Entec Timberwolf TW 35DH User manual

TIMBER

TIMBERWOLF

WOLF

IINNSSTTRRUUCCTTIIOONN

MMAANNUUAALL

EENNTTEECC

IINNDDUUSSTTRRIIEESS

LLTTDD

EENNTTEECC

HHOOUUSSEE,,

TTOOMMOO

IINNDDUUSSTTRRIIAALL

EESSTTAATTEE,,

CCRREEEETTIINNGG

RROOAADD,,

SSTTOOWWMMAARRKKEETT,,

SSUUFFFFOOLLKK

IIPP1144

55AAYY

TTEELLEEPPHHOONNEE

0011444499

776655880000

FFAAXX

NNUUMMBBEERR

0011444499

776655880011

wwwwww..ttiimmbbeerrwwoollff-uukk..ccoomm

TW 35/150DH

TW 35/150DH

CONTENTS

Section Page No.

INTRODUCTION 1

PURPOSE OF MACHINE 2

MACHINE DIMENSIONS & SPECIFICATIONS 2

PARTS LOCATION DIAGRAMS 3 & 4

SAFE WORKING 5

Operator’s Personal Protective Equipment Required 5

Basic Woodchipping Safety 5

General Safety Matters - Do’s and Dont’s 6

Noise Test 7

OPERATING INSTRUCTIONS 8

Safe Transportation 8

Hitching onto the Tow Ball 8

Unhitching the Chipper 8

Delivery 9

Operator’s Personal Protective Equipment Required 9

Manual Controls 9

Auto Controls 10

Emergency Stopping 10

Engine Controls 10

Hydraulic Oil Thermometer 10

Hydraulic Oil Lever Indicator 10

Diesel Tank Indicator 10

Starting the Engine 11

Stopping the Engine 11

Daily Checks Before Starting 11

Before Using the Chipper 11

Starting to Chip 12

Chipping 12

Blockages 12

SERVICE INSTRUCTIONS 13

Service Schedule 13

Engine Servicing 14

Safe Maintenance 14

Spares 14

Battery Removal and Maintenance 14

Change Blades 15

Check Fittings 16

Check Hoses 16

Tension Drive Belt 16

Tension Hydraulic Pump Belts 16

Change Hydraulic Oil and Filter 17

Service to the Safety Bar 17

Grease the Roller Drive Splines 18

Grease the Roller Box Slides 18

Greasing Rotor Bearings 18

Engine Manufacturer’s Handbook 18

WARRANTY STATEMENT 19

IDENTIFICATION PLATES 20

PARTS LISTS 22 - 36

AMENDMENTS 38 - 41

ISSUE 21

TIMBERWOLF

Thank you for choosing this Entec/Timberwolf brushwood chipper. Entec/Timberwolf

chippers are designed to give safe and dependable service if operated according to the

instructions.

Before using your new chipper, please take time to

read this manual which contains

IMPORTANT HEALTH AND SAFETY INFORMATION

and explains the chipper controls - failure to do so could result in :

- personal injury

- equipment damage

- damage to property

- a member of the general public becoming injured

This manual covers the operation and maintenance of the Timberwolf TW 35/150DH.

All information in this manual is based on the latest product information available at the

time.

All the information you need to operate the machine safely and effectively is contained

within pages 3 to 12. Ensure that all operators are adequately trained for operating

this machine especially with regard to safe working practices.

Entec's policy of constantly improving their products may involve major or minor

changes to the chippers or their accessories. Entec Industries reserves the right to

make changes at any time without notice and without incurring any obligation.

Due to improvements in design and performance during production, in some cases

there may be minor discrepancies between the actual chipper and the text in this

manual.

The manual should be considered a permanent part of the

machine and should remain with it if the machine is resold.

!CAUTION or WARNING

Be aware of this symbol and where shown

carefully follow the instructions

This caution symbol indicates important safety messages in this manual. When

you see this symbol be alert to the possibility of injury to yourself or others, and

carefully read the message that follows.

Always follow safe operating and maintenance practices

INTRODUCTION

1

TW 35/150DH

Serial No. Location

The serial number can be

found on top of the rotor

housing.

The Timberwolf TW 35/150DH brushwood chippers are designed to chip

solid wood material up to 150mm in diameter. The maximum cross-section

hardwood for continuous feed is 8500 sq. mm.They are capable of chipping

over 2.5 tonnes of brushwood per hour.

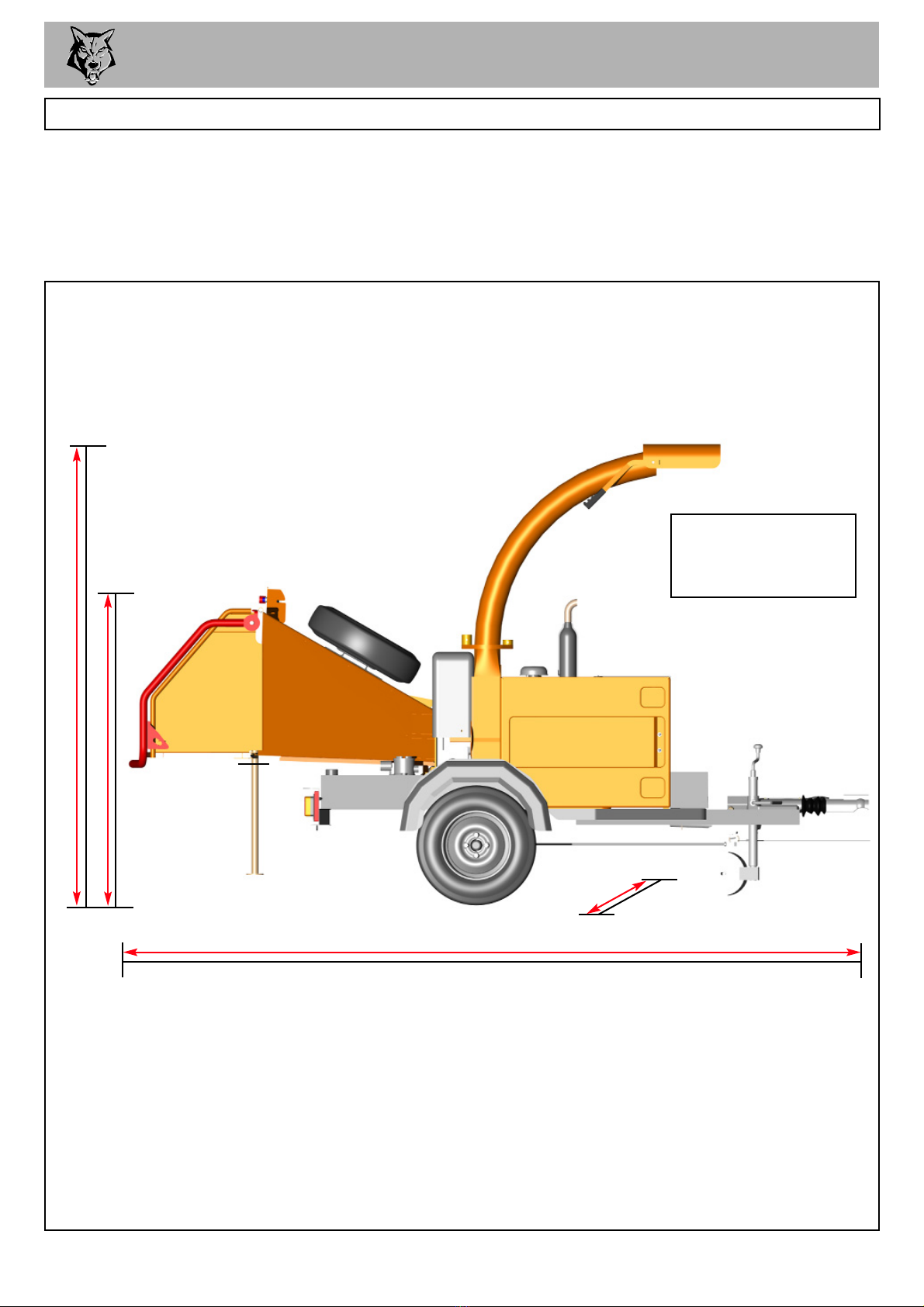

1400 mm

DIMENSIONS

2250 mm

3550 mm (3050 mm with feed table folded)

1400 mm

PURPOSE OF MACHINE

Engine Type Kubota 4 Cyl. Diesel

Maximum Power 26.1 KW (35 HP)

Cooling Method Water Cooled

Overall Weight 770 kilos

Starting Method Electric

Roller Feed Twin series hydraulic motors

Maximum Diameter Material 150mm (6")

Fuel Capacity 41 litres

Hydraulic Oil Capacity 13 litres

Material Processing Capacity 2.5 tonnes/hr

Fuel Type Diesel

Timberwolf TW 35/150DH Specification

fig 1.

TIMBERWOLF 2

TW 35/150DH

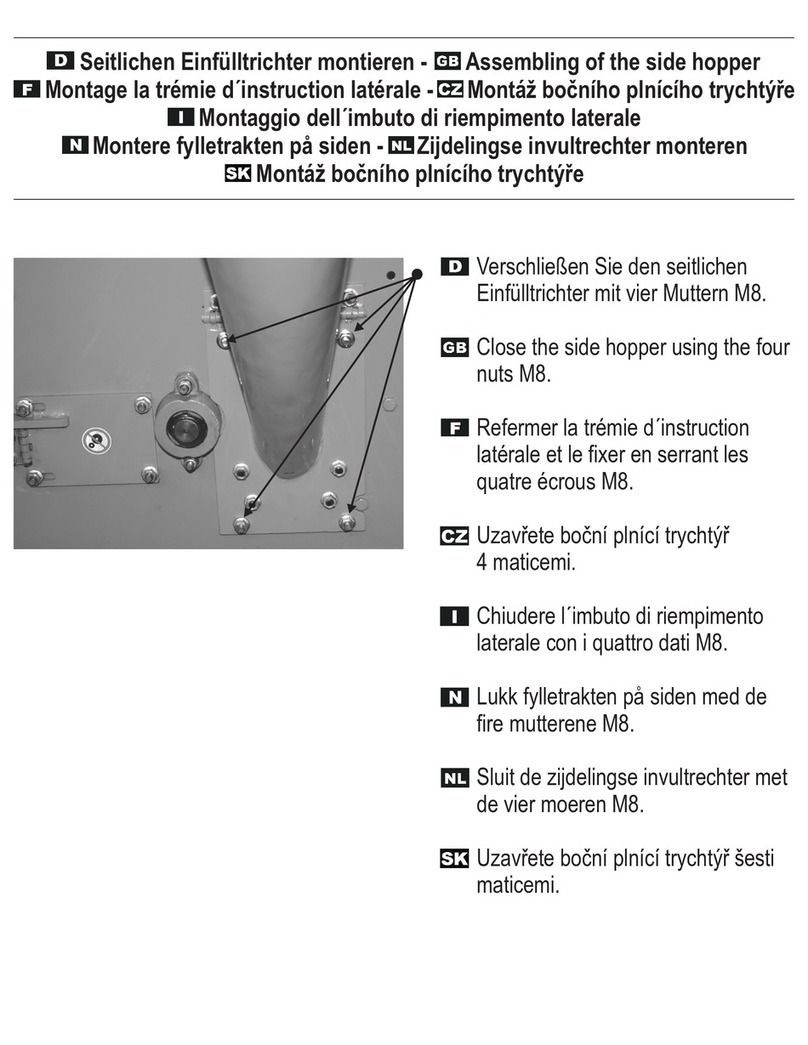

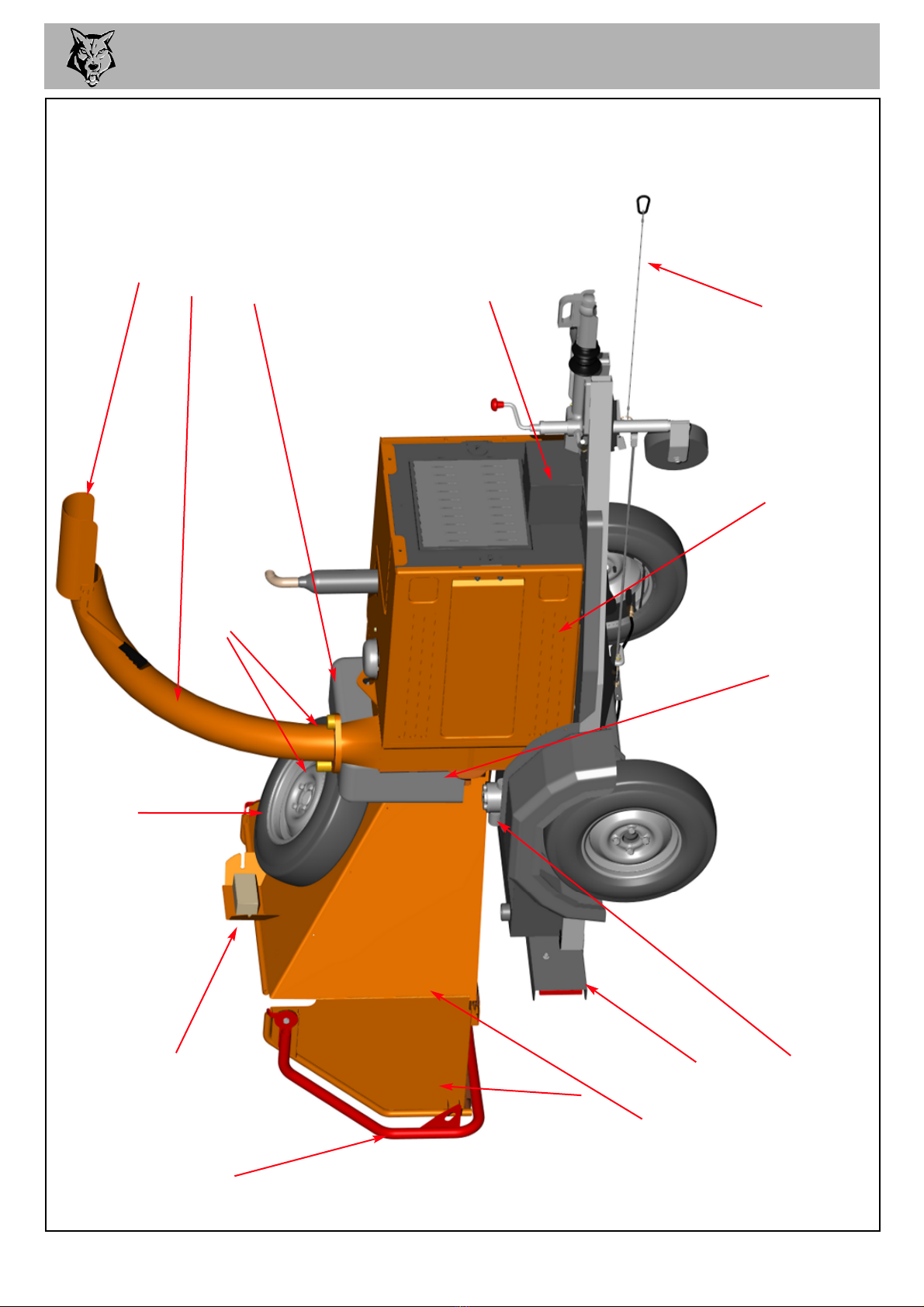

PARTS LOCATOR 3

CONTROL BAR

FEED TRAY

FUNNEL

DISCHARGE

BUCKET

DISCHARGE

TUBE

SPARE WHEEL

CLAMP NUTS

fig 2.

LIGHT BOARD

CONTROL BOX

BATTERY BOX

COVER

ROLLER

BOX COVER

SIDE PANELS

HYDRAULIC OIL

FILTER

ROTOR

HOUSING

BREAKAWAY

CABLE

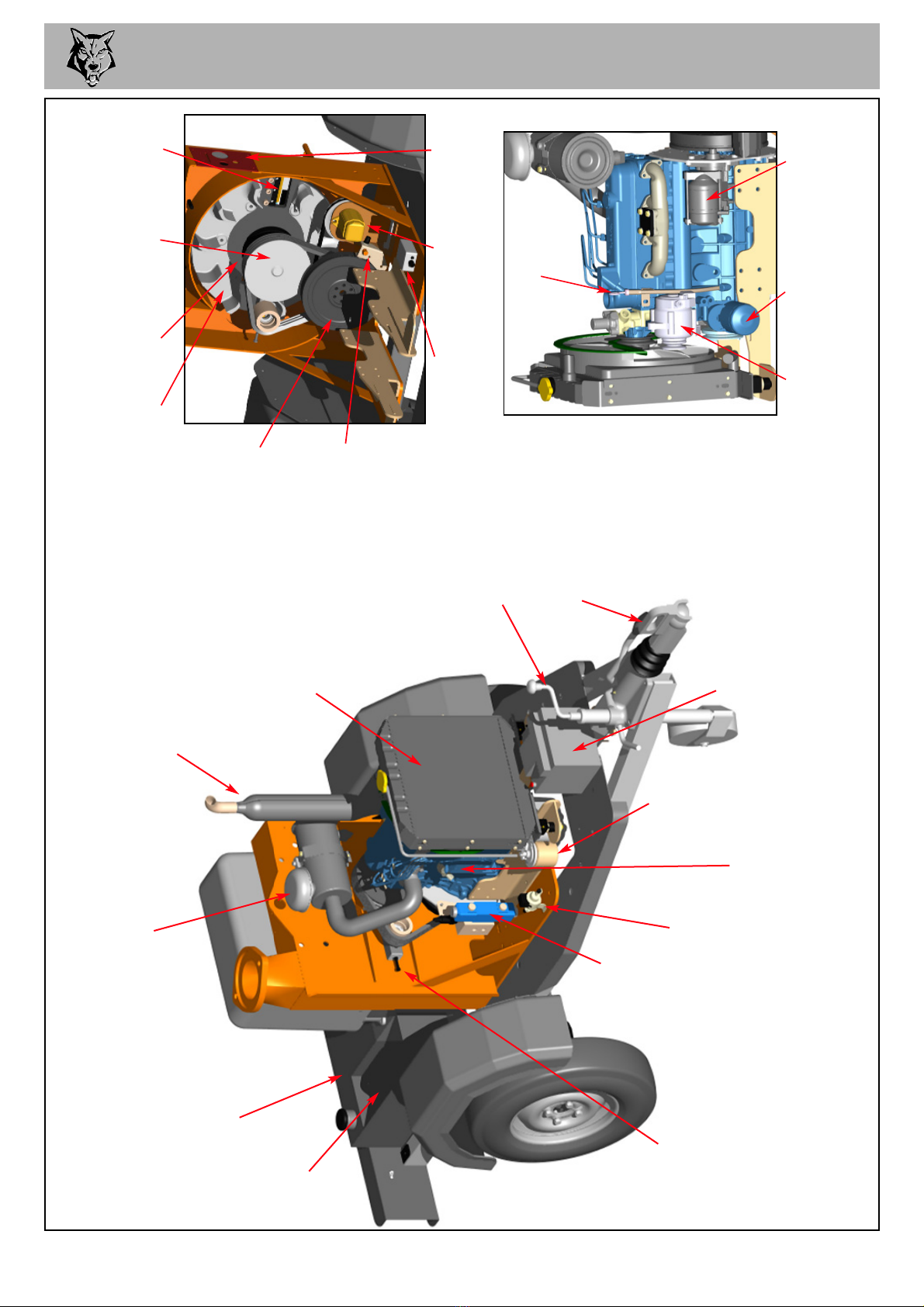

PARTS LOCATOR 4

fig 3.

JOCKEY WHEEL

ASSEMBLY

BATTERY

TOW HEAD

FUEL TANK

ENGINE

BLOCK

ROTOR

FAN

ROTOR

PULLEY

HYDRAULIC

PUMP

DRIVE

PULLEY

CUTTER

BLADE

TOOL BOX

BELT

TENSION

ADJUSTER

ELECTRIC

VALVE

FUEL PUMP

EXHAUST

FUEL

FILTER

NO STRESS

UNIT

NO

STRESS

SENSOR

DIP

STICK

OIL

FILTER

ALTERNATOR

CONTROL

PANEL

STARTER

MOTOR

RADIATOR

AIR FILTER

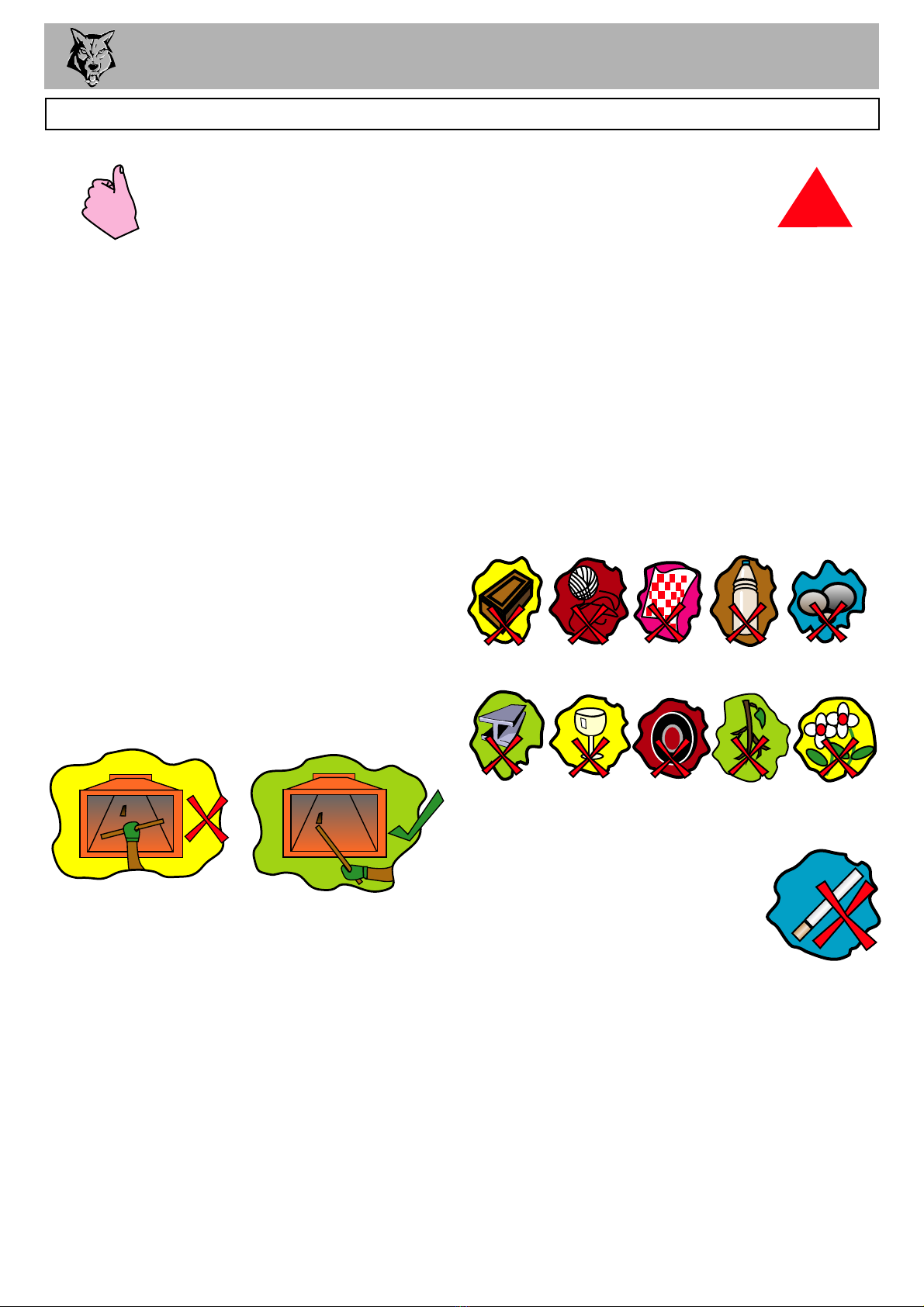

SAFE WORKING

OPERATOR'S PERSONAL PROTECTIVE EQUIPMENT REQUIRED

Chainsaw safety helmet fitted

with visor and recommended

ear defenders to the

appropriate specifications

Loose fit,

Heavy-duty gloves.

Close fitting heavy-duty

non-snag clothing

Face mask if

appropriate.

DO NOT wear rings,

bracelets, watches, jewellery

or any other items that could

be caught in the material and

draw you into the chipper.

BASIC WOODCHIPPING SAFETY

The operator should be aware of the following points:

MAINTAIN A SAFETY EXCLUSION ZONE around the chipper of at least 10 metres for the

general public or employees without adequate protection. - Use hazard tape to identify this

working area and keep it clear from debris build up. Chips should be ejected away from any

area the general public have access to.

HAZARDOUS MATERIAL. Some species of trees and bushes are poisonous. The chipping

action can produce vapour, spray and dust that can irritate the skin. This may lead to

respiratory problems or even cause serious poisoning. Check the material to be chipped before

you start. Avoid confined spaces and use a facemask if necessary.

BE AWARE when the chipper is processing material that is an awkward shape. The material

can move from side to side in the funnel with great force. If the material extends beyond the

funnel the brash may push you to one side causing danger. Badly twisted brash should be

trimmed before being chipped to avoid thrashing in the feed funnel.

BE AWARE that the chipper can eject chips out of the feed funnel with considerable force.

Always wear full head and face protection.

ALWAYS work on the side of the machine furthest from any local danger, e.g not road side.

WARNING

The Chipper will feed material through on its own. To do this, it relies on

sharp blades both on the feed rollers and the chipper rotor. To keep the

blades sharp, only feed the machine with clean brushwood.

DO NOT put muddy / dirty wood, roots, potted plants, bricks,

stones or metal into the chipper.

!

!

Safety Boots

5

SAFE WORKING 6

DO’S AND DONT’S

GENERAL SAFETY MATTERS

DO NOT use chipper unless available light is

sufficient to see clearly.

DO NOT use or attempt to start the chipper

without the feed funnel, belt guard, guards and

discharge unit securely in place.

DO NOT start the chipper running unless properly

guarded.

DO NOT stand directly in front of the feed funnel

when using the chipper. Stand to one side.

DO NOT allow -

DO NOT smoke when refuelling.

Petrol is explosive!

DO NOT let anyone who has not received

instruction operate the machine.

DO NOT climb on the machine at any time.

DO NOT handle material that is partially engaged

in the machine.

DO NOT touch any exposed wiring whilst

machine is running.

- to enter the machine, as damage is likely.

BRICKS STRING CLOTH PLASTIC STONES

METAL GLASS RUBBER ROOTS BEDDING

PLANTS

ALWAYS stop the chipper engine before making

any adjustments, refuelling, or cleaning.

ALWAYS check machine has stopped rotating

and remove chipper ignition key before

maintenance of any kind, or whenever the

machine is to be left unattended.

ALWAYS check machine is well supported and

cannot move.

ALWAYS run with the engine set to maximum

speed.

ALWAYS check (visually) for fluid leaks.

ALWAYS take regular breaks. Wearing personal

protective equipment for long periods can be

tiring and hot.

ALWAYS keep hands, feet and clothing out of

feed opening, discharge and moving parts.

ALWAYS use the next piece of material or a push

stick to push in short pieces. Under no

circumstances should you reach into the funnel.

ALWAYS keep the operating area clear of people,

animals and children.

ALWAYS keep the operating area clear from

debris build up.

ALWAYS keep clear of the chip discharge tube.

Foreign objects may be ejected with great force.

ALWAYS ensure protective guarding is in place

before commencing work. Failure to do so may

result in personal injury or loss of life.

ALWAYS use chipper in a well ventilated area -

exhaust fumes are dangerous.

!

SAFE WORKING

MACHINE:

NOTES:

TW 35/150DH

Tested Chipping 120mm x 120mm Corsican Pine

1.5m in length

113.2 dB 97.7 dB

1 METRE

96.5 dB

95.3 dB

94.0 dB

R= 4 metres

Noise levels between 90 and 114dBA will be experienced at the working position. Wear ear

defenders at all times to prevent possible damage to hearing. All persons within a 4 metre

radius must also wear good quality ear defenders.

NOISE TEST

7

fig 4.

Guaranteed Sound Power: 121db

OPERATING INSTRUCTIONS 8

SAFE TRANSPORTATION

WHEN towing a chipper the maximum speed limit is 60 mph.

ON rough or bumpy road surfaces reduce speed accordingly to protect your machine from

unnecessary vibration.

WHEN towing off road be aware of objects that may catch the chipper undergear.

WHEN towing off road ensure inclination is not excessive.

AVOID excessively pot holed ground.

WHEN reversing the chipper the short wheel base will react quickly to steering.

ALWAYS check the discharge is tight before moving.

KEEP tyre pressures inflated to 2.2 bar or 32 psi.

CHECK wheel nuts are tightened to 90Nm or 65 lbs ft.

CLEAR loose chippings and debris from the machine before departing.

ENSURE the feed funnel is closed and the catch is properly engaged before departing.

CHECK the ball head is well greased.

WIND jockey wheel assembly anticlockwise until the tow head is above the height of the ball

hitch on the vehicle.

REVERSE the vehicle so the ball hitch is directly below the tow head.

ATTACH the breakaway cable to a strong point on the vehicle, not the ball hitch.

ENSURE the barrel lock is retracted from the tow head.

GRASP handle on tow head and push back catch with thumb.

WIND the jockey wheel assembly clockwise, so lowering the tow head onto the ball hitch.

RELEASE handle and continue to wind jockey wheel clockwise. The tow head should snap

into place on the ball hitch. If it doesn't repeat previous 2 steps.

WIND jockey wheel up until fully retracted and the jockey wheel frame is seated in its notch on

the stem. The chipper weight should be fully on the vehicle.

RELEASE the jockey wheel clamp and slide the jockey wheel assembly fully up.

TIGHTEN clamp on the jockey wheel assembly.

CONNECT electrical plug to socket on rear of towing vehicle and check operation of all the

trailer and vehicle lights.

INSERT the barrel lock for security.

THE chipper is now properly attached to the vehicle.

HITCHING ONTO THE TOW BALL

ENSURE the chipper will not roll away after being disconnected from the vehicle.

DISCONNECT the electrical cable from the vehicle socket.

RELEASE the barrel lock.

RELEASE breakaway cable.

RELEASE the jockey wheel assembly clamp.

LOWER the jockey wheel assembly fully.

RETIGHTEN the jockey wheel assembly clamp.

WIND the jockey wheel assembly anticlockwise until it starts to take the weight of the chipper.

GRASP the handle and release the catch with your thumb.

CONTINUE to wind the jockey wheel anticlockwise. This should lift the tow head clear of the ball hitch.

DRIVE the vehicle clear of the chipper.

WIND the jockey wheel assembly to a suitable point where the chipper is level.

THE chipper is now fully detached from the vehicle.

UNHITCHING THE CHIPPER

OPERATING INSTRUCTIONS 9

DELIVERY

All Timberwolf 35/150DH machines have a full pre - delivery inspection before leaving the factory and

are ready to use. Read and understand this instruction manual before attempting to operate the

Chipper. In particular, read pages 5-7 which contain important health and safety information and

advice.

OPERATOR’S PERSONAL PROTECTIVE EQUIPMENT REQUIRED

CHAINSAW safety helmet fitted with visor and

recommended ear defenders to an appropriate

specification.

HEAVY-DUTY gloves.

CLOSE - FITTING heavy-duty non-snag clothing.

SAFETY footwear.

FACE MASK (if appropriate).

MANUAL CONTROLS

Do not rely on the red bar to keep the rollers stationary if it

is necessary to clear or touch the rollers. Always switch off

the machine before approaching the rollers.

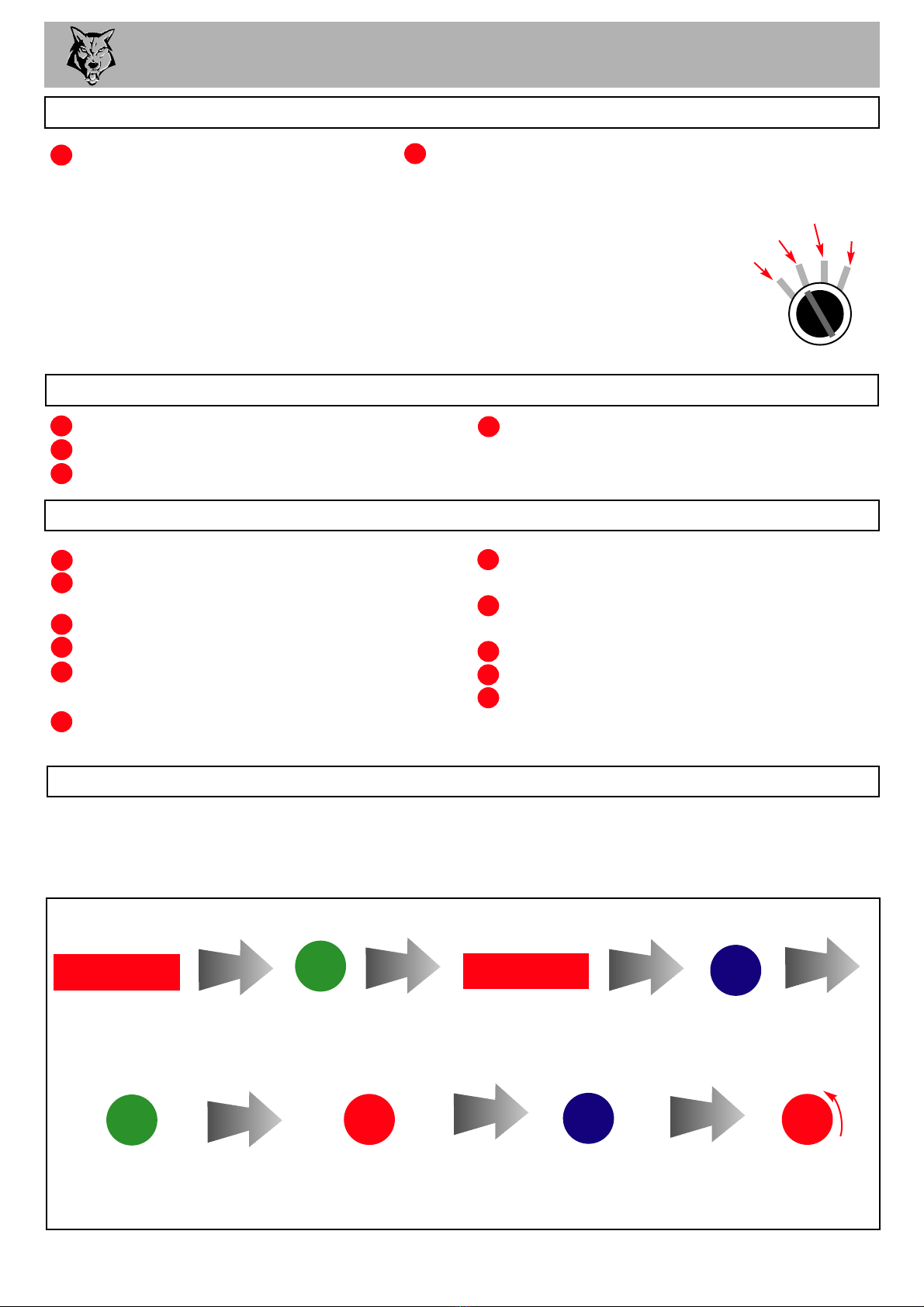

GREEN FORWARD

FEED BUTTON

BLUE REVERSE

FEED BUTTON

RED STOP FEED -

EMERGENCY STOP

BUTTON

RED SAFETY BAR

Control Panel Diagram

fig 5.

Roller control box - is the control box above the feed opening of the chipper funnel. Its function is to control

the feed rollers. The feed rollers draw material into the machine. It does not control the main rotor.

RED SAFETY BAR = This is the large red bar that surrounds the feed tray and side of the feed funnel.

The bar is spring loaded and connected to a switch that will interrupt the power to the rollers. The

switch is designed so that it only activates if the bar is pushed to the limit of its travel. The rollers stop

instantly, but can be made to turn again by pressing either the GREEN FEED or BLUE REVERSE

control buttons.

RED SAFETY BAR TEST

To ensure the safety bar is always operational it must be activated once before each work session.

The rollers will not function until the bar is activated. This procedure must be repeated each time

the ignition is switched off.

GREEN BUTTON = forward feed - Push the button once - this activates the rollers and will allow you

to start chipping (if the rotor speed is high enough).

RED BUTTON = stop feed / emergency stop - This button stops the rollers from feeding. It overrides

all other buttons or bars and will not allow the other buttons to function until it has been reset.

To reset, twist until it returns to its original position. The forward and reverse buttons will now function.

BLUE BUTTON = reverse feed - allows you to back material out of the rollers. The rollers will only

turn in reverse as long as you keep pressing the button. You do not have to press the STOP button

before pressing the GREEN FEED button to recommence feeding.

See page 5 for more detailed information.

OPERATING INSTRUCTIONS 10

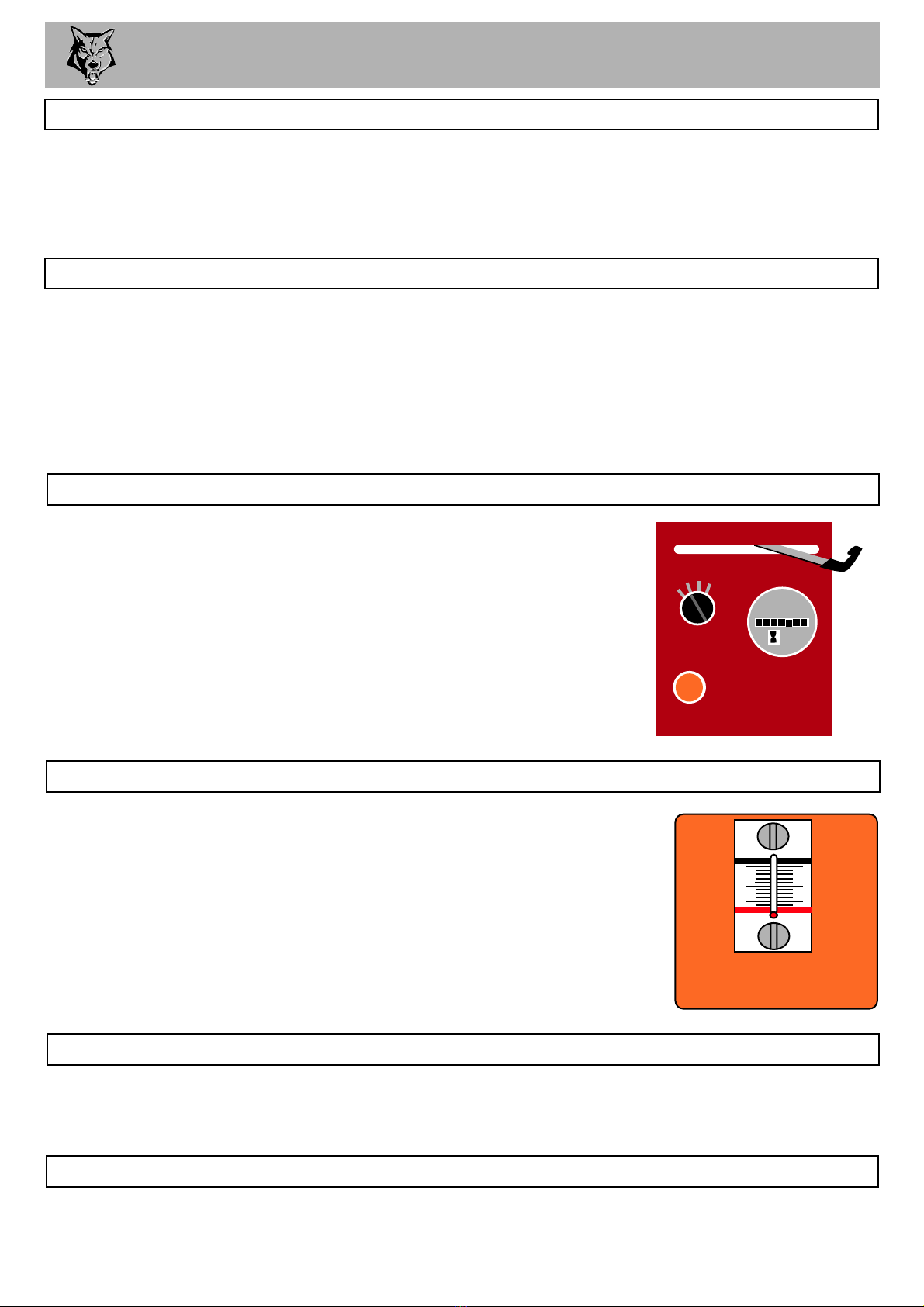

ENGINE CONTROLS

The engine speed is controlled by the horizontally adjustable

lever shown in the drawing. With the throttle lever in the FAST

position the machine is ready to chip. It MUST be fully

pushed to the left to achieve a suitable working speed.

If no wood is to be chipped for a few minutes the throttle

should be returned to the idle position.

fig 6.

AUTO CONTROLS

The no stress unit controls the feed rate of the material going into the chipping chamber. If the engine

speed is below the predetermined level the No Stress Unit will not allow the feed rollers to work in

either forward or reverse until the rotor speed rises above the predetermined level, at which point the

feed rollers will start turning without warning.

Push the RED STOP button or push the RED CONTROL BAR

(whichever is the quickest for you to reach).

Turn off the engine ignition key.

The emergency stop will prevent any more material being fed into the chipper. The rotor will still be

turning. The engine must be powered down to stop the rotor.

EMERGENCY STOPPING

This is situated on the side of the hydraulic oil tank. When the chipper is

running the oil temperature should not exceed 65oC. If it does, stop the

machine immediately. Failure to do so may result in damage.

Overheating can result from the chipper being worked extremely hard in

hot conditions, as the oil is not getting a chance to cool down. Stop the

chipper and allow oil to cool before continuing. If the temperature goes

above 65oC and the machine is not being worked hard or the air

temperature is not particularly hot this indicates low oil, a stuck hydraulic motor

or valve. Stop immediately and investigate.

HYDRAULIC OIL THERMOMETER

HYDRAULIC OIL LEVEL INDICATOR

When the chipper is on level ground the oil level should sit between the red line at the bottom of the

gauge and the black line at the top. If this level drops significantly it indicates an oil leak. Stop

immediately and investigate.

LA

fig 7.

FUEL LEVEL INDICATOR

This is located inside the tank. Remove the filler cap and look inside. A graduated plate helps to

judge the remaining fuel.

FAST SLOW

HEATERS ON

OFF START

HOURS

0000000

OPERATING INSTRUCTIONS 11

STARTING THE ENGINE

FOR COLD STARTING

Insert the key into the ignition switch.

Turn the key to the 'heat' position.

Hold it for 15 seconds.

Turn to the start position until the

engine fires.

Release the key and let it return to

the ignition position.

FOR WARM STARTING

Insert the key into the ignition switch.

Turn it to the 'heat' position.

Hold it for 5 seconds.

Turn to the start position until the

engine fires.

Release the key and let it return to

the ignition position.

LOCATE the machine on firm level ground.

CHECK machine is well supported and

cannot move.

CHECK prop stand is lowered and secure.

CHECK all guards are fitted and secure.

CHECK the discharge unit is in place and

fastened securely.

CHECK discharge tube is pointing in a safe

direction.

CHECK the feed funnel to ensure no objects

are inside.

CHECK feed table is in up position - to

prevent people reaching rollers.

CHECK controls as described below.

CHECK (visually) for fluid leaks.

CHECK fuel and hydraulic oil levels.

For parts location see diagrams on pages 3 & 4.

STOPPING THE ENGINE

Reduce the throttle to idle.

Leave the engine to run for a full minute.

Switch the key to the OFF position.

Remove the ignition key.

For more detailed information refer to the

Engine Owner’s Manual

BEFORE USING THE CHIPPER

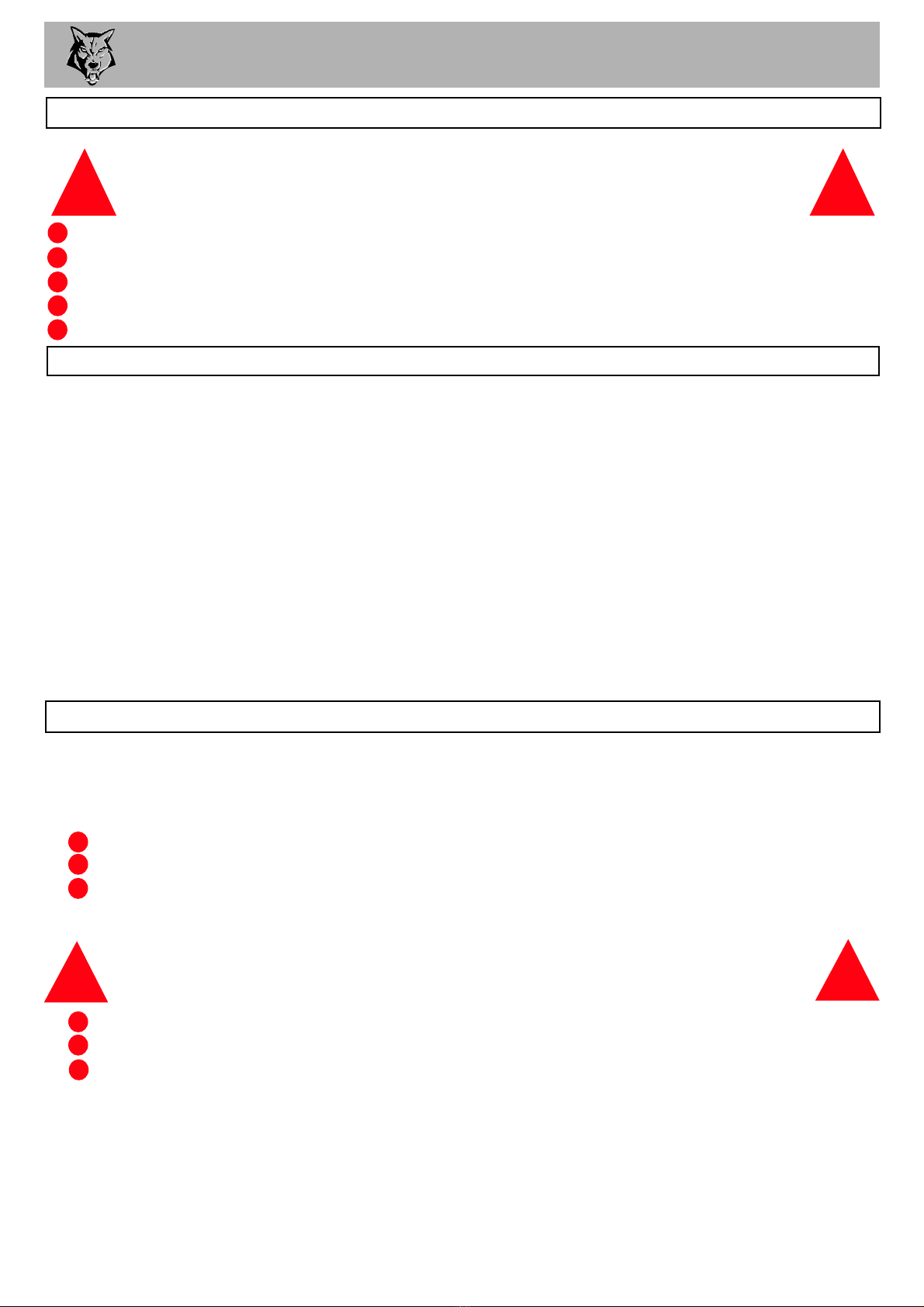

IT IS ESSENTIAL TO CARRY OUT THE FOLLOWING TESTS to check safety equipment - this sequence

of tests will only take a few seconds to carry out. We recommend that these tests are carried out daily.

Observing the function as described will confirm that the safety circuits are working correctly. This is also a

good opportunity to remind all operators of the control and emergency stop systems.

4

7

568

23

PRESS THE GREEN

BUTTON

THE ROLLERS

SHOULD RUN

PRESS THE RED BAR

THE ROLLERS SHOULD

STOP

PRESS THE BLUE BUTTON

THE ROLLERS SHOULD TURN

BACKWARDS ONLY WHILE THE

BUTTON IS PRESSED

PRESS THE GREEN

BUTTON AGAIN

THE ROLLERS SHOULD

RUN

PRESS THE EMERGENCY

RED BUTTON

THE ROLLERS SHOULD

STOP

PRESS THE BLUE

BUTTON

THE ROLLERS

SHOULD NOT TURN

TWIST TO RESET

THE RED BUTTON

THE MACHINE IS READY

TO USE

1

PRESS THE RED

BAR TO POWER

THE CONTROL

SYSTEM

DAILY CHECKS BEFORE STARTING

OFF

IGNITION START

HEAT

fig 8.

If the engine fails to start after 10 seconds leave for 1 minute and try again.

WITH THE ENGINE RUNNING AT FULL SPEED

OPERATING INSTRUCTIONS

STARTING TO CHIP

WARNING

Do not use or attempt to start the chipper without the

protective guarding and discharge unit securely in place.

Failure to do so may result in personal injury or loss of life.

!!

CHECK that chipper is running smoothly.

RELEASE the catch on the feed table and lower. Turn to release the red stop button.

PRESS the green control button. The rollers will commence turning.

STAND to one side of the feed funnel.

PROCEED to feed material into the feed funnel.

12

BLOCKAGES

Always be aware that what you are putting into the chipper must come out. If the chips stop coming

out of the discharge tube but the chipper is taking material in - STOP IMMEDIATELY. Continuing to

feed material into a blocked machine may cause damage and will make it difficult to clear.

If the chipper becomes blocked proceed as follows:

STOP the engine and remove the ignition keys.

REMOVE the discharge tube. Check that it is clear.

WEARING gloves, reach into the rotor housing and scoop out the majority of the debris causing

the blockage.

WARNING

Do not reach into the rotor housing with unprotected hands. There are

sharp blades and any small movement of the rotor may cause serious injury.

REPLACE the discharge tube.

RESTART the engine and increase to full speed.

ALLOW machine time to clear excess chips still remaining in rotor housing before you

continue feeding brushwood. Feed in a small piece of wood whilst watching to make sure

that it comes out of the discharge. If this does not clear it, repeat the process and carefully

inspect the discharge tube to find any obstruction.

NOTE

Continuing to feed the chipper with brushwood once it has become blocked will cause the chipper to

compact the chips in the rotor housing and it will be difficult and time consuming to clear.

AVOID THIS SITUATION - WATCH THE DISCHARGE TUBE AT ALL TIMES.

!!

CHIPPING

Wood up to 150mm diameter can be fed into the feed funnel. Put the butt end in first and engage it

with the feed roller. The hydraulic feed rollers will pull the branch into the machine quite quickly. Large

diameter material will have its feed rate automatically controlled by the no stress unit.

Sometimes a piece of wood that is a particularly awkward shape is too strong for the feed rollers to

break. This will cause the top roller to either bounce up and down on the wood or both rollers to stall.

If this occurs press the BLUE REVERSE button until the material has been released. Pull the material

out of the feed funnel and trim it so the chipper can handle it.

Both feed rollers should always turn at the same speed. If one or both rollers stop or suddenly slow

down it may be that a piece of wood has become stuck behind one of the rollers. If this occurs press

the BLUE REVERSE button and hold for 2 seconds - then repress GREEN FEED button. This should

enable the rollers to free the offending piece of material and continue rotation at the correct speed. If

the rollers continue to stall in the 'forward feed' or 'reverse feed' position push the RED STOP

BUTTON, turn engine off, remove ignition key and investigate.

SERVICE INSTRUCTIONS

ALWAYS IMMOBILISE THE MACHINE BY STOPPING THE ENGINE, REMOVING THE

IGNITION KEY AND DISCONNECTING THE BATTERY BEFORE UNDERTAKING

ANY MAINTENANCE WORK.

WARNING

Table 1. Service Schedule

Do jobs below:

Check engine oil - top up if necessary.

Check for engine oil / hydraulic oil leaks.

Check fuel level.

Check feed funnel, feed roller cover,

access covers, engine covers and

discharge unit are securely fitted.

Check blades.

Check radiator is clear.

Clean air filter element.

Check tyre pressure is 2.2 Bar (32 psi).

Check for tightness all nuts, bolts and

fastenings making sure nothing has

worked loose.

Tension main drive belts.

Tension hydraulic pump belts.

Grease the roller drive splines.

Check safety bar mechanism.

Check fuel pipes and clamp bands.

Check battery electrolyte level.

Check for loose electrical wiring.

Replace hydraulic oil filter - every year or

100 hours after service or repair work to

the hydraulic system.

Replace hydraulic oil.

Replace fuel pipes and clamp bands.

Check coolant.

Change engine oil.

Replace engine oil filter cartridge.

Check valve clearance.

Replace front rotor bearings.

Turn / replace anvils.

Axle & Tow head maintenance

Road brake maintenance

NOTE: Main Rotor Bearings are sealed for life. No greasing or lubrication is necessary.

!

!

13

Daily

Check

50

Hours

100

Hours

500

Hours

1

Year

}REFER TO YOUR ENGINE

SUPPLIERS MANUAL

DEPENDING ON WORKING ENVIRONMENT

OR

OR

}

RETURN TO DEALER OR

}

REFER TO SUPPLIERS INFORMATION SHEET

SERVICE INSTRUCTIONS

ALWAYS IMMOBILISE THE ENGINE BEFORE UNDERTAKING ANY MAINTENANCE

WORK ON THE CHIPPER BY REMOVING THE KEY AND DISCONNECTING THE BATTERY.

HANDLE blades with extreme caution to avoid injury. Gloves should always be worn when

handling the cutter blades.

AVOID contact with hydraulic oil and fuel.

THE drive belts should be connected while changing blades, as this will restrict sudden

movement of the rotor.

THE major components of this machine are heavy. Lifting equipment must be used for

disassembly.

CLEAN machines are safer and easier to service.

SAFE MAINTENANCE

Only fit genuine Entec replacement blades, screws and chipper spares. Failure to do so will

result in the invalidation of the warranty and may result in damage to the chipper, personal

injury or even loss of life.

SPARES

14

ENGINE SERVICING

Ensure servicing is performed in accordance with the Engine Manufacturer’s Handbook.

BATTERY REMOVAL AND MAINTENANCE

WARNING

Refer to the battery leaflet for safety and COSHH requirements. !

!

1. Remove the two M12 Nyloc nuts that retain the battery box top.

2. Remove the negative lead first and then the positive lead.

3. Clean, charge and/or top up the battery as required.

4. Refitting is the reverse of removal. Apply a smear of vaseline to the terminals to prevent

corrosion.

SERVICE INSTRUCTIONS 15

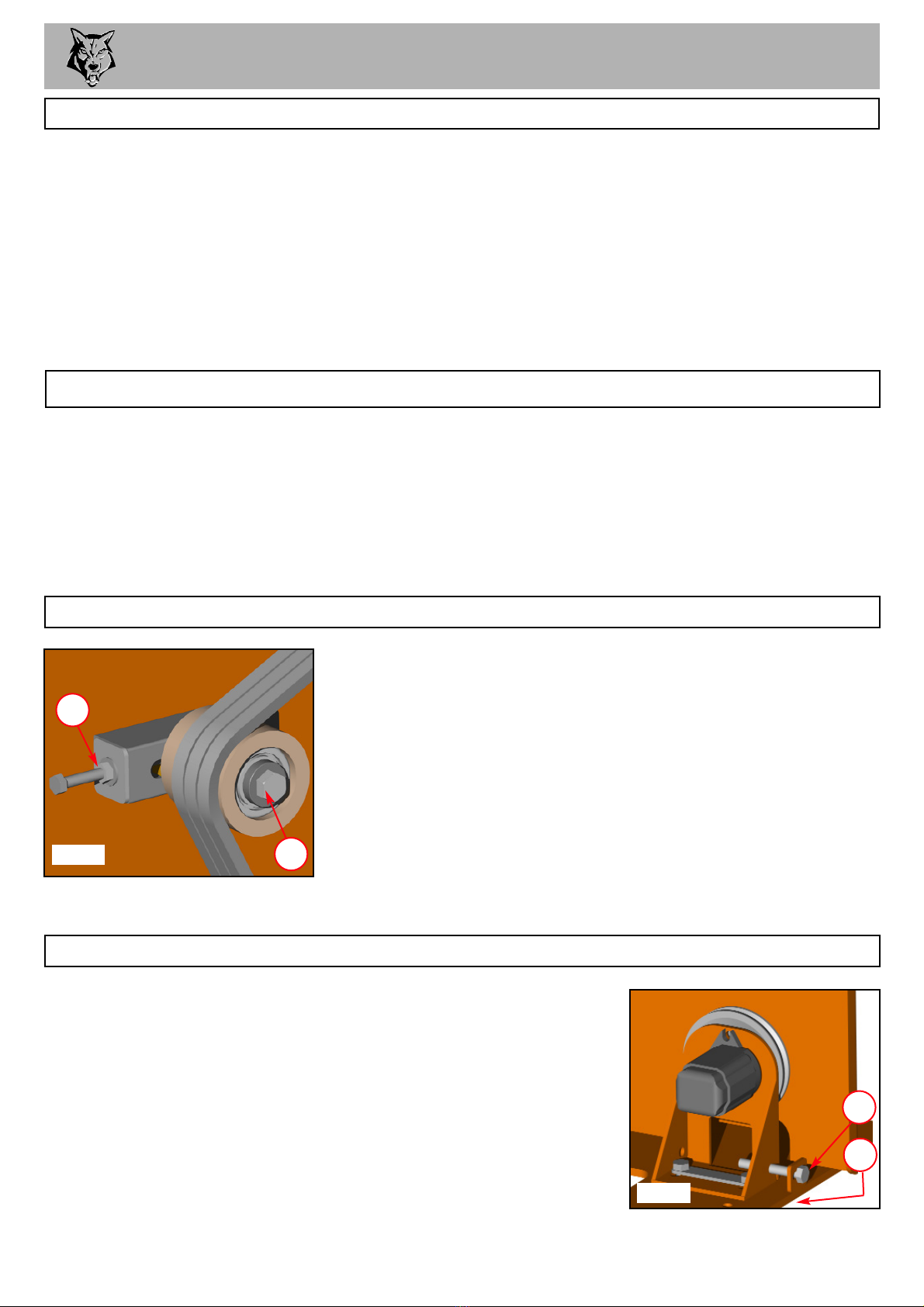

1. Turn the chipper off and remove the ignition keys.

2. Remove battery leads.

3. Remove bolt and washer retaining roller box

guard and lift guard.

4. Remove the two springs on the roller box slide.

5. NOTE: Rollerbox slide weighs in excess of 20kg.

Lift the roller box slide and wedge a suitably sized

piece of wood to hold in place.

6. Remove blade access cover.

7. Remove discharge tube. Turn the rotor by hand

by grasping fan section on rear of rotor disc until

blade is visible through aperture.

8. Use a small screwdriver to remove sap and debris

from Torx socket in screw - be particularly

careful to ensure every last piece has been

removed.

9. Undo blade screws using Torx socket drive

provided. Rotor will turn until Torx socket has

located on machine.

10. Before fitting replacement blades carefully

clean blade recess in rotor so that no debris

is trapped between blade and rotor.

11. When fitting blades replace any damaged

screws with new and coat each screw with

copperslip over the whole of the thread.

12. Retighten each screw to 60Nm (45lbs ft).

NOTE: This torque setting is vitally

important to ensure your bolts come out

at a later date and Entec recommend you

purchase a torque wrench for this and

other jobs on the chipper.

13. Grease all surfaces of the roller box sliding

mechanism (see fig.17, pg.18).

14. Replace blade access cover.

15. NOTE: Rollerbox slide weighs in excess of 20kg.

Remove wedge, lower roller box slide and

replace springs.

16. Close roller box guard and ensure bolt and

washer are tightened.

17. Refit battery leads.

WARNING

Wear riggers gloves for the blade changing operation.

CHANGE BLADES

fig 9. fig 10.

!

!

3

4

5

6

8

9

10

3

7

WARNING

Always sharpen blades on a regular basis. Failure to do so will

cause the machine to under perform and will overload engine and

bearings causing machine breakdown. Blades must not be

sharpened beyond the wear mark (see diagram). Failure to comply

with this could result in machine damage, injury or loss of life.

!

!

WEAR

MARK

fig 11.

SERVICE INSTRUCTIONS

TENSION HYDRAULIC PUMP BELT

1. Remove side panel.

2. Access the two nuts on the under side of the chassis beneath

pump bracket and slacken using a 19 mm socket spanner.

3. Adjust the M8 bolt on the outside plate until the desired tension is

achieved. Tension is correct when 4.5kg of force deflects one belt

6mm at the centre of its span. (Push the belt firmly with your index

finger, it should deflect to roughly the depth of your fingernail).

4. Ensure pulleys are aligned then retighten the two nuts to (80 Nm) 60 lbs/ft.

5. NOTE: Slack drive belts will cause poor performance and

belt/pulley wear.

The Timberwolf TW 35/150DH is subject to large vibrations during the normal course of operation.

Consequently there is always a possibility that nuts and bolts will work themselves loose. It is

important that periodic checks are made to ensure the security of all fasteners. Fasteners should be

tightened using a torque wrench to the required torque (see below).

Size Pitch Head Torque Nm Torque Ibft

General M8 Standard 13mm Hex 22 15

General M10 Standard 17mm Hex 45 32

General M12 Standard 19mm Hex 80 60

16

CHECK FITTINGS

TENSION DRIVE BELTS

CHECK HOSES

All the hydraulic hoses should be regularly inspected for chafing and leaks. The hydraulic system is

pressurized to over 130 Bar (1900 PSI) and thus the equipment containing it must be kept in good

condition.

Identify the hoses that run to the top motor. These have the highest chance of damage as they are

constantly moving. If any hydraulic components are changed new seals should be installed during

reassembly. Fittings should then be retightened.

2

fig 13.

3

1. Remove side panel.

2. Loosen bolt in centre of tensioner pulley with a 19mm spanner so

that pulley is able to slide with minimal wobble.

3. Turn nut in end of tensioner pulley slider until correct belt tension

is achieved and lock the tensioner pulley bolt back up again. Tension

is correct when 4.5kg of force deflects one belt 6mm at the centre of

its span. (Push the belt firmly with your index finger; it should

deflect to roughly the depth of your fingernail).

4. Run machine and test, recheck belt tension.

5. NOTE: Slack drive belts will cause poor performance and belt / pulley

wear.

2

3

fig 12.

SERVICE INSTRUCTIONS 17

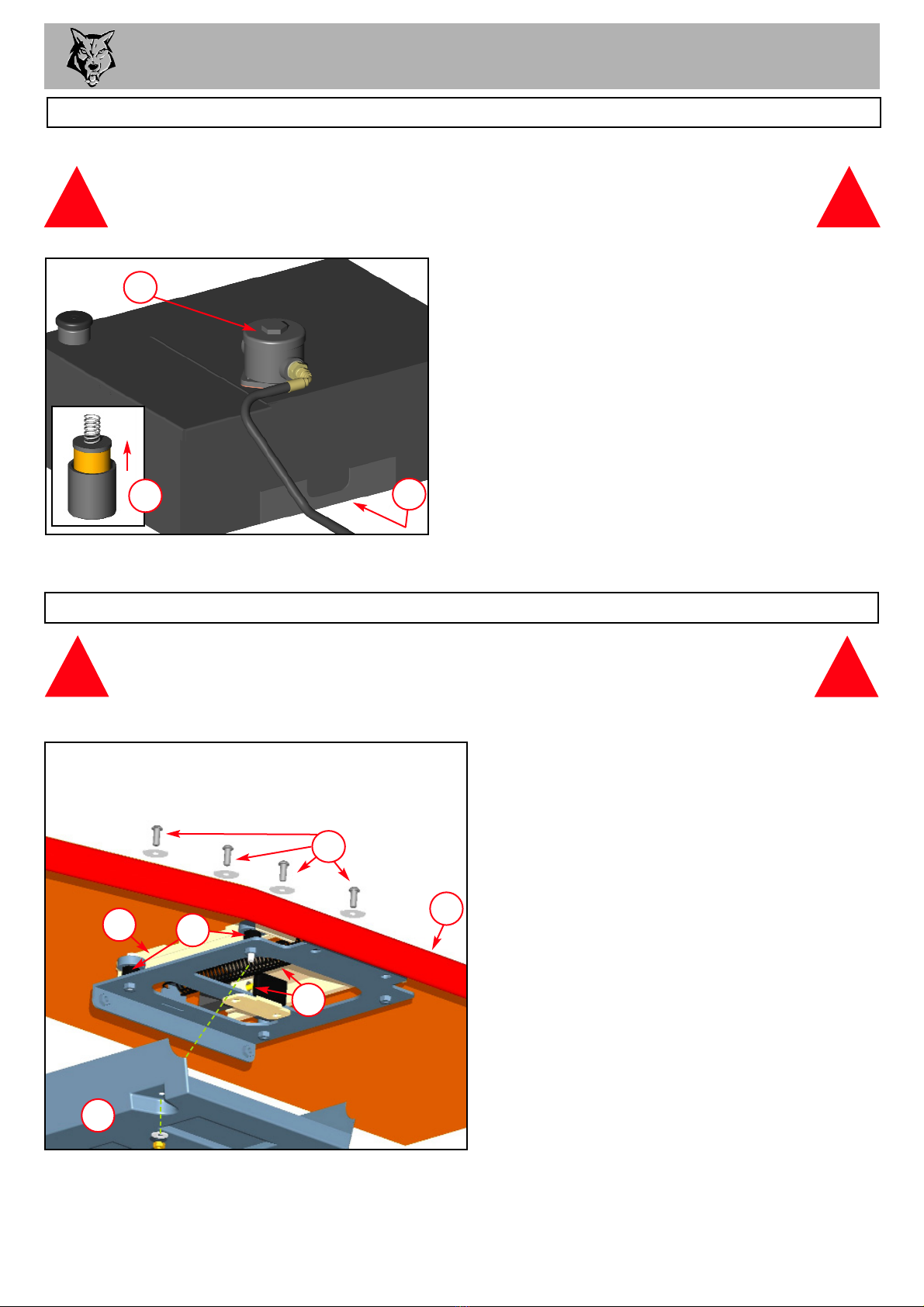

WARNING

To ensure that the safety bar is always available the following checks and

adjustments should be carried out monthly.

SERVICE TO THE SAFETY BAR (WHERE FITTED)

1. Remove the black plastic cover.

2. Use a bristle brush to remove any accumulated

debris or dirt.

3. Check that the switch is secure and the spring free

from debris.

4. Check all mounting bolts for security.

5. Hold the bar and check for side play. There should

not be any. If there is proceed as follows:

6. Locate the two hexagonal bearing pillars.

7. Slacken the screw on each pillar. The pillars are

eccentric. Turn the pillar slowly with a 19mm

spanner until the play just goes. Retighten the

pillar screws and check that the slide moves freely

without side play.

8. Apply fresh grease to each slide.

9. Refit the plastic cover.

!!

fig 15.

1

3

4

5

6

8

WARNING

Use plastic gloves to keep oil off skin and dispose of the used oil and filter in an

ecologically sound way. The oil and filter should be changed once a year

or at any time it becomes contaminated. Before starting check that

the chipper is standing level and brush away loose chips.

CHANGE HYDRAULIC OIL AND FILTER

1. Remove the black screw cap from the top of the filter

housing.

2. Partially remove filter element from inner cup. Leave

filter to drain for 15 minutes.

3. Remove filter element from cup when clear of hydraulic oil.

4. Remove drain plug and drain oil into a suitable container.

5. Replace drain plug.

6. Refill with VG 32 hydraulic oil until the level is half

way up the sight glass (about 15 litres).

7. Refit the filter cup, install a new filter element and refit the

black screw cap to the filter housing.

fig 14.

! !

2

1

4

NOTE: This is a non-adjustable air breather filter.

SERVICE INSTRUCTIONS 18

GREASE THE ROLLER DRIVE SPLINES

NOTE: This should be done four times a year or every 50 hours. If the grease in the splines is

allowed to dry out, rapid wear of the roller splines will occur resulting in a breakdown and the

need to fit replacement parts. This failure is not warranty.

1. Remove bolt and washer retaining roller box guard and lift guard (as

shown in fig 9).

2. Locate two grease nipples; one in the centre of each roller

shaft.

3. Use a pump action grease gun to apply a generous amount of

grease to each roller drive.

4. Close the roller box guard and refit the washer and bolt.

fig 16.

GREASE THE ROLLER BOX SLIDES

NOTE: This should be done regularly. In dirty or dusty conditions or during periods of hard

work it should be done weekly. If the slides become dry the top roller will tend to hang up and

the pulling-in power of the rollers will be much reduced. Excessive wear will ensue.

1. Turn the chipper off and remove the ignition keys.

2. Remove battery leads - ensure machine has come to a complete

stop.

3. Remove the bolt and washer retaining roller box guard and lift guard.

4. Remove the two springs on the roller box slide.

5. NOTE: Rollerbox slide weighs in excess of 20kg.

Lift the top roller and wedge a suitably sized piece of wood to hold

in place.

6. Apply thin grease with a brush to each slide on roller box and on

inner cheeks of slider.

7. NOTE: Rollerbox slide weighs in excess of 20kg.

Remove wedge, lower roller box slide and replace springs.

8. Close roller box guard and refit bolt and washer.

9. Refit battery leads.

fig 17.

ENGINE MANUFACTURER’S HANDBOOK

6

3

2

5

4

Refer to your Engine Manufacturer’s Handbook for detailed instructions on the following:

Changing the fuel filter.

Checking the engine oil.

Changing the engine oil.

Changing the engine oil filter.

GREASING ROTOR BEARINGS

Both front and rear bearings are sealed and do not need greasing.

This manual suits for next models

1

Table of contents

Other Entec Chipper manuals