envea ProGap 2.0-BS Ex User manual

OPERATING INSTRUCTIONS

ProGap 2.0-BS (Ex)

LEVEL DETECTION WITH FILLING STREAM DETECTION

ENVEA - SWR engineering - Gutedelstraße 31 – 79418 Schliengen - GERMANY

Tel : +49 (0) 7635 827248-0 / info.swr@envea.global / www.swr-engineering.com

2

TABLE OF CONTENTS Page

1. System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1 Normal use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.2 Identification of hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.4 Technical statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4. Mounting and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Typical components of a measurement point . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.2 Required equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.3 Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.4 Mounting of the Evaluation unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5. Use in hazardous areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.1 Electrical connection of sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.2 Electrical connection of receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6.3 Electrical connection of Evaluation unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7. Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 Basic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.2 Menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.3 Menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7.4 Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8. Error signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10. Default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11. Impuls output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3

1. System overview

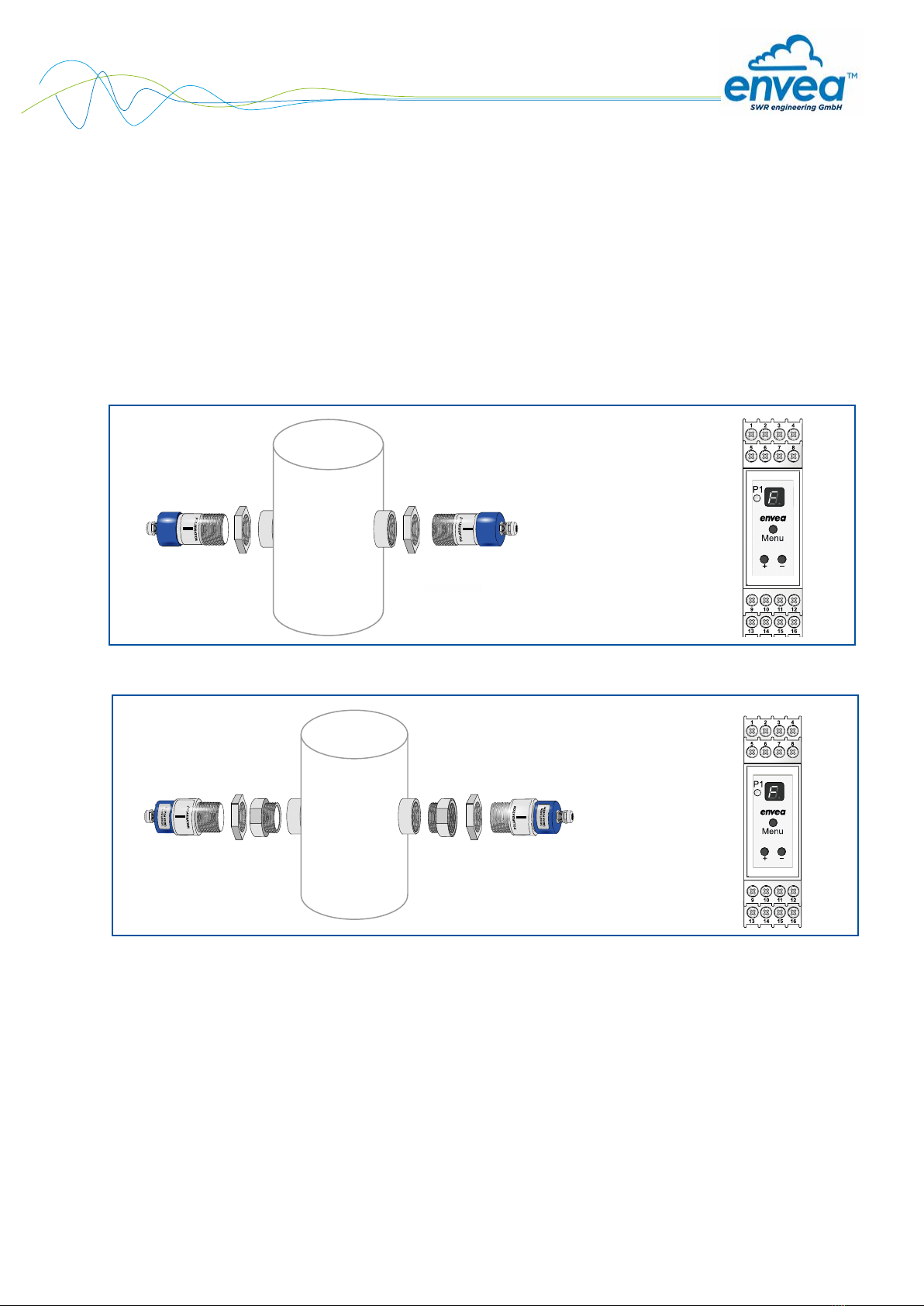

A measuring point consists of the following components:

•G-1½” welded bracket for assembly of the units

•2 x lock nut for locking the sender and receiver unit

•Process adapter (optional)

•Sender unit

•Receiver unit

•Evaluation unit

2. Function

The microwave barrier is a contact-free measuring method and can be used on both metallic and non-

metallic pipes, tanks, shafts, chutes, bellows etc. As non-conductive materials such as plastics are able to

penetrate, it can be used for detection from outside or through a window. In this way, the measurement can

be fully decoupled from the process – to measure aggressive, abrasive or coarse materials for instance.

In very difficult conditions – i.e. temperatures up to 200 °C, pressure to 20 bar as well as all dust Ex zones –

the ProGap 2.0-BS can be used with the aid of a process adapter. The filling stream detection can only be

guaranteed for metallically shielded tanks.

Fig. 1: Overview of measuring point: ProGap 2.0-BS

+

Fig. 2: Overview of measuring point: ProGap 2.0-BS Ex

+

4

3. Safety

The ProGap 2.0-BS dust sensor has a state-of-the-art, reliable design and has been tested and found to be in

a perfectly safe condition when it left the factory. Nevertheless, the system components may present dangers

to personnel and items if they are not operated correctly.

Therefore, the operating manual must be read in full and the safety instructions followed to the letter. If the device

is not used correctly for its intended purpose the manufacturer's liability and warranty will become void.

3.1 Normal use

•Only genuine spare parts and accessories from ENVEA - SWR engineering may be used.

3.2 Identification of hazards

•The operating manual refers to possible dangers when using the microwave barrier.

Warning!

•This symbol is used in the operating manual to denote actions which, if not performed correctly may

result in death or injury.

Attention!

•This symbol is used in the operating manual to denote actions which may result in danger to property.

3.3 Operational safety

•The microwave barrier may only be installed by trained, authorised personnel.

•During all maintenance, cleaning and inspection work on pipes or ProGap 2.0-BS components, make

sure that the system is in an unpressurised state.

•Switch off the power supply before performing any maintenance work, cleaning work or inspections on

pipes.

•The microwave barrier must be removed before welding work.

•The components and electrical connections must be inspected for damage at regular intervals. If any

signs of damage are found, this damage must be rectified before the devices are used again.

3.4 Technical statement

•The manufacturer reserves the right to adjust technical data concerning technical developments without

notice. ENVEA - SWR engineering will be delighted to provide information about the current version of

the operating manual, and any amendments made.

5

4. Mounting and installation

4.1 Typical components of a measurement point:

•G-1½” welded bracket for assembly of the units

•2 x lock nut for locking the units

•Process adapter (optional)

•Sender unit

•Receiver unit

•Evaluation unit

4.2 Required equipment

•Tested tools for the electrical connection

•60-mm open-ended spanner for lock nut

•Teflon tape for ensuring leak tightness

4.3 Sensor installation

Proceed as follows to install the sensor:

•Determine a installation site as free from vibrations as possible.

•We recommend a distance of 15 cm from adjacent walls.

•Weld on the sensor socket so that the faces of the sender and receiver are opposite each other on

the same level.

•It must be strictly ensured that the sensor socket is free of dirt and deposits.

•If the measuring point is not installed directly, the sensor socket can be closed with a cover

with G-1½” thread.

•It must be strictly ensured that the sender and receiver have the same orientation and are aligned

precisely to one another. (Polarisation label)

•Exceptional case: For distances up to 400 mm, the transmitter should be rotated 90° to attenuate the

signal.

•Once aligned, the sender and receiver unit must be locked with the lock nut.

•A maximum spacing between the sender and receiver of 25 m must not be exceeded.

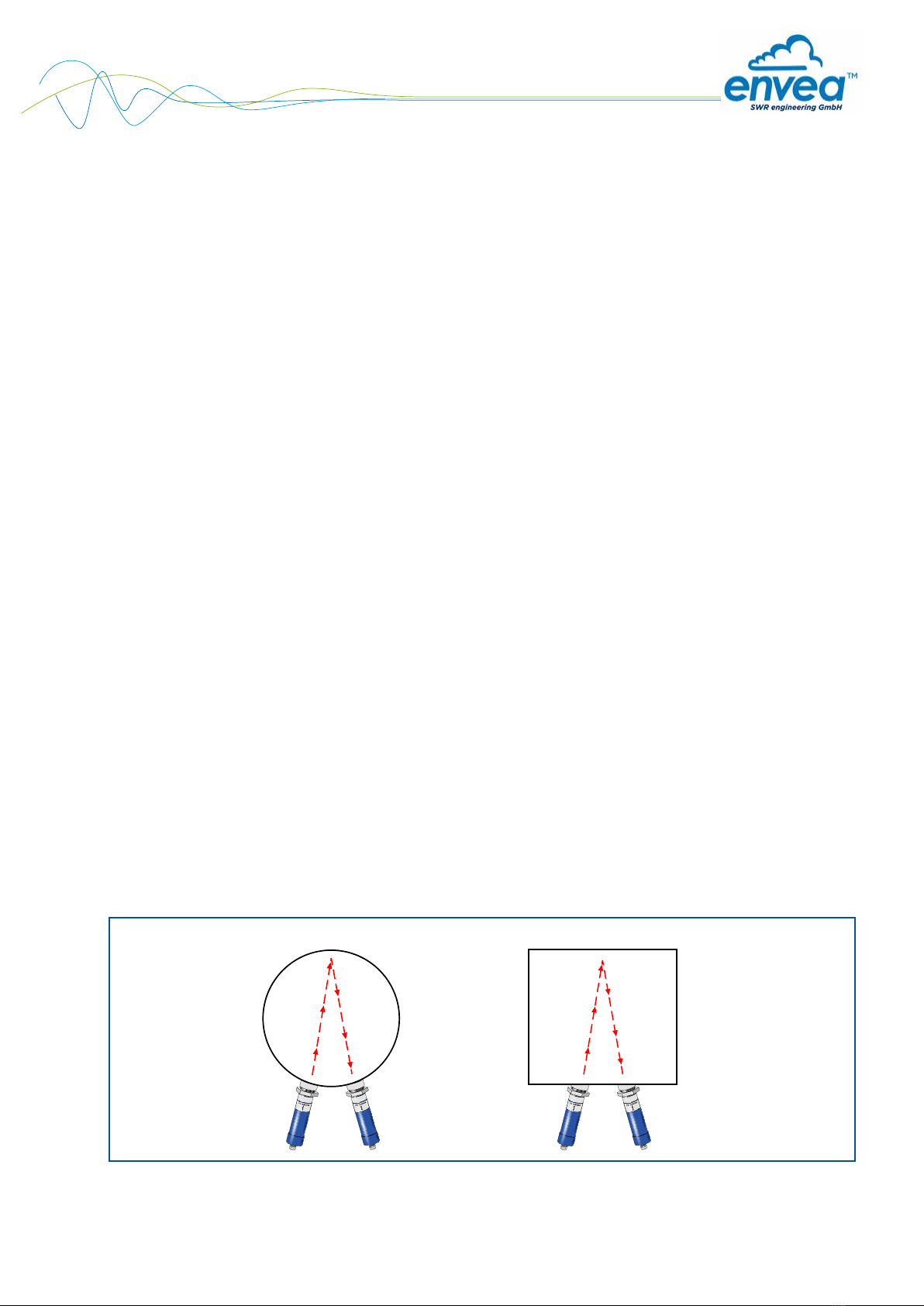

•If the sender and receiver cannot be installed opposite, installation on one side is possible (Fig. 3).

•If the material to be measured has a low bulk density or a low DK value, the sender and receiver can be

mounted on one side of the line (Fig. 3).

Fig. 3: Installation of the measuring point on one side

Round tank (metallic) Square tank (metallic)

6

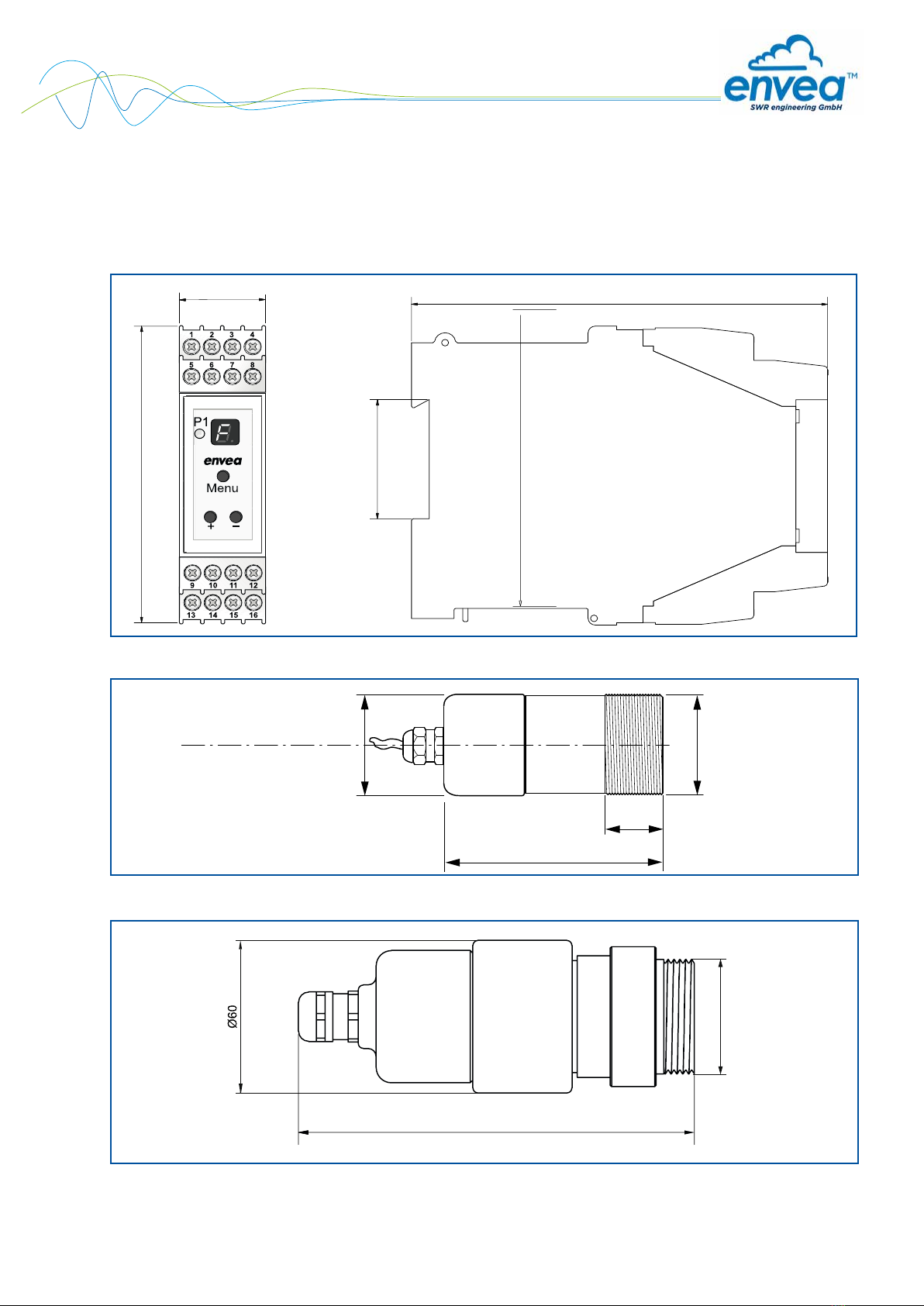

4.4 Mounting of the Evaluation unit

The evaluation unit can be installed at a maximum distance of 300 m from the sender and receiver unit.

The cable should be two-core, twisted and shielded. A minimum cross section of 0.75 mm2should be

maintained. For distances longer than 100 m, the cross-section should be adjusted to 1.5 mm2.

118

35

90

90

23

Fig. 4: Dimensions of evaluation unit in DIN Rail housing

Fig. 5: Dimensions of sender and receiver unit: ProGap 2.0-BS

103

ø 52

30

G 1 1/2"

155

G1 ½"

Fig. 6: Dimensions of sender and receiver unit: ProGap 2.0-BS Ex

G 1 1/2”

Ø 52

7

22 20 22

Non-explosive area

only with process

adapter

only with process

adapter

▼

▼

Explosive area

Dust Ex zone

Marking DustEx: II 3D Ex tc IIIC T85 °C Dc

5. Use in hazardous areas

Power supply

(observe type plate)

Voltage range

Power supply

24 V DC supplied by evaluation unit

Max. power consumption

1.5 W

Category II 3D Sensor in Zone 22

Housing protection class Sensor = IP65 / evaluation unit = IP40

Safety information for installation in explosive areas

1. Observe installation and safety instructions.

2. Install according to manufacturer’s instructions and applicable standards.

3. Do not operate the device outside the electrical and thermal parameters.

4. Mount the housing cover and cable entries properly to ensure the housing protection class.

5. Use cable glands and cable entries that are suitable for Category II 3D.

6. A process adapter must be used for installation of the ProGap 2.0-BS in an Ex zone.

Thermal data Category 3 (Zone 22)

Maximum permissible ambient temperature - 20 °C . . . + 60°C

Maximum surface temperature, sensor,

at +60 °C ambient temperature

+ 80 °C

Maximum process temperature, at +60 °C ambient

temperature, when using a Tecapeek process adapter

+ 220 °C

Maximum process temperature, at +60 °C ambient

temperature, when using a POM process adapter

+ 80 °C

8

6. Electrical connection

The evaluation unit can be installed at a maximum distance of 300 m from the sender and receiver unit. We

recommend an insulated, shielded cable with a minimum cross-section of 0.75 mm². From a cable length of

100 m, the cable cross-section must be enlarged to 1.5 mm². The sender/receiver system has an EMC screw

connection. This serves for mounting a cable shield. The shield should only be mounted on the sensor side.

Fig. 7: Electrical connection of sender

6.1 Electrical connection of sender

1 Power supply 0 V

2 Power supply +24 V

S1 Dip switch for setting the material flow

monitoring (Hi/ Lo)

Fig. 8: Electrical connection of receiver

6.2 Electrical connection of receiver

1 Power supply 0 V

2 Power supply +24 V

S1 Dip switch for setting the level monitoring

(Hi/ Lo)

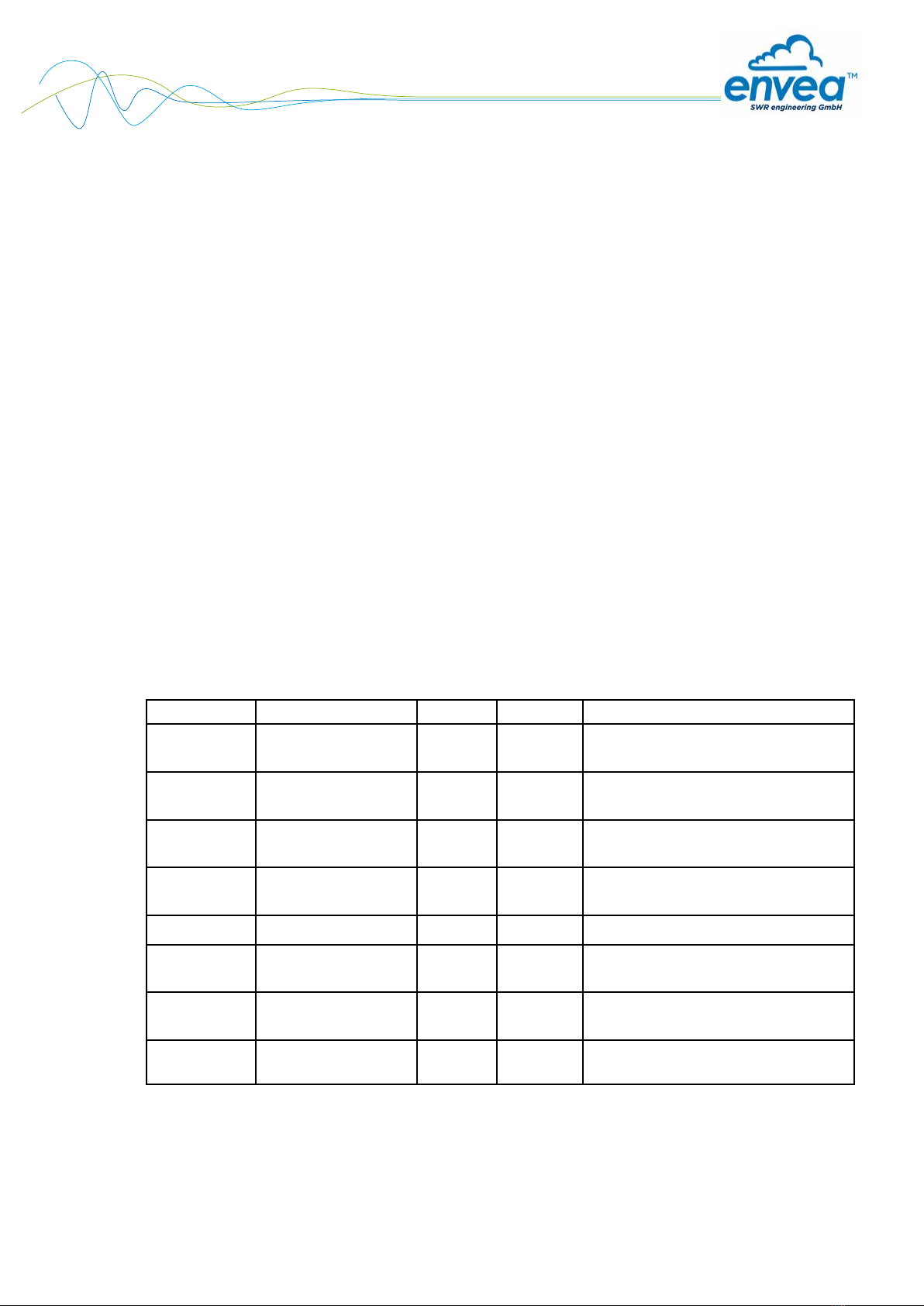

Fig. 9: Electrical connection of evaluation unit

6.3 Electrical connection of Evaluation unit

1 NA

2 NA

3 Power supply +24 V

4 Power supply 0 V

5 Open collector +

6 Open collector -

7 NA

8 NA

9 Sender cable 1 (0 V)

10 Sender cable 2 (+24 V)

11 Receiver cable 1 (0 V)

12 Receiver cable 2 (+24 V)

13 NA

14 Relay contact NC

15 Relay contact COM

16 Relay contact NO

Hi Lo

Hi Lo

9

7. Commissioning

7.1 Basic settings

Make sure that the transmitter and receiver are installed opposite each other. At distances up to 400 mm,

the transmitter should be rotated 90° to attenuate the signal. In addition, a dip-switch is installed in the

transmitter via which the sensitivity of the material flow detection can be set. If the dip switch is set to “High”,

even small movements of material will be detected. For a distance up to 400 mm it is recommended to select

the setting “Low”.

The receiver has the additional option of setting of the level monitoring via a dip-switch. If “High” is selected,

larger distances can be monitored, with a distance of up to 400 mm, “Low” should be selected.

For better distinction, an “S” is printed on the transmitter board and the dip switch is red. An “E” is printed on

the receiver board and the dip switch is white.

If the sensors are installed correctly, commissioning can be started via the 7-segment display on the

evaluation unit.

7.2 Menu description

The 7-segment display is deactivated in normal operation. Only the decimal point LED (DP) flashes

continuously. If the Menu button is pressed for longer than 5 seconds, the Parameter Settings menu is

activated. If the Parameter Settings menu is activated, the menu items are shown on the 7-segment display

with numerals 1-9. After activating the menu, the Menu button can be used to toggle between the individual

menu items. The + and – buttons are used to change parameters in the selected menu. Depending on

the menu item, the response by the decimal point LED (DP-LED) will change. Menu item 9 is used to quit

and save the parameter changes. The changed parameters are saved with the + button; all changes are

discarded with the – button. In both cases, the menu is quit by pressing the button. If no entry is made for

longer than five minutes, changed parameters will be discarded and the Parameter Settings menu closed.

10

7.3 Menu structure

Menu point Function

1

Sensitivity of motion detection

DP LED lights up: High sensitivity

Even small movements are detected

DP LED does not light up: Low sensitivity

Small movements are ignored

Status LED P1 lights up: Motion was detected

2

Switching threshold of motion detection (resolution: 20 levels)

DP LED flashes slowly: Reduced switching threshold

Even small movements are detected

DP LED flashes rapidly: Increased switching threshold

Small movements are ignored

Status LED P1 lights up: Motion detection is detected

3

Sensitivity of level detection

DP LED lights up: High sensitivity

High signal strength for higher distance

DP LED does not light up: Low sensitivity

Low signal strength for smaller distance

Status LED P1 lights up: No material is detected

4

Switching threshold of level detection (resolution: 20 levels)

DP LED flashes slowly: Reduced switching threshold

A high signal attenuation is required for alarm output

DP LED flashes rapidly: Increased switching threshold

Even low signal attenuation leads to alarm output

Status LED P1 lights up: No material was detected

5

Switching delay of relay and open collector (resolution: 20 levels)

DP LED flashes slowly: Low delay (minimum: 0.5 sec)

DP LED flashes rapidly: High delay (maximum: 10 sec)

Status LED P1: Flashes in relation to the response delay; the switch on and

off time of the LED corresponds to the actual delay time

6

Switching response of relay

DP LED lights up: Relay switches if material with motion is detected (filling process)

DP LED does not light up: Relay switches as soon as material motion is detected (flow / no flow)

DP LED flashes rapidly: Relay switches if material without motion is detected (filling level)

DP LED flashes slowly: Relay switches if sender and receiver detect

Status LED P1 lights up: Selected option is fulfilled

7

Switching response by open collector (OC)

DP LED lights up: OC switches if no error is detected

DP LED does not light up: OC switches as soon as material motion is detected (flow / no flow)

DP LED flashes rapidly: OC switches if material without motion is detected (filling level)

DP LED flashes slowly: OC switches if sender and receiver detect

Status LED P1 lights up: Selected option is fulfilled

8

Switching response of status LED

DP LED lights up: Status LED P1 indicates the status of the relay contact

DP LED does not light up: Status LED P1 indicates the status of the open collector

Status LED P1: Indicates the current status

If the open collector is used for error analysis, the status LED P1 always indicates the state of the

relay contact.

9

Quit Settings menu

With + button: Quit menu and save parameter changes

With - button: Quit menu and discard parameter changes

11

7.4 Start-up procedure

The following points should be checked before the initial start-up:

•Correct installation of the measuring point

•Correct alignment of the polarisation

•Correct connection between the sensors and evaluation unit

•Heat-up time of at least five minutes

The parameters are set via the 7-segment display for optimal measuring value output. It must first be ensured

that the receiver detects the signal from the sender. For this, the beam path between the units must be free

and menu items 3 + 4 set so that LED P1 lights up (no material detection).

Once it is ensured that the sender and receiver are detecting, the settings for the motion detection can

be made in menu 1 + 2. The motion detection is performed during the process and must be set so that

the current material is detected in the process (LED P1 lights up). After the motion detection is set, we

recommend checking again whether the receiver detects the signal from the sender during the process

(Menu 3+4, LED P1 lights up).

The microwave barrier must then be interrupted completely with the material to be measured. Once the

beam path is interrupted, it is necessary to check at menu items 3 + 4 that LED P1 has switched off (material

detection).

Once the process parameters are set, the switch-off delay of the relay and open collector output can be set at

menu item 5. In menu items 6 + 7, it is then necessary to select the desired switching response for the relay

and open collector output. For a better overview, the status LED P1 can be assigned to the state of the relay

contact or the open collector at menu item 8.

The open collector output must be supplied actively with a voltage (max. 30 V, 20 mA).

Once all parameters are set properly, these must be saved by pressing the + button at menu item 9.

The initial start-up is now completed, allowing the ProGap 2.0-BS to alarm reliably as soon as

the selected limit level is reached.

8. Error signalling

Error Cause Action

Relay contact does not switch

when filling level is reached

Low bulk density of material

Set microwave barrier for

sensitivity

Set motion detection as

insensitive

Check installation situation,

change if necessary

Low DK value of material

Sender and receiver do not see

each other

Polarisation distorted

Display of an “S” on the

7-segment display Sender unit was not detected

Check electrical connection;

Contact ENVEA -

SWR engineering

Display of an “E” on the

7-segment display Receiver unit was not detected

Check electrical connection;

Contact ENVEA -

SWR engineering

Display of a “P” on the

7-segment display Parameter saving failed Perform start-up again and save

parameters again

If several errors are active, these are shown sequentially on the 7-segment display.

12

9. Notes

•If a sensor error is detected (disconnected sensor or sender/receiver mixed up), the evaluation unit will

then report “Level detected”.

•In case of a parameter error, basic settings are used and the device continues working.

•A minimum distance of 15 cm to the wall is recommended in order avoid disturbing reflections.

•In case of restricted space or material with low bulk density or low DK value, installation on one side of

the vessel is possible.

•Various process parameters are available to protect the sensor, comply with ATEX zones or resolve

difficult process conditions.

•If the material is not detected, even with an installation on the same side, a special attenuation foil can be

obtained from ENVEA - SWR engineering.

Process adapters are essential to use this foil.

•In case of distances below 400 mm, we recommend rotating the sender or receiver by 90°.

•The pipe where the measuring point is installed must be earthed.

10. Default settings

If the + and – buttons are pressed simultaneously for longer than 10 s, all parameters are reset to the default

setting. If the parameters are still at the default setting “d” will flash in the display.

Menu point Parameter Default Range Description

1

Sensitivity of motion

detection

1 0 -1 High sensitivity

2Switching threshold

of motion detection 10 0 - 20 Medium threshold

3Sensitivity of level

detection 1 0 - 1 High sensitivity

4Switching threshold

of level detection 10 0 - 20 Medium threshold

5 Switching delay 1 0 - 20 Switching delay = 0.5 sec

6Function of relay

contact 1 0 - 3 Relay contact switches as soon as the

sender and receiver detect

7Function of open

collector 0 0 - 3 Open collector switches upon motion

detection

8 Function of LED P1 1 0 - 1 Status LED P1 indicates the status of

the relay output

13

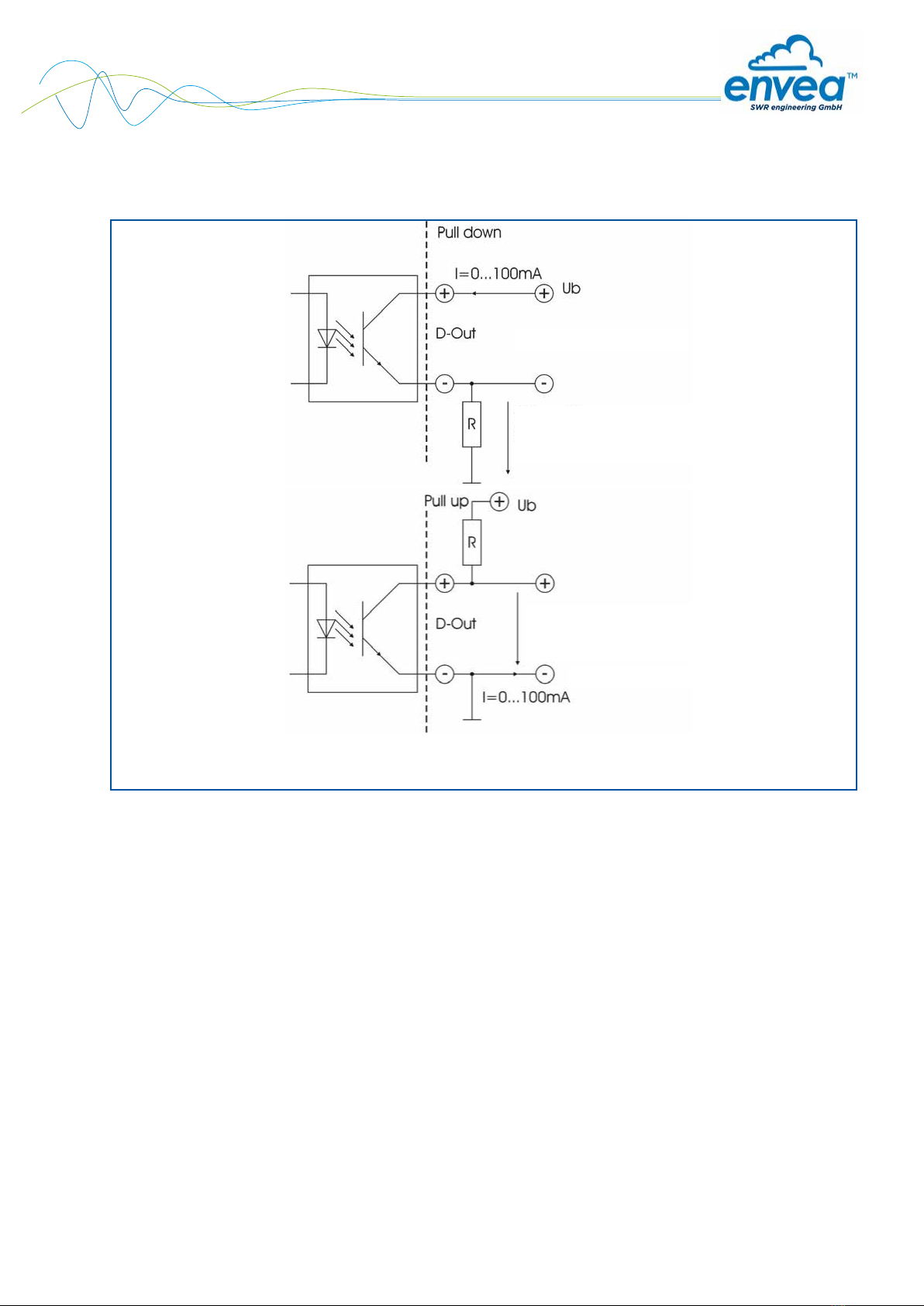

Open: 0 V

Closed: Ub - 0.7 VClosed: Ub - 0.7 V

Open: Ub

Closed: 0.7 VClosed: 0.7 V

Open Collector

Open Collector

11. Impuls output

R = (Ub - 0.7 V)/l

14

EN 06/04/2020

12. Technical data

Sensor

Material Housing: Stainless steel 1.4571 - sensor insulation: POM

Protection type IP65

Using in EX-Zones Outside: Cat. 3D

Inside: Cat. 1/3D (with process-adapter)

Process temperature - 20 ... + 80 °C

- 20 ... + 220 °C (with process adapter)

- 20 ... + 1000 °C (with ceramic flange)

Ambient temperature - 20 ... + 60°C

Operating pressure Max. 1 bar

Max. 20 bar (with process adapter)

Detection range 0.1 ... 25 m

Voltage supply 24 V DC supplied by evaluation unit

Power consumption Max. 20 VA

Current consumption Max. 850 mA

Operating frequency K band 24.125 GHz / ± 100 MHz

Transmission power Max. 5 mW

Dimensions of ProGap 2.0-BS Housing: L 103 mm / Ø 52 mm / thread: L 30 mm / Ø G 1½

Dimensions of ProGap 2.0-BS Ex Housing: L 155 mm / Ø 60 mm / thread: L 30 mm / Ø G 1½

Cable gland M16 (Ø 5-10 mm)

Weight of ProGap 2.0-BS Approx. 560 g

Weight of ProGap 2.0-BS Ex Approx. 880 g

Evaluation unit

Supply voltage 24 V DC ± 10 %

Power consumption 3.5 W

Current consumption 120 mA at 24 V

Relay contact

Max. switching power: 250 V AC

Max. inrush current: 6 A

Max. switching power 230 V AC: 250 VA

Max. switching current DC1: 3/110/220 V: 3/0.35/0.2 A

Min. switching load: 500 mW (10 V/5 mA)

Weight Approx. 172 g

Ambient operating temperature - 10 ... + 45°C

Dimensions 23 x 90 x 118 mm (W x H x D)

DIN rail fastening DIN 60715 TH35

Connection terminals cable cross-section 0.2 - 2.5 mm2[AWG 24-14]

Pulse output Open collector – max. 30 V, 20 mA

Protection type IP40

All rights reserved.

SWR engineering Messtechnik GmbH

Gutedelstraße 31 · 79418 Schliengen (Germany)

Fon +49 7635 827248-0· Fax +49 7635 827248-48 · www.swr-engineering.com

PART OF THE ENVEA GROUP

This manual suits for next models

1

Table of contents