EOM T1 Original Metal Series User manual

Simplify your process

Engineering

Operation &

Maintenance

Original™Series METAL Pumps

T1

WIL-10190-E-03

REPLACES WIL-10190-E-02

W

IL-10190-E-0

3

CS

C

l

a

s

s

I

&

I

I

O

z

o

n

e

D

e

p

l

e

t

i

n

g

S

u

b

s

t

a

n

c

e

s

NON

USE

U.S. Clean Air Act

Amendments of 1990

SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 3 HOW IT WORKS—PUMP & AIR DISTRIBUTION SYSTEM . . . . . . . . . . . . . . . .3

SECTION 4 DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

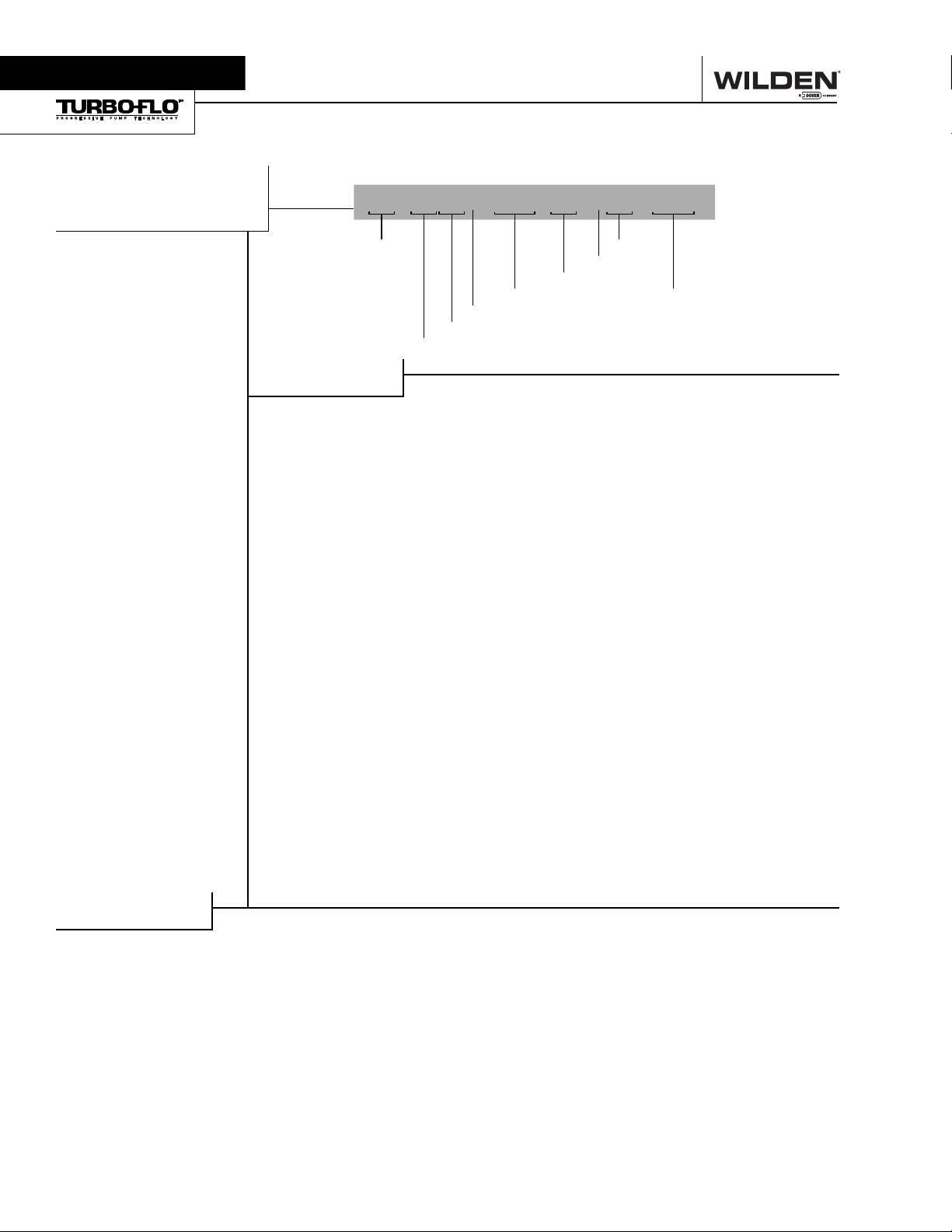

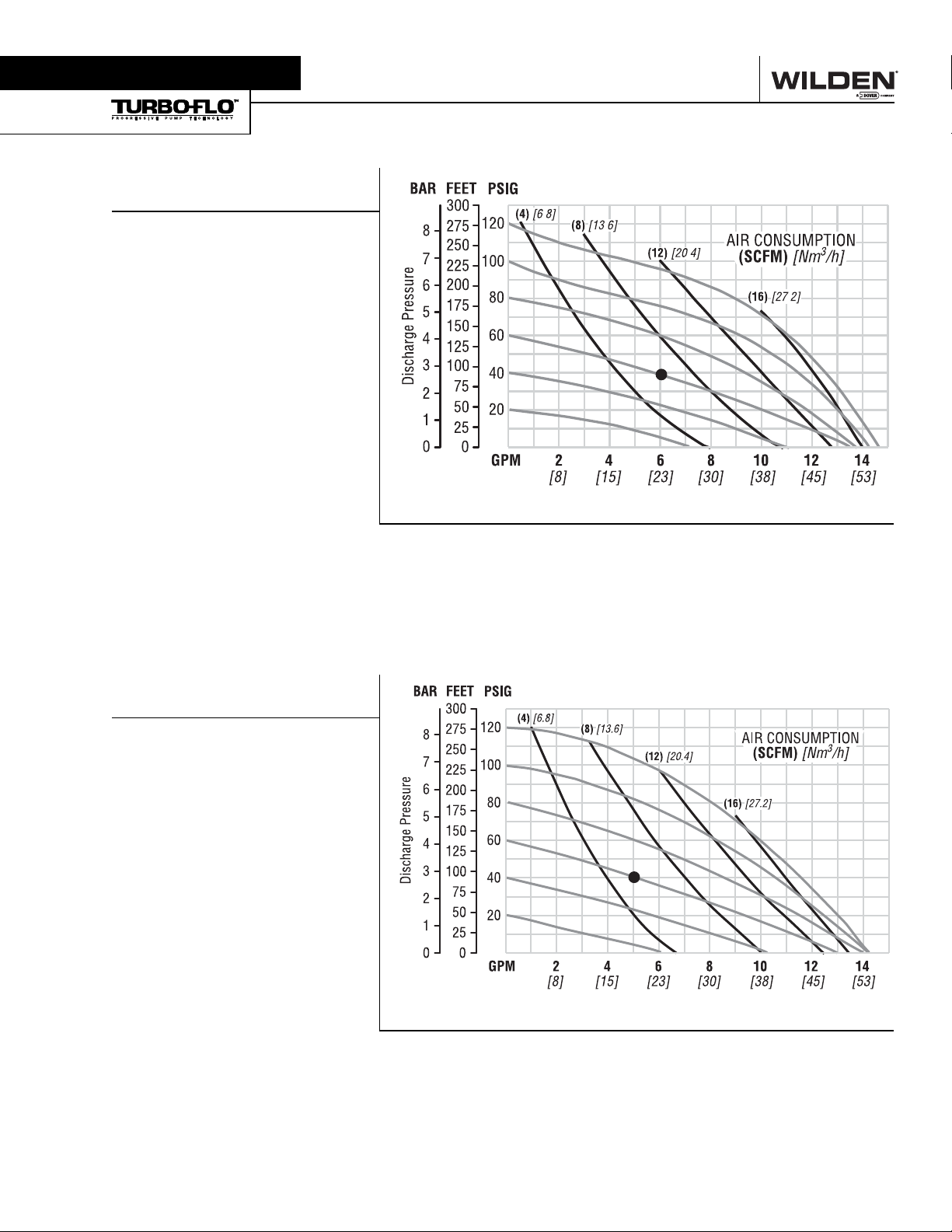

SECTION 5 PERFORMANCE

A. T1 Metal

Performance Curves

Rubber-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

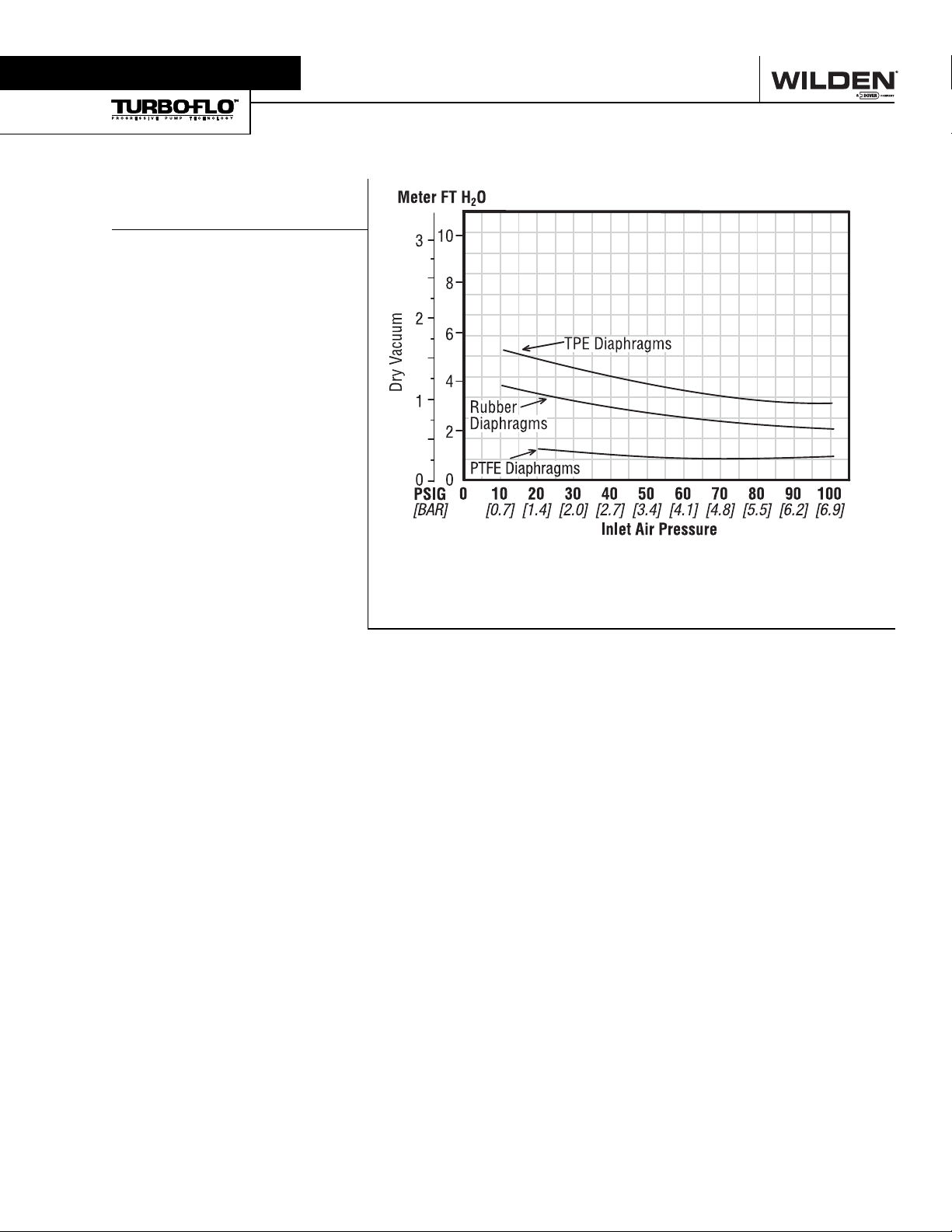

B. Suction Lift Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SECTION 6 SUGGESTED INSTALLATION, OPERATION & TROUBLESHOOTING. . . . . . . .8

SECTION 7 ASSEMBLY / DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Air Valve/Center Section Repair/Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

O-Ring Replacement/Center Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reassembly Hints &Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION 8 EXPLODED VIEW AND PARTS LISTING

T1 Metal Rubber/TPE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

T1 Metal PTFE-Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SECTION 9 ELASTOMER OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TABLE OF CONTENTS

1WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

TEMPERATURE LIMITS:

Nylon –17.8°C to 93.3°C 0°F to 200°F

Neoprene –17.8°C to 93.3°C 0°F to 200°F

Buna-N –12.2°C to 82.2°C 10°F to 180°F

EPDM –51.1°C to 137.8°C –60°F to 280°F

Viton®–40°C to 176.7°C –40°F to 350°F

Wil-Flex™ –40°C to 107.2°C –40°F to 225°F

Polyurethane 12.2°C to 65.6°C 10°F to 150°F

Saniflex™ –28.9°C to 104.4°C –20°F to 220°F

PTFE –28.9°C to 148.9°C –20°F to 300°F

CAUTION: When choosing pump materials, be sure

to check the temperature limits for all wetted compo-

nents. Example: Viton®has a maximum limit of 176.7°C

(350°F) but polypropylene has a maximum limit of only

79°C (175°F).

CAUTION: Maximum temperature limits are based

upon mechanical stress only. Certain chemicals will

significantly reduce maximum safe operating tempera-

tures. Consult engineering guide for chemical compat-

ibility and temperature limits.

CAUTION: Always wear safety glasses when operat-

ing pump. If diaphragm rupture occurs, material being

pumped may be forced out air exhaust.

WARNING: Prevention of static sparking — If static

sparking occurs, fire or explosion could result. Pump,

valves, and containers must be properly grounded when

handling flammable fluids and whenever discharge of

static electricity is a hazard.

CAUTION: Do not exceed 8.6 bar (125 psig) air supply

pressure.

CAUTION: Before any maintenance or repair is

attempted, the compressed air line to the pump should

be disconnected and all air pressure allowed to bleed

from pump. Disconnect all intake, discharge and air

lines. Drain the pump by turning it upside down and

allowing any fluid to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to pump to make sure all pipe line

debris is clear. Use an in-line air filter. A 5μ(micron) air

filter is recommended.

NOTE: Tighten clamp bands and retainers prior to

installation. Fittings may loosen during transportation.

NOTE: When installing PTFE diaphragms, it is impor-

tant to tighten outer pistons simultaneously (turning in

opposite directions) to ensure tight fit.

NOTE: Before starting disassembly, mark a line from

each liquid chamber to its corresponding air chamber.

This line will assist in proper alignment during reas-

sembly.

CAUTION: Verify the chemical compatibility of the

process and cleaning fluid to the pump’s component

materials in the Chemical Resistance Guide (see E4).

CAUTION: When removing the end cap using

compressed air, the air valve end cap may come out

with considerable force. Hand protection such as a

padded glove or rag should be used to capture the

end cap.

NOTE: All non lube-free air-operated pumps must

be lubricated. Wilden suggests an arctic 5 weight oil

(ISO grade 15). Do not over-lubricate air supply. Over-

lubrication will reduce pump performance.

Section 1

CAUTIONS—READ FIRST!

2

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

Section 2

PUMP DESIGNATION SYSTEM

MODEL

T1 = 13 MM (1/2”)

WETTED PARTS & OUTER

PISTON

AA = ALUMINUM /

ALUMINUM

AZ = ALUMINUM / NO PISTON

CENTER SECTION

YY = NYLON

AIR VALVE

B = BRASS

DIAPHRAGMS

BNS = BUNA-N (Red Dot)

FSS = SANIFLEX™

[Hytrel®(Cream)]

PUS = POLYURETHANE (Clear)

THU = PTFE W/HIGH-TEMP

BUNA-N BACK-UP

(White)

TNL = PTFE W/NEOPRENE

BACK-UP O-RING,

IPD (White)

TNU = PTFE W/NEOPRENE

BACK-UP (White)

TSU = PTFE W/SANIFLEX™

BACK-UP (White)

VTS = VITON®(White Dot)

WFS = WIL-FLEX™ [Santoprene®

(Orange Dot)]

XBS = CONDUCTIVE BUNA-N

(Two Red Dots)

VALVE BALL

BN = BUNA-N (Red Dot)

FS = SANIFLEX™

[Hytrel® (Cream)]

PU = POLYURETHANE (Brown)

TF = PTFE (White)

VT = VITON®(White Dot)

WF = WIL-FLEX™ [Santoprene®

(Orange Dot)]

VALVE SEAT

A = ALUMINUM

H = ALLOY C

S = STAINLESS STEEL

VT = VITON® (White Dot)

VALVE SEAT O-RING

BN = BUNA-N

FS = SANIFLEX™

[Hytrel® (Cream)]

PU = POLYURETHANE (Brown)

TF = PTFE

WF = WIL-FLEX™ [Santoprene®]

T1 ORIGINAL™

METAL

13 mm (1/2") Pump

Maximum Flow Rate:

54.9 lpm (14.5 gpm)

SPECIALTY CODES

0014 BSPT

MATERIAL CODES

Viton®is a registered trademarks of DuPont Dow Elastomers.

LEGEND

T1 /XXXXX/ XXX / XX /XXX / XXXX

O-RINGS

MODEL VALVE SEAT

VALVE BALLS

DIAPHRAGMS

AIR VALVE

CENTER SECTION

WETTED PARTS & OUTER PISTON

SPECIALTY

CODE

(if applicable)

NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION.

3WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow

pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

FIGURE 1 The air valve directs pres-

surized air to the back side of diaphragm

A. The compressed air is applied directly

to the liquid column separated by elasto-

meric diaphragms. The diaphragm acts

as a separation membrane between the

compressed air and liquid, balancing the

load and removing mechanical stress

from the diaphragm. The compressed

air moves the diaphragm away from the

center block of the pump. The oppo-

site diaphragm is pulled in by the shaft

connected to the pressurized diaphragm.

Diaphragm B is on its suction stroke; air

behind the diaphragm has been forced

out to the atmosphere through the

exhaust port of the pump. The move-

ment of diaphragm B toward the center

block of the pump creates a vacuum

within chamber B. Atmospheric pressure

forces fluid into the inlet manifold forcing

the inlet valve ball off its seat. Liquid is

free to move past the inlet valve ball

and fill the liquid chamber (see shaded

area).

FIGURE 2 When the pressurized

diaphragm, diaphragm A, reaches the

limit of its discharge stroke, the air valve

redirects pressurized air to the back

side of diaphragm B. The pressurized

air forces diaphragm B away from the

center block while pulling diaphragm A

to the center block. Diaphragm B is now

on its discharge stroke. Diaphragm B

forces the inlet valve ball onto its seat

due to the hydraulic forces developed

in the liquid chamber and manifold of

the pump. These same hydraulic forces

lift the discharge valve ball off its seat,

while the opposite discharge valve ball is

forced onto its seat, forcing fluid to flow

through the pump discharge. The move-

ment of diaphragm A toward the center

block of the pump creates a vacuum

within liquid chamber A. Atmospheric

pressure forces fluid into the inlet mani-

fold of the pump. The inlet valve ball is

forced off its seat allowing the fluid being

pumped to fill the liquid chamber.

FIGURE 3 At completion of the stroke,

the air valve again redirects air to the

back side of diaphragm A, which starts

diaphragm B on its exhaust stroke. As

the pump reaches its original starting

point, each diaphragm has gone through

one exhaust and one discharge stroke.

This constitutes one complete pump-

ing cycle. The pump may take several

cycles to completely prime depending on

the conditions of the application.

RIGHT STROKE MID STROKE LEFT STROKE

Section 3

HOW IT WORKS—PUMP DISTRIBUTION SYSTEM

4

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

A

B

C

F

G

H

J

K L

P

13 mm

(1/2”) FNPT

LIQUID DISCHARGE

10 mm

(3/8”) FNPT

AIR EXHAUST

13 mm

(1/2”) FNPT

LIQUID INLET

6 mm

(1/4”) FNPT

AIR INLET

E - ALUM.

D - S.S.

M-ALUM.

N - S.S.

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 28 1.1

B 117 4.6

C 198 7.8

D 203 8.0

E 208 8.2

F 224 8.8

G 175 6.9

H 140 5.5

J 112 4.4

K 84 3.3

L 102 4.0

M 30 1.2

N 30 1.2

P 8 0.3

BSP threads available for liquid inlet and discharge.

Section 4

DIMENSIONAL DRAWING

5WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

Height ...................................224 mm (8.8")

Width ....................................208 mm (8.2")

Depth ....................................178 mm (7.0")

Est. Ship Weight ........

Aluminum 6 kg (13 lbs)

Stainless Steel 9 kg (20 lbs)

Air Inlet .................................... 6 mm (1/4")

Inlet........................................ 13 mm (1/2")

Outlet ..................................... 13 mm (1/2")

Suction Lift ..........................1.22 m Dry (4')

9.14 m Wet (30')

Displacement per

Stroke.........................0.06 l (0.017 gal.)1

Max. Flow Rate........... 54.9 lpm (14.5 gpm)

Max. Size Solids ................. 1.6 mm (1/16")

1Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

(30 psig) head pressure.

Example: To pump 22.7 lpm (6.0 gpm)

against a discharge pressure head of 2.7

bar (40 psig) requires 4 bar (60 psig) and

10.2 Nm3/h (6 scfm) air consumption. (See

dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

Height ...................................224 mm (8.8")

Width ....................................208 mm (8.2")

Depth ....................................178 mm (7.0")

Est. Ship Weight ........

Aluminum 6 kg (13 lbs)

Stainless Steel 9 kg (20 lbs)

Air Inlet .................................... 6 mm (1/4")

Inlet........................................ 13 mm (1/2")

Outlet ..................................... 13 mm (1/2")

Suction Lift ..........................1.52 m Dry (5')

9.45 m Wet (31')

Displacement per

Stroke.........................0.06 l (0.017 gal.)1

Max. Flow Rate........... 54.1 lpm (14.3 gpm)

Max. Size Solids ................. 1.6 mm (1/16")

1Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

(30 psig) head pressure.

Example: To pump 18.9 lpm (5.0 gpm)

against a discharge pressure head of 2.7

bar (40 psig) requires 4 bar (60 psig) and

8.5 Nm3/h (5 scfm) air consumption. (See

dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

Section 5A

PERFORMANCE

T1 METAL

RUBBER-FITTED

[LPM]

Water Discharge Flow Rates

T1 METAL

TPE -FITTED

[LPM]

Water Discharge Flow Rates

6

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

Height ...................................224 mm (8.8")

Width ....................................208 mm (8.2")

Depth ....................................178 mm (7.0")

Est. Ship Weight ........

Aluminum 6 kg (13 lbs)

Stainless Steel 9 kg (20 lbs)

Air Inlet .................................... 6 mm (1/4")

Inlet........................................ 13 mm (1/2")

Outlet ..................................... 13 mm (1/2")

Suction Lift ..........................2.74 m Dry (1')

9.14 m Wet (30')

Displacement per

Stroke.........................0.05 l (0.014 gal.)1

Max. Flow Rate........... 53.0 lpm (14.0 gpm)

Max. Size Solids ................. 1.6 mm (1/16")

1Displacement per stroke was calculated at 4.8

bar (70 psig) air inlet pressure against a 2 bar

(30 psig) head pressure.

Example: To pump 22.7 lpm (6 gpm) against

a discharge pressure head of 2 bar (30 psig)

requires 4 bar (60 psig) and 10.2 Nm3/h (6

scfm) air consumption. (See dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation parameters

will fall in the center of the pump performance curve.

T1 METAL

PTFE-FITTED

[LPM]

Water Discharge Flow Rates

Section 5A

PERFORMANCE

7WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

These vacuum numbers will double when a small amount

of back pressure is placed on the discharge.

T1 METAL SUCTION

LIFT CAPABILITY

Suction lift curves are calibrated for

pumps operating at 305 m (1,000’)

above sea level. This chart is meant

to be a guide only. There are many

variables which can affect your

pump’s operating characteristics.

The number of intake and discharge

elbows, viscosity of pumping fluid,

elevation (atmospheric pressure) and

pipe friction loss all affect the amount

of suction lift your pump will attain.

Section 5B

SUCTION LIFT CURVE

8

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

The Model T1 Metal pump has a 13 mm (1/2") inlet and

13 mm (1/2") outlet and is designed for flows to 54.9 lpm

(14.5 gpm). The T1 Metal pump is manufactured with wetted

parts of aluminum or stainless steel. The center section of the

T1 Metal pump is of nylon construction. The air distribution

system consists of a brass air valve body, aluminum air valve

piston, Buna-N o-rings and a bronze center section bushing.

A variety of diaphragms, valve balls, valve seats, and o-rings

are available to satisfy temperature, chemical compatibility,

abrasion and flex concerns.

The suction pipe size should be at least 13 mm (1/2") diam-

eter or larger if highly viscous material is being pumped. The

suction hose must be non-collapsible, reinforced type as the

T1 is capable of pulling a high vacuum. Discharge piping

should be at least 13 mm (1/2"); larger diameter can be

used to reduce friction losses. It is critical that all fittings and

connections are airtight or a reduction or loss of pump suction

capability will result.

INSTALLATION: Months of careful planning, study, and selec-

tion efforts can result in unsatisfactory pump performance if

installation details are left to chance.

Premature failure and long term dissatisfaction can be avoided

if reasonable care is exercised throughout the installation

process.

LOCATION: Noise, safety, and other logistical factors usually

dictate that “utility” equipment be situated away from the

production floor. Multiple installations with conflicting require-

ments can result in congestion of utility areas, leaving few

choices for siting of additional pumps.

Within the framework of these and other existing conditions,

every pump should be located in such a way that four key factors

are balanced against each other to maximum advantage.

1. ACCESS: First of all, the location should be accessible. If

it’s easy to reach the pump, maintenance personnel will have

an easier time carrying out routine inspections and adjust-

ments. Should major repairs become necessary, ease of

access can play a key role in speeding the repair process and

reducing total downtime.

2. AIR SUPPLY: Every pump location should have an air line

large enough to supply the volume of air necessary to achieve

the desired pumping rate (see pump performance chart). Use

air pressure up to a maximum of 8.6 bar (125 psig) depending

upon pumping requirements. The use of an air filter before the

pump will ensure that the majority of any pipeline contami-

nants will be eliminated. For best results, the pumps should

use an air filter, regulator, and lubricator system.

3. ELEVATION: Selecting a site that is well within the pump’s

suction lift capability will assure that loss-of-prime troubles will

be eliminated. In addition, pump efficiency can be adversely

affected if proper attention is not given to elevation (see pump

performance chart).

4. PIPING: Final determination of the pump site should not be

made until the piping problems of each possible location have

been evaluated. The impact of current and future installations

should be considered ahead of time to make sure that inadver-

tent restrictions are not created for any remaining sites.

The best choice possible will be a site involving the shortest

and the straightest hook-up of suction and discharge piping.

Unnecessary elbows, bends, and fittings should be avoided.

Pipe sizes should be selected so as to keep friction losses

within practical limits. All piping should be supported indepen-

dently of the pump. In addition, it should line up without plac-

ing stress on the pump fittings.

Expansion joints can be installed to aid in absorbing the forces

created by the natural reciprocating action of the pump. If the

pump is to be bolted down to a solid foundation, a mount-

ing pad placed between the pump and foundation will assist

in minimizing pump vibration. Flexible connections between

the pump and rigid piping will also assist in minimizing pump

vibration. If quick-closing valves are installed at any point in the

discharge system, or if pulsation within a system becomes a

problem, a surge suppressor should be installed to protect the

pump, piping and gauges from surges and water hammer.

When pumps are installed in applications involving flooded

suction or suction head pressures, a gate valve should be

installed in the suction line to permit closing of the line for

pump service.

The T1 can be used in submersible applications only when both

wetted and non-wetted portions are compatible with the mate-

rial being pumped. If the pump is to be used in a submersible

application, a hose should be attached to the pump’s air exhaust

and the exhaust air piped above the liquid level.

If the pump is to be used in a self-priming application, be sure

that all connections are airtight and that the suction lift is within

the pump’s ability. Note: Materials of construction and elasto-

mer material have an effect on suction lift parameters. Please

refer to pump performance data.

Pumps in service with a positive suction head are most effi-

cient when inlet pressure is limited to 0.5–0.7 bar (7–10 psig).

Premature diaphragm failure may occur if positive suction is

0.8 bar (11 psig) and higher.

THE MODEL T1 WILL PASS 1.6 mm (1/16") SOLIDS. WHEN-

EVER THE POSSIBILITY EXISTS THAT LARGER SOLID

OBJECTS MAY BE SUCKED INTO THE PUMP, A STRAINER

SHOULD BE USED ON THE SUCTION LINE.

CAUTION: DO NOT EXCEED 8.6 BAR (125 PSIG) AIR

SUPPLY PRESSURE.

BLOW OUT AIR LINE FOR 10 TO 20 SECONDS BEFORE

ATTACHING TO PUMP TO MAKE SURE ALL PIPE LINE

DEBRIS IS CLEAR. ALWAYS USE AN IN-LINE AIR

FILTER.

PUMPS SHOULD BE THOROUGHLY FLUSHED WITH

WATER BEFORE INSTALLING INTO PROCESS LINES.

FDA AND USDA PUMPS SHOULD BE CLEANED AND/OR

SANITIZED BEFORE USE ON EDIBLE PRODUCTS.

Section 6

SUGGESTED INSTALLATION

9WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

OPERATION: Pump discharge rate can be controlled by

limiting the volume and/or pressure of the air supply to the

pump (preferred method). A regulator is used to regulate air

pressure. A needle valve is used to regulate air volume. Pump

discharge rate can also be controlled by throttling the pump

discharge by partially closing a valve in the discharge line of

the pump. This action increases friction loss which reduces

flow rate. This is useful when the need exists to control the

pump from a remote location. When the pump discharge

pressure equals or exceeds the air supply pressure, the

pump will stop; no bypass or pressure relief valve is needed,

and pump damage will not occur. The pump has reached a

“deadhead” situation and can be restarted by reducing the

fluid discharge pressure or increasing the air inlet pressure.

The Wilden T1 pump runs solely on compressed air and does

not generate heat, therefore your process fluid temperature

will not be affected.

RECORDS: When service is required, a record should be

made of all necessary repairs and replacements. Over a

period of time, such records can become a valuable tool for

predicting and preventing future maintenance problems and

unscheduled downtime. In addition, accurate records make

it possible to identify pumps that are poorly suited to their

applications.

MAINTENANCE AND INSPECTIONS: Since each applica-

tion is unique, maintenance schedules may be different for

every pump. Frequency of use, line pressure, viscosity and

abrasiveness of process fluid all affect the parts life of a

Wilden pump. Periodic inspections have been found to offer

the best means for preventing unscheduled pump downtime.

Personnel familiar with the pump’s construction and service

should be informed of any abnormalities that are detected

during operation.

NOTE: In the event of a power failure, the shutoff

valve should be closed, if the restarting of the pump

is not desirable once power is regained.

AIR OPERATED PUMPS: To stop the pump from

operating in an emergency situation, simply close the “shut-off” valve

(user supplied) installed in the air supply line. A properly functioning valve

will stop the air supply to the pump, therefore stopping output. This shut-

off valve should be located far enough away from the pumping equipment

such that it can be reached safely in an emergency situation.

®

Section 5A

SUGGESTED INSTALLATION

SUGGESTED OPERATION & MAINTENANCE

10

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

Pump will not run or runs slowly.

1. Check air inlet screen and air filter for debris.

2. Check for sticking air valve, flush air valve in solvent.

3. Check for worn out air valve. If piston face in air valve is

shiny instead of dull, air valve is probably worn beyond

working tolerances and must be replaced.

4. Check center block o-rings. If worn excessively, they will

not seal and air will simply flow through pump and out air

exhaust. Use only Wilden o-rings as they are of special

construction and ISO 15-5 wt oil with arctic characteris-

tics.

5. Check for rotating piston in air valve.

6. Check for over-torquing of air valve (lube-free only). Over-

torquing may cause air valve piston to stick.

Pump runs but little or no product flows.

1. Check for pump cavitation; slow pump speed down to

match thickness of material being pumped.

2. Check for sticking ball check valves. If material being

pumped is not compatible with pump elastomers, swelling

may occur. Replace ball check valves and o-ring with the

proper elastomers.

3. Check to make sure all suction connections are air tight,

especially clamp bands around intake balls.

Pump air valve freezes.

1. Check for excessive moisture in compressed air. Either

install dryer or hot air generator for compressed air.

Air bubbles in pump discharge.

1. Check for ruptured diaphragm.

2. Check tightness of clamp bands, and the integrity of the

o-rings, especially at intake manifold.

Product comes out air exhaust.

1. Check for diaphragm rupture.

2. Check tightness of piston plates to shaft.

Pump rattles.

1. See E9 Troubleshooting Guide.

2. Create false discharge head or suction lift.

Section 6

TROUBLESHOOTING

11 WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

Figure 1

Step 2. Figure 2

Utilizing the 3/8" box wrench, start by removing the four long

carriage bolts that hold the top and bottom manifolds to the

center section.

Step 3. Figure 3

Remove the top manifold and lift the center section off the

inlet manifold.

CAUTION: Before any maintenance or repair is attempted,

the compressed air line to the pump should be discon-

nected and all air pressure allowed to bleed from the pump.

Disconnect all intake, discharge, and air lines. Drain the

pump by turning it upside down and allowing any fluid to

flow into a suitable container. Be aware of any hazardous

effects of contact with your process fluid.

The Wilden model T1 has a 13 mm (1/2") inlet and outlet

and is designed for flows up to 54.9 lpm (14.5 gpm). The

single-piece center section, consisting of center block and

air chambers, is molded of nylon. All fasteners and hardware

are stainless steel and the air valve is manufactured of brass

or high-tech engineered thermoplastic. All o-rings used in the

pump are of a special material and shore hardness which

should only be replaced with factory-supplied parts.

TOOLS REQUIRED:

5/16" Wrench

3/8" Box Wrench

7/16" Wrench

3/16" Allen Wrench

Adjustable Wrench

Vise equipped with soft jaws (such as plywood, plastic

or other suitable material)

NOTE: The model used for these instructions incorporates

rubber diaphragms, balls, and seats. Models with Teflon®

diaphragms, balls and seats are the same except where

noted.

DISASSEMBLY:

Step 1.

Before starting disassembly, mark a line from each liquid

chamber to its corresponding air chamber. This line will assist

in proper alignment during reassembly.

Section 7

PUMP DISASSEMBLY

12

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

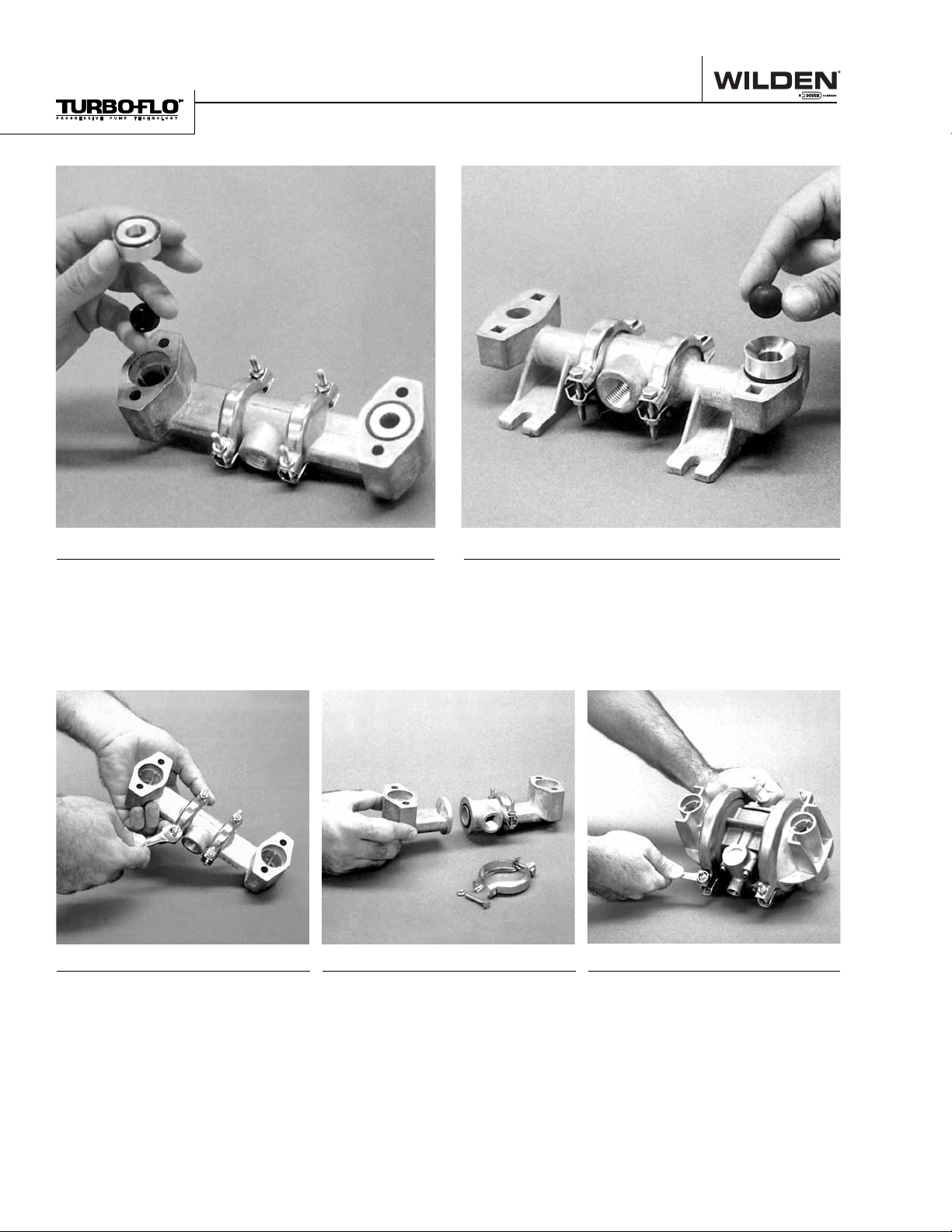

Step 4. Figure 4 Step 5. Figure 5

Step 6. Figure 6 Step 7. Figure 7 Step 8. Figure 8

Section 6

PUMP DISASSEMBLY

Remove the discharge valve balls, seats and o-rings

from the discharge manifold and inspect for nicks,

gouges, chemical attack or abrasive wear. Replace

worn parts with genuine Wilden parts for reliable

performance. PTFE o-rings should be replaced when

reassembled.

Inspect the ball retainer, retainer o-ring, and valve

ball from intake manifold. Check for nicks, gouges,

chemical attack or abrasive wear. Replace worn parts

with genuine Wilden parts for reliable performance.

PTFE o-rings should be replaced when reassembled.

Normally the inlet and discharge

manifoldshouldnotbedisassembled

during regular pump maintenance.

Should this be necessary completely

remove and disassemble manifold

clamp bands.

Inspect o-rings for wear or damage

and replace if necessary. PTFE

o-rings should be replaced when

reassembled.

Use a 7/16" wrench to remove one

set of clamp bands that secure one

liquid chamber to the one-piece

center section

13 WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

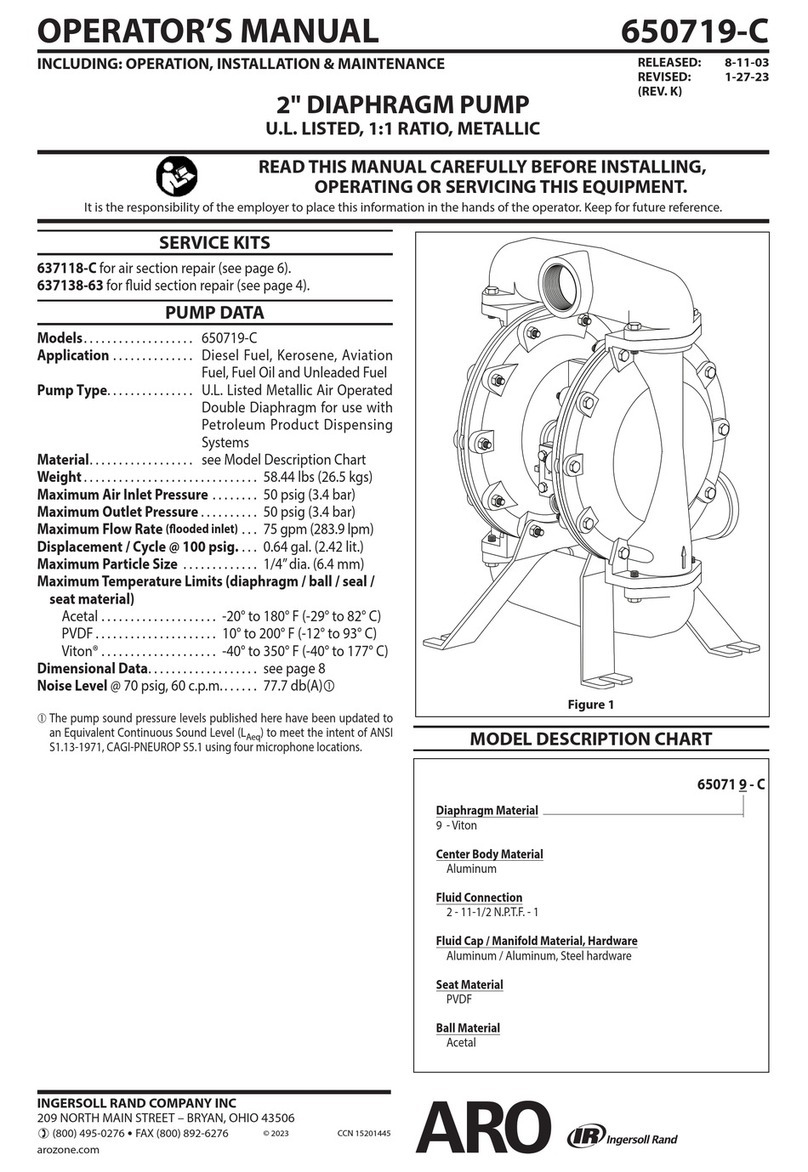

Step 9. Figure 9 Step 10. Figure 10

Step 11A. Figure 11A Step 11B. Figure 11B Step 12. Figure 12

Section 6

PUMP DISASSEMBLY

Lift the liquid chamber away from the center section to

expose the diaphragm and outer piston.

Using an adjustable wrench, or by rotating the

diaphragm by hand, remove the diaphragm assembly

from the center section.

NOTE: Due to varying torque values,

one of the following two situations

may occur: 1) The outer piston,

diaphragm and inner piston remain

attached to the shaft and the entire

assembly can be removed from the

center section.

2)The outer piston, diaphragm, inner

piston, and disc spring separate from

the shaft which remains connected

to the opposite side diaphragm

assembly. PTFE-fitted pumps come

standard with back-up diaphragms

(not shown).

To remove the diaphragm assembly

from the shaft, secure shaft with soft

jaws (a vise fitted with plywood or

other suitable material) to ensure

shaft is not nicked, scratched, or

gouged.Using an adjustable wrench,

remove diaphragm assembly from

shaft.Inspect all parts for wear and

replace with genuine Wilden parts if

necessary.

14

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

The center section assembly consists of both the air valve

body and piston and the center section. The unique design

of the air valve relies only on differential pressure to cause

the air valve to shift. It is reliable and simple to maintain. The

bushing in the center block, along with the diaphragm shaft,

provides the signal to tell the air valve to shift. The following

procedure will ensure that the air valve on your Wilden pump

will provide long trouble-free service. valve piston does not move freely after the above cleaning, the

air valve should be disassembled as follows: Remove the snap

ring from the top end of the air valve cylinder and apply an air jet

to the 3.175mm (1/8”) hole on the opposite end of the air valve

face. [CAUTION: The air valve end cap (P/N 01-2330-23 may

come out with considerable force. Hand protection such as a

padded glove or a rag should be used to capture the end cap.]

Inspect the piston and cylinder bore for nicks and scoring.

Inspect the air valve side of the center section for flatness

and to insure no nicks or other damage exists that would

prevent the air valve from sealing when installed. Inspect the

two channels and their ports to make sure they are clean and

the ports are open to the bushing. The air valve will not shift if

these ports are plugged or an o-ring is in the wrong groove of

the center section closing off a port. Inspect the anti-centering

pin holes found at the ends of the air valve piston and ensure

they are free of debris. Inspect the air valve gasket and muffler

plate gasket and replace if damaged. Attach the air valve

to the center section and tighten to the required torque

specifications*.

AIR VALVE BODY AND PISTON

ASSEMBLY AND DISASSEMBLY

The air valve body and piston (P/N 01-2000-07) can be

disconnected from the pump by removing the four socket-

head cap screws which attach it to the center section. The

piston in the air valve is aluminum with a dark gray anodized

coating. The piston should move freely and the ports in the

piston should line up with the ports on the face of the air valve

body. The piston should also appear to be a dull, dark gray

color. If the piston appears to be a shiny aluminum color, the

air valve is probably worn beyond working tolerances and

should be replaced.

If the piston does not move freely in the air valve, the entire air

valve should be immersed in a cleaning solution. (NOTE: Do

not force the piston by inserting a metal object.) This soaking

should remove any accumulation of sludge and grit which is

preventing the air valve piston from moving freely. If the air

The pump’s center section consists of a molded housing with

a bronze bushing. (Bushing is not removable.) This bushing

has grooves cut into the inside diameter. o-rings are installed

in these grooves. When the o-rings become worn or flat, they

will no longer seal and must be replaced. This is most easily

accomplished by using a tool called an o-ring pick, available

through most industrial supply companies.

There are two versions of center sections: PRE-ENHANCED

(pumps manufactured before March 1, 1992) and ENHANCED

(pumps manufactured since March 1, 1992). An encircled

letter “E” stamped on the top of the center section denotes

the ENHANCED type center section (Figure C).

If the encircled “E” is not present, a pre-enhanced shaft

(01-3800-09) must be utilized. An enhanced (non-dented)

shaft will not function correctly in the pre-enhanced center

section. The center section o-rings (01-3200-52) must be

installed in the appropriate grooves as shown (1, 3, 4, 6).

If the encircled “E” is present, an enhanced (01-3800-

03-07) shaft should be utilized to maximize performance. The

center section o-rings (01-3200-52) must be installed in the

appropriate grooves as shown (1, 3, 6, 8).

Figure A

1 3 6 8

ENHANCED CONFIGURATION

ENHANCED SHAFT

1 3 4 6

PRE-ENHANCED CONFIGURATION

PRE-ENHANCED SHAFT

Figure C

*Refer to Section 8D for the required torque specifications.

Section 6

AIR VALVE / CENTER SECTION REPAIR/MAINT.

O-RING REPLACEMENT/CENTER SECTION

15 WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

ASSEMBLY:

Upon performing applicable maintenance to the air distribution

system, the pump can now be reassembled. Please refer to

the disassembly instructions for photos and parts placement.

To reassemble the pump, follow the disassembly instructions in

reverse order. The air distribution system needs to be assem-

bled first, then the diaphragms and finally the wetted path.

Please find the applicable torque specifications on this page.

The following tips will assist in the assembly process.

• Clean the inside of the center section shaft bushing to

ensure no damage is done to new seals.

• Stainless bolts should be lubed to reduce the possibility of

seizing during tightening.

• Level the water chamber side of the intake/discharge mani-

fold to ensure a proper sealing surface. This is most easily

accomplished by placing them on a flat surface prior to

tightening their clamp bands to the desired torque (see this

page for torque specs).

• Be sure to tighten outer pistons simultaneously on PTFE-

fitted pumps to ensure proper torque values.

• Ensure proper mating of liquid chambers to manifolds prior

to tightening vertical bolts. Overhang should be equal on

both sides.

• Apply a small amount of Loctite 242 to the steel bore of the

shaft from the diaphragm assembly.

MAXIMUM TORQUE SPECIFICATIONS

Description of Part Metal Pumps

Air Valve 2.3 N•m (20 in-lbs)

Outer Piston 14.1 N•m (125 in-lbs)

Small Clamp Band 1.7 N•m (15 in-lbs)

Large Clamp Band (Rubber-Fitted) 7.4 N•m (65 in-lbs)

Large Clamp Band (Teflon®-Fitted) 9.6 N•m (85 in-lbs)

Vertical Bolts 14.1 N•m (125 in-lbs)

Section 6

REASSEMBLY HINTS & TIPS

16

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

Section 8

EXPLODED VIEW & PARTS LISTING

T1 METAL Rubber/TPE-Fitted EXPLODED VIEW

17 WILDEN PUMP & ENGINEERING, LLCWIL-10190-E-03

Rubber-Fitted

Item Part Description

Qty. Per

Pump

T1/AAYYB

P/N

T1/SSYYB

P/N

1 Air Valve Assembly11 01-2000-07 01-2000-07

2 Center Section 1 01-3153-23 01-3153-23

3 Center Block Glyd™ Ring 4 01-3220-55 01-3220-55

4 Shaft 1 01-3800-03-07 01-3800-03-07

5 Pistons/Outer 2 01-4570-01 01-4570-03

6 Pistons/Inner 2 01-3710-01 01-3710-01

7 Air Valve Gasket 1 01-2600-52 01-2600-52

8 Muffler Plate Gasket 1 01-3500-52 01-3500-52

9 Muffler Plate 1 01-3180-23 01-3180-23

10 End Cap w/Guide 1 01-2300-23 01-2300-23

11 End Cap w/o Guide 1 01-2330-23 01-2330-23

12 Buna-N O-Ring - 115 70 Shore 2 01-2390-52 01-2390-52

13 End Cap Snap Ring 2 01-2650-03 01-2650-03

14 Air Valve Cap Screw 1/4"-20 x 4-1/2" 4 01-6000-03 01-6000-03

15 Air Valve Cap Screw Nut 1⁄4"-20 4 04-6400-03 04-6400-03

16 Liquid Chamber 2 01-5000-01 01-5000-03

17 Discharge Manifold Elbow 2 01-5230-01 01-5230-03

18 Inlet Manifold Elbow 2 01-5220-01 01-5220-03

19 Manifold “T” Section 2 01-5160-01 01-5160-03

20 Clamp Band (Large) Assy. 2 01-7300-03 01-7300-03

21 Clamp Band (Small) Assy. 4 01-7100-03 01-7100-03

22 Vertical Bolt 1/4"-20 x 7-3/8" 4 01-6080-03 01-6080-03

23 Muffler 1 01-3510-99 01-3510-99

24 Diaphragm 2 * *

25 Valve Ball 4 * *

26 Valve Seat 4 01-1120-01 01-1120-03

27 Valve Seat O-Ring 4 * *

28 Manifold O-Ring 4 * *

29 Small Clamp Band Bolt #10-24 x 1" 8 01-6101-03 01-6101-03

30 Small Clamp Band Nut #10-24 8 01-6400-03 01-6400-03

31 Large Clamp Band Bolt 1/4"-20 x 1-3/4" 4 01-6070-03 01-6070-03

32 Large Clamp Band Nut 1/4"-20 4 04-6400-03 04-6400-03

33 Shaft Stud 2 N/A 01-6150-03

34 Vertical Bolt Nut 1/4"-20 4 04-6400-03 04-6400-03

35 Vertical Bolt Washer 4 01-6730-03 01-6730-03

36 Disc Spring 2 01-6802-08 01-6802-08

1Air Valve Assembly includes items 10, 11, 12, 13.

*Refer to corresponding elastomer chart in Section 9.

All boldface items are primary wear parts.

T1 METAL Rubber/TPE-Fitted PARTS LISTING

Section 6

EXPLODED VIEW & PARTS LISTING

18

WILDEN PUMP & ENGINEERING, LLC WIL-10190-E-03

NOTE: PTFE Diaphragm Models Assembled with

PTFE Gasket Kit At Factory (Not Shown)

Section 8

EXPLODED VIEW & PARTS LISTING

T1 METAL PTFE-Fitted EXPLODED VIEW

Table of contents

Other EOM Water Pump manuals

Popular Water Pump manuals by other brands

Ingersoll-Rand

Ingersoll-Rand ARO 650719-C Operator's manual

Maruyama

Maruyama MP2530CE Operator's manual

Mistral

Mistral MSP 12 A1 Translation of the original instructions

Pentair Jung Pumpen

Pentair Jung Pumpen Multistream 10/2 A1 instruction manual

BBC Elettropompe

BBC Elettropompe QM PT 7 instruction manual

AERMEC

AERMEC SAP 1500 manual

F.P.Z.

F.P.Z. VS6 Use instruction

Harvest Healthcare

Harvest Healthcare HARVEST 1 General User/ Safety Guide

Gardner Denver

Gardner Denver Wittig RFW 150 DV Operating and service manual

Wilo

Wilo Wilo-Drain TS 40/12 Installation and operating instructions

Biral

Biral EBZ-V manual

Masterflex

Masterflex MASTERSENSE MFLX07526-10 operating manual