10

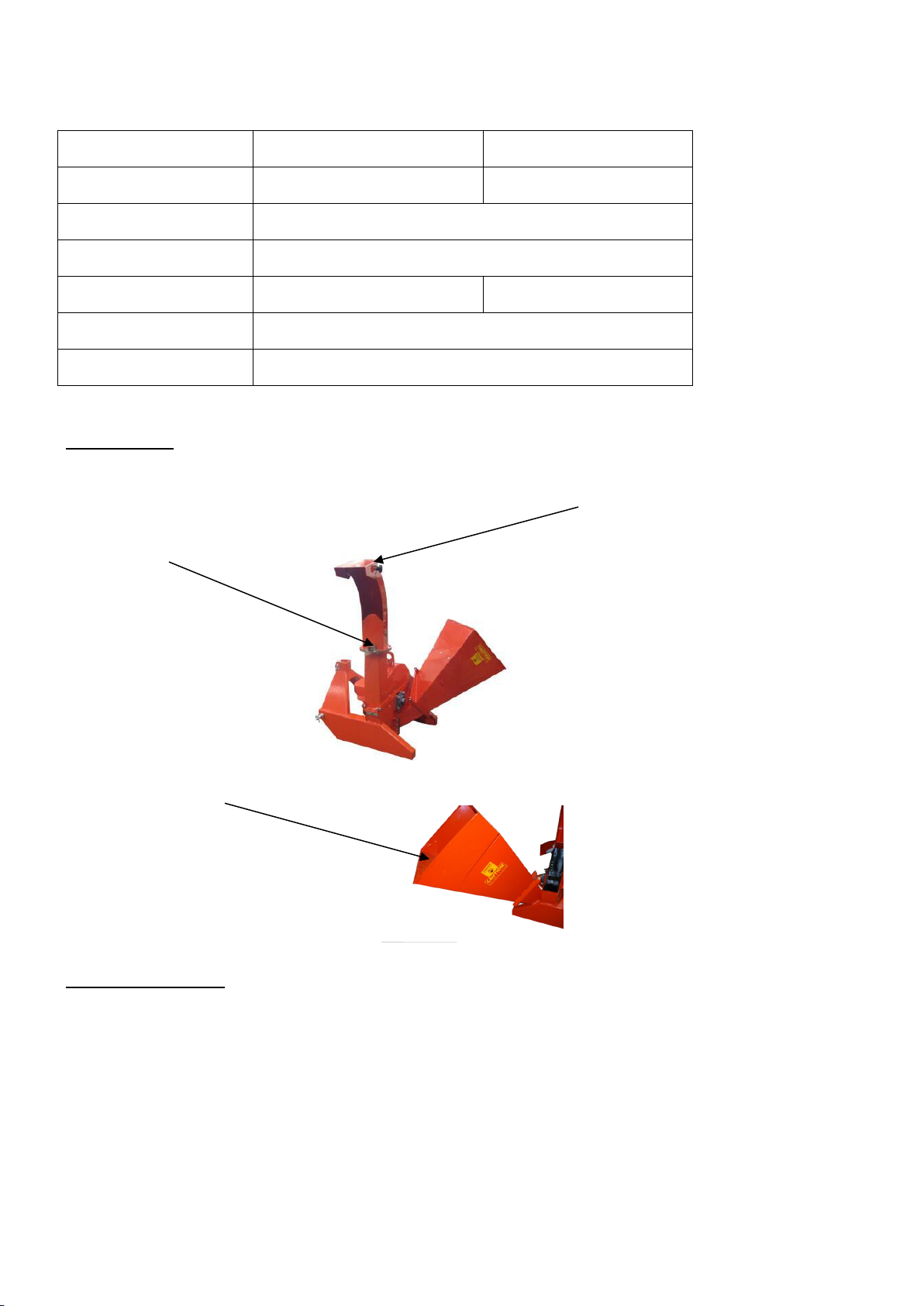

CONNECT THE MACHINE TO TRACTOR:

The machine must be connected to the tractor by the PTO operated at 540 t/rpm, with required weight and

power.

During the process of using, adjustment, maintenance, repair or displacement, the operator must use the

appropriate Personal Protection Equipment (PPE).

ATTENTION:

AVOID STATIONING IN FRONT OF THE MACHINE.

AVOID THE PRESENCE OF PEOPLE.

DURING THE ASSEMBLY, THE PTO MUST ALWAYS BE DISENGAGED.

Before assembling the machine, check whether it is laying on the land and paralleled , whether the lubricants

are at the correct level and whether all parts are in perfect condition. Also check whether the tractor is

suitable for carrying the machine. Make sure that the rotations of P.T.O. are the same as the machine. After

these checks, proceed as follows: - brake and switch off the tractor, remove the ignition key and go down; -

adjust the arms of tie rods to prevent any oscillation to the right and to the left of the machine; - Assemble

the cardan shaft and ensure that the bolts are inserted into the slots after checking the length. - apply the

three point linkage. - lift the machine slightly off the ground and raise the support feet.

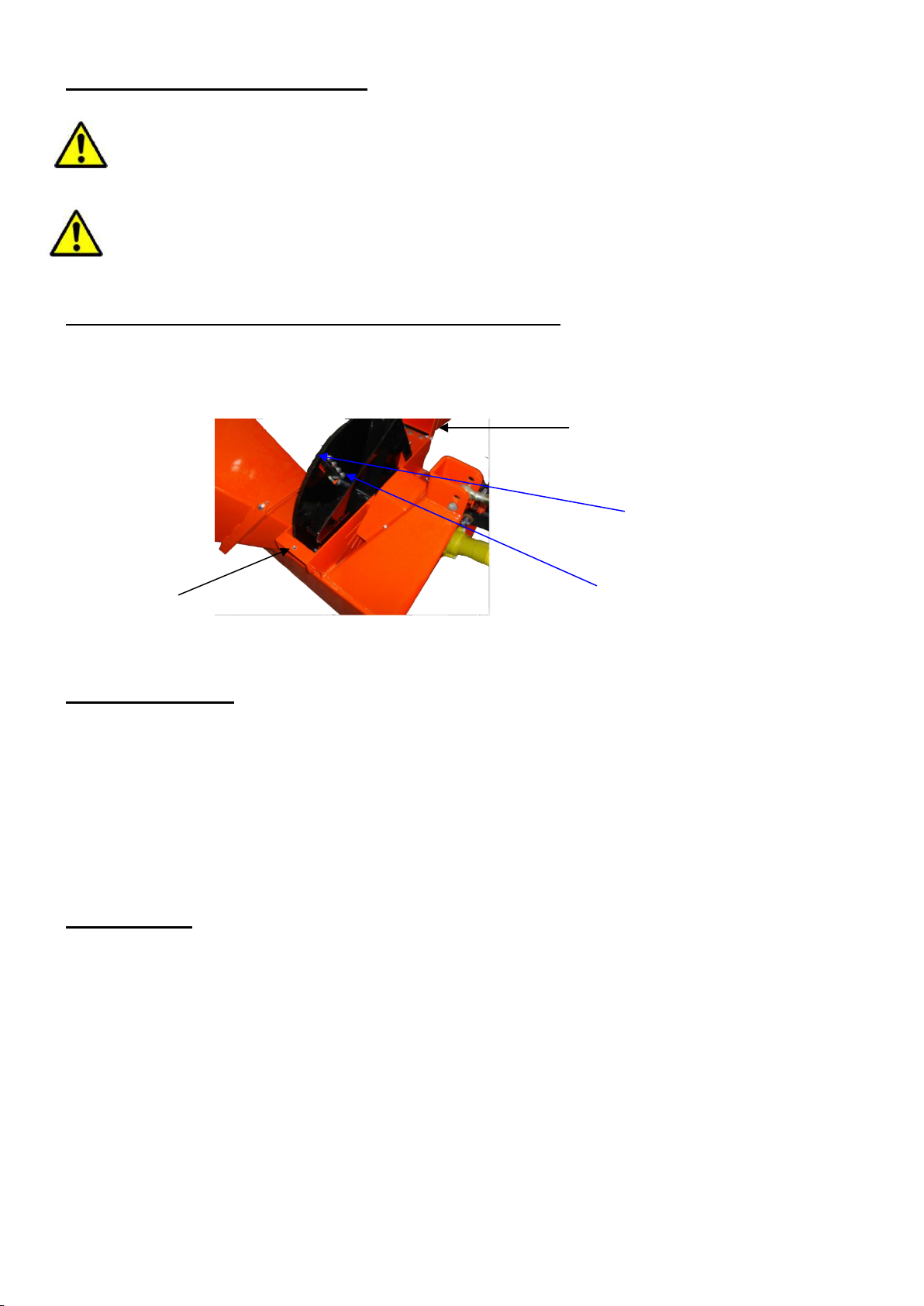

SPECIFICATIONS OF PTO CARDAN :

Insert the cardan shaft onto the spline shaft of the machine until the dowel locks into place.

Don’t use the cardan without protections.

Never extend the cardan

If the machine is connected to tractor for first time, please ensure that:

Under maximum steering conditions, the cardan is not fully closed to avoid damage to the speed

increaser or tractor.

In the case where the cardan is too long, it would be necessary to shorten it by cutting it.

The cardan shaft is the transmission part which drives the machine; it must be adapted to the machine: the

size and length.