Environment One E/One PLC User manual

E/ONE PLC

QUADPLEX PANEL

Installation and

Operation Manual

For Hardwired Pumps

Environment One Corporation

2 NA0702P01 REV A

12/03/2019

Contents

1 Overview ............................................................................................................................................................................................................................................3

2 E/One PLC Quadplex Menu Flowchart (Refer to section 5 for more info on these menus)................................................................................................................4

3 Wiring Instructions.............................................................................................................................................................................................................................5

4 Startup ...............................................................................................................................................................................................................................................5

5 User Menus and Touch Screen Interface ...........................................................................................................................................................................................6

5.1 Main Menu..............................................................................................................................................................................................................................6

5.2 Pump Data Menu ....................................................................................................................................................................................................................6

5.3 Active Alarm / Trouble Log ......................................................................................................................................................................................................7

5.4 Alarm History ..........................................................................................................................................................................................................................7

5.5 Set Points Menus.....................................................................................................................................................................................................................8

5.6 Options Menu .........................................................................................................................................................................................................................8

5.6.1 Voltage Data Menu.......................................................................................................................................................................................................8

6 System Parameters ............................................................................................................................................................................................................................9

6.1 Software Revision....................................................................................................................................................................................................................9

6.2 User Programmable Functions ................................................................................................................................................................................................9

6.2.1 Run Levels.....................................................................................................................................................................................................................9

6.2.2 Overpressure Current (High Amps) Setting ..................................................................................................................................................................9

6.2.3 Run Limit Setting ..........................................................................................................................................................................................................9

6.2.4 Cold Start......................................................................................................................................................................................................................9

6.2.5 Clear Trouble ................................................................................................................................................................................................................9

6.2.6 Restore Factory Defaults ..............................................................................................................................................................................................9

7 Normal Operation ............................................................................................................................................................................................................................10

7.1 Manual Run Operation ..........................................................................................................................................................................................................10

7.2 High Level Alarm Operation ..................................................................................................................................................................................................10

7.3 Audible Alarm Manual Silence...............................................................................................................................................................................................10

7.4 Pump Performance ...............................................................................................................................................................................................................10

7.4.1 Hour Meter (RUNTIME) ..............................................................................................................................................................................................10

7.4.2 Cycle Counter (CYCLES)...............................................................................................................................................................................................10

7.4.3 Last Cycle Runtime (LAST (s))......................................................................................................................................................................................11

7.4.4 Minimum Runtime (MIN RUN (s))...............................................................................................................................................................................11

7.4.5 Maximum Runtime (MAX RUN (s)) .............................................................................................................................................................................11

7.4.6 Average Runtime (AVG RUN (s)) .................................................................................................................................................................................11

7.4.7 Minimum Amps (MIN AMPS (A)) ................................................................................................................................................................................11

7.4.8 Maximum Amps (MAX AMPS (A))...............................................................................................................................................................................11

7.4.9 Average Amps (AVG AMPS (A))...................................................................................................................................................................................11

7.4.10 Minimum Volts (MIN VOLTS (VAC))............................................................................................................................................................................11

7.4.11 Maximum Volts (MAX VOLTS (VAC))...........................................................................................................................................................................11

7.4.12 Average Volts (AVG VOLTS (VAC)) ..............................................................................................................................................................................11

8 Trouble Operation............................................................................................................................................................................................................................11

8.1 Excessive Runtime Operation ................................................................................................................................................................................................11

8.2 Brownout Operation .............................................................................................................................................................................................................12

8.3 Overvoltage Operation..........................................................................................................................................................................................................12

8.4 Overpressure Operation........................................................................................................................................................................................................12

8.5 Comm Lost Indication............................................................................................................................................................................................................12

9 Diagnostics .......................................................................................................................................................................................................................................12

9.1 Alarm Test .............................................................................................................................................................................................................................12

10 Communication................................................................................................................................................................................................................................13

10.1 USB Interface.........................................................................................................................................................................................................................13

11 Trouble Shooting ..............................................................................................................................................................................................................................13

11.1 Troubleshooting Chart...........................................................................................................................................................................................................13

12 Appendix ..........................................................................................................................................................................................................................................15

12.1 Typical Field Wiring Diagram .................................................................................................................................................................................................15

12.2 Alarm Messages ....................................................................................................................................................................................................................16

12.3 Normal and Full Operational Ranges .....................................................................................................................................................................................16

3 NA0702P01 REV A

12/03/2019

1Overview

This manual provides information on the operation and use of Environment One PLC Quadplex Panels.If unsure of the

configuration of your panel, contact E/One factory for assistance.

The E/One PLC Quadplex panel is an Environment One full-featured Alarm/Monitor panel. The E/One PLC Quadplex

panel monitors for the following operating conditions:

•Pump Overpressure Condition – Pump operating at abnormally high current level

•Brownout Condition – Mains voltage 12% below nameplate rating

•Overvoltage Condition – Mains voltage 12% above nameplate rating

•High Liquid Level

•Low Liquid Level

•Real-time, High, and Low Voltage on the input

•Real-time and High current drawn by the Pump

•Pump failed to start

•Contactor fault

•Extended Pump Runtime

The E/One PLC Quadplex Panel displays pump status, operating parameters, and user options by means of the following

indicators:

•Touch Screen Interface to show Pump & Panel operating conditions & provide for interaction

In addition, the following pump operating parameters can be viewed from the E/One PLC Quadplex Panel:

•Real-time fluid level in tank

•Real-time pump Voltage and Amperage

•Cycles & Hours

•Latched fault conditions

The following features are field programmable:

•Run levels one through four

•Alarm Level

•Overpressure Current

•Extended Pump Runtime Limit

The following are the hardware features:

•IP65 / NEMA 4X Rated Enclosure

•Enclosure made from fiberglass

•Separate pump , control, and input Circuit Breakers

•Audible & Visual Alarm indicators (Silence for Audible Alarm)

•HAND / OFF / AUTO (HOA) switch for each pump (HAND = MANUAL RUN, OFF = PUMP WILL NOT RUN, AUTO =

PLC + PRESSURE TRANSDUCER CONTROL PUMP

•Touch screen interface

•Hinged aluminum deadfront

•Programmable Logic Controller (PLC)

4 NA0702P01 REV A

12/03/2019

Options Menu

Voltage Data Menu

Set Points Menu

Run Levels

Trouble Set Points

Active Alarm Log

Alarm History

Trouble Reset Menu

Main Menu

Pump 1 Data 1

Pump 2 Data 1

Pump 3 Data 1

Pump 4 Data 1

Pump 1 Data 2

Pump 2 Data 2

Pump 3 Data 2

Pump 4 Data 2

2E/One PLC Quadplex Menu Flowchart (Refer to section 5 for more info on these menus)

NOTE: VALUES SHOWN DO NOT REPRESENT ACTUAL

VALUES – REFER TO APPENDIX FOR EXPECTED VALUES.

5 NA0702P01 REV A

12/03/2019

3Wiring Instructions

WARNING – the E/One Alarm and Control panel is a high voltage system that controls power to an electric

motor(s). Care should be taken whenever performing service on the panel to avoid the risk of electrical shock

and/or damage to property. Because power may be supplied by multiple sources, circuit breakers alone may

not be sufficient to provide adequate protection.

The E/One PLC Quadplex panel wiring can change from model to model. All wiring shall be done in accordance with the

wiring decal on the inside cover of the panel enclosure. Typical wiring can be found in the Appendix of this manual.

4Startup

The E/One PLC Quadplex Panel should arrive from the factory ready to operate. The panel is properly installed and

started by following the steps below.

1. Mount and wire the panel per the instructions on the enclosure door.

2. Ensure that Pressure transducer in the station is set at the appropriate height (10” from the bottom of the tank).

If it is not, the off level will not be at the correct height, and the system may not function properly.

WARNING – Pressure transducer must have a range of 0-2.5m to ensure proper operation. If a different range is

used run levels will be improperly scaled.

3. ‘Cold Start’ the panel – refer to Cold Start section of this manual for more information.

4. Clear the Alarm History – Refer to the Alarm History Log section of this manual for more information.

5. If other than factory default settings are required, set all limits and levels. Factory defaults settings can also be

restored via the user menu. (Refer to the User Programmable Options section of this manual for more on this

feature).

6 NA0702P01 REV A

12/03/2019

5User Menus and Touch Screen Interface

The E/One Quadplex PLC panel includes a panel mounted touch screen interface to navigate the various menus and

select the user options (see Figures 2-8). The values displayed in the following figures are not realistic and are intended

to show only the number of digits that each field can contain. See appendix for the expected ranges of various values.

Refer to “System Parameters” section for definition of each field within the menus.

5.1 Main Menu

Real time panel voltage, Next to run (NTR) and real time fluid level in the tank are displayed on the main menu. Five

buttons on the main menu allow the user to access all of the functionality of the touch screen interface.

5.2 Pump Data Menu

The Pump Data menu allows the user to view pages of data for each pump. Each pump menu has two screens to display

amperage, total runtime, fluid level (inches), total cycles, min/max/average current, min/max/average runtime and last

runtime for that pump. Pump operational data may be reset on a screen by screen basis by holding the “RESET” button

for three seconds (Note that resetting the 1st screen of data will reset avg. cycle time (on screen 2), as it resets total

runtime and total cycles). Pump operational status will be indicated in the upper right, next to the arrow button

(Possibilities include “HAND”, “OFF”, “AUTO”, and “TRBL”). Data on additional pumps can be accessed via the left and

right arrow buttons.

Figure 3 – Pump Data Menu

Figure 2 – Main Menu

7 NA0702P01 REV A

12/03/2019

5.3 Active Alarm / Trouble Log

The Active Alarm Log shows any alarms / trouble conditions that are active in the station. This includes overpressure

(during the lockout period), overpressure final lockout, high level, low level, pump failed to start, contactor fault,

overvoltage, and brownout. It includes a time stamp and a description for each alarm / trouble condition. The log begins

with the most recent alarm / trouble condition, and lists them in reverse chronological order. Once a condition is

cleared, either manually (via pump trouble reset buttons) or automatically an entry will be added (highlighted in green)

showing the alarm was cleared with a timestamp. It will still exist in the alarm history (see section 5.4). The second

button from the right (ACK) will acknowledge an alarm, changing its status for awareness purposes. The arrow in the top

left will return the user to the Main Menu. The “Clear Trouble?” Button will open a menu where you can clear any

trouble conditions preventing a pump from running. This is especially useful for troubleshooting purposes.

5.4 Alarm History

The alarm history shows the last 100 alarms / trouble conditions detected by the panel, regardless of whether they have

been cleared manually or automatically. This includes overpressure (during the lockout period), overpressure final

lockout, high level, low level, pump failed to start, overvoltage, brownout, blocked line, contactor fault, and extended

pump runtime. It includes a time stamp and a description for each alarm / trouble condition. The log begins with the

most recent alarm / trouble condition, and lists them in reverse chronological order. Unlike the Active Alarm Log, events

will remain until the event limit is exceeded after which the oldest event will drop off when a new event is recorded. The

arrow button from the will return the user to the Main Menu.

Figure 4 – Active Alarm Log and Clear Trouble Menu

Figure 5 – Alarm History

8 NA0702P01 REV A

12/03/2019

5.5 Set Points Menus

Trouble Set Points and Run levels are accessed via the “Set Points” button in the Main Menu. Overpressure Amperage

and Run Limit may be edited via the trouble parameters panel. See sections 6.2.2 and 6.2.3 for more information

regarding these set points. Run levels 1-4 and the high level set point may be edited through the Run Levels menu. See

section 6.2.1 for more information regarding these set points. The arrows in the upper left will return the user to the

previous menu.

5.6 Options Menu

The options menu contains various options. The software version is displayed on this screen, and the user can access the

cold start and factory default options from this menu. In order to use these functions the buttons must be held for at

least 3 seconds (this is to prevent accidental deletion of operational data). See sections 6.2.4 and 6.2.6 for more

information regarding these options. The alarm light and buzzer can also be tested via this menu by simply holding the

respective button.

5.6.1 Voltage Data Menu

The Voltage Data Menu shows min/max/average voltages and overvoltage and brownout set points. These set points

are not editable. The min/max/average values may be reset by holding the “reset” button on the left for at least 3

seconds. The Voltage Data Menu is accessed via the options menu.

Figure 6 – Run Levels and Trouble Set Point Menus

Figure 7 – Options menu

Figure 7 – Options Menu

Figure 8 – Voltage Data Menu

9 NA0702P01 REV A

12/03/2019

6System Parameters

A number of system settings, some of which will be unique to the installation, can be set on-site. All of these settings

can be found within sub-menus in the Touch Screen Interface.

6.1 Software Revision

This read only field displays the revision of the software currently loaded into the panel. This information may be

required when speaking with E/One service personnel. This information can be found in the options menu.

6.2 User Programmable Functions

The following items can be used for system setup. In a Quadplex system all of these parameters are shared between the

4 pumps and cannot be set independently for each pump. Clearing of these values is also universal and affects all

pumps simultaneously.

6.2.1 Run Levels

Run levels 1-4 and the high level set point may be edited through the Run Levels Menu under the Set Points menu.

Simply press the correct set point value and a keyboard will appear allowing you to enter a new value (Note that off and

low level are not editable as they are based on the E/One pumps’ physical characteristics). For normal operation, the run

levels and alarm level must be set such that Off < Run 1 < Run 2 < Run 3 < Run 4 < High. This ensures that all pumps have

an opportunity to turn on before alarm is reached and that the sequencing works as intended. The Touch screen

interface will prevent the user from entering values which do not satisfy this criteria.

6.2.2 Overpressure Current (High Amps) Setting

This field displays the limit that is currently set for the Overpressure / High current protection feature. Though it is

possible to change this setting, it is not advised unless directed by E/One service personnel, as changing this limit will

affect how the overpressure protection feature performs. Doing so without proper guidance may void the product

warranty and can cause damage to the system.

6.2.3 Run Limit Setting

The Run Limit option is a user editable feature that can be set from the Trouble set points Menu. The factory default

setting for this feature is 10 minutes. This feature will cause a trouble alarm to be activated if an individual pump run

cycle exceeds the set value.

6.2.4 Cold Start

The Cold Start option is found within the Options menu. In order to cold start the panel the button must be held for a

minimum of 3 seconds. Cold Starting the panel erases all stored operating parameters listed within the Pump

Performance section (Section 7.4), and should be done when the panel is first installed. All previously stored operating

parameters will be cleared.

6.2.5 Clear Trouble

The Reset menu accessed from the active alarm log allows the user to manually clear trouble conditions for one or all

pumps. This is intended to be used for troubleshooting purposes after a pump has been locked out. If the trouble

condition persists, the pump will be locked out again on the next run. A successful, trouble free 5-second manual or

automatic run will also clear certain trouble conditions.

6.2.6 Restore Factory Defaults

The Restore Factory Defaults function will restore all set points and limits to factory original. This functionality is

accessed through the Options Menu. In order to restore factory defaults the button must be held for a minimum of 3

seconds. Restoring the factory default values returns the following fields to their factory preset conditions as follows:

Overpressure Limit [12.5 A], Run Limit [10 MINUTES], Run Levels 1,2,3,4,High [16, 18, 20, 22, 26].

10 NA0702P01 REV A

12/03/2019

7Normal Operation

Under normal operating conditions, the E/One PLC Quadplex panel will perform as follows when power is applied:

1. During the boot-up period, all panel indications and outputs will be OFF.

During this boot up sequence, all operating parameters are recovered from non-volatile memory. If this is the

first time the panel has been started, these will be the factory defaults and all operating parameters will be 0.

Otherwise, these values will be what they were the last time the panel operated. If the panel requires a reset to

restore factory defaults, refer to the Restore Factory Defaults feature in the User Programmable Functions

section (Section 6.2) of this manual.In addition, a Cold Start may be needed to clear out the Pump Performance

operating parameters; refer to the Cold Start feature within the user programmable functions section of this

manual.

2. Under normal conditions, the Touch Screen Interface will display the real-time Panel Voltage, Station Fluid level,

and NTR at all times.

3. After each completed pump run cycle, the Pump data screens are updated to reflect the most current data.

Refer to the Pump Performance section of this manual for more on this feature.

7.1 Manual Run Operation

The lead pump can be operated manually by pressing and holding the HOA switch on the dead-front in the Manual Run

position (Labelled on deadfront). The pump will run and all the operational data associated with it will be available on

its data screen. The Manual Run feature is capable of bypassing trouble conditions – it should be used with caution in

cases where overpressure or overvoltage / brownout are a factor. Releasing the switch will stop the pump. Each pump

can be operated individually by using its own HOA switch.

7.2 High Level Alarm Operation

A High Level Alarm is initiated if the liquid level in the tank reaches the high level as determined by the Pressure

Transducer or backup high level float. If a High Level is detected, the panel will energize the contactors for all 4 pumps

(if they are not already energized), and turn on the alarm light and buzzer. This condition will remain until the 4 pumps

have pumped the station below 2 inches below the alarm level. This is the most critical alarm condition as it indicates

that the pumps cannot keep up with inflow or the pressure transducer is malfunctioning.

7.3 Audible Alarm Manual Silence

Any time the audible alarm / buzzer is activated by the system, and the PLC is functioning, it can be silenced by pressing

the ‘SILENCE’ button located on the exterior underside of the enclosure. If the buzzer has been activated due to a PLC

failure then the Alarm Breaker must be switched off to silence the buzzer.

7.4 Pump Performance

Pressing the Pump Data button on the main menu will display data for each pump e.g. runtime / total cycles. All

parameters are non-volatile (retained through a power loss), unless otherwise stated. Pressing the Voltage Data button

on the Options Menu will display mains voltage data e.g min/max/average voltage. The following values are displayed

on the Pump Data and Voltage Data menus.

7.4.1 Hour Meter (RUNTIME)

Accumulated runtime - The time is displayed as Runtime: HH:MM:SS, where HH are the total hours, MM minutes, and

SS seconds since the last reset. The maximum runtime value that can be stored is 99999:59:59 (> 11 years). Beyond this

limit the value displays as 99999:MM:SS (minutes and seconds will continue to cycle but hours will display as 99999).

7.4.2 Cycle Counter (CYCLES)

Accumulated cycles - The value is displayed as Cycles: XX, where XX are the total accumulated pump cycles since the last

reset. The maximum cycle value that can be displayed is 9999999.Beyond this limit the value displays as 9999999 until

reset to 0 by the user.

11 NA0702P01 REV A

12/03/2019

7.4.3 Last Cycle Runtime (LAST (s))

Last runtime represents the duration of the previous completed pump cycle. This value is displayed as LAST (s): XXs,

where XX is the last runtime duration in seconds. This parameter is not saved through power loss.

7.4.4 Minimum Runtime (MIN RUN (s))

The minimum runtime represents the duration of the shortest completed pump cycle since the last reset. This value is

displayed as MIN RUN (s): XXXs, where XXX is the minimum runtime duration in seconds.

7.4.5 Maximum Runtime (MAX RUN (s))

The maximum runtime represents the duration of the longest completed pump cycle since the last reset. This value is

displayed as MAX RUN (s): HH:MM:SS and has the same limits as the normal hours.

7.4.6 Average Runtime (AVG RUN (s))

The average runtime represents the duration of the average completed pump cycle since the last reset. This value is

displayed as AVG RUN (s): XXXs where XXX is the average runtime duration in seconds.

7.4.7 Minimum Amps (MIN AMPS (A))

The minimum Amperage reading represents the minimum amperage draw the motor has experienced while running

since the last reset. This value is displayed as MIN AMPS (A):X.XA where X.X is the minimum Amperage to the nearest

tenth. This parameter is not saved through power loss.

7.4.8 Maximum Amps (MAX AMPS (A))

The maximum Amperage reading represents the maximum amperage draw the motor has experienced while running

since the last reset. This value is displayed as MAX AMPS (A): X.XA where X.X is the maximum Amperage to the nearest

tenth. This parameter is not saved through power loss.

7.4.9 Average Amps (AVG AMPS (A))

The average Amperage reading represents the average amperage draw the motor has experienced while running since

the last reset. This value is displayed as AVG AMPS (A): X.XA where X.X is the average Amperage to the nearest tenth.

This parameter is not saved through power loss.

7.4.10 Minimum Volts (MIN VOLTS (VAC))

The minimum Voltage reading represents the minimum voltage the motor has experienced while running since the last

reset. This value is displayed as MIN VOLTS (VAC): XV where X is the minimum Voltage to the nearest volt. This

parameter is not saved through power loss.

7.4.11 Maximum Volts (MAX VOLTS (VAC))

The maximum Voltage reading represents the maximum voltage the motor has experienced while running since the last

reset. This value is displayed as MAX VOLTS (VAC): XV where X is the maximum Voltage to the nearest volt. This

parameter is not saved through power loss.

7.4.12 Average Volts (AVG VOLTS (VAC))

The average Voltage reading represents the average voltage the motor has experienced while running since the last

reset. This value is displayed as AVG VOLTS (VAC): XV where X is the average Voltage to the nearest volt. This

parameter is not saved through power loss.

8Trouble Operation

Several less serious operating conditions can be detected and indicated to warn of pending, more serious faults. These

conditions do not warrant an immediate response and may clear themselves given time.

8.1 Excessive Runtime Operation

Excessive Runtime is a trouble condition that is initiated if an individual pump run cycle exceeds the set Run Limit value.

If the Run Limit is exceeded, the alarm history will show a run limit exceeded trouble condition. Pump operation will be

unaffected.

12 NA0702P01 REV A

12/03/2019

8.2 Brownout Operation

Brownout is a motor protection feature that will disable power to the motor if the incoming AC Mains Voltage is below a

predefined limit, typically 12% of the nominal nameplate rating. In the brownout mode, the pumps are prevented from

starting (if the pump is off), or is shut off (if the pump is running) until the voltage returns to within the desired range of

operation, typically 10% of the nominal nameplate rating. When in the Brownout Protection mode, the panel will

disable power to the pumps, whether the motor is running or not and indicate a trouble condition.

8.3 Overvoltage Operation

Overvoltage is a motor protection feature that will disable power to the motor if the incoming AC Mains Voltage is

above a predefined limit, typically 12% of the nominal nameplate rating. In the Overvoltage mode, the pump is

prevented from starting (if the pump is off), or is shut off (if the pump is running) until the voltage returns to within the

desired range of operation, typically 10% of the nominal nameplate rating. When in the Overvoltage Protection mode,

the panel will disable power to the pumps, whether the motor is running or not and indicate a trouble condition.

8.4 Overpressure Operation

Overpressure is a motor protection feature that will disable power to the motor if the amperage rises above a

predefined limit. Refer to the Trouble menu within the Set Points menu to see what the current value for this setting is.

This limit can be changed under direction of the factory to accommodate various system variables. When an

Overpressure condition is detected, the pump is shut off and a 20 minute lockout period begins. During this time, the

Overpressure condition is logged on the Touch Screen Interface and the pump is not allowed to run regardless of the

liquid level in the tank. After the 20 minute lockout, the pump is allowed to run; if the Overpressure condition is still

present a second lockout period begins, and the cycle will repeat. During the first three lockout periods, the panel alarm

light will be lit. If after the third lockout period (60 minutes) the condition has not been removed and the pump

attempts to start, the panel will indicate an alarm condition including the Alarm Lamp and Audible Alarm. After the third

failed retry, the pump is disabled indefinitely until it can be serviced. In an Overpressure condition, the 20 minute

lockout period can be bypassed by pressing the Reset Button for the effected pump. This should only be performed by

E/One Certified Service Personnel. If all pumps are locked out due to overpressure at the same time, the panel will

indicate a “Blocked Line” alarm and display visual and audible alarms. See section 8.5 for more information on the

blocked line condition.

8.5 Blocked Line Operation

If all pumps are locked out due to overpressure at the same time, the panel will indicate a “Blocked Line” alarm and

display visual and audible alarms. This is a critical trouble condition as it means a high level alarm is inevitable. The most

likely cause of a blocked line condition is a blockage in the discharge line or the main, which is causing all pumps in the

station to experience overpressure conditions.

8.6 Comm Lost Indication

This error indicates that the communication link between the PLC and Touch screen interface which make up the E/One

Sentry PLC Quadplex Panel is not functioning properly. In this situation, the touch screen will not display any live

information (only alarm history up to point of disconnection) but the PLC which controls the pumps will function

normally. If this condition is present, check the Ethernet cable that connects the two devices, and ensure the PLC is

functioning properly.

9Diagnostics

The interface allows the user to test both alarm outputs, buzzer and alarm light via buttons on the options menu.

9.1 Alarm Test

This test is intended to prove functionality of audible and visual alarm. Holding the button (s) will energize the alarm

light and/or the buzzer. If either do not turn on when the test is performed, the panel should be serviced.

13 NA0702P01 REV A

12/03/2019

10 Communication

The E/One PLC Quadplex Panel can be read by an external device to provide system operating parameters for system

monitoring and predictive maintenance.

10.1 USB Interface

All PLCs can be connected to a laptop or desktop computer in order to read all system variables and configuration data.

Using the free software, Somachine Basic v1.6 from Schneider Electric, the user can read in all data (even that which is

not visible via the Touch Screen Interface) and troubleshoot in more depth.

11 Trouble Shooting

The following chart is meant to address some common panel related issues. For more detailed information or pump

specific troubleshooting, please refer to the appropriate Service Manual or contact E/One service personnel.

11.1 Troubleshooting Chart

Fault Symptom Possible Cause Test

Brownout

Voltage being

measured by PLC is

too low

Low incoming voltage

•This testing may need to be done by qualified personal

•

Check voltage at panel per manual

Blown fuse or circuit

breaker

•Verify all fuses or breakers feeding the panel are on (closed)

Malfunctioning voltage

transducer

•Verify that the voltage transducer is functioning properly

Excessive heat in panel

•Verify outside air temperature is below 120 F to ensure proper analog

input operation

Overvoltage

Voltage being

measured by PLC is

too high

High incoming voltage

•This testing may need to be done by qualified personal

•Check voltage at panel per manual

Malfunctioning voltage

transducer

•Verify that the voltage transducer is functioning properly

Excessive heat in panel

•Verify outside air temperature is below 120 F to ensure proper analog

input operation

Overpressure Excessive pump

pressure

Discharge valve closed,

check valve malfunction,

line restriction, grinder

restriction, bad motor

•Remove pump from discharge and retest with no discharge (pump

back into station)

If problem is still present then refer to Service Manual for more testing

Run Limit Pump running longer

then set time

Tank size too large, stator

worn, high in-flow

•Check amperage

•Change Excessive Run Time Limit

No pump via

pressure

transducer

Pump will not run on

own but will run in

manual run

Pressure Transducer not

working, Tank ventilation

blocked trouble condition

present.

•Perform continuity test per Service Manual to determine if the

Transducer is faulty

•Verify that the tank ventilation is clear

Panel will not

power up

Touch screen display

will not power up

Touch screen display not

plugged in or properly, no

power to the PLC, faulty

display, faulty PLC

•Check to see that the display and PLC are plugged in properly, if this

still does not fix try another display

•Check that wiring is correct per wiring schematic

•Check between neutral and both sides of the alarm breaker for 120v

to determine if it is bad

Contactor in

panel will not

engage

Pump will not run No power to contactor coil,

contactor bad

•Check voltage at A1 to A2 coil on contractor

•Check continuity on contactor coil

•

Check for faulty contactor trouble condition

Contactor in

panel engages

but pump will

not run

Pump will not run

No power coming out of

contactor, loose wires,

pump not working

•Check for power across L1 & L2 (L1 & N) to see if power is going into

the contactor, if no power then check incoming and breaker

•Then check T1 & T2 to see if it is going through the contactor, if not

then replace the contactor

•Check voltage at the terminal block to see if power is there

•If all this is ok then refer to Service Manual for trouble shooting the

pump

14 NA0702P01 REV A

12/03/2019

Fault Symptom Possible Cause Test

Panel does not

protect against

fault conditions

No trouble faults,

pump is not disabled

for Brownout,

Overvoltage,

Overpressure, etc…

panel contactor not

functioning, panel

contactor mis-wired, faulty

PLC, set points not properly

entered

•Verify contactors are open when pumps not called to run by PLC

Manual run not

working

Manual run does not

make pump run

Panel mis-wired, faulty

HOA switch, faulty

contactor

•Check wiring of panel, all wires need to be per wiring instruction

15 NA0702P01 REV A

12/03/2019

12 Appendix

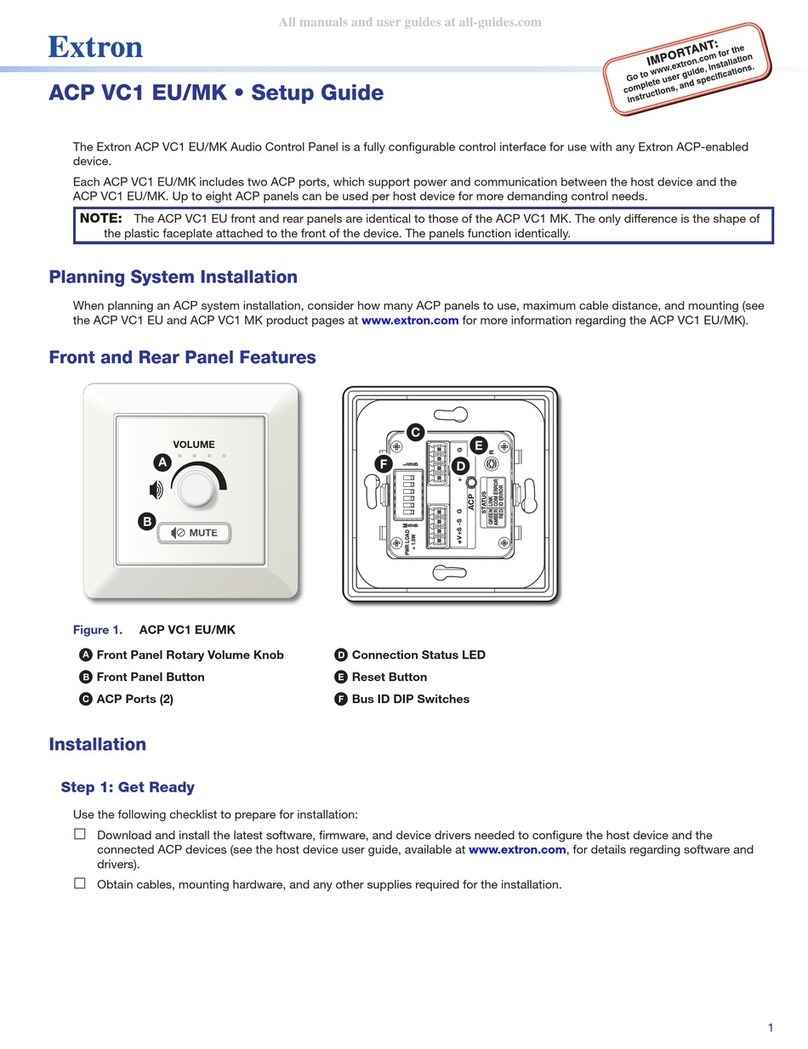

12.1 Typical Field Wiring Diagram

16 NA0702P01 REV A

12/03/2019

12.2 Alarm Messages

The following messages may be displayed on the touch screen interface in the active alarm log or alarm history to

indicate various system conditions.

•HIGH FLUID LEVEL – indicates a high level is present per high level float or transducer

•LOW FLUID LEVEL – indicates a low level is present per low level float or transducer

•LOW VOLTAGE – indicates the AC mains voltage feeding a pump is below the minimum limit

•HIGH VOLTAGE – indicates the AC mains voltage feeding a pump is above the maximum limit

•P1/2/3/4 OVERPRESSURE – indicates a pumps current draw is above the maximum limit

•P1/2/3/4 OP PERMALOCK – indicates a pump has been locked out due to repeated overpressure states

•P1/2/3/4 RUN LIMIT – indicates a pump runtime has exceeded the limit set under the Run Limit setting

•BLOCKED LINE – indicates that all pumps are locked out due to overpressure conditions

•P1/2/3/4 FAILED TO START – indicates that a pump failed to start when called to run by the PLC

•C1/2/3/4 FAULT – indicates that a contactor failed to close when called by the PLC, or failed to open when not

called by the PLC, and not being manually run.

12.3 Normal and Full Operational Ranges

The following list includes the typical operating ranges and measurable ranges for all variables that are displayed via the

touch screen interface.

•Voltage: Expected range:230VAC – 250VAC / Measurable Range: 0VAC - 300VAC

•Current: Expected Range (during operation): 5-10A / Measurable Range: 0-20A PER PUMP

•Fluid Level: Expected Range: 12”-26” / Measurable Range: 10-72” (Below 10” displays as 10”)

•Runtime: Expected Range: 0-99999 H / Recordable Range: N/A

•Cycles: Expected Range: 0-1000000 cycles / Measurable Range: N/A

•Cycle time (min/max/average/last Run): Expected Range: 0-300s / Measurable Range: 0 -9999s

17 NA0702P01 REV A

12/03/2019

Environment One Corporation

2773 Balltown Road

Niskayuna, New York 12309–1090

Voice: (01) 518.346.6161

Fax: 518.346.6188

www.eone.com

A Precision Castparts Company

Table of contents

Popular Control Panel manuals by other brands

Bentel Security

Bentel Security FireClass FC500IP installation manual

Lenz

Lenz Digital Plus LZV200 operating manual

urmet domus

urmet domus ELKRON DK500M-P Guide

Vitrum

Vitrum Scene Installation and operation

DSC

DSC PowerSeries Neo installation instructions

ADEMCO

ADEMCO LST700 Series Insallation & maintenance manual