maintenance

The Thread Guard has no moving parts and can be

disassembled for cleaning.

1. Remove the black cold air outlet tting with a spanner

wrench.

2. Remove the small O-ring, plastic bushing, brass

generator and thin plastic “washer”.

3. Clean all parts especially the six small orices in the

brass generator.

4. Reassemble in the reverse order (thin plastic washer

rst, then the generator, bushing and O-Ring).

5. Tighten the cold air outlet tting to 50 in-lbs or more.

6. If the orices in the generator require frequent cleaning,

this indicates that the compressed air is not being

ltered or the lter element requires changing.

7. Change the lter element as needed.The lter/regulator

supplied with some Thread Guard models utilizes a 5

micron element.

8. Be sure to shut off the compressed air supply to the

lter before attempting to change the element or before

any maintenance.

1. Do not operate a Thread Guard at compressed air

pressures above 150 psig (10.3 Bar).

2. Do not operate a Thread Guard at compressed air

temperatures above 110oF (43oC).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses

with side shields.

NOTE: There is no need to limit compressed air pressure

to a maximum of 30 psig (2 bar). It is not possible to

block the ow of air from the Thread Guard to register 30

psig (2 bar) on a test gauge.

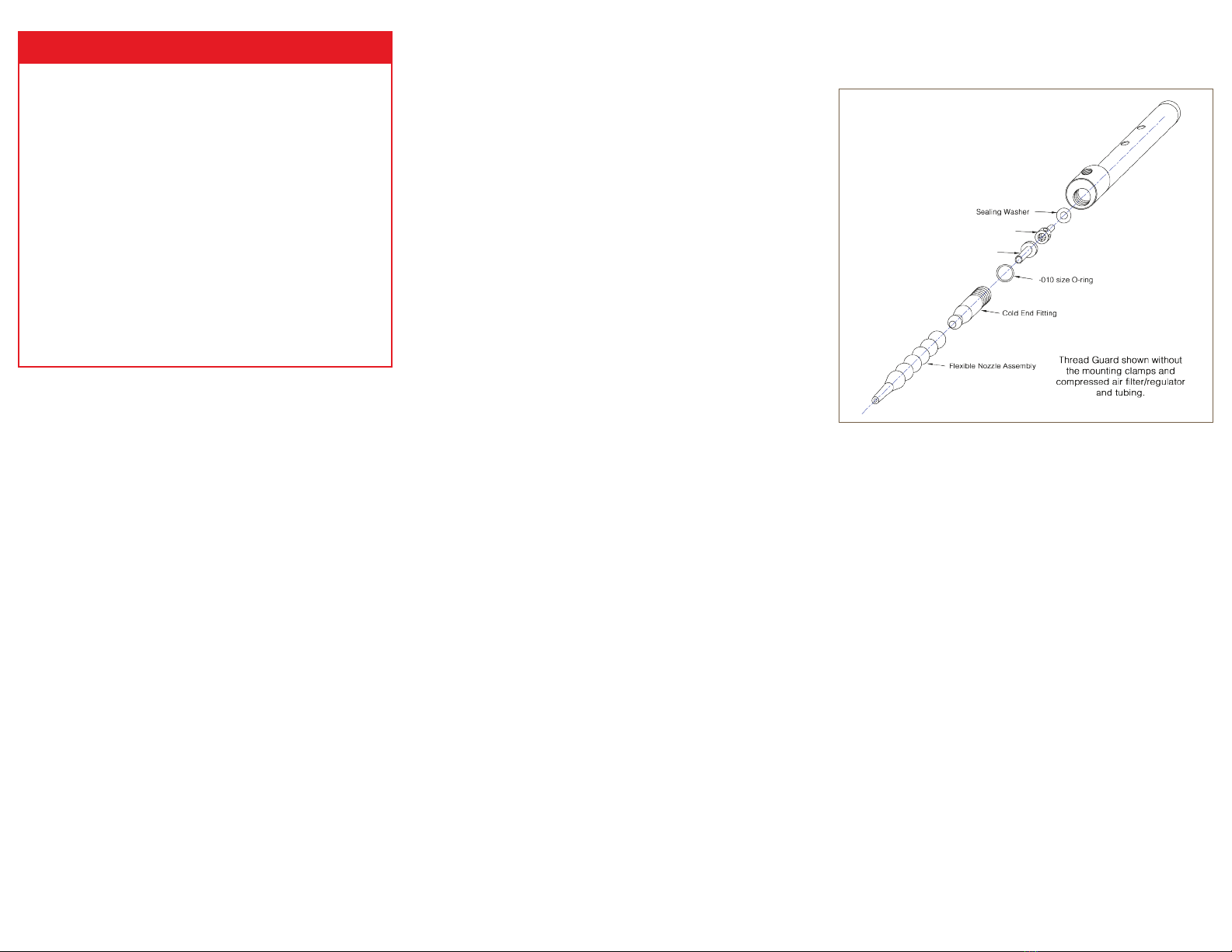

tHreaD GuarD®aSSembLy

LimiteD warranty

Vortec compressed air products manufactured by ITW Air

Management will be replaced or repaired if found to be

defective due to manufacture defect within ten years from

the date of invoice.

Refer to our website www.pelmareng.com for full

warranty details and limitations. ITW Air Management

makes no specific warranty merchantability or warrant of

fitness to a particular purpose.

Insufficient airow may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure too low.

3. Partial or complete blockage of internal compressed air

path, due to dirt. See Maintenance section for cleaning

instructions; and Compressed Air Supply section for

lter recommendations.

4. Loose cold cap. This may occur if not tightened properly

after disassembled for cleaning.

If trouble persists, please contact Vortec at

888-754-6329

trOubLeSHOOtinG

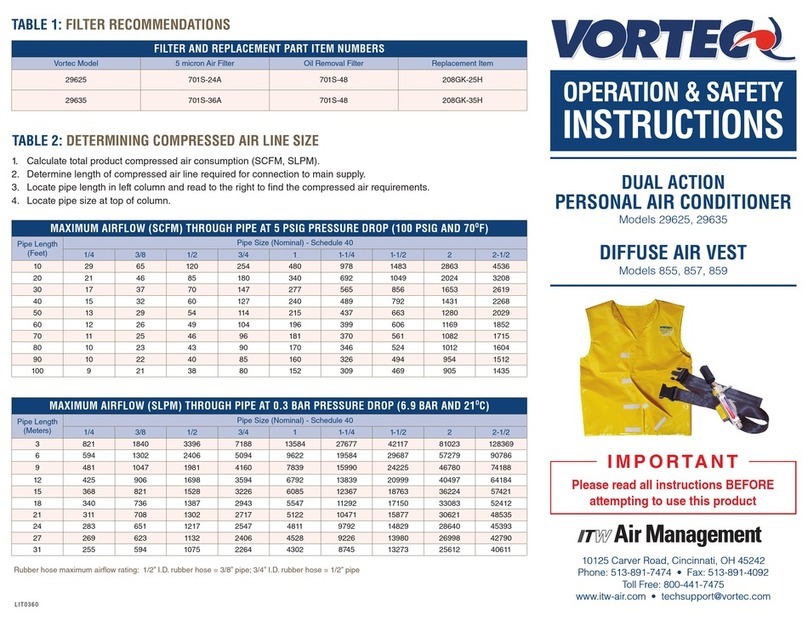

The compressed air supply must be ltered to remove

water and dirt using a 5 micron or smaller lter. A

combination lter/regulator is included with some Thread

Guard models to accomplish this. If oil is present in the

compressed air supply, remove the oil using a 0.01 micron

(maximum) coalescing air lter. Failure to use a lter may

cause clogging (and freezing) of the compressed air paths

inside the Vortec product. Filter recommendations are

given in Table 1.

Filter elements must be changed on a regular basis.

Frequency of change is determined by the condition of

the compressed air supply. Filters should be installed in

the compressed air supply line as close as possible to the

Vortec product.

The appropriate size of compressed air supply line should

be selected to ensure optimal performance of the Vortec

product. Please refer to Table 2 to determine what supply

line size is recommended for your application.

Contact Vortec at 1-800-441-7475 for further assistance.

cOmpreSSeD air SuppLy

inStaLLatiOn anD OperatiOn

1. Use two supplied mounting clamps to attach the Thread

Guard to an appropriate location on your machine.

Do not block either of the hot exhaust holes with the

mounting clamps.

2. Mount the lter/regulator (if supplied) to a xed 1/8”pipe

so that the lter bowl points downward.

3. Cold airow and temperature can be changed by

adjusting the pressure regulator (if included or supplied

separately) in the compressed air supply.

4. Set the pressure regulator to the lowest pressure that

permits adequate cooling of the needle.

intrODuctiOn

The Thread Guard is designed to use ltered compressed

air to cool needles on commercial sewing machines without

the use of any refrigerants. The Thread Guard consumes

8 SCFM of compressed air at 100 psig and approximately

5 SCFM if operated at 60 psig.

Model 424

(Drawings shown below are not to scale)

8H Bushing (see Table 1)

8 cfm Generator (see Table 1)

GeneraL Safety cOnSiDeratiOnS

warninG: cOmpreSSeD air cOuLD cauSe

DeatH, bLinDneSS Or injury