controller 2 is shipped with feed through headers pre-installed on

the terminals.

Follow the below steps to secure the headers to IQ System Controller 2, as

shown in Feed through headers for I/O-1 and I/O-2 image.

1. Insert the wires from the transformer controller and the external

contactor into the feed through header.

NOTE: Supports AWG 28 to AWG 16 wire sizes

2. Tighten the screws on the top (torque 0.22Nm to 0.25Nm) to secure

the wires.

Follow same procedure for generator dry contact connections (There are 3

terminals on the Gen-I/O port as shown in Feed thorugh header for genera-

tor I/O image. Use the rst and third terminal for wiring.)

Auxiliary contacts In IQ System Controller 2

Line diagram for auxiliary contact connections used for shedding excess load and PV.

Feed through headers for I/O-1 and I/O-2

Feed through header for generator I/O

2. Tighten these screws to

hold the wires in place

1. Insert wires here

Insert wires in these

terminals

Generator Connections

An auto-start generator can be integrated with the Enphase Storage system

without the need for any external ATS.

NOTE: This system is only compatible with permanently installed, hardwired

generators that are non-separately derived as per NEC 250.35(B).

Steps for connecting a generator are listed below:

A ) Wire the L1 and L2 AC wires from the generator into the generator lugs

on the IQ System Controller 2.

B ) Ensure that the ground terminal of the generator is connected to the

ground bar inside IQ System Controller 2. Size the generator’s equipment

grounding conductor as per NEC 250.122 and generator manufacturer’s

instructions.

C ) Connect the neutral wire from generator to an appropriately sized posi-

tion on the neutral bar inside IQ System Controller 2.

NOTE: IQ System Controller 2 does not switch the neutral and the ground

from the generator. It only switches the feeders i.e., L1 and L2. Therefore,

the generator needs to be congured as a non-separately derived system.

D ) Buy and install an appropriately sized breaker for the generator on the

IQ System Controller 2’s busbar and connect the L1 and L2 generator cables

from IQ System Controller 2’s ATS board to this breaker.

NOTE: The maximum allowed breaker size is 80A. Select an Eaton BR

breaker model that has the hole for the additional fastener as per NEC

480.36(D). Available models: BR220B, BR230B, BR240B, BR250B. Eaton

breaker BR260, BR280 already has the hole.

8

E ) Purchase and install a hold-down screw kit (SKU: EP200G-NA-HD-200A)

to secure the Generator breaker.

F ) Install a pair of generator CTs (CT-200-SPLIT) for L1 and L2 at the IQ

System Controller 2’s Generator input terminal for power monitoring when

the generator is running. Detailed CT wiring is described in step 9.

G ) Use Enphase Installer App mobile application to commission and pro-

gram IQ System Controller 2 to control the generator.

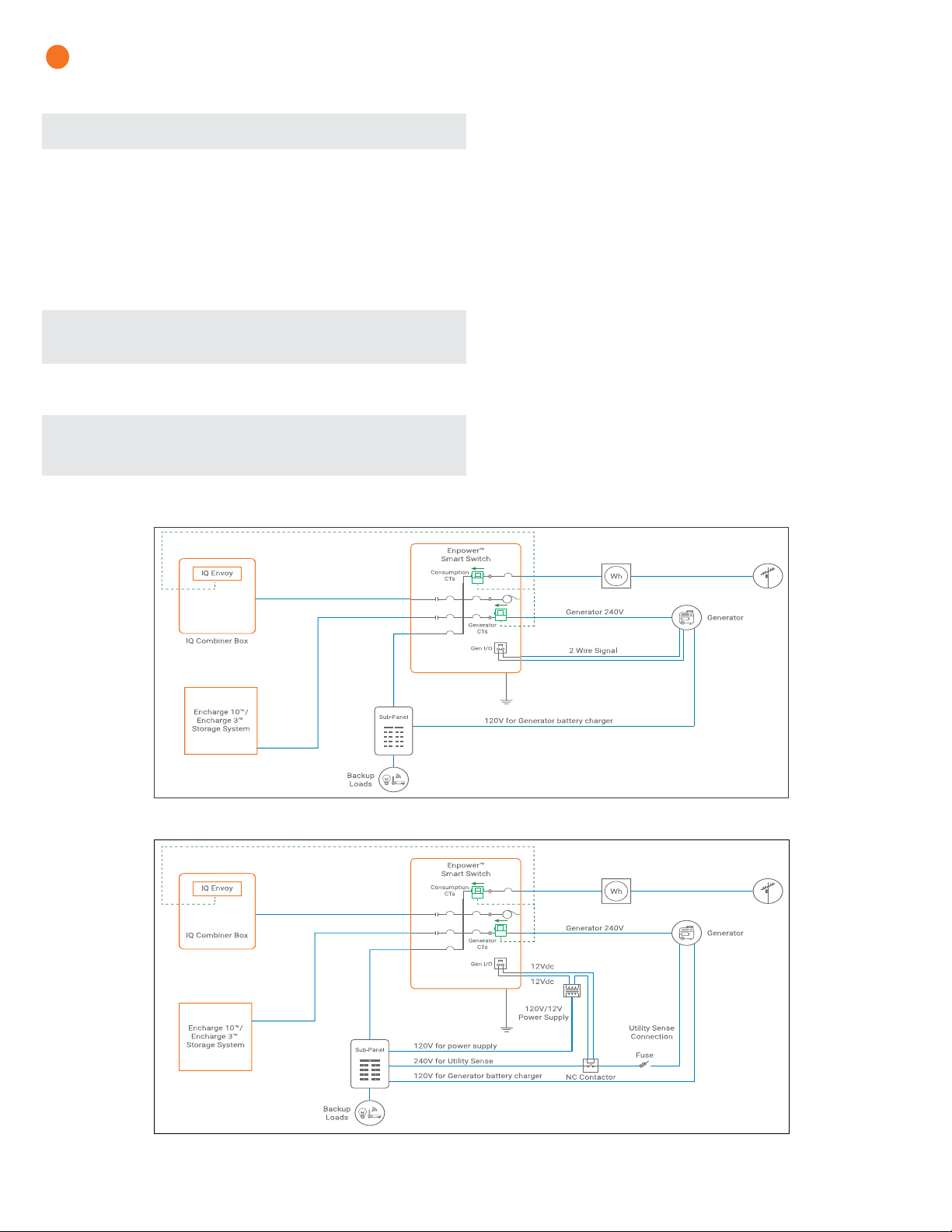

H ) For 2-wire autostart generators, wire the Generator I/O port in IQ System

Controller 2 to the 2-wire remote start terminals of the generator. Refer Step

7 for steps on how to secure the auxiliary contacts to IQ System Controller

2. Follow local code requirements for wire sizing.

I ) Autostart generators typically require a constant 120 Vac for battery

charger. This power can be drawn from the backup loads panel protected by

a breaker so that it is powered even during an outage.

J ) For permanently installed Propane/Natural gas generators, have a certi-

ed contractor install the gas line required to supply the unit.

K ) Some utility-sense based generators like the Generac Guardian come

with the capability to auto start generators when system goes off grid by

sensing the absence of the 240V utility power. For such utility-sense based

remote start generators, install the utility sensing generator start/stop

control circuit. Wire the primary of a 120V/12V power supply to the backup

loads panel. Connect the secondary to the Generator auxiliary contact relay

on the IQ System Controller 2. Wire the other end of the relay to the coil

of the Normally Close contactor. Connect the contactor to 240V from the

backup loads panel for utility sensing. Wire the other end of the contactor to

the Generator through a fuse.

Line diagram for 2-wire remote start generator connection

Line diagram for utility sense based remote start generator connection

Use the Enphase Installer App to commission the IQ System Controller

2. Once connected to the IQ Gateway, refer to the Installer Toolkit help

topics for more information.

CONFIGURE and ACTIVATE

OPERATION

If you do not see the IQ System Controller 2 information in Enphase

App, check that the IQ Gateway and the Internet connection are

Field Adjustable Trip Points

IQ System Controller 2 has adjustable voltage and frequency trip points

that may need to be set depending upon local requirements. An installer

can request Enphase Customer Support for making requested changes

to the IQ System Controller 2 trip points. It is important to ensure that all

electrical code requirements as well as requirements imposed by local

Authorities Having Jurisdictions (AHJ) are followed while setting the trip

points.

11

10

Close and energize IQ System Controller 2

* WARNING: Before energizing, make sure that ALL IQ System Control-

ler 2 connections are properly installed and conductors terminated.

A ) Reconnect the deadfront ground cable to the grounding bar, torque as

shown in the table on the unit label (and on page 4 of this guide), and

replace the deadfront using the six reserved screws. Tighten the cover

screws using a Phillips screw driver.

* WARNING! Risk of equipment damage. Ensure that no conductors are

pinched before replacing the cover.

* WARNING! Conductors are factory provided for the generator, AC

combiner and IQ Battery. If no generator is used with the system, these

conductors will not be terminated. If the IQ Combiner does not connect to

the IQ System Controller 2, these will also not be terminated. When these

wires are not terminated, they should remain stowed in the clips on the

plastic frame supporting the panel board interior and their end caps should

not be removed.

+ DANGER: Risk of electric shock. There are many potential sources

of voltage. Check any Enphase IQ Battery, PV, or other generation source

for voltage.

B ) You must ensure that all electrical circuits external to IQ System Controller

2 are completed and safe before energizing IQ System Controller 2.

9

Install the Generator CTs to standalone IQ Gateway or IQ

Gateway in the IQ Combiner box

A pair of generator CTs will be connected in parallel to the consumption CTs, if

present.

A ) Make sure that the main load center wires are de-energized until you have

secured the CT wires in the terminal blocks.

B ) Before running the CT wires through the conduit, use colored tape to mark

one of the CTs and the free end of its wires.

C ) Clamp the marked CT on Line 1 of the generator branch circuit inside the

IQ System Controller 2 box with the arrow on the CT pointing towards the

Generator breaker.

D ) Clamp the unmarked CT on Line 2 of the generator branch circuit inside the

IQ System Controller 2 box with the arrow pointing towards the Generator

breaker.

E ) Bring the CT lead wires out of IQ System Controller 2 to the standalone IQ

Gateway or IQ Gateway in the IQ Combiner box

F ) Use a screwdriver to loosen the screw on the IQ Gateway terminal block

door and open the door.

G ) Unscrew the Consumption CT wires if present

H ) For the marked CT

a. If the Consumption CT is present, use NEC approved wiring method

to splice the white wire of the CT with the white wire of Line 1 of the

consumption CT.

b. Connect the spliced white wires to the upper “C1” terminal of IQ

Gateway (“IA•” terminal for the Envoy-S Metered).

c. Splice the blue wire of the CT with the blue wire of Line 1 of the

consumption CT.

d. Connect the spliced blue wires to the lower “C1” terminal of IQ Gateway

(“IA” terminal for the Envoy-S Metered).

I ) For the unmarked CT

a. If the Consumption CT is present, use NEC approved wiring method

to splice the white wire of the CT with the white wire of Line 2 of the

consumption CT.

b. Connect the spliced white wires to the upper “C2” terminal of IQ

Gateway (“IB•” terminal for the Envoy-S Metered).

c. Splice the blue wire of the CT with the blue wire of Line 2 of the

consumption CT.

d. Connect the spliced blue wires to the lower “C2” terminal of IQ Gateway

(“IB” terminal for the Envoy-S Metered).

J ) Tighten each of the IQ Gateway terminal block screws to 5 in-lbs (0.56

Nm).

K ) Close and secure the terminal block door of the Envoy.

C ) If you work on an IQ6/7/M-series retrot system, and you plan

to energize IQ System Controller 2 and connect the PV without

commissioning the system in the same day, follow the sequence

below:

a. Leave the AC combiner breaker in the load panel where it was

originally placed, instead of connecting the AC combiner L1 and

L2 circuits to the terminal lugs in IQ System Controller. This way

your PV systems can still be functional before commissioning.

b. OPEN the NFT and IQ Battery breakers

c. CLOSE the breakers in the following order:

• Main breaker

• Load breaker

* WARNING! At commissioning, you must reconnect the AC

combiner L1 and L2 circuits back to the terminal lugs in IQ System

Controller as shown in step 5(F) in this document.

NOTE: If not commissioning the system you must ensure that the

DC switches on all IQ Batteries are turned off to avoid the depletion of

charge on the IQ Batteries.

D ) If you plan to commission the system, follow the instructions in the

Enphase Installer App for energizing IQ System Controller 2.

E ) Energize the circuit feeding the IQ System Controller 2. If installed,

turn the breaker feeding the IQ System Controller 2 to the on

position.

F ) Close and secure the door of the IQ System Controller 2.

Enphase Customer Support: enphase.com/en-us/support/contact

Safety and Advisory Symbols

+DANGER: This indicates a hazardous situation, which if not avoided, will

result in death or serious injury.

*WARNING: This indicates a situation where failure to follow instructions

may be a safety hazard or cause equipment malfunction. Use extreme

caution and follow instructions carefully.

✓NOTE: This indicates information particularly important for optimal system

operation. Follow instructions carefully.

Safety Instructions

+DANGER: Risk of electric shock. Risk of re. Only qualied electricians should

install, troubleshoot, or replace the IQ System Controller 2.

+DANGER: Risk of electric shock. Risk of re. Do not attempt to repair the IQ

System Controller 2. Tampering with or opening the IQ System Controller 2

will void the warranty. If the IQ System Controller 2 fails, contact Enphase

Customer Support for assistance at enphase.com/en-us/support/contact.

+DANGER: Risk of electric shock. Do not use Enphase equipment in a manner

not specied by the manufacturer. Doing so may cause death or injury to

persons, or damage to equipment.

+DANGER: Risk of electric shock. Do not install the IQ System Controller 2

without rst removing AC power from the photovoltaic system and ensuring

that the DC switch on the Enphase IQ Batteries are off. Disconnect the power

coming from the photovoltaics and ensure that the DC switch on the IQ

Battery batteries are off before servicing or installing.

+DANGER: Risk of electric shock. Risk of re. Do not work alone. Someone

should be in the range of your voice or close enough to come to your aid

when you work with or near electrical equipment.

+DANGER: Risk of re. Do not allow or place ammable, sparking, or explosive

items near the IQ System Controller 2.

+DANGER: Risk of electric shock. In areas where ooding is possible, install

the IQ System Controller 2 at a height that prevents water ingress.

*WARNING: Risk of equipment damage. IQ System Controller 2 is shipped

and stored on its back. The upright position is only needed when installed.

*WARNING: You must install the IQ System Controller 2 only on a suitable wall

using an Enphase wall-mount bracket.

*WARNING: Before installing or using the IQ System Controller 2, read all

instructions and cautionary markings in this guide and on the equipment.

*WARNING: Do not install or use the IQ System Controller 2 if it has been

damaged in any way.

*WARNING: Do not sit on, step on, place objects on, or insert objects into the

IQ System Controller 2.

*WARNING: Do not place beverages or liquid containers on top of the IQ

System Controller 2. Do not expose the IQ System Controller 2 to ooding.

✓NOTE: Perform installation and wiring, including protection against lightning

and resulting voltage surge, in accordance with all applicable local electrical

codes and standards.

✓NOTE: Because IQ Battery is grid forming, you must install signage in accord-

ance with NEC articles 705, 706, and 710.

✓NOTE: Using unapproved attachments or accessories could result in dam-

age or injury.

✓NOTE: Install properly rated over current protection as part of the system

installation.

✓NOTE: To ensure optimal reliability and to meet warranty requirements, the

IQ System Controller 2 must be installed and/or stored according to the

instructions in this guide.

✓NOTE: The IQ System Controller 2 is compatible only with the IQ Combiner

4/4C tted with USB hub, USB radios, and production and Consumption/

PCS CTs. The IQ Combiner with the IQ Gateway inside is required for

operation of the IQ System Controller 2. Earlier versions of the Enphase IQ

Gateway communications gateway are incompatible.

✓NOTE: The Enphase IQ System Controller 2 is intended to operate with an

Internet connection through the IQ Gateway. Failure to maintain an Internet

connection may have an impact on the warranty. See Limited Warranty for

full terms and services (enphase.com/warranty).

✓NOTE: When replacing an Enphase IQ System Controller 2, you must replace

it with an IQ System Controller 2 of the same type, with the same AC current

rating.

✓NOTE: Properly mount the IQ System Controller 2. Ensure that the mounting

location is structurally suited to bearing the weight of the IQ System Control-

ler 2.

✓NOTE: During use, storage, and transport, keep the IQ System Controller 2:

• Properly ventilated

• Away from water, other liquids, heat, sparks, and direct sunlight

• Away from excessive dust, corrosive and explosive gases, and oil smoke

• Away from direct exposure to gas exhaust, such as from motor vehicles

• Away from falling or moving objects, including motor vehicles. If mounted

in the path of a motor vehicle, we recommend a 91cm (36-inch)

minimum mounting height

• In a location compliant with re safety regulations

• In a location compliant with local building codes and standards

1NOTE: IQ System Controller 2 is not suitable for use as service equipment

in Canada.

SAFETY

IMPORTANT SAFETY INSTRUCTIONS. SAVE THESE INSTRUCTIONS. This guide contains important instructions that you must follow during installation

and maintenance of the Enphase IQ System Controller 2. Failing to follow any of these instructions may void the warranty (enphase.com/warranty).

In Case of Fire or Other Emergency

In all cases:

• If safe to do so, switch off the AC breaker for the IQ System Controller 2

circuit, and if an isolator switch is present, switch off the AC isolator for the

IQ System Controller 2 circuit.

• Contact the re department or other required emergency response team.

• Evacuate the area.

In case of re:

• When safe, use a re extinguisher. Suitable types are A, B, and C dry chemical

re extinguishers. Additional extinguishing media include carbon dioxide, or

alcohol-resistant foams.

In case of ooding:

• Stay out of water if any part of the IQ System Controller 2 or wiring is

submerged.

• If possible, protect the system by nding and stopping the source of the

water, and pumping it away.

• If water has contacted the UNIT, call your installer to arrange a inspection.

If you are sure that water has never contacted the battery, let the area dry

completely before use.

In case of unusual noise, smell or smoke:

• Ensure nothing is in contact with the IQ System Controller 2 or in the venting

area on top of the IQ System Controller 2.

• Ventilate the room.

• Contact Enphase Customer Support at enphase.com/en-us/support/contact.

Safety Instructions, continued

Environmental Protection

ELECTRONIC DEVICE: DO NOT THROW AWAY. Waste elec-

trical products should not be disposed of with household

waste. Refer to your local codes for disposal requirements.

This manual suits for next models

11

Table of contents

Other enphase Controllers manuals