Enpirion EN5367QI User manual

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 1 of 8

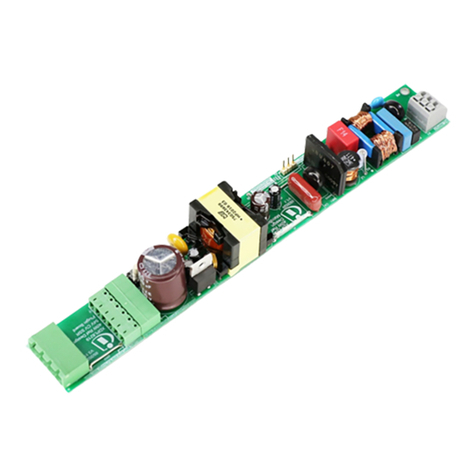

Enpirion EN5367QI DC-DC Converter

w/Integrated Inductor Evaluation Board

Introduction

Thank you for choosing Enpirion, the source for ultra small foot print power converter

products! This evaluation board user guide applies to EN5367QI. The EN5367QI is a 6A

device. In addition to this document, you will also need the latest device datasheet.

•The EN5367QI features integrated inductor, power MOSFETS, controller, a bulk

of the compensation network, and protection circuitry against system faults. This

level of integration delivers a substantial reduction in footprint and parts count

over competing solutions. The evaluation board is optimized for engineering ease

of testing through programming options, clip leads, test points etc.

•The EN5367QI features a customer programmable output voltage by means of a

resistor divider. The resistor divider allows the user to set the output voltage to

any value within the range 0.75V to (VIN-VDROPOUT). The evaluation board, as

shipped is populated with a 4 resistor divider option. The upper resistor is fixed

and has a phase lead capacitor in parallel. One of 4 lower resistors is selected

with the jumper option for different output voltages to change VOUT, retain the

upper resistor and capacitor values and change only the lower resistor.

•This device has no over-voltage protection feature. If making modifications to the

board, we strongly recommend the customer to ensure the feedback loop is truly

closed before powering up the device especially if the load can not withstand the

input voltage.

•The input and output capacitors are X5R or X7R multi-layer ceramic chip

capacitors. The Soft-start capacitor is a small 47nF X7R MLCC. Pads are

available to have multiple input and output capacitors. This allows for evaluation

of performance over a wide range of input/output capacitor combinations.

•The jumper labeled LLM/SYNC pin controls the SYNC pin. LLM (light-load mode)

function is not available on this part. This pin should be pulled LOW if the SYNC

function is not to be used. Do not leave this pin floating or high.

•The jumper labeled VDROOP should be left grounded. This function is not

available on this part.

•Clip-on terminals are provided for POK, and ENA, pins.

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 2 of 8

•Banana jacks are provided for VIN and VOUT power terminals. Several signal and

GND clip-on test points are also provided to measure VIN, VOUT, and GND nodes.

•A jumper is provided for controlling the Enable signal. Enable may also be

controlled using an external switching source by removing the jumper and

applying the enable signal to the ENA clip-on terminal.

•A jumper is also provided to connect a POK pull-up resistor to the input supply.

This jumper is especially useful to measure the disable current and eliminates

having to subtract the current drawn by the POK resistor.

•Foot print is also provided for a SMA connector to SYNC input. A switching input

to this pin allows the device clock to be phase locked to an external signal. This

external clock synchronization allows for moving any offending beat frequency to

be moved out-of-band. A swept frequency applied to this pin results in spread

spectrum operation and reduces the peaks in the noise spectrum of emitted EMI.

•The board comes with input decoupling and reverse polarity protection to guard

the device against common setup mishaps.

Quick Start Guide

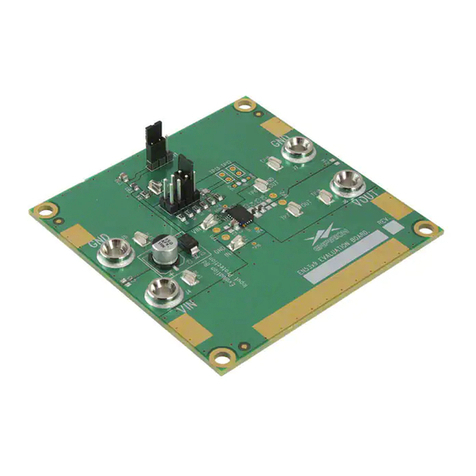

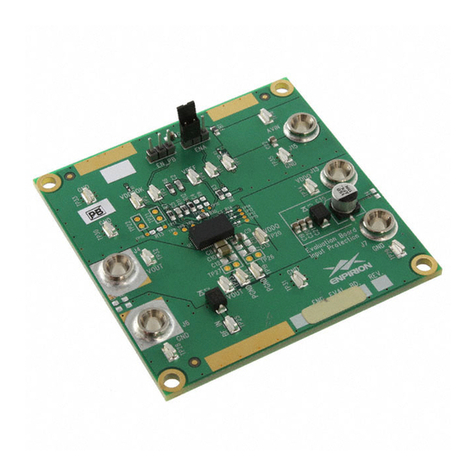

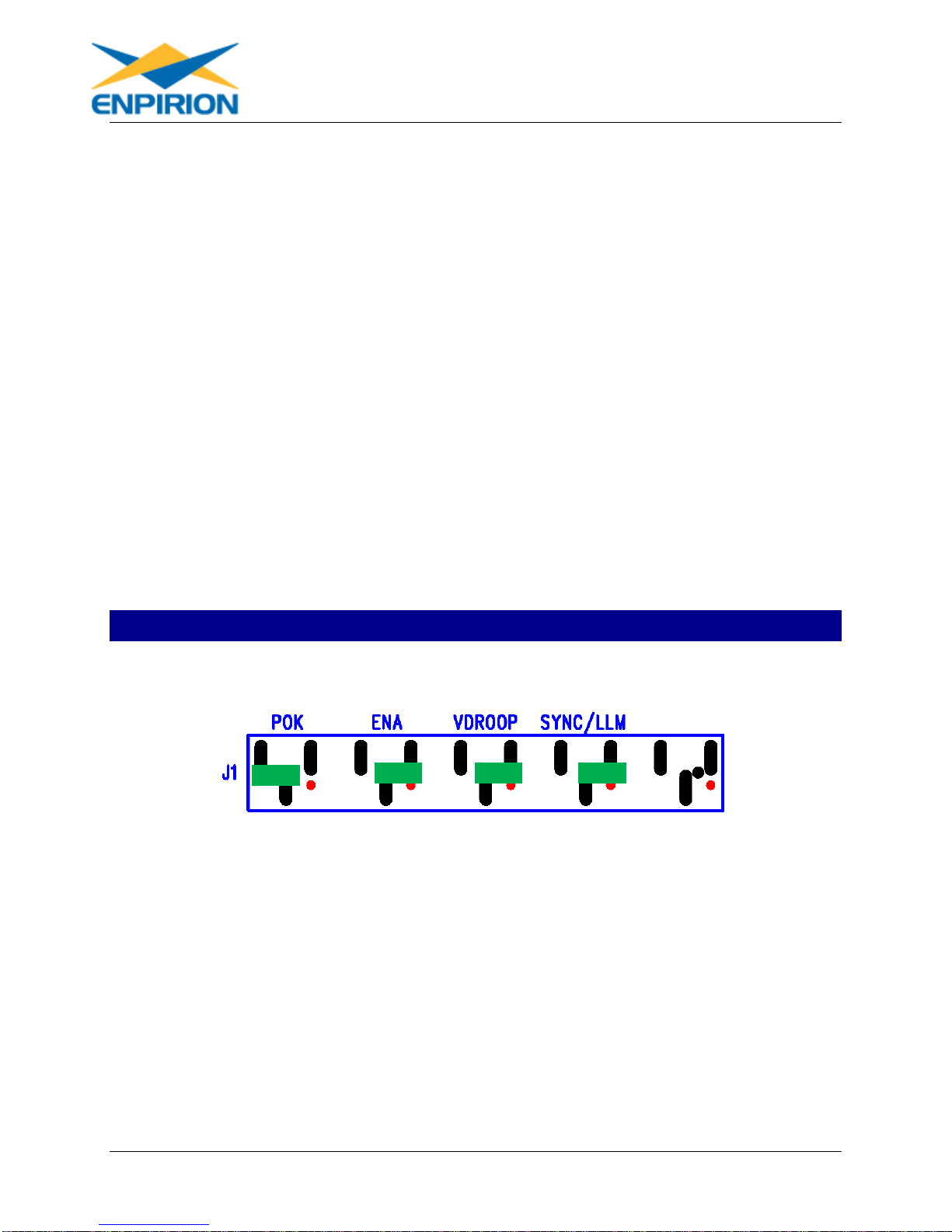

STEP 1: Set the “ENABLE” jumper to the Disable Position, as shown in Figure 1.

Figure 1: Shows POK, Enable, VDROOP and SYNC/LLM Jumpers.

POK PWR jumper as shown connects the pull-up resistor to VIN.

Enable jumper shown is in DISABLE position. SYNC/LLM jumper as

shown ties this pin Low. VDROOP jumper as shown is low, and

should stay grounded.

STEP 2: Connect Power Supply to the input power connectors, VIN (+) and GND (-) as

indicated in Figure 1 and set the supply to the desired voltage. The device disable

current may be measured in this configuration.

CAUTION:be mindful of the polarity. Even though the evaluation board comes with

reverse polarity protection diodes, it may not protect the device under all conditions.

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 3 of 8

STEP 3: Connect the load to the output connectors VOUT (+) and GND (-), as

indicated in Figure 1.

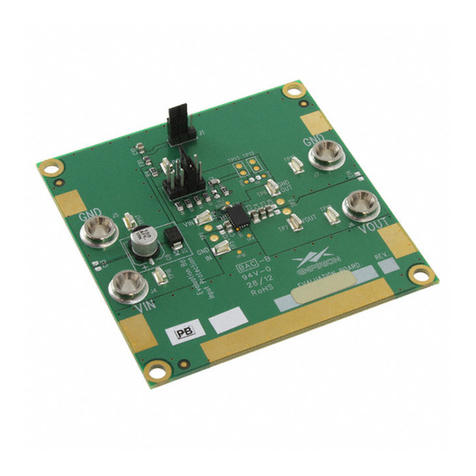

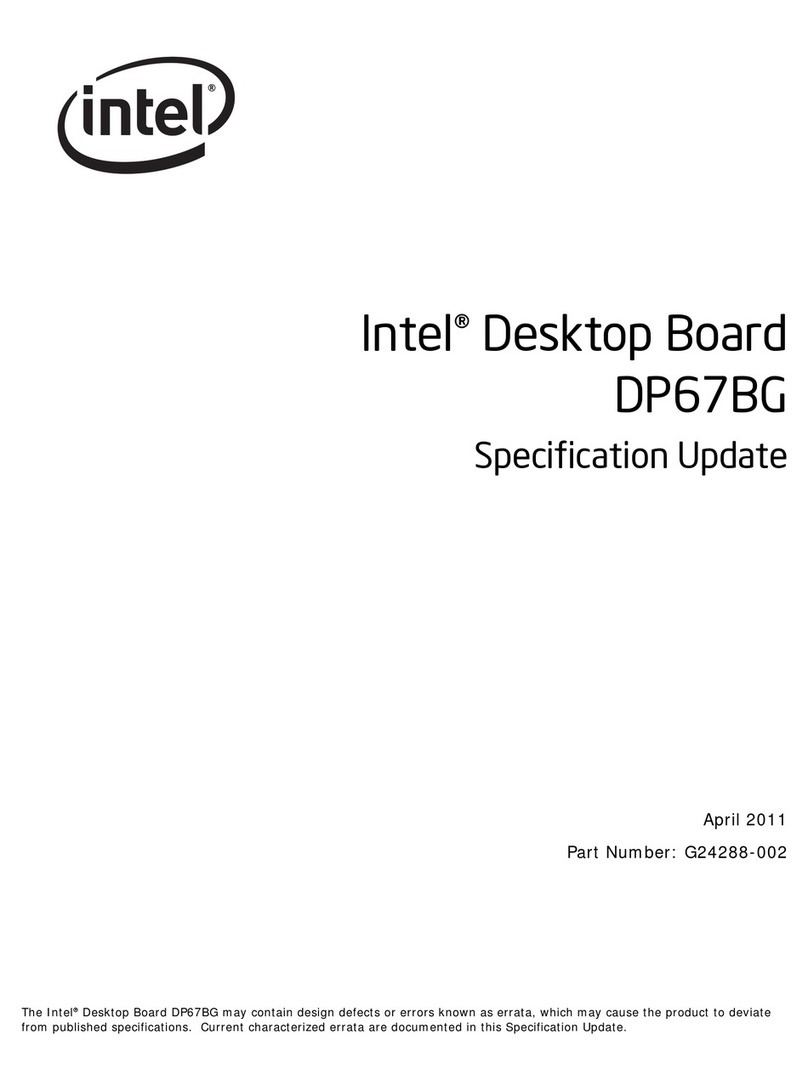

STEP 4: Select the output voltage setting jumper. Figure 2 shows what output voltages

are achieved by selecting each jumper position. Populating multiple jumper positions

will allow you to select higher output voltages. You can populate up to all four jumper

positions for the highest VOUT of approximately 3.73V with the resistors populated on the

board.

Figure 2: Output Voltage selection jumpers

Jumper shown selects 1.55V output

(Jumper positions from left to right are: 2.25V, 1.55V, 1.2V and 1.0V)

STEP 5: Set the POK PWR and SYNC/LLM jumpers to desired positions (see Figure 1).

You should disable POK when measuring low value input currents. The SYNC/LLM

jumper should be tied low unless external frequency synchronization is required.

STEP 6: Apply VIN to the board and move the ENA jumper to the enabled position. The

EN5367QI is now powered up! Various measurements such as efficiency, line and load

regulation, input / output ripple, load transient, drop-out voltage measurements may be

conducted at this point. The over current trip level, short circuit protection, under voltage

lock out thresholds, temperature coefficient of the output voltage may also be measured

in this configuration.

CAUTION: The maximum allowable VIN for this device is 5.5V.

STEP 6A: Power Up/Down Behavior – Remove ENA jumper and connect a pulse

generator (output disabled) signal to the clip-on test point below ENA and Ground. Set

the pulse amplitude to swing from 0 to 2.5 volts. Set the pulse period to 10msec. and

duty cycle to 50%. Hook up oscilloscope probes to ENA, POK and VOUT with clean

ground returns. Apply power to evaluation board. Enable pulse generator output.

Observe the VOUT voltage ramps as ENA goes high and again as ENA goes low. The

device when powered down ramps down the output voltage in a controlled manner

before fully shutting down. The output voltage level when POK is asserted /de-asserted

as the device is powered up / down may be observed as well as the clean output

voltage ramp and POK signals.

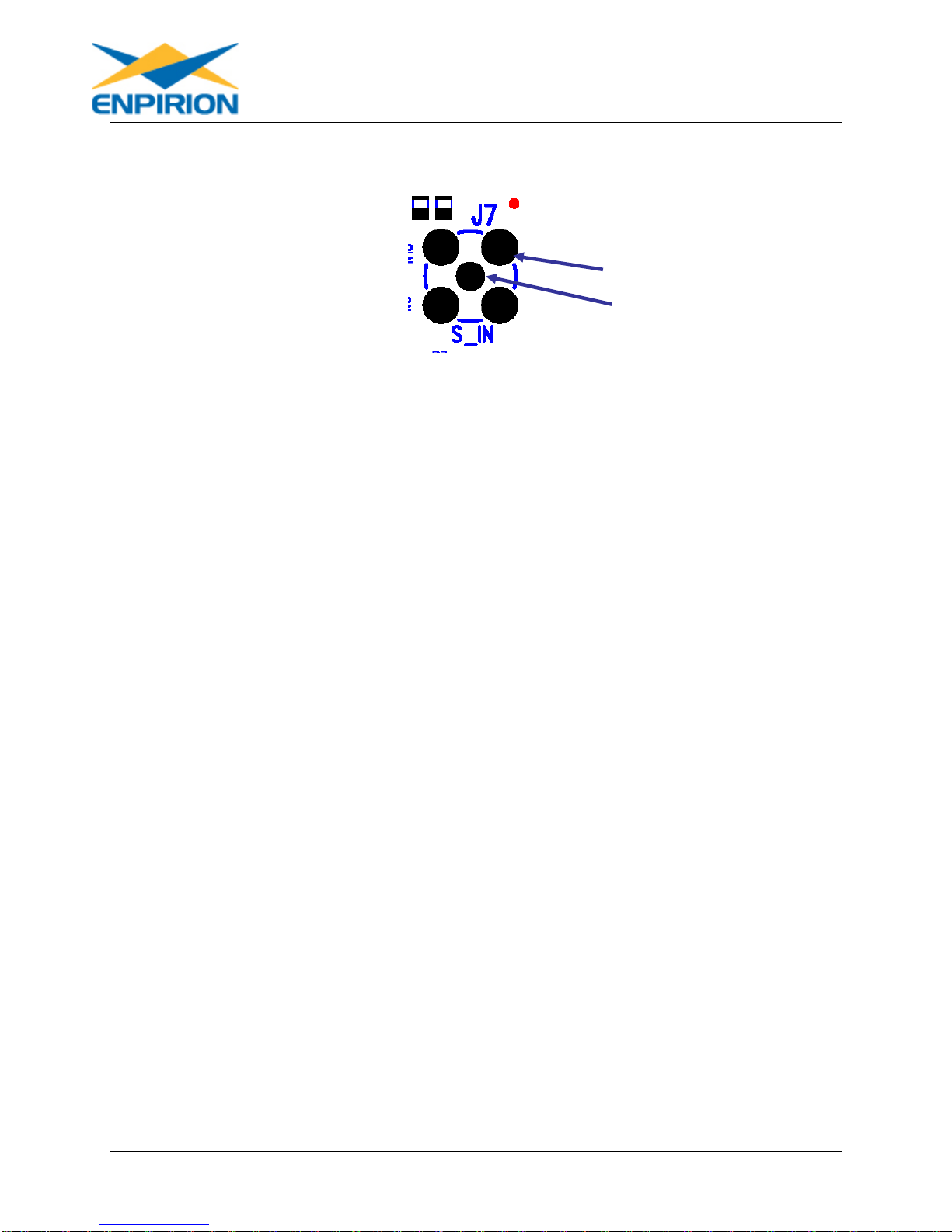

STEP 7: External Clock Synchronization / Spread Spectrum Modes: In order to

activate this mode, it may be necessary to a solder a SMA connector at J7. Alternately

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 4 of 8

the input clock signal leads may be directly soldered to the through holes of J7 as

shown below.

Figure 3: SMA Connector for External Clock Input

Power down the device. Move ENA into disable position. Connect the clock signal as

just indicated. The clock signal should be clean and have a frequency in the range of

the nominal frequency ±15%; amplitude 0 to 2.5 volts with a duty cycle between 20 and

80%. With SYNC signal disabled, power up the device and move ENA jumper to

Enabled position. The device is now powered up and outputting the desired voltage.

The device is switching at its free running frequency. The switching waveform may be

observed between test points SW and GND. Now enabling the SYNC signal will

automatically phase lock the internal switching frequency to the externally applied

frequency as long as the external clock parameters are within the specified range. To

observe phase-lock connect oscilloscope probes to the input clock as well as to the SW

test point. Phase lock range can be determined by sweeping the external clock

frequency up / down until the device just goes out of lock at the two extremes of its

range.

For spread spectrum operation the input clock frequency may be swept between two

frequencies that are within the lock range. The sweep (jitter) repetition rate should be

limited to 10 kHz. The radiated EMI spectrum may be now measured in various states –

free running, phase locked to a fixed frequency and spread spectrum.

Before measuring radiated EMI, place a 10uF/0805, X7R capacitor at the input and

output edges of the PCB (C14 and C15), and connect the input power and the load to

the board at or near these capacitors. The added capacitor at the input edge is for high-

frequency decoupling of the input cables. The one added at the output edge is meant to

represent a typical load decoupling capacitor.

GND

Ext. Clock

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 5 of 8

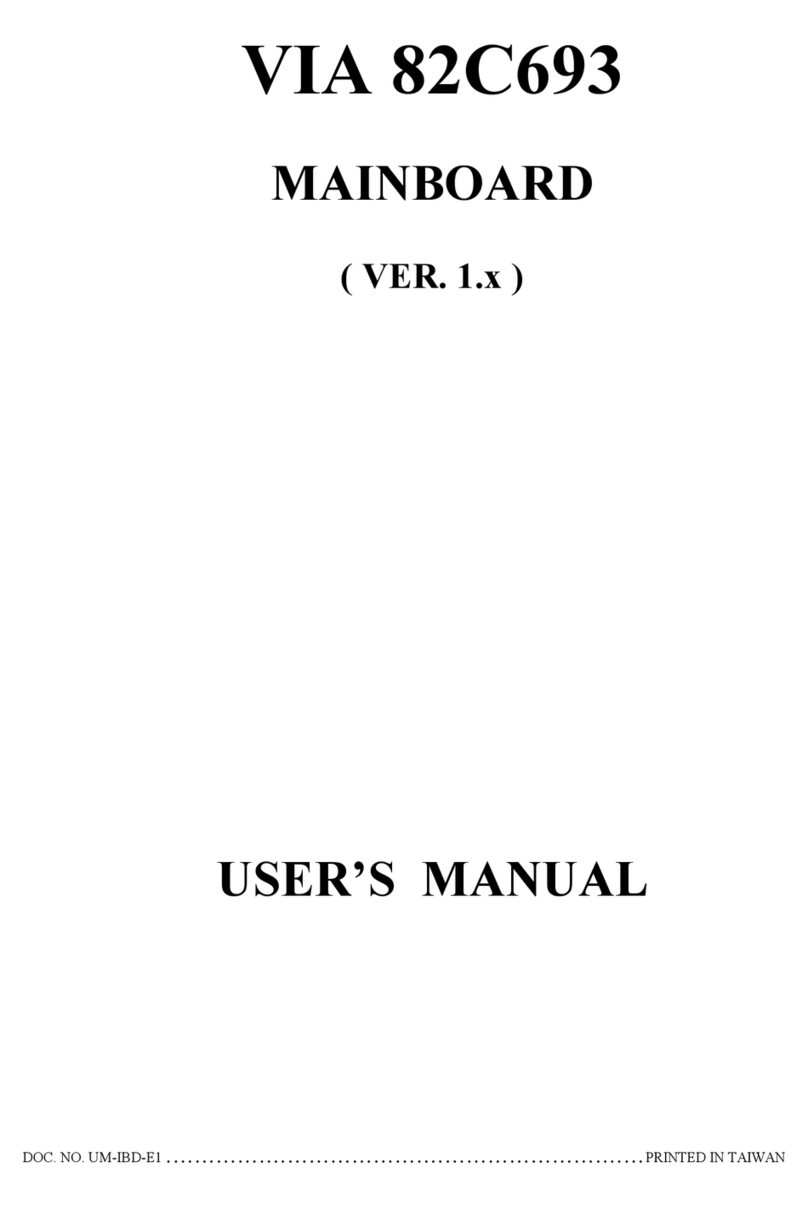

Figure 4: Evaluation Board Layout Top and Assembly Layers

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 6 of 8

Use combination

1206/0805 footprint C6-7

0805 0805

0805

0805

1206

1206 1206

1206

0805

0402

0402

0805

0805

0805

0805

0805

0805

PVIN

PVIN

S_IN

C16

0402

J1

1

2

3

5

6

7

9

10

11

13

14

15

17

18

19

R2

C1

C2

R5

R3

R4

TP23

TP24

U1

EN5367QI

NC1

1

NC2

2

NC3

3

NC4

4

NC5

5

NC6

6

NC7

7

NC8

8

NC9

9

VOUT

10

VOUT

11

VOUT

12

VOUT

13

VOUT

14

VOUT

15

VOUT

16

VOUT

17

NC18

18

NC(SW)19

19

NC(SW)20

20

PGND

21

PGND

22

PGND

23

PGND

24

PGND

25

PGND

26

PGND

27

SYNC/LLM 36

BGND 35

VDDB 34

BTMP 33

PG 32

PVIN 31

PVIN 30

PVIN 29

PVIN 28

NC54 54

NC53 53

NC(SW)52 52

NC(SW)51 51

NC(SW)50 50

NC(SW)49 49

NC48 48

AVIN 47

AGND 46

NC45 45

VFB 44

SS 43

RLLM 42

EAOUT 41

NC40 40

POK 39

ENABLE 38

VDROOP 37

ENA

VDROOP

SYNC/LLM

0805

POK

R8

J7

C10

TP26 TP27

C17

R10R11R12

R13

TP3TP4

TP5 TP6

TP7

TP8

TP9

Provision for

dynamic voltage

adjustment

R9 C11

EAOUT VFB

VFB

EAOUT

VFB

TP29

C3

TP30

FB1

C4

C5

C6

C7

TP10 TP11 TP12

R14

C8

TP13

TP14

TP15

C9R1

TP16

AVIN

J2

1

3

5

2

4

6

87

ENA

VDROOP

SYNC/LLM

POK

AGND

N/U

0805

0805

0805

0805

TP17

J3

J4

J5

J6

+

C13D1U2

R15

C14

TP1

1

2

TP2

1

2

R6

C15

VOUT

VOUT

PVIN

SMA 2

TP22

1

2

SCH 05820

PCB 05707

05837 Caps on back

05839 Caps on top and back

SMA 2

TP25

1

2

R7

VIN

GND

VOUT

GND

TP18TP19

TP20

TP21

VIN

GND

VOUT

0402

GND

C18

C12

Use combination

1206/0805 footprint C4-5

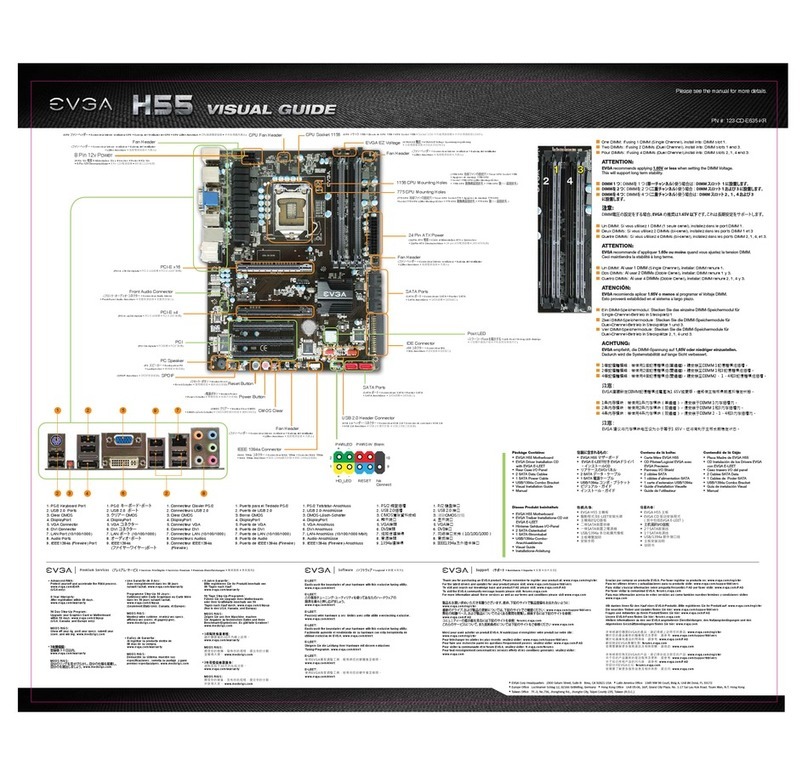

Figure 5: EN5367QI Evaluation Board Schematic

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 7 of 8

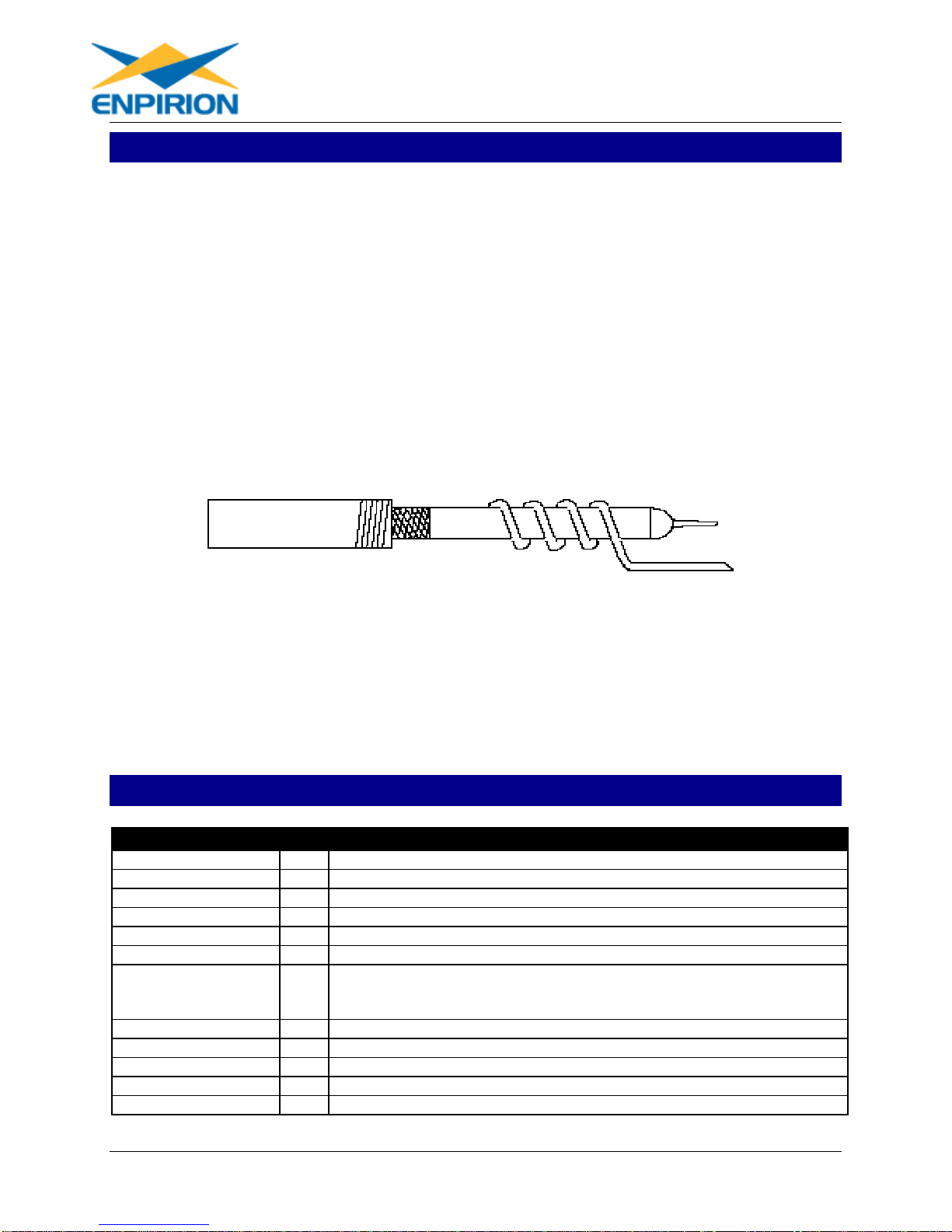

Test Recommendations

Recommendations

To guarantee measurement accuracy, the following precautions should be observed:

1. Make all input and output voltage measurements at the board using the test

points provided (TP18 to TP21). This will eliminate voltage drop across the

line and load cables that can produce false readings.

2. Measure input and output current with series ammeters or accurate shunt

resistors. This is especially important when measuring efficiency.

3. Use a low-loop-inductance scope probe tip shown below to measure

switching signals and input / output ripple to avoid noise coupling into the

probe ground lead. Input ripple, output ripple, and load transient deviation are

best measured near the respective input / output capacitors. For more

accurate ripple measurement, please see Enpirion App Note regarding this

subject.

4. The board includes a pull-up resistor for the POK signal and ready to monitor

the power OK status at clip lead marked POK.

5. A 47nF soft-start capacitor is populated on the board for ~3msec soft-start

time.

6. The over-current protection circuit typically limits the maximum load current to

approximately 1.5X the rated value.

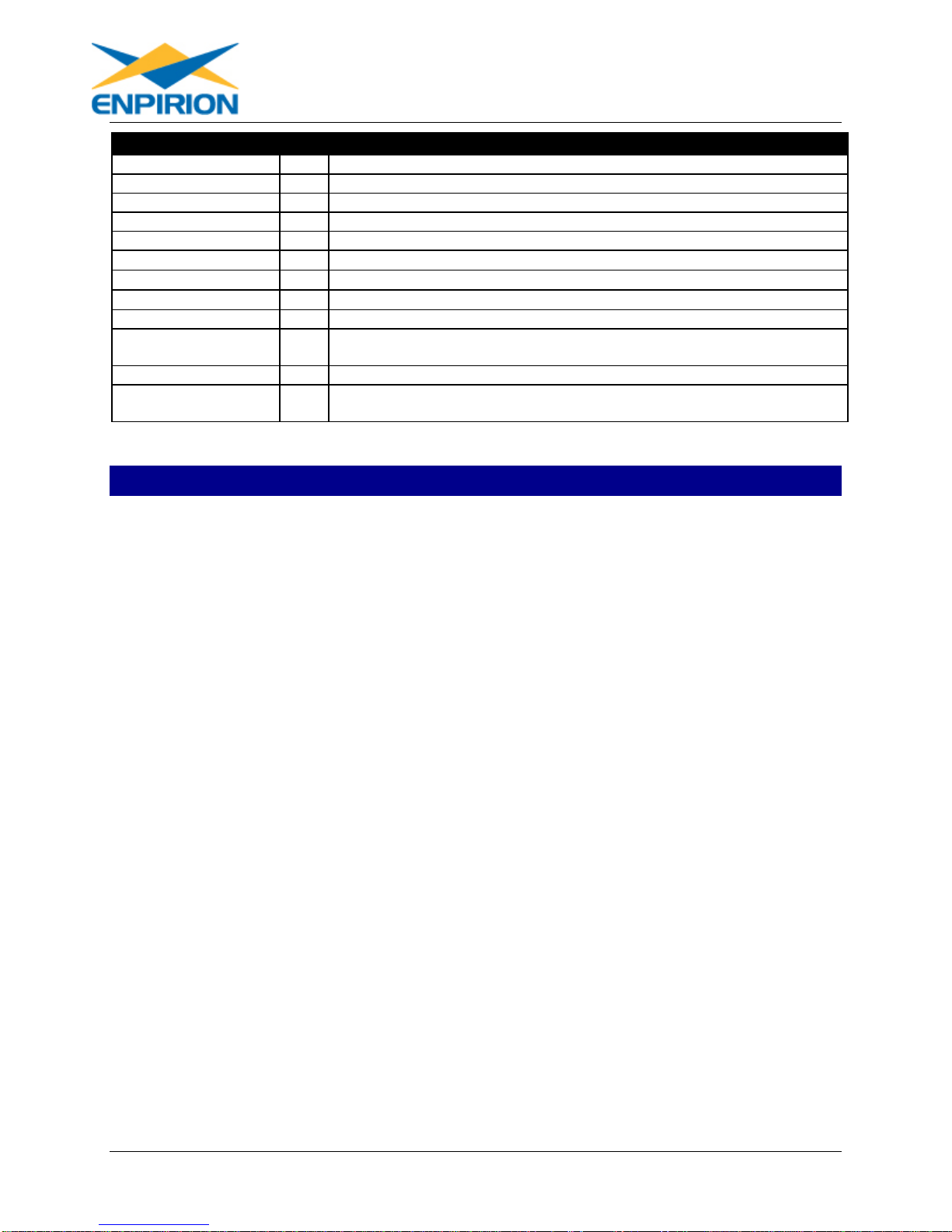

Bill of Materials

Designator Qty Description

C1, C2, C16 3 CAP, 0.1UF 10V X7R 0402 10%

C3, C7 2 CAP, 10UF 0805 X7R 10% 10V CERAMIC

C4, C10 2 CAP, 47000PF 50V X7R 0805

C5, C6 2 CAP, 47UF 10V X5R 1206, CERAMIC

C9 1 CAP, CERAMIC 18PF 5% 50V NP0 0805

C13 1 CAP, 150UF 20% 10V ALUMINUM ELECTROLYTIC

C8, C11, C12, C14,

C15, C17, C18, J7,

R6, R9-R13 14

NOT USED

D1 1 S2A DIODE

FB1 1 SMT FERRITE BEAD 4000MA 0805 (Wurth Electronik 742792012)

J1 1 CONNECTOR, CUSTOM, VERTICAL HEADER, SMT

J2 1 CONNECTOR HEADER 8POS. 100” STR TIN (Molex 90131-0124)

J3-J6 4 BANANA JACK (Keystone 575-4)

EN5367QI Evaluation Board User Guide

Jan. 2012

Page 8 of 8

Designator Qty Description

R1 1 RESISTOR 150KOHM 1/8W 0.1% 0805 SMD

R2 1 RESISTOR 442KOHM 1/8W 0.1% 0805

R3 1 RESISTOR 0.125W 249KOHM 0.1% 0805

R4 1 RESISTOR 140KOHM 1/8W 0.1% 0805 SMD

R5 1 RESISTOR 75.0KOHM 1/8W 0.1% 0805 SMD

R7 1

RESISTOR 10 OHM 0.1% 0402

R8 1

RESISTOR 200K OHM 0.1% 0805

R14 1

RESISTOR 100K OHM 0805 1%

R15 1 RES 3.57K OHM 1/8W 1% 0805

TP6-TP9, TP18-

TP21, TP29, TP30 10 TEST POINT SURFACE MOUNT (Keystone 5016)

U1 1 EN5367QI 6A QFN GOOD TESTED PRODUCT

U2 1

TRANSIENT VOLTAGE SUPPRESSOR, 6.5V, BIDIRECTIONAL

(Fairchild SMBJ6V5CA)

Contact Information

Enpirion, Inc.

Perryville III Corporate Park

53 Frontage Road - Suite 210

Hampton, NJ 08827 USA

Phone: +1-908-894-6000

Fax: +1.908-894-6090

www.enpirion.com

Enpirion reserves the right to make changes in circuit design and/or specifications at

any time without notice. Information furnished by Enpirion is believed to be accurate and

reliable. Enpirion assumes no responsibility for its use or for infringement of patents or

other third party rights, which may result from its use. Enpirion products are not

authorized for use in nuclear control systems, as critical components in life support

systems or equipment used in hazardous environments without the express written

authority from Enpirion.

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Intel:

EN5367QI-E EVB-EN5367QI

Table of contents

Other Enpirion Motherboard manuals