Eljen Mantis M5 Series Guide

DRAFT

System Design & Installation Manual

www.eljen.com

CORPORATION

Innovative Environmental Products & Solutions Since 1970

TM

Vermont

November 2015

2015 Vermont Mantis M5Design & Installation Manual Page 2 www.eljen.com

Table of Contents

Topic

Page

Numbers

Glossary of Terms

3

Mantis M5Series General Description

4

1.0 General System Information

7

2.0 Systems for Level Sites

10

3.0 Systems for Sloped Sites

10

4.0 Trench Installation Guidance

11

5.0 Bed Systems Installation Guidance

13

6.0 Mound System Installation Guidance

15

7.0 Pumped System Guidance

18

8.0 System Ventilation Guidance

19

9.0 Recommended Notes on Design Plans

21

Tables

Table 1 Specified Sand Sieve Requirements

3

Table 2 Mantis M5 Trench Sizing Table

5

Table 3 Mantis M5 Bed Sizing Table

6

Mantis M5Drawings

Fig. 1 Mantis M5Components

4

Fig. 2 Mantis M5Series Cross Section

9

Fig. 3 Mantis M5Series Plan View

10

Fig. 4 Mantis M5Multiple Trench Cross Section

12

Fig. 5 Mantis M5Multiple Trench Plan View

12

Fig. 6 Mantis M5In-Ground Bed System Cross Section

14

Fig. 7 Mantis M5Bed System Plan View

14

Fig. 8 Mantis M5Raised or Fill Bed System Cross Section

17

Fig. 9 Mantis M5Sloped Bed System Cross Section

17

Fig. 10 Mantis M5Series Pressure Distribution –Orifice Layout

18

Fig. 11 Mantis Series Venting Diagram

19

Fig. 12 Mantis Series 2” By-Pass Line

19

Fig. 13 Mantis Series 2” By-Pass Line, Close Up

20

2015 Vermont Mantis M5Design & Installation Manual Page 3 www.eljen.com

Glossary of Terms

Mantis M5Series Units The Mantis M5Series units come preassembled and are 5 feet in length (as measured

from the Support Distribution Pipe) and 12” high. 12” and 24” wide models are available.

The 12” wide model is designated the Mantis M5.1, and the 24” wide model is the Mantis

M5.2. All models have 6” of specified sand under and to the sides of the product. 1” of

specified sand is placed over the units prior to backfill.

Support Distribution Pipe The Mantis M5Series Support Distribution Pipe is 5 feet in length and constructed from

crush resistant PVC Pipe. The pipes provide 3 pre-drilled one inch holes at specified

spacing located at the 12, 5 and 7 o’clock position.

Filter Support Module There are 5 Filter Support Modules for each M5unit. All Filter Support Modules are 4”

thick. The 5.1 model is 12” wide and the 5.2 model is 24” wide.

Specified Sand The Specified Sand envelope around the Mantis M5Series (6” minimum underneath, 6”

minimum on the sides, 1” minimum on the top, and 8” in-between the Support Modules)

shall meet the requirements as indicated in the Specified Sand Requirements chart listed

in Table 1 listed below. This sand is a WASHED CONCRETE SAND OR VERMONT 1-

913(C)2 SAND FROM THE REGULATIONS, WITH LESS THAN 10% PASSING #100

SIEVE AND LESS THAN 5% PASSING A #200 SIEVE.

Note: Specified Sand under the Mantis M5units must be stabilized so differential settling

does not occur over time. This can be accomplished by using a mechanical or hand

methods. Specified Sand between the modules must be stabilized using a tamping rod.

Please contact Eljen Corporations Technical Services Department if more information is

needed.

Ask your material supplier for a sieve analysis to verify that your material meets the

required specifications.

Table 1: SPECIFIED SAND SIEVE REQUIREMENTS

Eljen Mantis M5Series

Specified Sand Requirements

Sieve Size

Sieve Square

Opening Size

Specification

Percent Passing

(Wet Sieve)

0.375”

9.5 mm

100.0

#4

4.75 mm

95.0 –100.0

#8

2.36 mm

80.0 –100.0

#16

1.18 mm

50.0 –85.0

#30

600 µm

25.0 –60.0

#50

300 µm

5.0 –30.0

#100

150 µm

< 10.0

#200

75 µm

< 5.0

Request a sieve analysis from your material supplier to ensure that

the system sand meets the specification requirements listed above.

Design Flow The estimated design flow used to size a system is 70 gallons per day per person. For

the first 3 bedrooms of a home, it is assumed that there are 2 people per bedroom. For

each additional bedroom, there is 1 person per bedroom. Minimum design is a 2 bedroom

home or 280 gpd for residential systems.

2015 Vermont Mantis M5Design & Installation Manual Page 4 www.eljen.com

Mantis M5General Description

Note: To receive design standards for specially engineered dosing systems or commercial systems, contact Eljen’s Technical Resource Department at

1-800-444-1359. Mantis M5 series systems must be designed and constructed according to this Design & Installation Manual and the State of Vermont

Environmental Protection Rules, Chapter 1, effective September 29, 2007 (hereinafter the Regulations).

________________________________________________________________________________________________________________________

How the Mantis M5Series System Works

The Eljen Mantis M5Series is a wastewater disposal technology comprised of a proprietary filtering process that applies

clarified effluent to the soil. The Mantis M5Series performance is based on accepted industry principals of increasing the

receiving soils long term acceptance rate by keeping the biological growth off the native soils and within the system. This

technology utilizes 3 dimensional surface areas to improve effluent quality, resulting in greater reliability and ease of

operation.

•The Support Distribution Pipe provides internal distribution, a venting conduit for the system and secures the five

Filter Support Modules in place. This distribution pipe is centered within the Filter Support Module to distribute

septic effluent.

•Septic effluent is filtered through the Filter Support Modules. Each module consists of a cuspated core

surrounded by Bio-Matt geo-textile fabric. Its unique design provides increased surface area within each module.

This area is known as the Internal Surface Optimization envelope, ISO for short. The ISO envelope provides an

increased surface area that greatly exceeds the Filter Support Module’s footprint, a traditional gravel footprint or

that of a gravelless replacement technology.

•Open air channels within the modules support aerobic bacterial growth on the Filter Support Modules geotextile

fabric interface, surpassing the surface area provided by traditional absorption systems.

•Effluent is transferred into the Specified Sand layer which supports unsaturated flow into the native soil. This

Specified Sand and soil interface maintains soil structure while maximizing the available absorption of the native

soil.

•The Specified Sand layer also protects the soil from compaction and helps maintain existing pore spaces in the

soil. This preserves the soil’s natural infiltration capacity which is critical for long-term performance, especially in

finer textured soils.

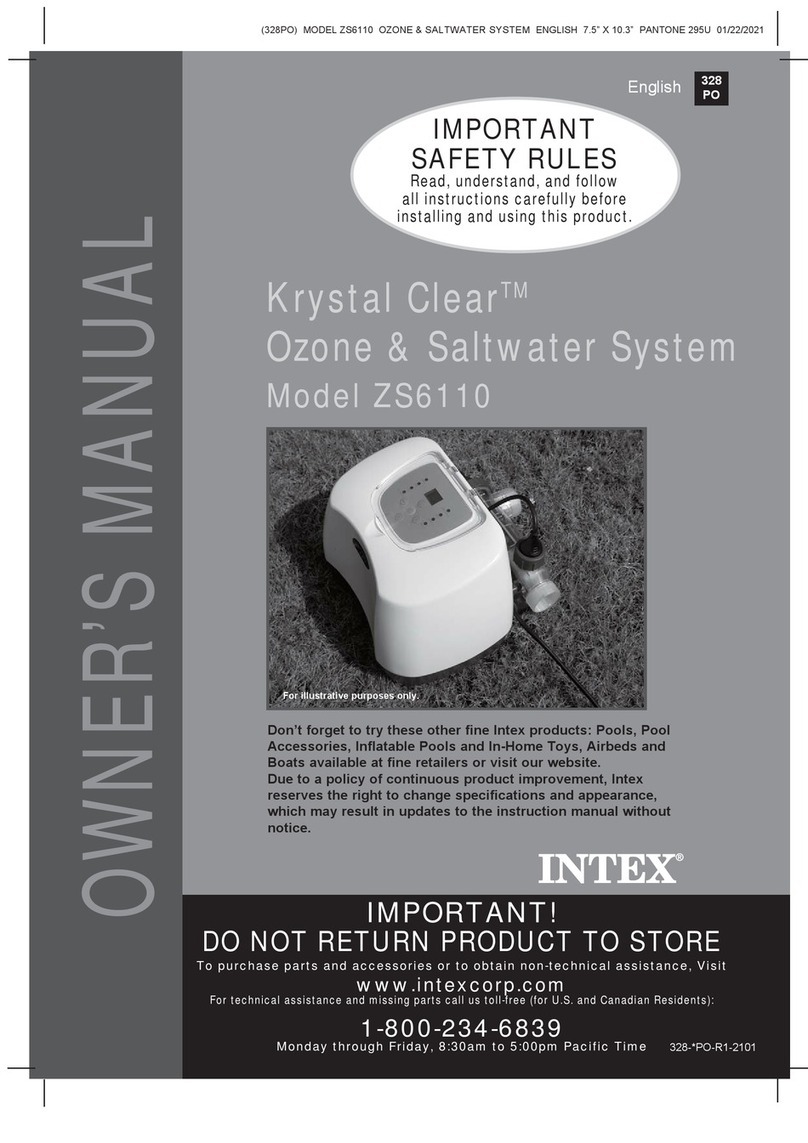

FIGURE 1: MANTIS M5COMPONENTS

2015 Vermont Mantis M5Design & Installation Manual Page 5 www.eljen.com

Mantis M5Series Sizing

TABLE 2: Mantis M5Trench Sizing Table

Notes:

1.Minimum absorption area has been adjusted to reflect the maximum reduction of 50%.

2.Number of Mantis M5Series units is determined on the current application rates defined in the regulations.

3.For number of Mantis M55.2 units, divide by 15 ft² per unit and round up to the nearest whole number of units.

4.For number of Mantis M55.1 units, divide by 10 ft² per unit and round up to the nearest whole number of units.

5.The minimum number of bedrooms for residential designs shall be 2 bedrooms unless otherwise dictated by the

regulations.

Percolation

Rate

2 Bedroom

Minimum

Absorption Area

3 Bedroom

Minimum

Absorption Area

Additional Absorption

Area per Additional

Bedrooms over 3

Commercial Absorption

Area based on 100 gallons

of design flow per day

1 - 4 94 140 24 34

5 - 8 132 198 33 48

9 - 12 162 243 41 58

13 - 16 187 280 47 67

17 - 20 209 314 53 75

21 - 24 229 343 58 82

25 - 28 247 371 62 89

29 - 32 264 396 66 95

33 - 36 280 420 70 100

37 - 40 296 443 74 106

41 - 44 310 465 78 111

45 - 48 324 485 81 116

49 - 52 337 505 85 121

53 - 56 350 524 88 125

57 - 60 362 543 91 130

61 - 64 374 560 94 134

65 - 68 385 578 97 138

69 - 72 396 594 99 142

73 - 76 407 611 102 146

77 - 80 418 627 105 150

81 - 84 428 642 107 153

85 - 88 438 657 110 157

89 - 92 448 672 112 160

93 - 96 458 686 115 164

97 - 100 467 700 117 167

101 - 104 476 714 119 170

105 - 108 485 728 122 174

109 - 112 494 741 124 177

113 - 116 503 754 126 180

117 - 120 512 767 128 183

2015 Vermont Mantis M5Design & Installation Manual Page 6 www.eljen.com

Mantis M5Series Sizing

TABLE 3: Mantis M5Bed Sizing Table

Notes:

1.Minimum absorption area has been adjusted to reflect the maximum reduction of 50%.

2.Number of Mantis M5Series units is determined on the current application rates defined in the regulations

3.For number of Mantis M55.2 units, divide by 15 ft² per unit and round up to the nearest whole number of units.

4.For number of Mantis M55.1 units, divide by 10 ft² per unit and round up to the nearest whole number of units.

5.The minimum number of bedrooms for residential designs shall be 2 bedrooms unless otherwise dictated by the

regulations.

Percolation

Rate

2 Bedroom

Minimum

Absorption Area

3 Bedroom

Minimum

Absorption Area

Additional Absorption

Area per Additional

Bedrooms over 3

Commercial Absorption

Area based on 100 gallons

of design flow per day

1 - 4 117 175 30 42

5 - 8 165 248 42 59

9 - 12 203 304 51 73

13 - 16 234 350 59 84

17 - 20 261 392 66 94

21 - 24 286 429 72 103

25 - 28 309 464 78 111

29 - 32 330 495 83 118

33 - 36 350 525 88 125

37 - 40 369 554 93 132

41 - 44 387 581 97 139

45 - 48 405 607 102 145

49 - 52 421 631 106 151

53 - 56 437 655 110 156

57 - 60 452 678 113 162

61 - 64 467 700 117 167

65 - 68 482 722 121 172

69 - 72 495 743 124 177

73 - 76 509 763 128 182

77 - 80 522 783 131 187

81 - 84 535 802 134 191

85 - 88 548 821 137 196

89 - 92 560 840 140 200

93 - 96 572 858 143 205

97 - 100 584 875 146 209

101 - 104 595 893 149 213

105 - 108 607 910 152 217

109 - 112 618 927 155 221

113 - 116 629 943 158 225

117 - 120 640 959 160 229

2015 Vermont Mantis M5Design & Installation Manual Page 7 www.eljen.com

1.0 General System Information

1.1 TREATMENT FIELD SIZE AND NUMBER OF UNITS: System size will vary depending on design flow and soil analysis.

Tables 2 - 3 indicate the minimum number of Mantis units required for various soil percolation rates and design flows.

Groundwater mounding and linear loading rate analyses are required when designing a wastewater system in Vermont.

Please refer to the Vermont Wastewater System & Potable Water Supply Rules for more information.

1.2 NON-RESIDENTIAL BUILDINGS & RESIDENTIAL INSTITUTIONS: Commercial systems require different sizing and

design criteria as compared to residential systems. Please contact Eljen’s Technical Resource Department at 1-800-444-

1359 for more information on commercial systems.

1.3 DEPTH TO GROUND WATER OR RESTRICTIVE LAYER: As required by state regulations; a minimum of 3 feet of

separation distance from the bottom of the Mantis M5 unit to the seasonal high water table and 4 feet separation from the

bottom of the Mantis M5unit to bedrock. This distance is measured from the bottom of the Mantis M5unit and not from the

bottom of the sand layer.

1.4 SPECIFIED SAND SPECIFICATION FOR TRENCH AND BED SYSTEMS: The first 6 inches of Specified Sand

immediately under, between Filter Support Modules, between unit rows and around the perimeter of the Mantis M5Series

system must be a WASHED CONCRETE SAND (meeting the requirements of Table 1 of this Manual) OR VERMONT

1-913(C)2, WITH LESS THAN 10% PASSING A #100 SIEVE AND LESS THAN 5% PASSING A #200 SIEVE.

Note: Specified Sand under the Mantis M5units must be stabilized so differential settling does not occur over time. This can

be accomplished by using a mechanical or hand methods. Specified Sand between the modules must be stabilized using

a tamping rod. Please contact Eljen Corporations Technical Services Department if more information is needed.

1.5 VEHICULAR TRAFFIC AND PAVED AREAS OVER SYSTEM: All vehicular traffic is prohibited over the Mantis system.

This is due to the compaction of material required to support traffic loading. Compaction greatly diminishes absorption

below the system and reduces the void space that naturally exists in soils for oxygen transfer and water migration. For

shallow installations, light-weight track-mounted machines are best for setting the final grade. It is also permissible to back-

blade the soil to set final minimum cover.

1.6 INGROUND TRENCHES & BEDS: Distribution methods permitted for use with these Mantis M5systems are:

Gravity

Pump to d-box with timed dosing

Pipe-in-Pipe Pressure Distribution

1.7 SHALLOW PLACEMENT, ELEVATED, OR MOUND SYSTEMS: Distribution methods permitted for use with these

Mantis M5systems are:

Pump to d-box with timed dosing

Pipe-in-Pipe Pressure Distribution

Pump to d-box distribution: The d-box shall be placed to center feed the laterals so that no lateral would exceed 50’ (100’

total).

A maximum of 500 lf total is permitted for pump to d-box distribution. Pipe-in-pipe pressure distribution has no maximum

length.

Shallow placement, elevated or mound systems with a design flow of greater than 1000 gpd must utilize pipe-in-pipe

pressure distribution.

2015 Vermont Mantis M5Design & Installation Manual Page 8 www.eljen.com

1.0 General System Information

1.8 SYSTEM AREA SLOPE: The maximum ground slope shall not exceed 30% for wastewater systems on subdivided lots

in existence before June 14, 2002. The maximum ground slope shall not exceed 20% for wastewater systems on lots that

are subdivided on or after June 14, 2002. The limitation on maximum slope shall not apply to replacement systems that are

subject to the variance provisions of Section 1-806 of these Rules.

1.9 SYSTEM VENTING: Eljen mandates venting when the system has greater than 18” of cover material as measured

from the top of the unit to finished grade. This will ensure proper aeration of the units.

1.10 BACKFILL & FINISH GRADING: Complete backfill with a minimum of five inches of clean porous fill measured from

the top of one inch specified sand over the module. Backfill exceeding 18 inches measured from the top of the module

requires venting at the far end of the trench or bed. Use well graded sandy fill that is clean, porous and devoid of large

rocks. Do not use wheeled equipment over the system. A light track machine may be used. Divert surface runoff from the

soil treatment area. Finish grade to prevent surface ponding. Seed and loam system area to protect from erosion.

1.11 EFFLUENT FILTERS: Effluent filters are recommended as a means of preventing solids from leaving the tank.

1.12 DISTRIBUTION PIPE LAYOUT: No additional distribution pipe is needed to connect units to one another. The support

distribution pipe runs through the center of the units and provides distribution for all configurations. For bed systems, the

distal ends of rows may be connected with non-perforated pipe.

1.13 GARBAGE DISPOSALS: The use of a garbage disposal is not recommended as they can cause septic system

problems by generating an increased amount of suspended solids, grease and nutrients. Design drawings shall include a

note “Garbage disposals shall not be used with this system”.

State regulations require that the system is upsized by 25%

NOTE: Eljen recommends the use of septic tank outlet effluent filters on all systems, especially on those systems that a

garbage disposal is installed, even if the tanks design capacity has been increased. Filters with higher filtration are

recommended for systems with garbage disposals.

1.14 ADDITIONAL FACTORS EFFECTING RESIDENTIAL SYSTEM SIZE: Homes with expected higher than normal

water usage should consider increasing the septic tank volume as well as increasing the size and number of units in the

disposal area. For example: Homes with tubs holding more than 100 gallons or utilizing other high use fixtures and

homes with higher than normal occupancy should consider septic tank and drain field modifications.

1.15 WATER SOFTENERS OR CONDITIONERS: Discharge of water softener or conditioner backwash to Eljen Products

is not allowed. Discharge from these devices shall be into a separate disposal system meeting the requirements of State

and Local Regulations.

1.16 PLANS AND SPECIFICATIONS: Typical treatment system drawings and specifications are shown at the end of this

manual. When used in conjunction with a permit sketch, site specific specifications, and manufacturer installation criteria,

these documents will normally be sufficient to assure a system can be properly installed. In some instances where a

complex system is encountered, formal plans and specifications may be required. This determination is left to the

discretion of the District Health Department.

2015 Vermont Mantis M5Design & Installation Manual Page 9 www.eljen.com

1.0 General System Information

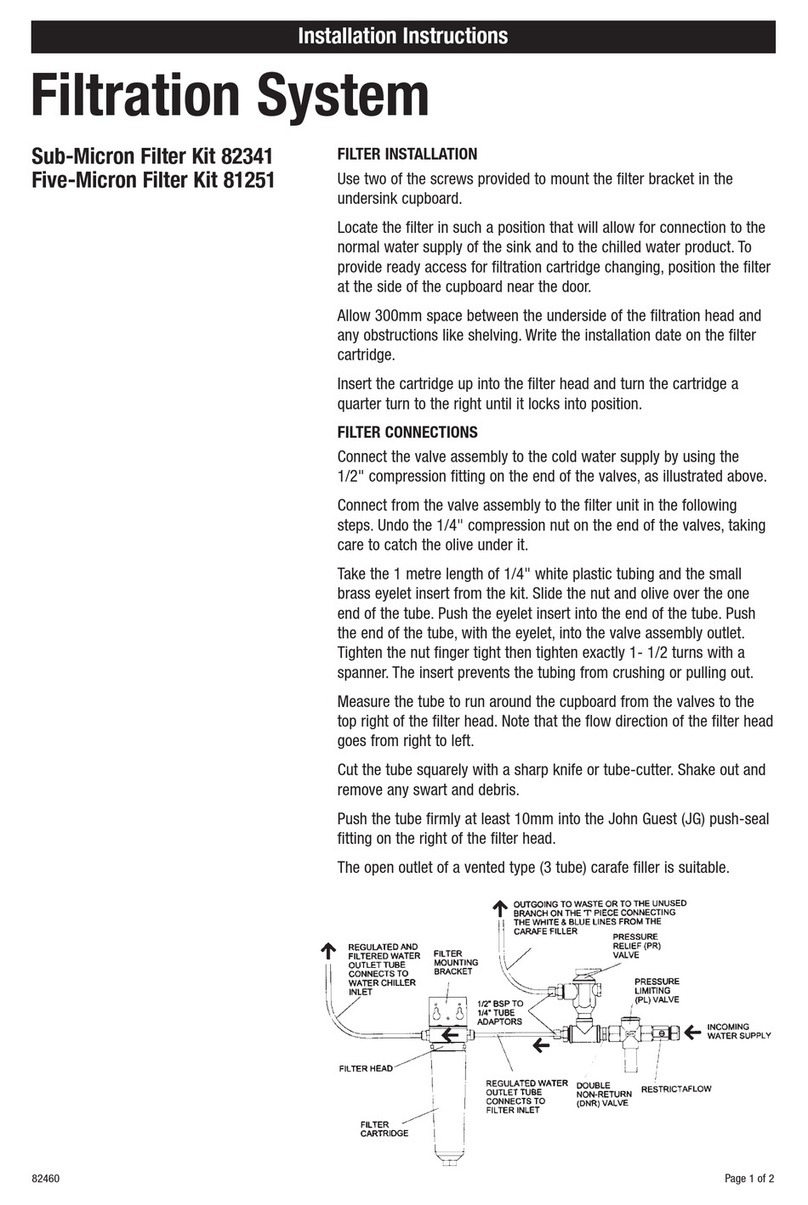

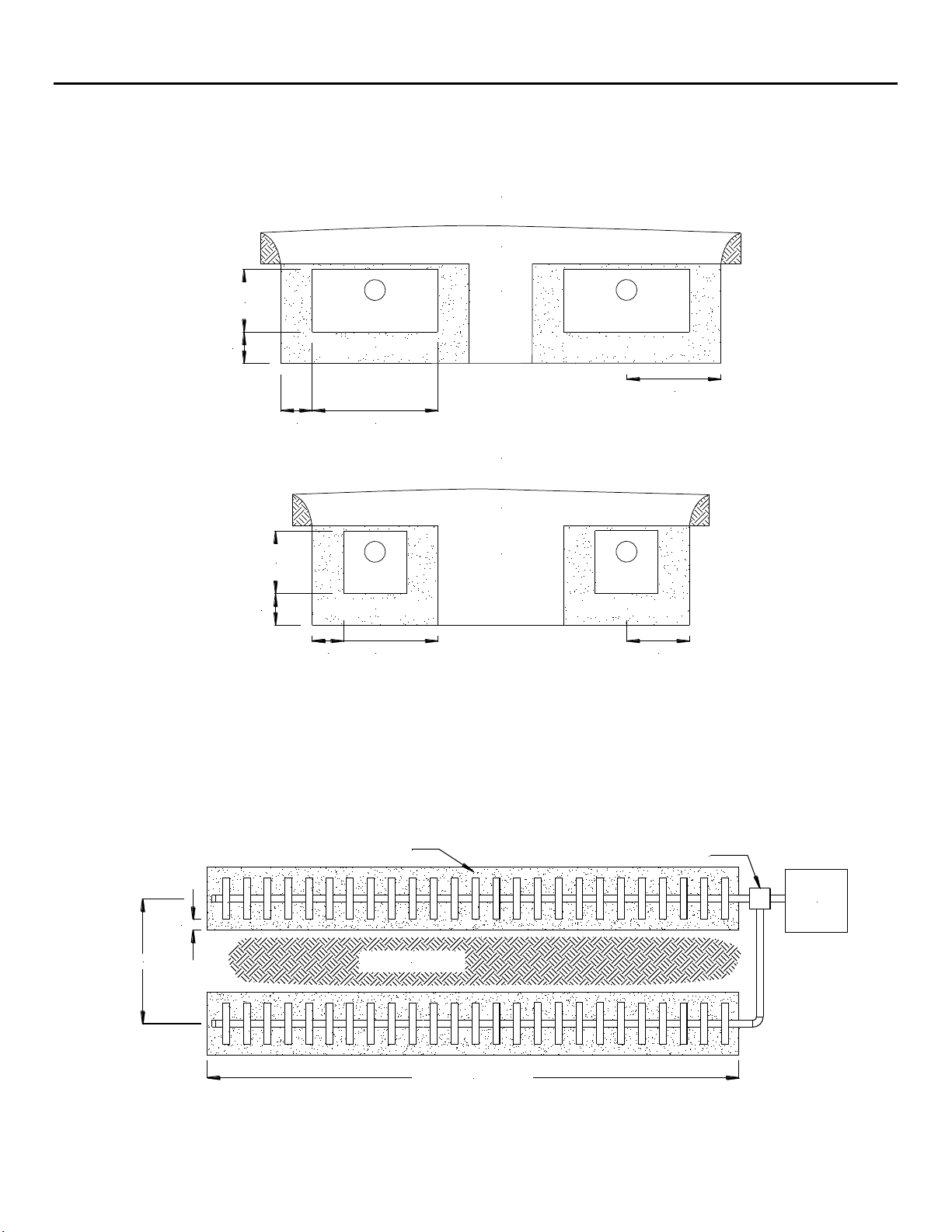

FIGURE 2: MANTIS M5CROSS SECTION

36"

SPECIFIED SAND

TOPSOIL

CLEAN BACKFILL

VEGETATIVE COVER

ø 4" WITH

HOLESAT 12,

5 & 7 O'CLOCK

6" MIN

24"

6"

1"

8" MIN

6"

MANTIS 5.2

24"

SPECIFIED SAND

TOPSOIL

CLEAN BACKFILL

VEGETATIVE COVER

ø 4" WITH

HOLESAT 12,

5 & 7 O'CLOCK

6" MIN

12"

6"

1"

8" MIN

18"

MANTIS 5.1

12"

18"

12"

6"

FIGURE 3: MANTIS M5PLAN VIEW

60"

8" 4"

24"

60"

8" 4"

12"

MANTIS 5.2 MANTIS 5.1

2015 Vermont Mantis M5Design & Installation Manual Page 10 www.eljen.com

2.0 Design for Level Sites

2.1 BED/MOUND SYSTEMS ROW SPACING: Design level in-ground or raised systems with a minimum of 12-inches of

spacing between unit rows. The Mantis M5units and Specified Sand must be installed level at their design elevations.

2.2 TRENCH ROW SPACING: The minimum separation shall be 4’ of naturally occurring, undisturbed soil between

adjacent absorption trenches. The Mantis M5units and Specified Sand must be installed level at their design elevations.

3.0 Design for Sloped Sites

3.1 BED/MOUND SYSTEM ROW SPACING: Design level in-ground or raised systems with a minimum of 12-inches of

spacing between units. The Mantis M5units and Specified Sand must be installed level at their design elevations.

3.2 TRENCH ROW SPACING: The minimum separation shall be 4’ of naturally occurring, undisturbed soil between

adjacent absorption trenches. The Mantis M5units and Specified Sand must be installed level at their design elevations.

2015 Vermont Mantis M5Design & Installation Manual Page 11 www.eljen.com

4.0 Trench Installation Guidance

1. Carefully lay out all boundaries defining the location and elevation for all system components.

2. Prepare the site according to state and local regulations. Do not install a system on frozen or saturated soils. Take

precautions not to compact or smear the area with heavy machinery.

3. Plan all drainage requirements above (up-slope) the system and set soil grades to insure storm water drainage and

surface water is diverted away from the absorption area once the system is complete.

4. Excavate a minimum thirty-six inch (36”) wide level trench for the Mantis 5.2 unit or a minimum twenty-four inch (24”)

wide level trench for the Mantis 5.1 unit. Remove all organic soil, roots, and rocks within the absorption trench area.

5. Scarify receiving layers including sidewalls to eliminate soil smearing. Once scarifying is completed, avoid walking over

prepared absorption area until the Specified Sand has been placed on the bottom of the trench.

6. Place, compact, and rake a minimum 6” level layer of Specified Sand along the trench bottom. Specified Sand must

meet the minimum requirements listed on Table 1 of this manual. Ask your material supplier for a sieve analysis report

to verify that the sand you are going to install meets this specification. A hand tamper or a vibratory plate compactor is

sufficient for stabilization of the Specified Sand layer.

7. Center the Mantis units in the trench with the fabric side up, adjust the Filter Support Modules to ensure they are spaced

evenly and have not shifted during placement.

8. Connect the units by inserting the Support Distribution Pipe to one another. Direction changes are accomplished by

using a variety off the shelf fittings.

9. Install a termination cap or vent piping if required at the distal (far) end of the distribution pipe.

10. Begin placing Specified Sand between the Filter Support Modules and to the sides of the units.Specified Sand must

be placed lightly and may be accomplished with a backhoe or other suitable equipment. DO NOT dump full loads of

Specified Sand directly on the units.

11. Steps for placement of Specified Sand.

a. Starting at the top center of the units, use a minimal amount of Specified Sand necessary to set in place

the bottom section of the Filter Support Modules at their correct spacing.

b. Stabilize the sand that is in-between the Filter Support Modules with a tamping tool. Ensure that the void

area under the Support Distribution Pipe is filled and compacted with Specified Sand.

c. Additional Specified Sand is lightly added between the Filter Support Modules and along the sides of the

Mantis units to bring the sand fill 1-inch above the Filter Support Modules to account for sand settling.

d. Continue to moderately tamp and compact the sand that is in-between the Filter Support Modules. Spread

additional Specified Sand as necessary.

12. Set distribution box to the proper elevation to achieve a 1/8”drop per foot to the first unit. Make the connection to the

beginning of the first unit from the distribution box with SDR-35 pipe or equivalent.

13. Complete backfill over the Mantis M5units followed by topsoil to a depth of 6” –18” as measured from the top of the

units. 1” of the fill is Specified Sand, immediately on top of the unit. Systems with total cover that exceeds 18” as

measured from the top of the units to finished grade shall be vented at the distal (far) end of the system. Backfill material

shall be well graded sandy fill; clean, porous, and devoid of large rocks. Divert surface runoff with diversion ditches or

berms. Finish grade to prevent surface ponding. Seed or sod excavated areas to protect against erosion. Do not drive

or pave over the absorption area.

2015 Vermont Mantis M5Design & Installation Manual Page 12 www.eljen.com

4.0 Trench Installation Drawings

FIGURE 4: MANTIS M5MULTIPLE TRENCH CROSS SECTION

SPECIFIED SAND

NATIVE

SOIL

6" 24"

SPECIFIED SAND

12"

6"

SPECIFIED SAND

6" MIN COVER

INCLUDES 1" OF SPECIFIED SAND

NATIVE

SOIL

6" 24"

SPECIFIED SAND

18"

PER

PRODUCT

6"

6" MIN COVER

INCLUDES 1" OF SPECIFIED SAND

MANTIS 5.1

MANTIS 5.2

PER

PRODUCT

FIGURE 5: MANTIS M5MULTIPLE TRENCH PLAN VIEW

NATIVE SOIL

SEPTIC

TANK

PER DESIGN

6"

PER DESIGN

DISTRIBUTION BOX

SPECIFIED SAND

2015 Vermont Mantis M5Design & Installation Manual Page 13 www.eljen.com

5.0 Bed Systems Installation Guidance

1. Carefully lay out all boundaries defining the location and elevation for all system components.

2. Prepare the site according to state and local regulations. Do not install a system on frozen or saturated soils. Take

precautions not to compact or smear the area with heavy machinery.

3. Plan all drainage requirements above (up-slope) the system and set soil grades to insure storm water drainage and

surface water is diverted away from the absorption area once the system is complete.

4. Excavate the bed area. Remove all organic soil, roots, and rocks within the absorption area.

5. Scarify receiving layers including sidewalls to eliminate soil smearing. Once scarifying is completed, avoid walking over

prepared absorption area until the Specified Sand has been placed on the bottom of the absorption area.

6. Place, compact, and rake a minimum 6” level layer of Specified Sand along the trench bottom. Specified Sand must

meet the minimum requirements listed on Table 1 of this manual. Ask your material supplier for a sieve analysis report

to verify that the sand you are going to install meets this specification. A hand tamper or a vibratory plate compactor is

sufficient for stabilization of the Specified Sand layer.

7. Place the Mantis units in their rows with the fabric side up, adjust the Filter Support Modules to ensure they are spaced

evenly and have not shifted during placement.

8. Connect the units by inserting the Support Distribution Pipe to one another. Direction changes are accomplished using

a variety of off the shelf fittings.

9. Install a termination cap or vent piping if required at the distal (far) end of the distribution pipe.

10. Begin placing Specified Sand between the Filter Support Modules and to the sides of the units. Specified Sand must

be placed lightly and may be accomplished with a backhoe or other suitable equipment. DO NOT dump full loads of

Specified Sand directly on the units.

11. Steps for placement of Specified Sand.

a. Starting at the top center of the units, use a minimal amount of Specified Sand necessary to set in place

the bottom section of the Filter Support Modules at their correct spacing.

b. Stabilize the sand that is in-between the Filter Support Modules with a tamping tool. Ensure that the void

area under the Support Distribution Pipe is filled and compacted with Specified Sand.

c. Additional Specified Sand is lightly added between the Filter Support Modules and along the sides of the

Mantis units to bring the sand fill 1-inch above the Filter Support Modules to account for sand settling.

d. Continue to moderately tamp and compact the sand that is in-between the Filter Support Modules. Spread

additional Specified Sand as necessary.

12. Set distribution box to the proper elevation to achieve a 1/8” drop per foot to the first unit. Make the connection to the

beginning of the first unit row from the distribution box with SDR-35 pipe or equivalent.

13. Complete backfill over the units followed by topsoil to a depth of 6” – 18” as measured from the top of the units. 1” of

the fill is Specified Sand, immediately on top of the unit. Systems with total cover that exceeds 18” as measured from

the top of the units to finished grade shall be vented at the distal (far) end of the system. Backfill material shall be well

graded sandy fill; clean, porous, and devoid of large rocks. Divert surface runoff with diversion ditches or berms. Finish

grade to prevent surface ponding. Seed or sod excavated areas to protect against erosion. Do not drive or pave over

the absorption area.

2015 Vermont Mantis M5Design & Installation Manual Page 14 www.eljen.com

5.0 Bed System Installations Drawings

FIGURE 6: MANTIS M5IN-GROUND BED SYSTEM CROSS SECTION

12" Min

6" OF MIN COVER

INCLUDES 1" OF SPECIFIED SAND

SPECIFIED SAND

24"

SPECIFIED SAND

12"

6"

6" OF MIN COVER

INCLUDES 1" OF SPECIFIED SAND

6"

PER

PRODUCT

MANTIS 5.1

MANTIS 5.2

12" Min

PER

PRODUCT

FIGURE 7: MANTIS M5BED SYSTEM PLAN VIEW

D-BOX

PER DESIGN

PER DESIGN

SPECIFIED SAND

6"

Note: Units distal ends should not be tied together for sloped bed configurations.

2015 Vermont Mantis M5Design & Installation Manual Page 15 www.eljen.com

6.0 Mound System Installations Guidance

1. Carefully lay out all boundaries defining the location and elevation for all system components.

2. Prepare the site according to state and local regulations. Do not install a system on frozen or saturated soils. Take

precautions not to compact or smear the area with heavy machinery.

3. Plan all drainage requirements above (up-slope) the system and set soil grades to insure storm water drainage and

surface water is diverted away from the absorption area once the system is complete.

4. Above ground vegetation shall be closely cut and removed from the ground surface throughout the area to be used for

the placement of the fill material. The area shall then be plowed to a depth of seven (7) to eight (8) inches, parallel to

the land contour with the plow throwing the soil upslope to provide a proper interface between the fill and natural soils.

Tree stumps shall be cut flush with the surface of the ground and roots shall not be pulled. Once plowing is completed,

the area should be fenced to prevent vehicles and equipment from entering the plowed area, unless the fill material is

going to be in place within 24 hours of the plowing. If the site cannot be plowed, a backhoe bucket fitted with chisel

teeth may be used to “till” the site by creating furrows that are parallel to ground contour.

5. Place, stabilize, and rake a minimum 6” level layer of Specified Sand along the mound basal area. Specified Sand must

meet the minimum requirements listed on Table 1 of this manual. Ask your material supplier for a sieve analysis report

to verify that the sand you are going to install meets this specification. A hand tamper or a vibratory plate compactor is

sufficient for stabilization of the Specified Sand layer.

6. Place the Mantis units in their rows with the fabric side up, adjust the Filter Support Modules to ensure they are spaced

evenly and have not shifted during placement.

7. Connect the units by inserting the Support Distribution Pipe to one another.

8. Distribution methods permitted for use with the Mantis M5systems in shallow placement, elevated, or mound systems

are:

Pump to d-box with timed dosing

Pipe-in-Pipe Pressure Distribution

Pump to d-box distribution: The d-box shall be placed to center feed the laterals so that no lateral would exceed 50’

(100’ total).

A maximum of 500 lf total is permitted for pump to d-box distribution. Pipe-in-pipe pressure distribution has no maximum

length.

Shallow placement, elevated or mound systems with a design flow of greater than 1000 gpd must utilize pipe-in-pipe

pressure distribution.

9. Install a termination cap or vent piping if required at the distal (far) end of the distribution pipe.

10. Begin placing Specified Sand between the Filter Support Modules and to the sides of the units. Specified Sand must

be placed lightly and may be accomplished with a backhoe or other suitable equipment. DO NOT dump full loads of

Specified Sand directly on the units.

2015 Vermont Mantis M5Design & Installation Manual Page 16 www.eljen.com

6.0 Mound System Installations Guidance

11. Steps for placement of Specified Sand.

a. Starting at the top center of the units, use a minimal amount of Specified Sand necessary to set in place the

bottom section of the Filter Support Modules at their correct spacing.

b. Compact the sand that is in-between the Filter Support Modules. Ensure that the void area under the Support

Distribution Pipe is filled and compacted with Specified Sand.

c. Additional Specified Sand is lightly added between the Filter Support Modules and along the sides of the Mantis

units to bring the sand fill 1-inch above the Filter Support Modules to account for sand settling.

d. Continue to moderately tamp and compact the sand that is in-between the Filter Support Modules. Spread

additional Specified Sand as necessary.

12. Set distribution box to the proper elevation to achieve a 1/8” drop per foot to the first unit. Make the connection to the

beginning of the first unit row from the distribution box with SDR-35 pipe or equivalent.

13. Complete backfill over the units followed by topsoil to a depth of 6” – 18” as measured from the top of the units. 1” of

the fill is Specified Sand, immediately on top of the unit. Systems with total cover that exceeds 18” as measured from

the top of the units to finished grade shall be vented at the distal (far) end of the system. Backfill material shall be well

graded sandy fill; clean, porous, and devoid of large rocks. Divert surface runoff with diversion ditches or berms. Finish

grade to prevent surface ponding. Seed or sod excavated areas to protect against erosion. Do not drive or pave over

the absorption area.

2015 Vermont Mantis M5Design & Installation Manual Page 17 www.eljen.com

6.0 Mound System Installations Drawings

FIGURE 8: MANTIS M5RAISED OR FILL BED SYSTEM CROSS SECTION

SPECIFIED SAND

24" 12"

GRADE, LOAMAND SEED

STABILIZE SLOPE

MIN 3" LOAM SEED

PLOWOR "TILL" NATIVE MATERIAL PER STEP4

OF MOUND INSTALLTION GUIDELINES

STATE OR LOCAL FILL REQUIREMENTS

SPECIFIED SAND

12" 12"

ORIGINAL GRADE

GRADE, LOAMAND SEED

STABILIZE SLOPE

MIN 3" LOAM SEED

STATE OR LOCAL FILL REQUIREMENTS

ORIGINAL GRADE

MANTIS 5.1 & MANTIS 5.1 LowPro

MANTIS 5.2

12" MIN

12" MIN

PLOWOR "TILL" NATIVE MATERIAL PER STEP4

OF MOUND INSTALLTION GUIDELINES

18"

18"

3 1

3 1

FIGURE 9: MANTIS M5SLOPED BED SYSTEM CROSS SECTION

Note: Units distal ends should not be tied together for this configuration.

STABALIZE 3:1 SLOPE

WITHAMIMIMUM OF

3" OF LOAMAND SEED

SPECIFIED

SAND

PER CODE

12" MIN

TOPSOILAND SEED TO PROTECT

FROM EROSION

STATE OR LOCAL FILL

REQUIREMENTS

18" MIN

12" MIN

PLOW OR "TILL" NATIVE MATERIAL PER STEP 4

OF MOUND INSTALLTION GUIDELINES

18" MIN

NOTE: Elevated mound systems require a minimum of 12 inches of Specified Sand below the units.

2015 Vermont Mantis M5Design & Installation Manual Page 18 www.eljen.com

7.0 Pumped System Guidance

7.1 PUMP DOSED DISTRIBUTION BOX: Specify an oversized distribution box for pumped systems. Provide velocity

reduction in the D-box with a tee or baffle.

7.2 PRESSURE OR PUMPED DOSED DESIGN CRITERIA: Dosing volume must be set to deliver a maximum of 6 gallons

per Mantis 5.2 per dose cycle or 3 gallons per Mantis 5.1 per dose cycle.

Distribution methods permitted for use with these Mantis M5systems are:

Pump to d-box with timed dosing

Pipe-in-Pipe Pressure Distribution

Pump to d-box distribution: The d-box shall be placed to center feed the laterals so that no lateral would exceed 50’ (100’

total).

A maximum of 500 lf total is permitted for pump to d-box distribution. Pipe-in-pipe pressure distribution has no maximum

length.

Shallow placement, elevated or mound systems with a design flow of greater than 1000 gpd must utilize pipe-in-pipe

pressure distribution.

7.3 LOW PRESSURE DISTRIBUTION: Pressure lines should have a minimum 1 1/4 inch inside diameter. Orifices should

be designed at 3/16 inch to 1/4 inch in diameter and at pre-determined intervals per design and code. Design requirements

will vary depending on length of system and dose volume. At least one drain hole per line at the 6 o’clock position must

added to each line.

Flushing ports are required at the distal end of all pressure distribution networks. Flushing valves and vents can be

consolidated in larger systems by using valves on the outlet manifold.

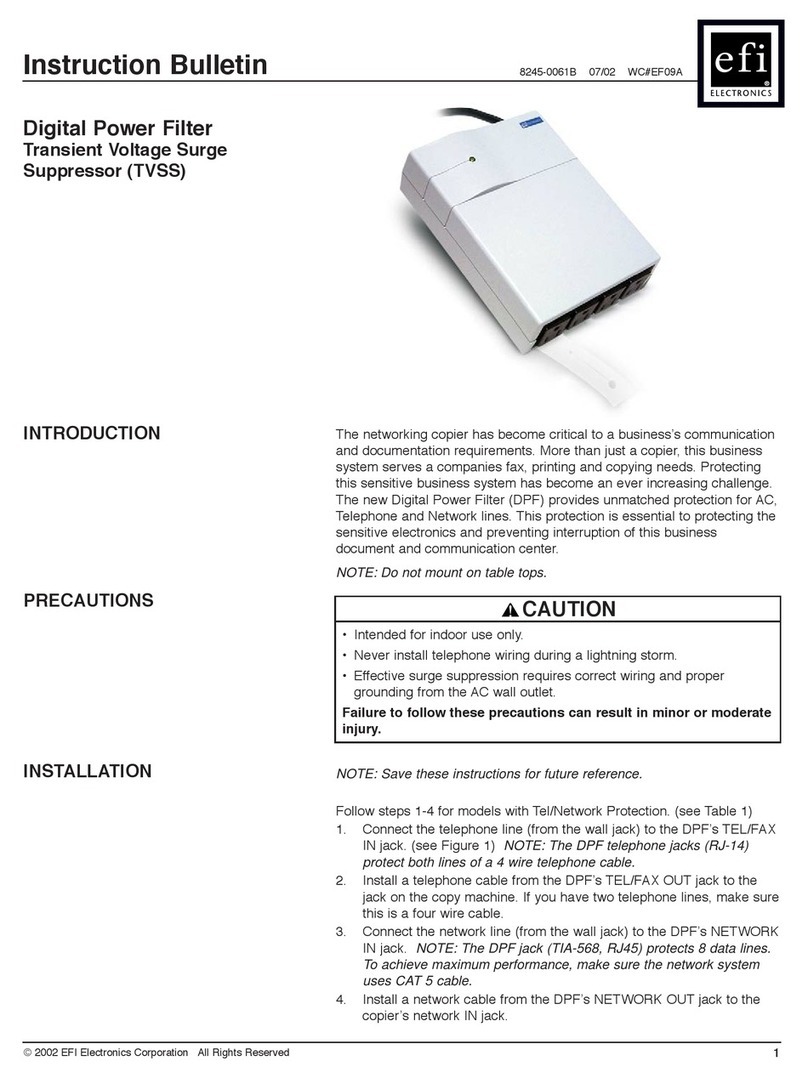

FIGURE 10: MANTIS M5SERIES PRESSURE DISTRIBUTION –ORIFICE LAYOUT

FROM

PUMP CHAMBER

LOW PRESSURE PIPE

(LPP)

CAP END OF 4" PIPE

4" DIAMETER

PERFORATED PIPE

4" DIAMETER PERFORATED PIPE

HOLESAREAT 12, 5 & 7 O'CLOCK

ENSURE LPP ORIFICE IS NOT POINTING

DIRECTLY INTOA12 O'CLOCK HOLE

LOW PRESSURE PIPE (SIZE PER DESIGN)

PRESSURE PIPE CROSS SECTION FOR ALLAPPLICATIONS

2015 Vermont Mantis M5Design & Installation Manual Page 19 www.eljen.com

8.0 System Ventilation Guidance

8.1 SYSTEM VENTILATION: Air vents are required at the distal end of unit rows on all absorption systems with more than

18 inches of soil cover as measured from the top of the Mantis units or located under impervious surfaces. This will ensure

proper aeration of the Mantis system. The extension of the distribution pipe at the distal end of each row to the vent provides

adequate delivery of air into the Mantis system, as shown in Figure 10.

The vent is usually a 4-inch diameter pipe extended to a convenient location behind shrubs. Corrugated pipe can be used

to vent the system. Make sure the pipe has a pitch towards the surface so it does not accumulate water or condensation

that will close of the airflow to the system.

If a pump dosed system is specified with greater than 18 inches of cover, an additional 2-inch minimum airline must be

extended from the D-box back to a knockout or riser on the septic tank or pump chamber. This maintains the continuity of

airflow from the field.

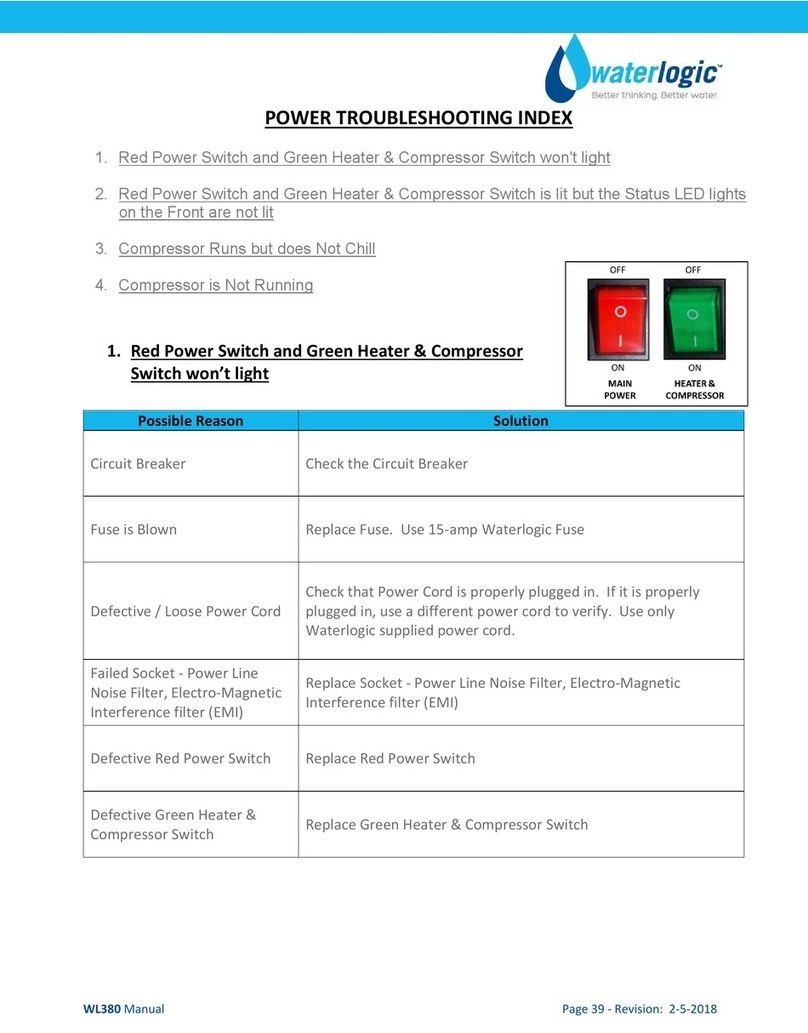

FIGURE 11: MANTIS M5 SERIES VENTING DIAGRAM

MOUNDED BACKFILL OVER UNITS

CLEAN BACKFILL

FINISHED GRADE

SHRUB

2015 Vermont Mantis M5Design & Installation Manual Page 20 www.eljen.com

8.0 System Ventilation Example Drawing

FIGURE 12:MANTIS M5SERIES 2” BY-PASS LINE

OR SEPTIC TANK

PUMP CHAMBER

PER DESIGN

PER DESIGN

SPECIFIED SAND

6"

2" BY-PASS AIR LINE

FIGURE 13:MANTIS M5SERIES 2” BY-PASS LINE, CLOSE UP

SEPTIC

TANK

PUMP

TANK

MIN 2" DIABY-

PASSAIR LINE

D-BOX

OUT TO SYSTEM

Other manuals for Mantis M5 Series

2

Table of contents

Other Eljen Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Water Factory Systems

Water Factory Systems SteamerGard WT-400 Use and care instructions, installation

Rewatec

Rewatec Prefilter Maxi Assembly instructions and mounting guide

OptiPure

OptiPure ScaleX2 SX2-11 Installation, operation & maintenance manual

GLOW

GLOW UV400 User's manual & installation instructions

Trox Technik

Trox Technik PFC Installation and maintenance manual

Nimbus Water Systems

Nimbus Water Systems Cascade NS-14 Owner's manual and installation guide