Envirco MAC 10 VE5 RSR Manual

Updated 7/05

*** READ AND SAVE THESE INSTRUCTIONS ***

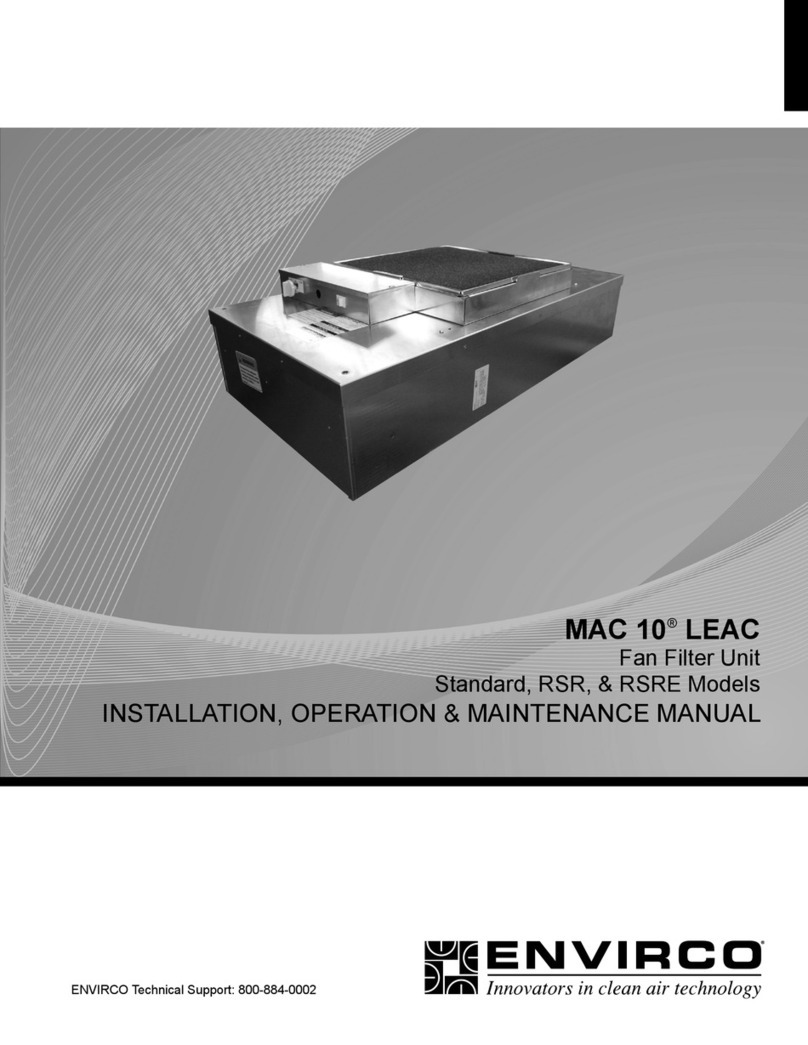

MAC 10Original VE5FAN FILTER MODULE

INSTALLATION AND SERVICE MANUAL

STANDARD, RSR, RSRE MODELS

Mac 10and VE5are registered Trademarks of the

Envirco Corporation, Albuquerque, New Mexico, U.S.A.

US Patents 4,560,395 and 5,470,363 Other patents issued and pending in foreign countries

MAC 10 Original VE5 SERVICE MANUAL

PAGE 1

READ AND SAVE THESE INSTRUCTIONS

WARNING!

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING :

A. Installation work and electrical wiring must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated

construction.

B. When cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities.

C. If this unit is to be installed over a tub or shower, it must be marked as appropriate

for the application.

D. Use this unit only in the manner intended by the manufacturer. If you have any

questions, contact the manufacturer:

ENVIRCO CORPORATION FEDDERS INTERNATIONAL

Envirco Office Headquarters

5601 Balloon Fiesta Parkway N.E. No. 728 Fuzhou Road

Albuquerque, New Mexico 87113 Haungpu District

U.S.A. Shanghai 200001 PRC

Tel : (505) 345-3561 Tel : (86) 512 6258 7180

Fax : (505) 345-8875 Fax : (86) 512 6258 0035

TRION LTD. FEDDERS INTERNATIONAL,

INC.

The Cavendish Centre DP Computers Building

Winnall Close 128 Joo Seng Road #05-01

Winchester, Hampshire, SO23 0LB, UK Singapore 368356

Tel : 44 1962 840465 Tel : 65 286 0995

Fax : 44 1962 828619 Fax : 65 286 0859

E. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally.

MAC 10 Original VE5 SERVICE MANUAL

PAGE 2

Table of Contents

Title Page

I. SERVICE: CLEANING THE MAC 10 VE5 PREFILTER.............................3

II. SERVICE: REMOVAL AND REPLACEMENT OF THE HEPA/ULPA

FILTER (STANDARD UNIT)...............................................................................4

III. SERVICE: REMOVAL AND INSTALLATION OF THE ROOM SIDE

REPLACEABLE FILTER (RSR/RSRE) ..............................................................5

IV. SERVICE: REMOVAL AND INSTALLATION OF THE MOTOR

(STANDARD AND RSR MODELS) ....................................................................7

V. SERVICE: REMOVAL AND INSTALLATION OF THE RSRE MOTOR...9

VI. ON/OFF SWITCH -SPEED/AIRFLOW ADJUSTMENT ..........................11

VII. TROUBLE SHOOTING:...........................................................................12

VIII. MAC 10 VE5 WIRING DIAGRAMS.......................................................13

IX. MAC 10 VE5 REPLACEMENT PARTS LIST: .........................................14

VII. LIMITED WARRANTY.............................................................................15

X. TESTING..................................................................................................15

MAC 10 Original VE5 SERVICE MANUAL

PAGE 3

I. SERVICE: Cleaning the MAC 10 VE5 Prefilter

WARNING!

Disconnect the unit from the electrical power source before attempting any

service.

Tools Required: None

Note: To keep the filter in top operating condition, washing the foam prefilter is

recommended every three to six months.

Step 1. To gain access to the prefilter, remove the ceiling panel next to the unit, if

applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Remove the prefilter from the snap-in frame.(see Figure 1)

Step 4. Clean the prefilter by hand washing in water with a mild detergent or by using

a vacuum cleaner. Allow prefilter to dry completely before replacing.

Step 5. Reassemble by reversing the above steps.

MAC 10 Original VE5 SERVICE MANUAL

PAGE 4

. Figure 1

II. SERVICE: Removal and Replacement of the HEPA/ULPA

Filter (Standard Unit)

WARNING!

Disconnect the unit from the electrical power source before attempting any

service.

Tools Required: Phillips Head Driver

Step 1. Remove unit from ceiling.

Step 2. Remove the 10 screws holding the HEPA/ULPA filter to the lid assembly.

Step 3. Lift the lid assembly off the HEPA/ULPA filter (see Figure 2). Discard the used

filter as per requirements of the applicable regulations.

Note: Before replacing with a new HEPA/ULPA filter, carefully inspect the new filter for

any visible damage. Also inspect the gasket in the “tee” bar to insure a tight seal.

Replace as necessary.

Step 5. Replace with the new HEPA/ULPA filter and assemble by reversing the above

steps.

Figure 2

Lid Assembly

Prefilter

HEPA/ULPA

Filter

MAC 10 Original VE5 SERVICE MANUAL

PAGE 5

III. SERVICE: Removal and Installation of the Room Side

Replaceable Filter (RSR/RSRE)

WARNING!

Disconnect the unit from the electrical power source before attempting any

service.

Tools Required: 7/16” hex head wrench

4” x 4” x 3/8” filter support blocks

Manpower Required: 2

Step 1. Remove the diffuser screen by shifting it to one side and lowering it out of the

housing.

Step 2. Install filter support blocks in all four corners of the unit. These blocks slide

into place and support the filter during the removal process.

Step 3. Remove the six screws and clips, remove filter blocks and lower the filter as

shown in Figure 3.

Step 4. Inspect filter for visible damage, if damaged set aside for replacement or

repair.

Step 5. Place the filter against the filter-sealing surface of the RSR unit. Install the four

filter support blocks as previously described.

Step 6. Install filter clips and screws, hand tight (until gasket compression begins) in

the order shown in Figure 4. After all six clips are hand tight, tighten screws to

create 50% compression (0.25”) on the gasket, using the same order.

Step 7. Remove filter support blocks and reinstall screen.

Note: Tighten filter clip bolts as necessary to insure no bypass leakage. DO NOT over

tighten.

Figure 3

Filter Clip

and Bolt

Fan

Filter

RSR Filter

Diffuser Screen

MAC 10 Original VE5 SERVICE MANUAL

PAGE 6

Figure 4

4

1

2

3

5

6

MAC 10 Original VE5 SERVICE MANUAL

PAGE 7

IV. SERVICE: Removal and Installation of the Motor (Standard

and RSR models) WARNING!

Disconnect the unit from the electrical power source before attempting any

service.

WARNING!

Electrical service should be performed by licensed electricians or authorized

ENVIRCO service technicians.

Tools Required: Phillips Head Driver

3/8” (10mm) Hex Head Wrench

Pliers

5/32”(0.40 cm) Allen wrench

Step 1. To gain access to the motor, remove the ceiling panel next to the unit, if

applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Remove the prefilter off the prefilter frame.(see Section II)

Step 4. Loosen the electrical box cover screws (2), and slide/lift off cover.

Step 5. Make note of all wire locations for reinstallation later.

Step 6. Disconnect the two brown wires from the capacitor, using a pair of pliers.

Step 7. Disconnect the motor wiring from the rotary switch and rocker switch or speed

control and rocker switch and remove the grommet from the motor leads.

Save this grommet for reinstallation.

Step 8. Remove the six screws to free the venturi ring and remove the motor/blower

assembly from the lid assembly. If using a power drivers, set the unit to a low

torque setting to avoid stripping the sheet metal screws.(see Figure 5)

Step 9. Using a 5/32”(0.40 cm) Allen wrench remove the blower wheel from the motor

shaft. Remove motor from the venturi ring using a hex wrench.

Step 10.Replace with the new motor and reassemble by reversing the above steps. Set

the spacing between the venturi ring and the blower wheel at 0.06”(0.15 cm)

clearance.

MAC 10 Original VE5 SERVICE MANUAL

PAGE 8

Figure 5

Disconnect motor leads from capacitor,

ON/OFF switch, and three-speed switch

or speed control.

Prefilter

Motor

Venturi Ring

Blower Wheel

MAC 10 Original VE5 SERVICE MANUAL

PAGE 9

V. SERVICE: Removal and Installation of the RSRE Motor

WARNING!

Disconnect the unit from the electrical power source before attempting any

service.

WARNING!

Electrical service should be performed by licensed electricians or authorized

ENVIRCO service technicians.

Step 1. To gain access to the motor, remove the gel seal filter (see Section III).

Step 2. While supporting the baffle assembly from below, remove the four corner

screws on the baffle assembly and lower the assembly.(see Figure 6)

Step 3. Prior to removing motor/blower assembly, remove electrical box cover (located

underneath the lid panel) to expose motor connectors. Disconnect the power.

Step 4. While supporting the motor/blower assembly from below, remove the eight

screws on the motor plate and lower the motor/blower assembly.(see Figure 7)

Figure 6

Gel Seal Filter

Lid Panel

Motor Plate

(Motor/Blower Assy)

Electrical connectors located

on inner prefilter wall

Plenum

Baffle Assembly

MAC 10 Original VE5 SERVICE MANUAL

PAGE 10

Step 4. Remove the six screws to free the venturi ring and remove the motor/blower

assembly from the motor plate.(see Figure 9)

Step 5. Using a 5/32”(0.40 cm) Allen wrench remove the blower wheel from the motor

shaft. Remove motor from the venturi ring by remove the three # 10 bolts.

Step 6. Before removal of the motor mount bracket, measure the precise location of

the bracket on the motor. Remove the bracket.

Step 7. Replace with the new motor and reassemble by reversing the above steps. Set

the location of the motor mount bracket as measured (see above Step 6). Set

the spacing between the venturi ring and the blower wheel at 0.06”(0.15 cm)

clearance. When reinstalling the motor plate, align the plate to insure that the

leads will reach the electrical box.

Figure 7

Blower Wheel

Venturi Ring

Motor

Motor Plate

Machine Screw

Grommet

Wellnut

MAC 10 Original VE5 SERVICE MANUAL

PAGE 11

VI. ON/OFF Switch -Speed/Airflow Adjustment

All MAC 10 units are equipped with a three-position rotary switch, which is located on

the side of the electrical box.(see Figure 8)

Recommended fan speed during initial start-up and operation is the “LOW” speed. As

airflow eventually decreases due to filter loading, fan speed may be increased by

moving the rocker switch to the top or “MEDIUM” position, and finally to the “HIGH”

position. Periodic airflow velocity readings(Per I.E.S. Specifications) should be

conducted to determine the filter condition and appropriate fan speed setting.

Figure 8

Optional Speed Control

Units furnished with the optional speed control (the speed control is standard with 2x2

and 2x3 units) enable adjustment of airflow at any setting within the recommended

performance range. The speed control knob is located on the side of the electrical box,

adjacent to the on/off switch.

Figure 9

Airflow/speed is adjusted by rotating the knob (see Figure 9):

Clockwise àLowers the speed

Counter-Clockwise àIncreases the speed

Fully rotating the speed control knob to the left or counter-clockwise will turn the unit

off.

ON/OFF SwitchElectrical EntranceSpeed Control

ON/OFF SwitchElectrical Entrance3-Speed

Switch

MAC 10 Original VE5 SERVICE MANUAL

PAGE 12

Note : When turning the unit “ON” from the “OFF” position of the speed control, the fan

is at the highest speed. Turning the speed control knob clockwise will lower the airflow.

VII. Trouble Shooting:

Low Air Velocity

Step 1. Check prefilter media; replace or clean as necessary.

Step 2. Flip switch from “Low” to “Medium” or “Medium” to “High” on units with 3-speed

switch.

Step 3. Adjust variable speed control (only units with optional Speed Control) for

higher blower output.

Step 4. Check power supply for proper voltage, amperage and distribution frequency.

Step 5. Replace HEPA/ULPA filter if the air velocity remains low.

High Air Velocity

Step 1. Flip switch from “HIGH” to “MEDUIM” to “LOW” on units with 3-speed switch.

Step 2. Adjust variable speed control (only units with optional Speed Control) for lower

blower output.

Non-Laminar Flow and/or Excessive Contamination

Step 1. Insure that no large obstructions are upstream of airflow pattern.

Step 2. Determine that no other air-moving devices are operating in or around clean

room which disrupt room’s airflow pattern.

Step 3. Check air velocity and if low, conduct the “Low Air Velocity” procedure outlined

above.

Step 4. Conduct smoke and photometer test on HEPA filter. Seal or replace HEPA

filter as necessary.

MAC 10 Original VE5 SERVICE MANUAL

PAGE 13

VIII. MAC 10 VE5 Wiring Diagrams

Figure 10

Figure 11

Standard Wiring for MAC 10

ON/OFF switch

Speed Control 10µCapacitor

Optional Wiring for MAC 10

With Speed Control

MAC 10 Original VE5 SERVICE MANUAL

PAGE 14

IX. MAC 10 VE5 Replacement Parts List:

Description Quantity ENVIRCO Part Number

per unit 115V 220V

277V

________________________________60 Hz___50 -60 Hz______60 Hz_______

Prefilter 162981-001 62981-001 62981-001

Motor 163764-001 63764-002 63764-003

Capacitor 161485 61485 61485

ON/OFF Switch 163739 63739 63739

Speed Control (Optional) 163011 63015 63016

(CE Marked) 63742

Pressure Switch (Optional) 63415 63415 63415

Transformer (Optional) 63667 63666 63665

Current Sensor (Optional) 24235-001 24235-001 24235-001

Power cord (Optional) 63042-001 63042-004 63042-013

Standard Filter: HEPA ULPA (Optional)

2’ x 2’ 169514-004 69514-018

2’ x 3’ 169514-019 69514-012

2’ x 3.5’ 169514-020 69514-021

2’ x 4’ 169514-006 69514-007

HEPA Filter (RSR):

2’ x 2’ 169391-005 69391-006

2’ x 3’ 169391-012 69391-013

2’ x 3.5’ 169391-010 69391-011

2’ x 4’ 169391-001 69391-002

Optional Accessories:

Fluorescent lighting

Ionizing bar

Solid state speed control on 2x4, and 2x31/2units -(standard on all other sizes)

12”(30.48 cm) diameter A/C intake collar

Gel Seal Filter (RSR unit only)

ULPA Filter (Standard and RSR)

Replacement parts are available through your authorized ENVIRCO representative. If

you cannot locate a representative in your area, contact our Parts Department at:

ENVIRCO CORPORATION

5601 Balloon Fiesta Parkway NE

Albuquerque, NM 87113, U.S.A.

Tel: (505) 798-4412

Tel: (800) 545-6598

Fax: (505) 345-8875

MAC 10 Original VE5 SERVICE MANUAL

PAGE 15

VII. LIMITED WARRANTY

ENVIRCO CORPORATION (“ENVIRCO”) warrants the equipment will be free of defects

in materials and workmanship under normal use for a period of three (3) years. The

HEPA filter shall only be warranted against loading for a period of two (2) years when

operated in cleanroom conditions. ENVIRCO’s sole obligation under this warranty is to

repair or replace any parts of the equipment which are defective for a period of three

(3) years from the invoice date, provided that the repair or replacement is actually

performed within the three(3) year period from the invoice date. The buyer agrees to

assume any incidental expenses including but not limited to the cost of transporting the

defective equipment to ENVIRCO’s repair facility. The buyer’s sole remedy under this

limited warranty is the repair or replacement of any defective part of the equipment.

ENVIRCO DISCLAIMS ANY IMPLIED WARRANTIES INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. In no event

shall ENVIRCO be liable for punitive, incidental, or consequential damages arising out

of this sale, including, but not limited to damage to persons or property, loss of use,

loss of time, inconvenience, equipment rental, loss of earnings or profit or any other

commercial loss. This warranty excludes certain expendable items such as light tubes,

prefilters, etc. ENVIRCO expressly disclaims and excludes from this warranty any

responsibility for equipment failures and/or defects attributable to improper

maintenance, abuse, accident or modification of the equipment (such as application of

an adjustable frequency drive).

X. TESTING

Each MAC 10 VE5 filter unit is thoroughly tested at the factory before shipment.

However, because of the “rigors” of shipping, ENVIRCO encourages its re-test after

installation.

ENVIRCO recommends that the customer contact an independent organization, with

technicians trained and experienced in performance evaluation and maintenance of

clean air equipment.

Some of the testing procedures performed on the MAC 10 VE5 include PS challenge of

HEPA filters to assure specified performance, along with air velocity measurement and

adjustment tests.

Recommended Testing

All units that are airflow tested at Envirco are tested using a Shortridge Airdata

Multimeter 800 series with a Velgrid head. The recommended method of

reading is to place one corner of the Velgrid head 1-1/4” from the corner of the

filter face and then take four reading evenly spaced along the four foot side, then

repeat these reads for the other long side. This gives a total of eight reading to

test the unit. All advertised data is based on using the Velgrid with 8 readings

(128 velocity points). Envirco recognized the using 8 reading during a

MAC 10 Original VE5 SERVICE MANUAL

PAGE 16

cleanroom start-up may be time consuming and recommends using 3 Velgrid

readings taken on a diagonal, as shown below.

Recommended Testing –8 readings with a Velgrid

Factory Approved Testing –3 readings with a Velgrid

This manual suits for next models

2

Table of contents

Other Envirco Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Trox Technik

Trox Technik MFI-Ex Installation and maintenance manual

Eljen

Eljen Mantis M5 Series Installation and System Design Guide

Neptun

Neptun Classic NCTF-O 8000 operating instructions

CALEFFI

CALEFFI DISCAL 5517 Series Installation, commissioning and servicing instructions

Vortec

Vortec THREAD GUARD 424 Operation & Safety Instructions

Hydac

Hydac FluidAqua Mobil FAM 15 Maintenance instructions