10 / 24 23656a GB/2019-06

1

electronic GmbH & Co. KG • Heinrichstraße 3-4 • 12207 Berlin • Deutschland • [email protected]1.5 Warnings and safety instructions

General

• In accordance with its intended use and this Operating Manual, the filter aggregate

must only be used together with a SONOREX TECHNIK RM/TM ultrasonic bath.

Accordingly, the safety instructions as stated in the operating manual for the

SONOREX TECHNIK RM/TM ultrasonic bath also apply.

• All safety instructions given in the pump operating manual (appendix) apply as well.

• Do not bring cleaning agents in contact with eyes or skin.

• Avoid ingesting or breathing in cleaning agents.

• Do not operate the filter aggregate without liquids!

• The filter aggregate is designed for use in liquid temperatures of up to 70 °C.

• Only operate the filter aggregate with aqueous cleaning agents.

Do not use any of the following liquids:

- combustible liquids, solvents (non-aqueous) and non-combustible liquids like

TRI, PER, methylene chloride and the like.

- aggressive cleaning agents such as acids and chemicals that (for example)

contain or separate chlorine ions, such as certain disinfectants, washing-up

liquids, household cleaners or saline solutions.

• Do not expose the filter aggregate to corrosive influences.

• Device damage resulting from the use of unsuitable cleaning chemicals will void the

warranty.

• Keep the filter aggregate and the stand clean and dry.

• Use only the connection material supplied.

• If the device changes ownership, make sure to provide the new owner with the

Operating Manual and safety instructions as well.

Operation and transport

• Place the filter aggregate upright on a solid, dry surface. Note the required ambient

conditions (Chapter 1.4).

• Only connect the filter aggregate to outlets with a grounded socket.

• Do not allow the unit to run unattended.

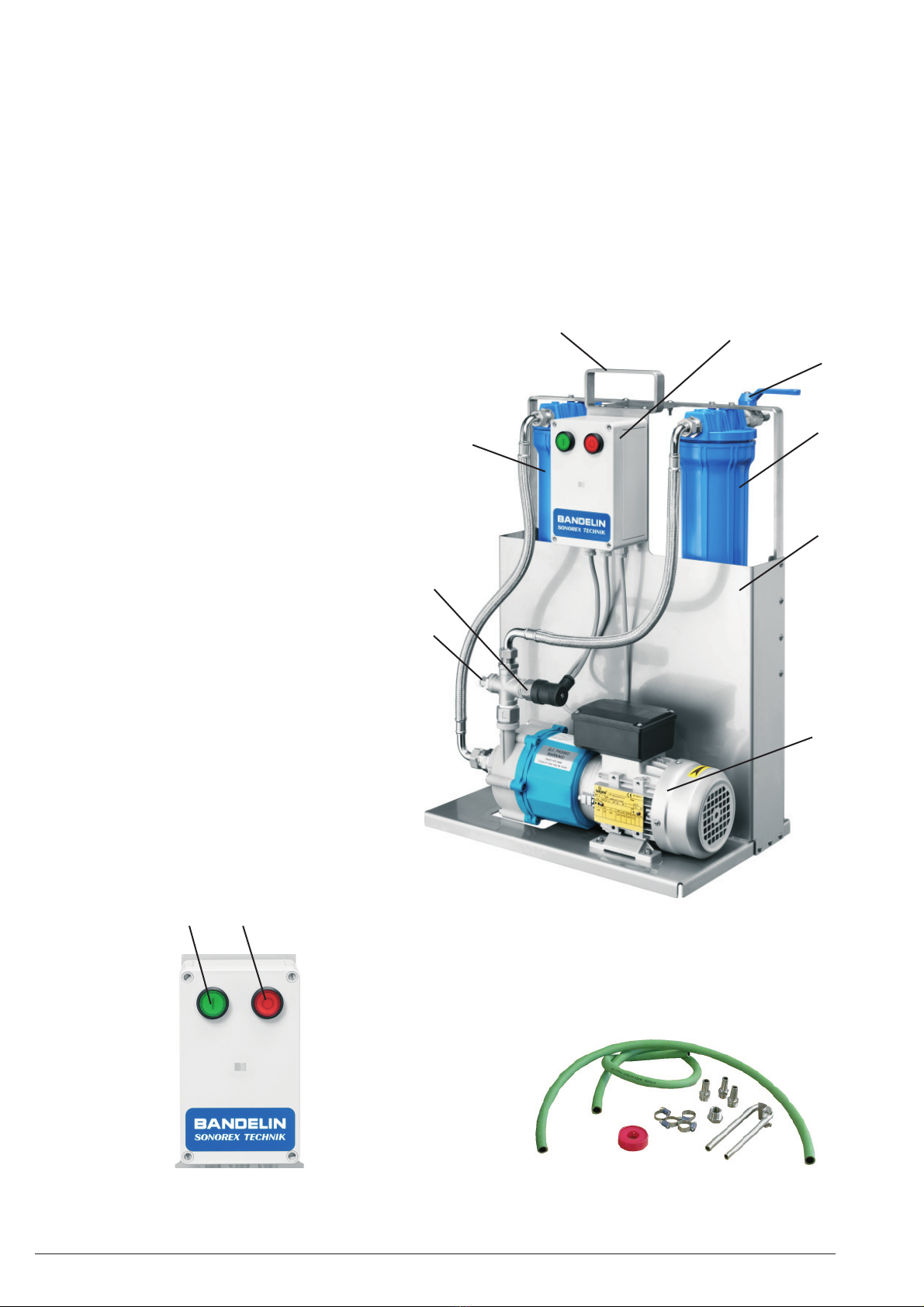

• The filter aggregate has a handle for transport purposes.

Damage and defects

• Disconnect the device from mains power immediately if defects are identified.

• Defective or damaged filter aggregates must only be serviced by the manufacturer

or by trained, authorised personnel.

• Always replace defective parts with SONOREX original parts or parts of the same

quality.

• Replace defective mains cables completely.