ensto enervent Plaza eco EDA User manual

Ventilation unit with heat recovery

Planning, installation and operational instructions manual

www.enervent.

EDA

Enervent Digital Automation

This instruction covers all ventilation units with EDA-control.

Before installing and operating this unit,

please read this manual thoroughly, and retain it for further reference.

2

TABLE OF CONTENTS

TABLE OF CONTENTS

OVERVIEW

WARNING 3

TYPE MARKING 3

TYPE DESCRIPTION 4

FOREWORD 4

OPERATING PRINCIPLE 4

DUCT HEAT INSULATION 5

INSTALLATION

EQUIPMENT 6

INSTALLATION 6

DRAINING THE VENTILATION UNIT 8

DEFINING ADDRESSES FOR OPERATING PANELS 9

USER GUIDE

STARTING THE UNIT 10

SUPPLY AND EXTRACT AIR CALIBRATION 10

OVERVIEW ON VENTILATION 10

CONTROL PANEL AND CONTROL 11

MAINTENANCE

MAINTENANCE 25

FAULT ALARMS 26

HEAT EXCHANGER BELT REPLACEMENT 27

TROUBLESHOOTING 28

TECHNICAL INFORMATION

TECHNICAL INFORMATION 30

DIMENSION DRAWINGS 31

HEAT RECOVERY EFFICIENCY 41

CHARACTERISTIC CURVES 44

CONTROL CHARTS AND WIRING DIAGRAMS 52

WATER COIL PRINCIPLE CHARTS 53

CONTROL CHARTS 54

WIRING DIAGRAMS 58

OUTER WIRING 67

INFORMATION ABOUT MODBUS 67

AIR FLOW REGULATION OF UNIT WITH EDA CONTROL 69

DECLARATION OF CONFORMITY 69

THE PARAMETERS OF EDA CONTROL 73

VENTILATION UNIT QUICK GUIDE

Copyright Enervent® 2013. All rights reserved.

3

Enervent EDA MD EN 2013_1

OVERVIEW

!

• Cut the power to the unit before opening the maintenance hatch!

After opening the maintenance hatch wait for two (2) minutes before starting the main-

tenance work! The fans rotate for a while even after the power is cut and the after heater

in EDE-models can be hot. There are no user-serviceable parts inside the control panel

or inside the electrical cabinet, leave the service of these parts to a professional. It is im-

portant during troubleshooting not to turn on the power to the unit before being as-

sured what the problem is.

• Theunitmustbedisconnectedfromtheelectricnetworkifvoltagetests,insulation

resistance measuring or other measurings/electrical work, which can harm sensitive

electronic equipment are done.

WARNING

• Theregulationandcontrolequipmentoftheunitcancauseleakagecurrent.Thereforethefaultcurrentprotec-

tion doesn’t always work correctly with the unit. The electrical connections must be made according to prevai-

ling local directives.

• AllventilationdeviceswithEDA-controlaretobeequippedwithovervoltageprotection.

• Ventilationsystemswithwatercoilshavetobeequippedwithdampersinordertopreventfreezing

of the coil during power cuts.

TYPE MARKING

Inside the ventilation unit is a type shield. Fill in the type shields data here to have it easily available when it is needed, e.g.

when buying new lters. Before you start reading, please check the type marking of the unit.

This manual covers the following units:

EnerventPlazaecoEDA

Enervent Pingvin eco EDA

Enervent Pingvin eco XL EDA

Enervent Pandion eco EDA

Enervent Pelican eco EDA

Enervent Pegasos eco EDA

Enervent Pegasos Cooler

Enervent Pegasos eco XL EDA

Enervent Pegasos XL Cooler

Enervent LTR-2 eco EDA

Enervent LTR-3 eco EDA

Enervent LTR-6 eco EDA

Enervent LTR-7 eco EDA

Enervent LTR-7 eco XL EDA

ilmastointilaite

ventilation unit

TYYPPI/TYPE:

SRJ.NRO/SERIAL NO:

W/ V/ HZ / A:

ENSTO ENERVENT OY

KIPINÄTIE 1 06150 PORVOO

TEL +358 (0)207 528800 FAX +358 (0) 207 528844

4

OVERVIEW

Enervent LTR-3 eco EDE - CG

TYPE DESCRIPTION

Ventilation unit

frame Choice of fan

(no markings

=alternative

current fans)

Control/possible

after heating

FOREWORD

All Enervent ventilation units are designed and manufactured for use all year round. In Finland the ventilation units have

been installed in houses and other spaces for over 20 years and their popularity is increasing each year. Because of the

knowledge and experience we have amassed during these years, we can now manufacture more energy ecient and user

friendly ventilation units. The Enervent unit series is the result of a long product development. All units in the series are

very versatile and exible.

eco Ventilation unit with direct current fans.

ED Ventilation unit with EDA control, without after heater.

EDE Ventilation unit with EDA control, with after heater.

EDW Ventilation unit with EDA control and water after heater. Delivery includes cooling coil and

freezeprotection,2-wayvalve,valveactuator,ducttemperaturesensorandatemperaturecontroller.

CG Cooling Geo (groundcooling) cooling equipment. Delivery includes water cooler, 3-way valve, valve

actuator and relay control for pump. Also read the separate CG-instruction.

CW Cooling Water water cooler. Delivery includes water cooler, 3-way valve and valve actuator.

CX Cooling Expansion evaporator. Delivery includes evaporator coil and control which prevents the com-

pressor from starting too often (the ouside unit is not included). Also read the separate CX-instruction.

EDX Combination of ventilation unit and heat pump. Delivery includes evaporator coil, electrical duct heater

and outside unit. The refrigerant piping is not included. Also read the separate EDX-instrction.

Cooler (CO) Ventilation unit with built-in cooling apparatus.

Possible cooling mode

OPERATING PRINCIPLE

The ventilation units are based on a regenerative heat recovery This is achieved with a rotating heat exchanger through

which incoming air and extract air ow in opposite direction. Aluminium foils within the heat exchanger transfer heat

from the extract air to the supply air. A characteristic of the regenerative heat exchanger is its high rate of heat recovery

(or eciency).

The eciency varies from 75% to 85%, depending on the proportion of supply air and extract air (the heat from the supply

air fan is taken into account). Thanks to their high eciency, the units save heating energy at the same time as they provide

excellent indoor air quality; therefore they pay themselves back in a relatively short time.

5

Enervent EDA MD EN 2013_1

OVERVIEW

DUCT HEAT INSULATION

Ventilation ducts must be thermally insulated to prevent water from condensing to the inner or external duct surfaces in any

circumstances. Additionally, the air temperature must not decrease or increase excessively in the ducts because of external fac-

tors. The ventilation engineer calculates the insulation requirements depending on the placement of the ducts and the air temperatu-

res.When the insulation materials are designed, it must be taken into account that the extract air temperature may decrease signicantly

belowzerodegrees.TheOptimizersoftware,whichisavailablefromEnstoEnervent’swebsite,canbeusedtocalculatetheextractair

temperature with dierent outside air temperatures. Calculation software available from insulation material manufacturers can also be

used when designing the insulation material thickness.

Table 1: Ventilation duct thermal insulation in heating use

Supply air duct from the ventilation unit to the

supply valve

The insulation must be designed and implemented so that the

maximum air temperature change in the duct is less than 1°C.

Extract air duct from the supply valve to the venti-

lation unit

The insulation must be designed and implemented so that the

maximum air temperature change in the duct is less than 1°C.

Table 2: Ventilation duct thermal insulation in cooling use

Supply air duct from the ventilation unit to the

supply valve

The insulation must be designed and implemented so that the

maximum air temperature change in the duct is less than 1°C. At

least 18 mm of cellular rubber insulation on the duct surface and

sucient additional insulation.

Extract air duct from the supply valve to the venti-

lation unit

The insulation must be designed and implemented so that the

maximum air temperature change in the duct is less than 1°C.

Ventilation Duct Insulation Examples:

Outside air duct (fresh air duct)

Cold spaces: 100 mm of sheet, mat, or pipe-covering insulation (plus the blown wool, when used).

Warm/semi-warm spaces*:

Option 1: 80 mm insulation with vapour-proof external surface

Option 2: 20 mm of cellular rubber insulation on the duct surface and 50 mm insulation with vapour-proof external surface.

The insulation must prevent water vapour from condensing to the external duct surface and excessive air temperature rise during sum-

mer.

Supply air duct

Cold/semi-warm spaces*:

In standard ventilation the insulation must be designed and implemented so that the maximum air temperature change in the duct is

less than 1°C. For example, 100 mm of sheet, mat, or pipe-covering insulation can be used (plus the blown wool, when used).

Warm spaces: Insulation is not required in standard ventilation.

In heating and cooling use see tables 1 and 2.

Extract air duct

Warm spaces: Insulation is not required in standard ventilation.

Cold/semi-warm spaces*:

In standard ventilation the insulation must be designed and implemented so that the maximum air temperature change in the duct is

less than 1°C. For example, 100 mm of sheet, mat, or pipe-covering insulation can be used (plus the blown wool, when used).

In heating and cooling use see tables 1 and 2.

Exhaust air duct

Cold spaces: 100 mm of sheet, mat, or pipe-covering insulation

Warm/semi-warm spaces:

Option 1: 80 mm insulation with vapour-proof external surface

Option 2: 20 mm of cellular rubber insulation on the duct surface and 50 mm insulation with vapour-proof external surface.

The insulation must prevent water vapour from condensing to the external and internal duct surfaces.

Circulation air duct

The insulation must be designed and implemented so that the maximum air temperature change in the duct is less than 1°C.**

*) A semi-warm space refers also to dropped ceilings, sub-oors, and casings.

**) When Kotilämpö systems are renewed, the recycling air duct can be left as it is.

Sound insulation is not taken into account in these insulation instructions and examples.

6

INSTALALTION

EQUIPMENT

INCLUDED IN THE DELIVERY OF THE UNIT:

1. Enervent ventilation unit

2. Control panel

3. Control panel cable RJ4P4C, length 20 m (installation in a min 16 mm conduit)

SEPARATELY SOLD EXTRA EQUIPMENT:

4. Extra control panels max. 4/unit

5. Control panel cable RJ4P4C, length 20 m

6. Fine lter F7 inside the device

7. Fine lter cassette F7 in duct casing

8. Push button for over pressure function

9. CO2carbon dioxide sensor ( max. 2 can be connectedt)

10. %RH humidity sensor (max. 2 can be connected)

11. Room temperature sensor

12. Pressure-dierence transmitter for the lters (lter quard)

13. Outside air and exhaust air dampers

14. Damper motor s with spring or electrical return

15. Duct silencers

16. HRW pressure-dierence transmitter (HRW defrosting)

17. CO carbon monoxide sensors (relay controlled)

18. Push button for boosting function

19. Button LAP 5 for extended duty function in oce mode

20. Pressure-dierence switsh (cooker hood/central vacuum cleaner indication)

21. Presence sensor LA14

22. KNX gateway

23. Freeway WEB

INSTALLATION

InstallthePlaza,Pingvin,Pandion,PelicanandPegasosunitsinawarmspace(over+5°C)suchasanutilityoralaundry

room but not a garage (separate re area). Avoid installing the units in humid spaces or close to humid spaces. Likewise

spaces with poor ventilation such as closets and cabinets are not suited as installation spaces. The unit is installed hanging

onthewall(Plaza,Pingvin,PingvinXL,Pandion)orstandingontheoor(Pandion,Pelican,Pegasos).Apartitionwallisto

be preerd to an exterior wall for the units installed on a wall.

The LTR-2, LTR-3, LTR-6 and LTR-7 units can be installed in either a warm or cold space. The unit must be equipped with 100

mm extra insulation, if it is installed in a cold space. Suitable places for installation are for instance store rooms or the attic.

The unit should be placed on a plain surface on an elastic material that absorbs sound. For example, a 100 mm thick insula-

tion plate is suitable as bedding

If the unit is used to ventilate an area with a swimming pool, the unit must be drained. For more information see the drai-

nage instruction on the next spread.

PHASES OF INSTALLATION:

N.B.! To reduce the weight of the unit you can remove the heat recovery wheel before mounting the unit.

Plaza, Pingvin Pingvin XL and Pandion on the wall

1. Mark and cut the holes into the ceiling.

2. Draw the ducts through the holes to the required height. The gaps between duct and steam barrier are then

sealed, with for instance ventilation tape.

3. Place a piece of insulation material behind the unit to reduce the transfer of machine noise or vibration. We re-

commend that soft cellular plastic is used (not included in delivery). The unit surface should be equipped

with extra insulation (i.e. cellular plastic) if the unit is placed with one side towards an exterior wall or there is risk

that condense might develop on the exterior of the unit.

4. Pingvin and Pandion units: Install the rear attachment bracket directly to the wall at required height. Place the

unit onto the rear bracket and fasten it to the wall with the two top brackets. Attach the rear bracket with plate

screws to the bottom of the unit. It is crucial for Pingvin unit drainige that the unit is slightly tilted back .

Plaza: Place the unit on the wall and fasten it to the wall with the two top brackets.

4. Connect the unit to the ductsystem. It is recommended that silencers be installed to the extract and supply air

ducts.

5. Drain the unit. Read the drainage instruction.

7

Enervent EDA MD EN 2013_1

INSTALLATION

Pandion on the oor, Pelican and Pegasos

1. Install the unit on the oor or on a level built for the unit so that it stands on its own rubber pads. Leave at least

a 10 mm opening between the back of the unit and the wall and at least a 15 mm opening to the sides. Also

take into account the space needed for drainage below the unit.

2. Make sure that there is at least 95 cm of free space in front of the unit’s maintenance hatch and remember to

leave the electric wirings easily accessible. The unit has a connecting plug. The connecting cable is located in

the front corner above the smaller door. The length of the cable is 120 cm.

3. Connect the ducts to the unit with exible connectors. Silencers are recommended for the supply air and

extract air ducts.

4. Drain the unit. Read the drainage instruction.

LTR-2, LTR-3, LTR-6 and LTR-7

1. Place the unit on the insulation plate (i.e. 100 mm insulation covered with chipboard) in a storage room or in

the attic on a custom made shelf. Take into consideration the potential need for a drain.

2. Check that there is enough free space on top (above the service hatch) (LTR-2 and LTR-3 min. 50 cm, LTR-6 min

60 cm, LTR-7 min. 70 cm) and that the electrical inlets are accessible. Take into consideration that opening the

hatches requires a certain amount of space.

3. Connect the ducts to the spigots on the unit. It is recommended that silencers be installed to the extract and

supply air ducts.

4. Drain the unit. Read the drainage instruction.

N.B! Detailed dimension drawings can be found in the Chapter Technical information at the end of this manual.

Installation of duct coil

Some of the models have the after heating/cooling water coils in the duct. The duct coil is placed in the supply air duct

after the ventilation unit. The supply air temperature sensor is placed in the duct after the coil. The water coil return water

sensor is placed on the return water pipe of the coil. VEAB CWK duct coolers are manufactured only in one handedness.

Make sure the service hatch can be opened at need.The air ow direction is marked on the coil.The coil must not be turned

the oposite way, becuse the condense water drain will not work properly. Tilt the coil a little towards the condens water

drain to ensure eective draining.

8

INSTALALTION

DRAINING THE VENTILATION UNIT

All Enervent-units with cooling must be drained. We recommend that also other units are drained. When air cools down

(condenses) condense water forms i.e. in winter time when the humid inside air meets the cold heat recovery wheel or

if the unit is equipped with cooling. The condense water drain must not be directly connected to a sewer! The condense

water should be led in a falling, at least Ø15 mm pipe, through a water lock to a oor drain or such. The pipe must at all

timeslielowerthanthebottomoftheventilationunit.Theremustnotbeanylongerhorizontalsectionsonthepipeand

there mustn’t be more than one water lock. If the unit is equipped with more than one condense water draines, each one

must have a water lock of its own.

There is under pressure in the ventilation unit. We recommend a hight dierence of (A) 75 mm, or at least the under pres-

sure divided with 10 in millimeters (i.e. 500 Pa under pressure -> 50 mm), between the unit drain and the water lock drain.

We recommend that the hight of backwater in the water lock (B) is 50 mm, or at least the under pressure divided with

20 in millimeters (i.e. 500 Pa under pressure -> 25 mm hight of backwater). Over pressure is prevailing in a duct coil. We

recommend the hight dierence (A) between the duct coil drain and the water lock drain is 25 mm. The water lock hight

of backwater (B) must be 75 mm, or at least the under pressure divided wit 10 in millimeters (i.e. 500 Pa under pressure ->

50 mm). The water lock must be lled with water before starting up the unit. The water lock might dry up if water is not

accumulated in it. If this happens, ait might get into the pipe and hinder water from entering the water lock, which might

result in an irritating ”bubbling” sound.

Piccolo - EC •

Plaza - EC •

Pingvin - EC •

- EDE/-EDW •

- EDE/-EDW-CG • •

- EDX-E • •

Pandion - EC ••

- EDE/-EDW ••

- EDE-CG • • •'

- EDW-CG • •

- EDX-E • • •'

Pelican - PRO greenair HP ••

- EC ••

- EDE/-EDW ••

- EDE/-EDW-CG • • •'

- EDX-E • •

Pegasos - EC ••

- EDE/-EDW ••

- EDE/-EDW-CG • •

- EDE/-EDW-Co ••

- EDX-E • • •'

Pegasos XL - EC ••

- EDE/-EDW ••

- EDE/-EDW-CG • •

- EDE/-EDW-Co ••

- EDX-E • •

LTR-2 - EC •

- EDE/-EDW •

- EDE/-EDW-CG • •

- EDX-E • •

LTR-3 - EC •

- EDE/-EDW •

- EDE/-EDW-CG • •

- EDX-E • •

LTR-6 - EC •

- EDE/-EDW •

- EDE/-EDW-CG • • •'

- EDX-E • • •'

LTR-7 - EC •

- EDE/-EDW •

- EDE/-EDW-CG • •' •

- EDX-E • • •'

LTR-7 XL - EC •

- EDE/-EDW •

- EDE/-EDW-CG • •

- EDX • •

EMB - W-CG •

- X-E •

• condensedrain

•• twocondensedrainofthesamesize

•’ option

1/4”(inner thread)

DN32

G½”(VEAB, outer thread)

DN32 (duct case)

A

B

9

Enervent EDA MD EN 2013_1

INSTALLATION

DEFINING ADDRESSES FOR OPERATING PANELS

Four (4) operating panels can be connected to an ventilation unit with EDA-control. If an unit is controlled with more than

one panel, Modbus-addresses have to be dened for the panels in order for them to work in parallel.The address is dened

with the short-circuit plugs delivered with the panel.

1. Remove the cover plate from the back of the panel.

2. Release the panel cable, if it is connected or shut o the ventilation unit.

3. Choose a dierent address for each operating panel by short-circuiting the corresponding pins with the plugs as

shown below.

330

PANEL CABLE

ADDRESS PINS

address 1

address 2

address 3

address 4

10

USER GUIDE

USER GUIDE

STARTING THE UNIT

Before the unit is ready for use the following installations should take place:

- Assemble the unit as stated in the chapter Installation in this manual.

- Connect the drainage outlet with its own hose to an outow supplied with a water lock (if the unit ventilates a

space with swimming pool or if it is equipped with cooling).

- Install the duct and the silencers.

- EDW model coil, valve, valve actuator, return water temperature sensor and supply air duct sensor are installed

and connected.

- Water circulation of the EDW model coil is connected.

- Assemble the terminals onto the ducts.

- Provide the outside air duct with an outside air grating. N.B! the grating must not be provided with an insect net

because it is dicult to keep clean.

- Make the roof pass-through. We recommend the use of a factory made, insulated roof pass-through.

- Insulate the ducts as instructed.

- Provide the unit with the appropriate power supply.

- Connect the control panel to the unit with the RJ4P4C cable provided (to the connector OP1 of mother board).

The unit’s mother board is in the electrical connection box. In vertical units the connection box is behind the

smallerdoorunderacoverplatefastenedwithscrews.Inhorizontalunitstheconnectionboxisundertheser-

vice hatch in the upper part of the unit.

- Program the external bus. NOTE! The programming must be nished before the RJ45-bus connector is con-

nected to the mother board.

- Fill out the warranty and all possible changes in the parameter list (eld settings) at the end of this instruction.

Open the unit’s maintenance hatch when all the above mentioned installation work is done. Check that the unit is clean

on the inside, that there are no extra articles inside the unit and that the lters are clean. Close the maintenance hatch

carefully.

NB! The device is not to be started or used when the hatch is open!

SUPPLY AND EXTRACT AIR CALIBRATION

After the unit has been switched on its airows must be calibrated to its planned values. When making the calibration all

lters should be clean, all supply and extract air valves, the roof pass-through and the outside air grating should be in place.

The outside air grating must not be provided with an insect net. The extract air ow should be ca. 5 - 10 % higher than

the supply air ow. To achieve optimal values during calibration the airows should be measured at each duct opening.

A suitable measuring instrument would be a thermo anemometer. With the help of registered values the airow can be

regulated to achieve the projected values. A correctly calibrated ventilation unit is quiet and gives a good heat return and

it also upholds a small under-pressure in the house. The under-pressure stops humidity from entering the walls and ceiling.

OVERVIEW ON VENTILATION

The ventilation unit should never be switched o. Always keep the ventilation at suitable power! If the ventilation is insuf-

cient, the humidity indoors becomes too high and can result in the formation of condensation on cold window surfaces.

A relative humidity of 40 - 45 % indoors is recommended (room temperature of 20 - 22°C). At these levels condensation will

not form and the humidity will be at a healthy level. Check the indoors humidity levels regularly. This can be done with a

hygrometer. When the humidity rises above 45 % one should increase the ventilation and when the humidity goes lower

than 40 % one should lower the ventilation. Check regularly that the lters are not dirty! During winter the extract air lter

becomes dirtier more quickly than the supply air lter. As a result of this the airow lessens, which leads to a lower humidity

indoors. This also leads to lower temperatures. Check the lters each month! At each lter inspection, check that the heat

exchanger is functioning correctly, meaning that it is rotating. Cover both the outside air intake and the exhaust air outtake

if the unit is not to be used for a longer period. This way you stop moisture from condensing on e.g. the fans’electric motors.

11

Enervent EDA MD EN 2013_1

USER GUIDE

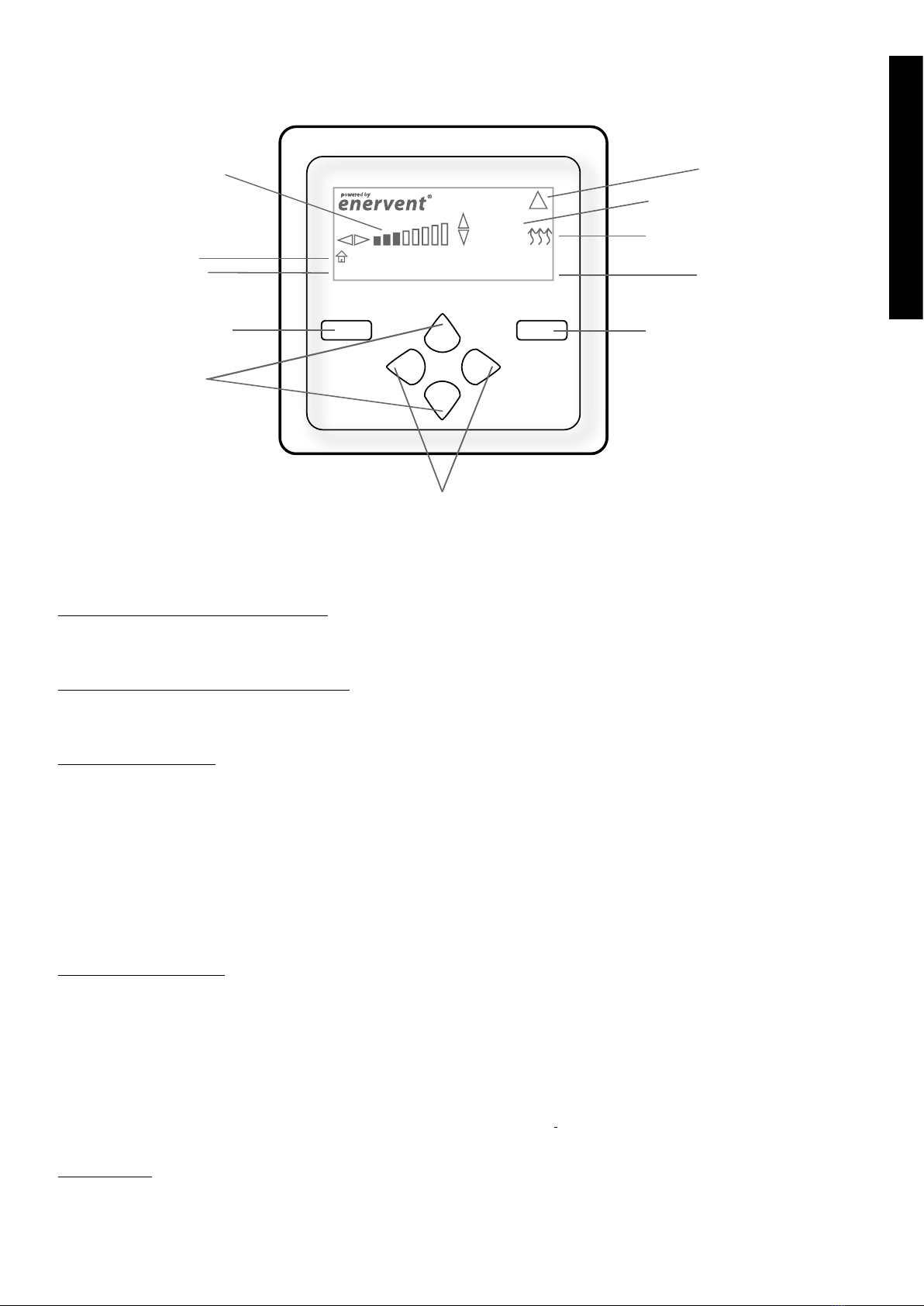

THE CONTROL SYSTEM AND OPERATING PANEL

CONTROL PANEL BUTTONS

Buttons for quick adjustment of fan speed

Press the right arrow to increase fan speed.

Press the left arrow to decrease fan speed.

Buttons for quick adjustment of temperature

Press the up arrow to increase temperature.

Press the down arrow to decrease temperature.

Left multi-choice button

By pressing the left multi-choice button while the display is in its initial starting mode, you get to the list of ”quick

functions”. From the list you can choose which functions you immediately want to activate. The selection of functions

available on this list is made in Main Menu / Settings / Quick Choice.

The following quick choice functions are available:

- Overpressure or switch for the replace

- Boosting

- Maximum heating or cooling

- Night cooling allowed or prevented

Right multi-choice button

By pressing the right multi-choice button while the display is in its initial starting mode you get to the“Main Menu”. In the

Main Menu the following options are available:

- Reading and resetting an alarm.

- Setting time and date. NOTE! The year has to be set.

- Reading of measured temperature and humidity.

- Setting of time program at both week and year level.

- Inspection of the ventilation unit’s technical information.

- With a password you can go to the“Settings”menu (only for experts).

Keypad lock

The keypad lock is activated by pressing the left multi-choice button (Quick functions) and directly pressing the ”arrow

up” . You unlock in the same way.

+

+

-

-

Quick functions Menu

Status: Home

20°C

INFO row

Fan speed settings

Function

selected with

left multifunction button

Left multifunction

button

Buttons for quick

adjustment

of temperature

Buttons for quick

adjustment of

fan speed

Right multifunct

ion

button

Function

selected

with right multifunction button

Function symbol

T

emperature settings

!

Alarm

USER GUIDE

12

USER GUIDE

DISPLAY

Setting the fan speed

Fan speed settings on direct current models

(unit with direct current fans)

Coloured bars on the display show which ventilation eect is active:

1 = 20 - 29 %, 2 = 30 - 39 %, 3 = 40 - 49 %, 4 = 50 - 59 %, 5 = 60 - 69 %, 6 = 70 - 79 %, 7 = 80 - 89 %, 8 = 90 - 100 %. The exact

valueisshownonthedisplay,withanaccuracyofonepercent,forashortwhilewhenthebuttons+and-forfanspeed

adjustment are pressed. The ventilation eect which is active is shown under boosting, if the fans are in boost mode, oth-

erwise the initial setting is show. If a dierence in the fans’speeds has been set in the “settings”menu, then the number of

bars on the display is reduced depending on the dierence in speed. If a speed dierence has not been set, the maximum

number of bars is eight.

Example:

The extract air fan’s normal speed is 50 % and the supply air fan’s normal speed is 40 %. The dierence in speed is 1, so on

the display are shown 8 - 1 = 7 bars.

Temperature Settings

The chosen temperature setting is shown in numbers. It is the extract air temperature or the room temperature if a room

temperature sensor has been installed.

Function symbols

The symbol is showing which temperature control is active

The unit is cooling.

The unit is only using heat recovery to heat up / cool down the supply air.

The unit is heating.

20°C

V

V

V

V

V

V

V

V

!

Status: Home

INFO row

This row shows which mode the ventilation unit is in. The unit can be in one of the following statuses:

Home / Away / Long away / Boosting (°C or %RH or CO2) / Overpressure / Max heat or cooling / Stove / Ce Va Cl / Night

cooling

Service and alarm messages

The symbol for Service and alarm messages appears on the display if some error occurs with the unit or if the unit is in

need of service.

13

Enervent EDA MD EN 2013_1

USER GUIDE

CONTROL OVERVIEW

To get to the main menu of the control panel, press the right multi-choice button. In the menu, you navigate by using the

up or down arrow. When you are in the menu the function alternatives, which are: ”Exit”; ”Reset”; ”Choose” and ”Change”,

are shown on the bottom edge of the display. You can select these options by pressing the multi-choice button on the

corresponding side.

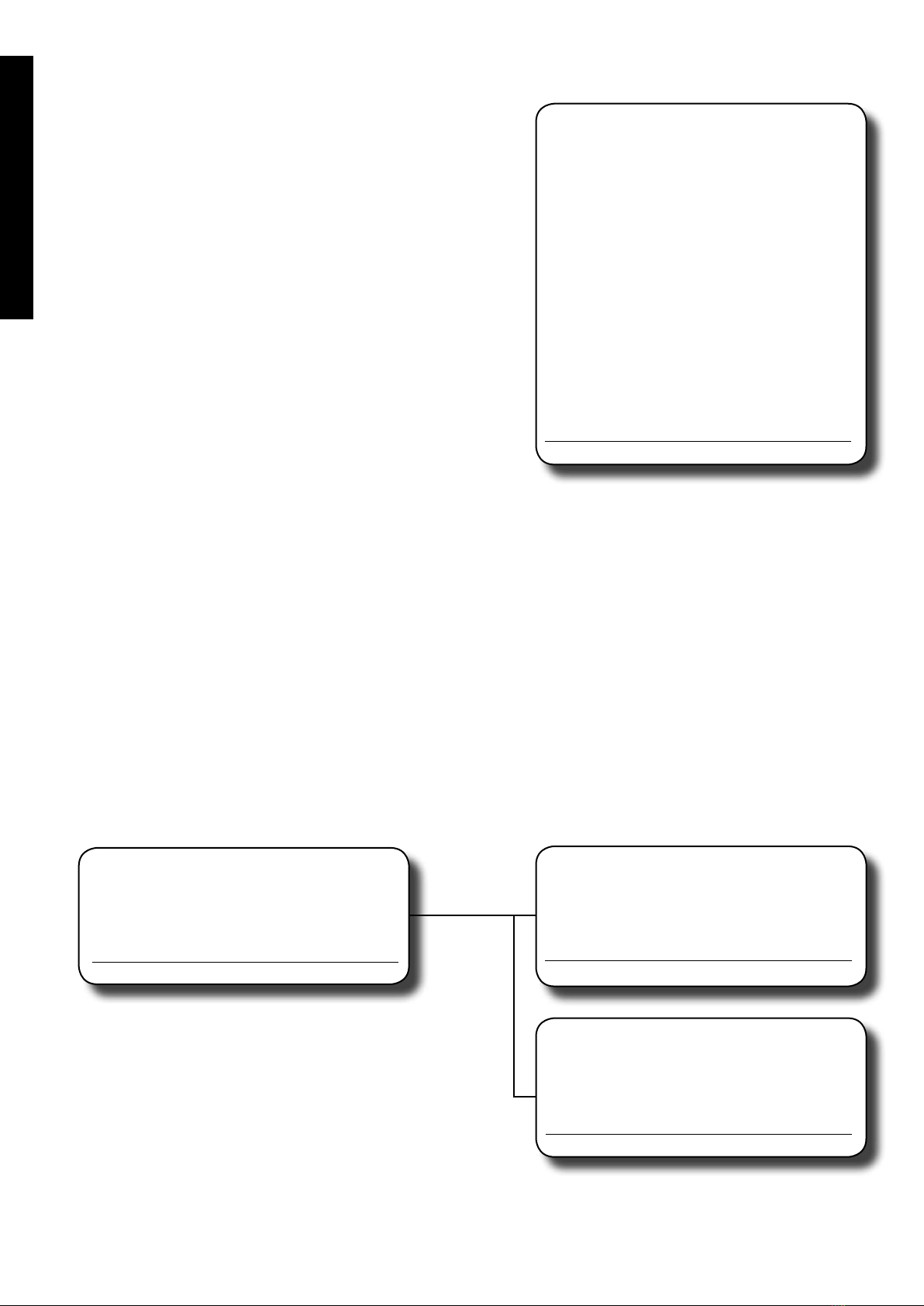

MENU STRUCTURE

Main menu:

Timeprograms

Measurements

Settings

Info

Alarm

Date and time

Year timer

Week timer

Temperatures

Situation controls

Boosting functions

Display settings

Quick choise

Other settings

Night cooling

Fan speed

page 16

page 15

page 16

page 16 Stove+CeVaCl+Overpr

Over pressure

page 17

Normal spd

CO2

Boosting settings

Humidity

page 18

page 16

Temp. boost

Away

HRC

Long away

page 20

page 23

page 24

page 23

page 19

page 19

page 19

page 19

page 21

page 22

page 22

page 21

page 22

page 23

page 23

page 23

page 23

page 14 END USER

VENTILATION ENGINEER

MANUFACTURER

XXX (=General settings) page 23

YYY (Standard duct pressure) page 19

14

USER GUIDE

MAIN MENU

ALARM

All alarm and service messages are visible in the unit’s Alarm menu. 20 alarms are shown in the list. An alarm can have one

of the following three statuses; ON, RES reset, but still active or OFF.

The alarms are divided into three classes, class A, class AB and class B. Class A alarms shut down the unit. Class AB-alarms set

the unit in failsafe mode. In failsafe mode the extract air fan runs on smallest eciency and the supply air fan stands still1.

Class B alarms do not aect the unit’s function. An alarm symbol is ashing in the display when class A and class AB alarms

are active. The light is not shown at class B alarms.

The unit doesn’t start before a class A alarm has been reset. Class AB-alarms reset automatically and the unit automatically

starts when the alarm no longer is valid.

For example TE30 min. alarm: If the extract air temperature has dropped below the set value for more than 10 min an alarm

i activated (ON) and the units goes into failsafe mode (AB-alarm). If the alarm is reset the alarm changes to RES mode, but

the failsafe situation continues. The unit does not start before the temperature rises over the set value and the alarm goes

into OFF mode.

There are two relay outputs for alarms on the EDA motherboard: ALM A and ALM B. Output ALM A conducts when a class

A alarm is active. Output ALM B conducts when an A- or AB-alarm is active and the time is within the alarm B output vali-

dity. The alarm B output can conduct weekdays between 9 am and 10 pm.

1 In passive house models also the extract air fan stops.

Main menu

Alarm

Measurements

Time programs

Info

Settings

Exit Choose

Alarm 1-20/20

Alarm name space

Alarm time DD:MM:YY HH:MM

Alarm text

Exit Reset

15

Enervent EDA MD EN 2013_1

USER GUIDE

DATE AND TIME

Setting up time, month and year. Weekday displayed automatically.

List of alarms

Alarm name Class Explanatory text row -- Alarm

limit

Delay NOTE!

TE5 min AB or B After HRC

supply air cold

+5°C 10 min Unit in failsafe mode.

TE10 min AB Supply air cold +10°C 10 min Unit in failsafe mode.

TE10 max A Fire risk supply temp high +55°C 2 sec Unit starts only after reset.

TE20 max A Fire risk room temp high +55°C 10 sec Highest measured room temperature is

higher than the set value. Unit starts only

after reset.

TE45 min A Watercoolerfreezerisk +8°C 2 sec Only EDW-units. Unit starts only after

reset.

TE30 min AB or B Extract air cold +15°C 10 min Unit in failsafe mode.

TE30 max A Fire risk extract temp high +55°C 2 sec Unit starts only after reset.

ELH-problem A Electrical coil overheating 2 sec Alarm information from ELH power to

input DI10. Unit starts only after reset.

Freezepro-

blem

BFreezeprobleminfo 2 sec Only Cooler-units.

E-stop A External emergency stop 0 sec The loop is connected to input DI1 (clo-

sing)

Fire risk A External 0 sec The loop is connected to input DI2 (clo-

sing)

Service

reminder

B 6

mnths

PDS10 B Pressure switch 2 sec Use of electrical heater is prohibited until

pressure dierence recovered.

SF A Deviation alarm 10 Pa 200 s Standard duct pressure control, the de-

viation for the alarm can be set

EF A Deviation alarm 10 Pa 200 s Standard duct pressure control, the de-

viation for the alarm can be set

Date and time

Time: 08:00

Day: 01 Thursday

Month: 1

Year: 2011

Exit Change

16

USER GUIDE

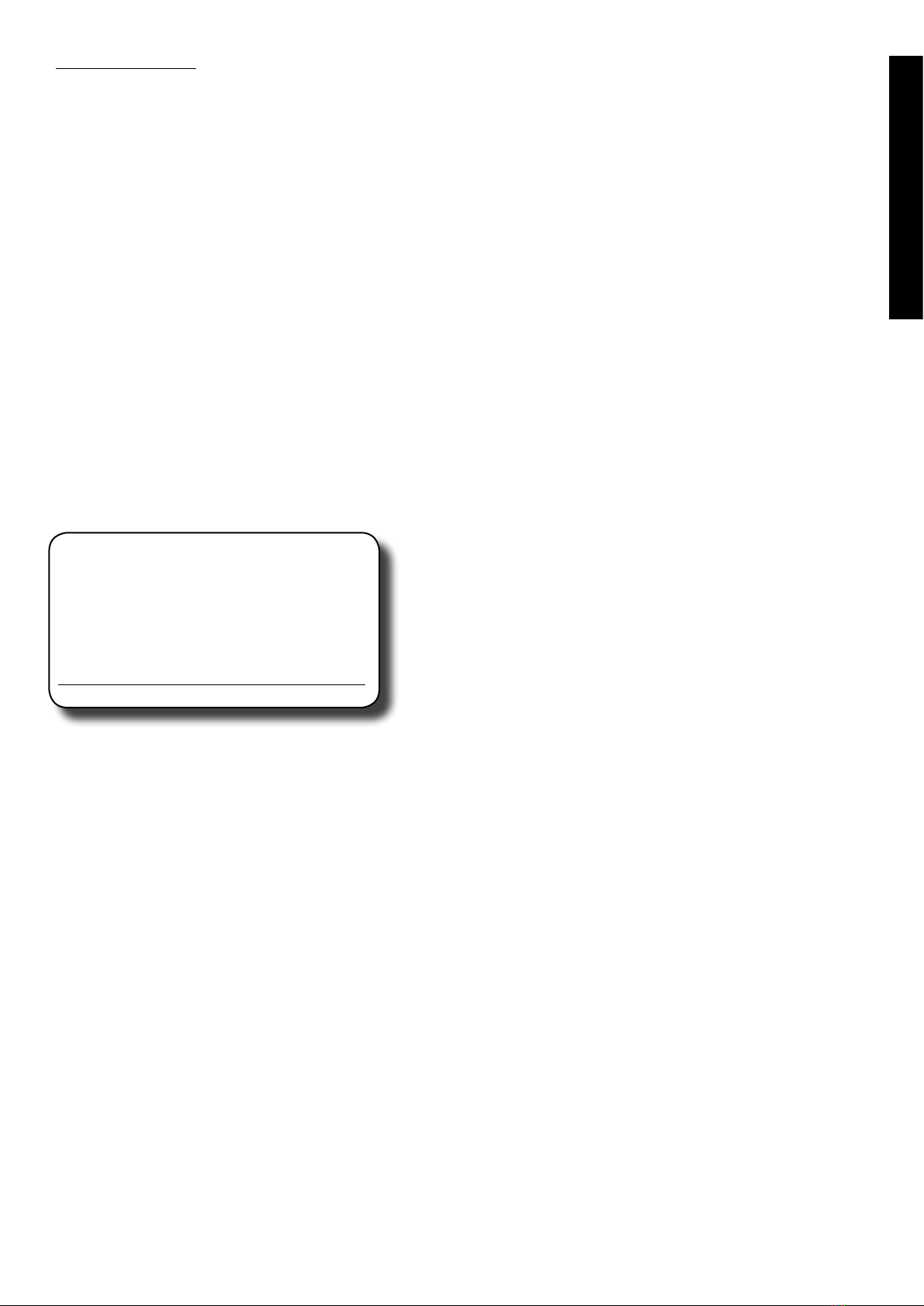

MEASUREMENTS

The Measurements menu is an informative menu where you can

read the dierent measurement results. Also measurements from

extra equipment like CO2and RH% sensors can be read here.

Explanations of the measurements:

Fresh air Outside air temperature

HRC sply Supply air temperature after the heat recovery

Sply Supply air temperature

Exhst Extract air temperature

Exhst water Return water temperature (EDW models)

NA No sensor connected

Exhaustair Exhaust air temperature

Room t. OP Room temperature, control panel measure result*

Exhst humidity Extract air humidity level

48 h humidity The average extract air humidity level during the

last 48 hours

HRC ŋ sply Supply air heat recovery rate

HRC ŋ exhst Extract air heat recovery rate

HRC -100...0 the unit is asking for cooling

0...+100(only)heatrecoveryinuse

+100...+200theunitisaskingforheating

+200...+300theunitisaskingforheatingofthe

additional heating unit (only EDX-E)

RH_1 Measurement of separate humidity sensor*

RH_2 Measurement of separate humidity sensor*

CO2_1 Measurement of carbon dioxide sensor*

CO2_2 Measurement of carbon dioxide sensor*

* sensor extra equipment

TIME PROGRAMS

In the Timeprogram menu you program the week and year

timers. For the week timer there are 20 program slots in which

yousetupwhentheprogramison(hh:mm–hh:mm+day)and

what function the unit is to perform during the time program.

For the year timer there are 5 program slots in which you set

up the time programs on and o time (dd.mm.yyyy, hh:mm) and

what function the unit is to perform during the time program.

Measurements

Fresh air xx,x°C

HRC sply xx,x°C

Sply xx,x°C

Exhst xx,x°C

Exhst. water /NA xx,x°C

Exhaustair

xx,x°C

Room t. OP xx,x°C

Exhst humidity xx %

48 h humidity xx %

HRC ŋ sply xx %

HRC ŋ exhst xx %

(HRC)

RH_1 xx %

RH_2 xx %

CO2_1 xx ppm

CO2_2 xx ppm

Exit

Time programs

Week timer

Year timer

Exit Choose

Week timer

Timeprogram: 1

On : 00:00 - 00:00

Su Mo Tu We Th Fr Sa

Function: Choose here

Exit Change

Year timer

Timeprogram: 1

Start: dd.mm.yyyy 00:00

End: dd.mm.yyyy 00:00

Function: Choose

Exit Change

If the end time for the time program is smaller than the start time,

the control interprets that the time program continues over the

day limit. In this case the next day also needs to be an allowed day. Example: Start: 16:00, End: 08:00, Allowed days: Mo, Tu,

We. This time programming means that the program start on Monday at 16:00, ends on Tuesday at 08:00, starts again on

Tuesday at 16:00 and ends on Wednesday at 08:00. After that the program is active again next Monday at 16:00.

17

Enervent EDA MD EN 2013_1

USER GUIDE

INFO

Informative menu that displays the unit’s technical details and program versions.

Info

Enervent

Pingvin eco EDE

Mother v. 2.11

Display v.. 2.01

SN 60387

Exit

Time program events:

Ventilation eect (1-8) for ventilation units with alternating current fans. The number of available ventilation eects

depend on the fan eect’s initial settings. If the speed of the supply air and extract air fan is the same, the number of avai-

lable eects are 8. If the dierence in speed is of 1, then the available number of eects are 7, if the dierence is of 3, then

the number is 5 etc.

Ventilation eect (20-100%) for ventilation units with eco direct current fans. The maximum available ventilation ef-

fect depends on the fan eect’s initial settings. If the speed of the supply air and extract air fan is the same, the maximum

eect available is 100%. If the dierence in speed is 10% then the available eect is 90% etc.

Away: The unit is set to the Away state.

Long away: The unit is set to the Long away state.

Max heat: Maximum heat is turned on. Event continues until the timer runs out or the limit value is reached.

Max cooling: Maximum cooling is turned on. Functions in the same way as max heat.

No heating: heating prohibited.

No cooling: Cooling prohibited.

Temp. drop: The temperatures set point is lowered according to the amount set in settings.

Timerly: Timed relay (DO2) is connected to activate at set time.

18

USER GUIDE

SETTINGS

In this menu, you enter the settings needed for taking the unit into use. The code is 6143.

Settings:

USER GUIDE

Temperatures

Situation controls

Boosting functions

Display settings

Quick choise

Other settings

Night cooling

Fan speed

Stove+CeVaCl+Overpr

Over pressure

Normal spd

CO2

Boosting settings

Humidity

Temp. boost

Away

HRC

Long away

page 20

page 23

page 24

page 24

page 19

page 19

page 19

page 19

page 22

page 22

page 21

page 22

page 3

page 23

page 23

XXX (=General settings) page 24

YYY (Standard duct pressure) page 19

page 21

page 23

19

Enervent EDA MD EN 2013_1

USER GUIDE

FAN SPEED

Fan speed

Normal spd.

Over pressure

Stove+CeVaCl+Overpr

YYY (=Constant duct pressure)

Exit Choose

Normal spd.

Supply fan #

Extract fan #

Ulkol. max: ##°C

Ulkol. min: ## °C

Back Change

Over pressure

Supply fan #

Extract fan #

OP t: # min

Exit Change

The dierence in speed between the supply air and extract air fan

is set in the normal speed menu. The set values do not dene

the fan speeds, just the dierence between them. The set values

aect the fan speed columns in the EDA control panel basic view

- the number of columns decline with the quantity of dierence.

For more information see the chapter about display symbols on

page 10.

The fan speed, during overpressure, is selected so that there is

enough natural draft in the chimney while lighting a re in the

replace. 10 – 15 minutes is usually enough.

Stove+CeVaCl+Overpr

CH CVC COC OCC

Sply # # # #

Exhst # # # #

Exit Change

Speeds for supply air and extract air fans can be set separately

for dierent combinations of the cooker hood, central vacuum

cleaner and the overpressure function.

CH = Cooker hood on, examples of fan speeds; extract 3 (or

30 %) and supply 5 (or 50 %).

CVC = Central vacuum cleaner on, examples of fan speeds;

extract 3 (or 30 %) and supply 5 (or 50 %).

COC = Cooker hood and central vacuum cleaner/over-pressure

and cooker hood/central vacuum cleaner and over pres-

sure on at the same time, examples of fan speeds; ex-

haust 3 (or 30 %) and supply 7 (70 %).

OCC = Overpressure, cooker hood and central vacuum cleaner

all on at the same time, examples of fan speeds; extract

3 (or 30 %) and supply 7 (or 80 %).

YYY (=Constant duct pressure)

Const. ductpr. □

CDPC EC P-a: ## Pa

CDPC EC I-t: ## s

CDPC EC R-t: ## s

CDPCECDz: ##Pa

CDPC AC Delay: ## s

CDPCACDz: ##Pa

??? ## Pa

??? ## Pa

??? Max: ## Pa

??? Min: ## Pa

??? Max: ## Pa

??? Min: ## Pa

TV: ## s

PV: ## s

???: ## Pa

Back Change

20

USER GUIDE

TEMPERATURES

Temp. settings

Exhst msrmnt ##,#°C

Sply msrmnt: ##,#°C

Temp ctrl mde From

Setpoint: ##,#°C

Min: ##,#°C

Max: ##,#°C

OP 1 □

OP 2 □

OP 3 □

OP 4 □

OP 5 □

Temp. trans 1 □

Temp. trans 2 □

Temp. trans 3 □

Exit Change

Extract msrmnts: Displays the extract air or room

temperature (depending on selected

temperature regulation) with one

decimal accuracy.

Supply msrmnts: Displays the supply air temperature

with one decimal accurancy.

Temp ctrl mode: Selection of temperature regulation.

Options are constant extract air regu-

lation or constant room temperature

regulation.

Setpoint: Selection of extract air or room

temperature setpoint with 1/10 de-

gree accuracy. Fast setup with one

degreeaccuracywith+and-onthe

control panel.

Min: Set lowest allowed supply air tempera-

ture.

Max: Set highest allowed supply air tempe-

rature.

OP1-OP5: Selection of control panels that partici-

pate in room temperature regulation.

If several panels are selected the room

temperature is shown as an average

value of the selected panels’measure

ments. One panel is included in the

standard delivery.

Temp.trans 1-3: Selection of temperature sensor (extra

equipment) that participate in room

temperature regulation. If several

panels are selected the temperature

is shown as an average value of the

selected panels measurements.

This manual suits for next models

13

Table of contents

Other ensto Fan manuals