ePropulsion MPPT096020G User manual

2023.07 Version 1.0

Copyright © 2023 ePropulsion. All Rights Reserved

G Battery Solar Charge MPPT

controller 2

kW User Manual

Model: MPPT096020G

1

Acknowledgement

Thanks for choosing ePropulsion products, your trust and support in our company are sincerely

appreciated. We are dedicated to providing high-performance electric outboards, electric

inboards, sup/kayak motors, reliable lithium batteries and accessories.

Welcome to visit www.epropulsion.com and contact us if you have any concerns.

Using This Manual

Before use of the product, please read this user manual thoroughly to understand the correct

and safe operations. By using this product, you hereby agree that you have fully read and

understood all contents of this manual. ePropulsion accepts no liability for any damage or injury

caused by operations that contradict this manual.

Due to ongoing optimization of our products, ePropulsion reserves the rights of constantly

adjusting the contents described in the manual. ePropulsion also reserves the intellectual

property rights and industrial property rights including copyrights, patents, logos and designs,

etc.

This manual is subject to update without prior notice, please visit our website www.ePropulsion.

com for the latest version. If you find any discrepancy between your products and this manual,

or should you have any doubts concerning the product or the manual, please visit www.

ePropulsion.com.

ePropulsion reserves the rights of final interpretation of this manual.

This manual is multilingual, in case of any discrepancy in the interpretation of different language

versions, the English version shall prevail.

Symbols

ePropulsion considers safety of great importance and recommends that anyone that comes

into close contact with its products, such as those who install, operate, maintain or service

ePropulsion products, exercise care, common sense and comply with the safety information in

this manual and on the machine’s safety decals.

The following are the relevant information marks in the user manual or the product labels:

Hazardous or warning signs indicate a potentially hazardous or hazardous situation which, if not

avoided, will result in death or serious injury. Special attention and attention should be paid to

the safety of you or the products involved.

Important warning:

Tips or important informations help quickly grasp the use of the product and improve effic

iency. Please read and follow the instructions following the safety warning signs.

2

Caution:

When installing, operating, maintaining or serving ePropulsion products, there are many safety

risks in the process. You need to be alert, perform relevant operations reasonably, and pay

attention to safety.

Electric shock hazard:

The areas or equipment may be at risk of electric shock. The equipment uses 102.4V DC power.

When operating electricity-related electrical connectors, switches, cables and other electricity-

related items, power off the system to prevent electric shock.

90mm

86mm

60mm

56mm

13mm

OO

OO

OO

OO

OO

3

Table of Contents

Acknowledgement.................................................................................................. 1

Using This Manual.................................................................................................. 1

Symbols ................................................................................................................. 1

1 Product Overview ................................................................................................ 4

1.1 Product list .............................................................................................................4

1.2 Parts and Diagram.................................................................................................6

1.3 Specifications ........................................................................................................7

1.4 Dimensions ............................................................................................................8

1.5 Reference Table for Number of PV Modules in Series ........................................8

1.6 Port Pin Definitions................................................................................................9

1.6.1 6P Connector Definitions............................................................................9

1.6.2 Solar Panel Connector Definitions .......................................................... 10

1.6.3 Battery Connector Definitions ................................................................. 10

1.6.4 Temperature Cable Definitions................................................................ 11

1.6.5 485essA box Definitions ......................................................................... 12

1.6.6 CAN cable and T-Terminal Definitions..................................................... 12

1.7 Protection............................................................................................................ 13

2 Installation ........................................................................................................ 14

2.1 Note before Installation...................................................................................... 14

2.2 Installation........................................................................................................... 14

3 Operation........................................................................................................... 19

4 Troubleshooting ................................................................................................ 20

5 Warranty............................................................................................................ 21

5.1 Out of Warranty .................................................................................................. 22

5.2 Limited Warranty Claim Procedures.................................................................. 23

6 Statement.......................................................................................................... 24

4

1 Product Overview

This product can real-time detect the power generation of the solar panel and track the maxi-

mum voltage-current value to achieve the maximum power output for charging the battery. It is

designed for off-grid photovoltaic systems and serves as the core control component that coor-

dinates the operation of the solar panel, battery, and devices in off-grid photovoltaic systems.

1.1 Product list

Items Qty. Figure Function

MPPT controller 1

Used to coordinate the

operation of solar panels

and batteries, allowing

solar panels to charge

batteries at maximum

power output

6P Connector (RJ45

Communication

Terminal)

1See Figure 1-3 Used for communication

connection

Temperature Cable 1Used for temperature

data collection

Solar Panel

Connector (Male

and Female)

1 See Figure 1-4

Used to connect solar

panels, providing power

to the MPPT controller

(already installed on the

MPPT controller)

Battery Connector

(Female) 1 See Figure 1-5

Used to connect the

battery, providing power

to the battery (already

installed on the MPPT

controller)

Mounting Bracket 2

Used to fix MPPT

controller on the boat

wall

M4 Countersunk

Screws 4 M4X4

Used to fix the mounting

bracket on the MPPT

controller

Plastic Expansion

Granules 4 / Used to fix self-tapping

screws

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

5

Items Qty. Figure Function

M4 Self-tapping

Screws 4 M5x20 Used to fix mounting

bracket on the boat wall

Hexagonal Column

Head Triple

Combination Bolts

4 M4X22 Used to fix mounting

bracket on the boat wall

Hexagonal Nuts 4 M4 Used to fix bolts

485essA box 1 Connect to 6P Connector

CAN cable 1 Connect to T-Terminal

T-Terminal 1 Connect to CAN bus

User Manual 1 / /

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

6

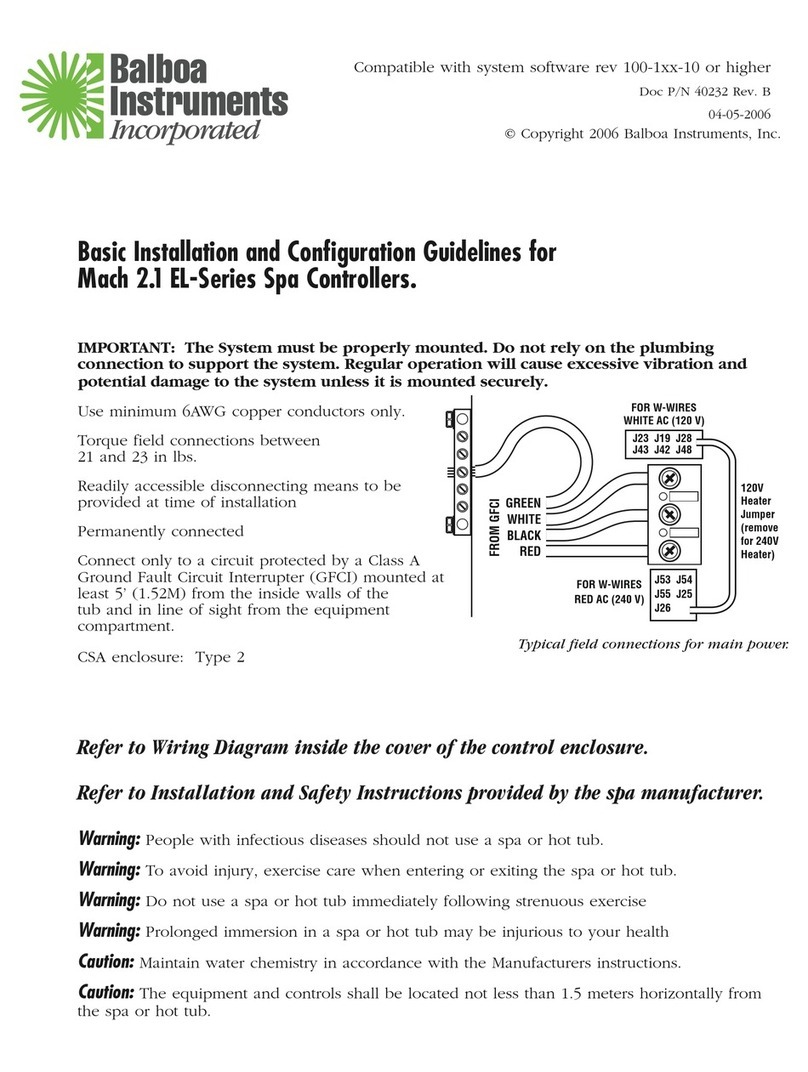

1.2 Parts and Diagram

No. Name No. Name

1Indicator 6 Output Power Cable

2RJ45 Serial Communication

Interface 7Mounting Holes for Installation

Accessories

3Temperature Sensor Line Interface 8 Heat Sink

4 Earth Connection Point 9 /

5 Input Power Cable 10 /

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

Figure 1-1

7

1.3 Specifications

Model MPPT096020G

Electrical Parameters

Voltage Platform 96Vdc

Output Voltage Range 72Vdc - 120Vdc

Voltage Deviation < +/- 0.2 V

Maximum Charging Current 20 A

Photovoltaic voltage input range 140Vdc-250Vdc

Rated Input Power** 2080 W

Standby Power Consumption <1.8 W

Conversion Efficiency (Peak) 98%

Structural Parameters

Product Size 290x220x90mm

Package Size 391x331x205mm

Net Weight (kg) ≈4.3

Environment

Operating Temperature -20℃- 55℃

Storage Temperature -40℃- 70℃

Humidity 10%rh - 95%rh

IP Protection Level IP65

The photovoltaic array voltage must not exceed this limit.

These power limits refer to the maximum power that the MPPT controller can handle. High

power arrays can be used without damaging the MPPT controller.

8

1.4 Dimensions

1.5 Reference Table for Number of PV Modules in Series

Voc * N = PV Input <250Vdc

Individual PV

Module Voltage

Level

Voc<23V Voc<31V Voc<34V Voc<38V Voc<46V Voc<62V

Max Best Max Best Max Best Max Best Max Best Max Best

Number of

Modules in Series

N

10 98776655443

N: N in the table represents the number of PV modules in series, and the data is for

reference only.

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

Figure 1-2

9

1.6 Port Pin Definitions

1.6.1 6P Connector Definitions

No. Specification Definition

1 N/A N/A

222AWG 485A

3 N/A N/A

422AWG 485B

5 N/A N/A

6 N/A N/A

Note:

Before connecting, distinguish between the network cable connector and the 6PIN connector.

The network cable connector is used to connect to the MPPT controller's No.2 interface

(RJ45 Serial Communication Interface), and the 6PIN connector is used to connect to the 485

interface of the MPPT controller.

Figure 1-3

10

1.6.2 Solar Panel Connector Definitions

Solar Panel Terminal

No. Specification Definition

111AWG Positive (+)

211AWG Negative (-)

1.6.3 Battery Connector Definitions

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

B AT + B AT -

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

B AT + B AT -

Figure 1-4

Figure 1-5

11

Battery Output Terminal

No. Specification Definition

BAT+ 11AWG Positive (+)

BAT- 11AWG Negative (-)

1.6.4 Temperature Cable Definitions

The temperature line ’s Port 2 is connected to the Temp Sensor of the MPPT controller , and

Port 1 is used to collect the ambient temperature of the battery .If the battery itself has

temperature detection(such as the G102 battery),this line can be optional installed.

Figure 1-7

Figure 1-6

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

12

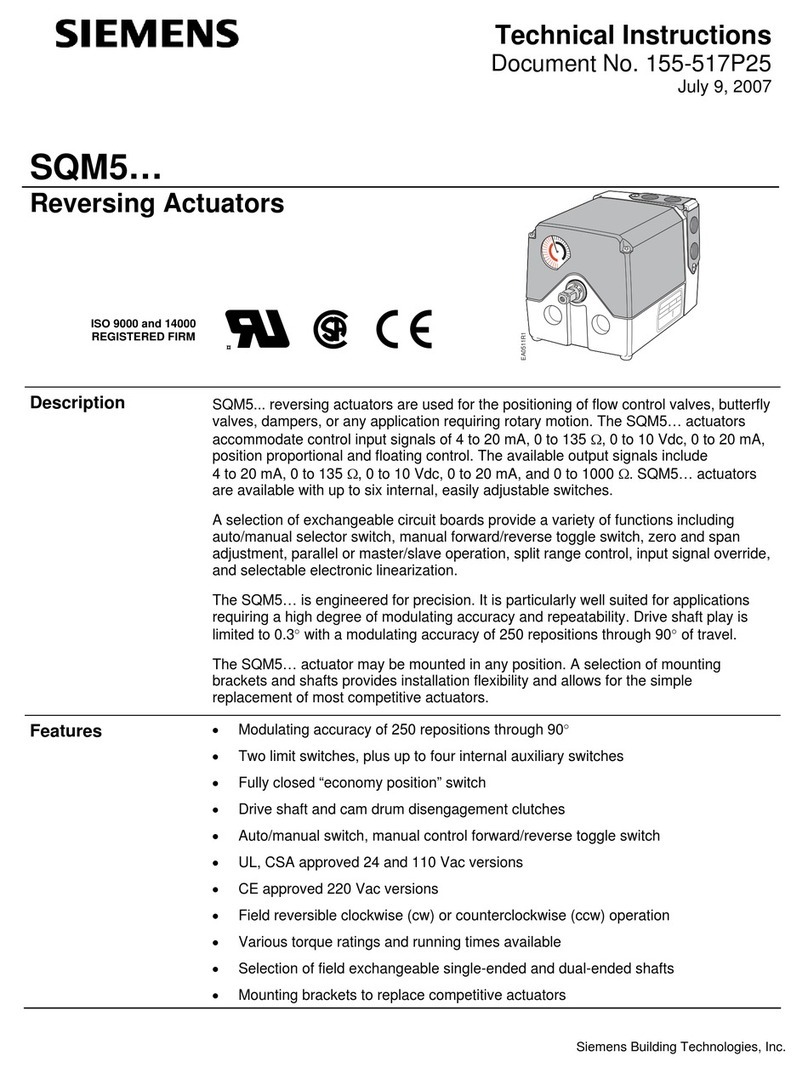

1.6.5 485essA box Definitions

The 485essA module has 4 interfaces, and interfaces 1, 2, and 3 can all be used to connect the

6P Connector, while interface 4 is connected to the A end of the CAN cable.

Figure 1-9

1.6.6 CAN cable and T-Terminal Definitions

The A end of the CAN cable is connected to interface 4 of the 485essA box (refer to Figure 1-9).

Figure 1-10

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

滚滚长江东逝水

1、When installing one 485 essA box, the number of the MPPT contorller is as

shown in Figure1-9;

2、When two 485 essA boxes are installed, the 485 essA box with the smaller last four digits is

numbered 1 to 3, and larger last four digits is numbered 4 to 6 (in parentheses).

essA

(4)

(6) (5)

CAN

1

23

Last Four Digits

13

When there is only one 485essA box, interface 3 of the T-Terminal (refer to Figure 1-9) is

connected to the B end of the CAN cable and interface 1 is connected to the CAN bus.

When there are two or more 485essA boxes, the interface 3 and interface 1 of the two T-Terminals

are connected to each other, and then connected to the B end of the CAN cable and the CAN

bus.

1.7 Protection

Reverse Connection Protection - Protects against

positive and negative polarity reversal at the

battery and photovoltaic array terminals.

Photovoltaic Array Short Circuit

Protection

Internal Overtemperature Protection - Reduces

power operation Heatsink Temperature Limit

Battery Overvoltage Protection Battery Disconnection

Protection

Figure 1-11

I/X-CAN-T TO

CAN device

7

8

1

2

5

4

3

6

A

7

8

1

2

5

4

3

6

B

B

A

A

BAT+

BAT-

1

2

1

2

1

2 3

4

滚滚长江东逝水

14

2 Installation

2.1 Note before Installation

Installation Position:

炴Install the MPPT controller in a dry, well-ventilated location that allows for easy disassembly

and maintenance.

炴Do not install on flammable building materials; do not install on highly flammable

materials; do not install in hazardous areas with explosion risks.

炴Avoid exposure to harsh environments, such as high humidity, flammable and explosive

areas, or places with excessive dust accumulation.

炴Do not install the MPPT controller in enclosures with open or liquid-filled batteries.

炴The heat sink of the MPPT controller may reach temperatures exceeding 40 煓during

operation, so install the MPPT controller in a place where it is not easily touched.

炴Ensure adequate ventilation when installing the MPPT controller inside an enclosure.

Installing it in a sealed enclosure may cause overheating, reduced power operation, and

shortened product lifespan.

Safety Information:

炴Use insulated tools during installation.

炴Disconnect all power sources to the MPPT controller before installing or adjusting the

MPPT.

炴Do not operate or install the MPPT controller alone. Please ask nearby people for

assistance in case of an accident.

炴The MPPT controller must be installed by qualified technicians or personnel trained in safe

installation practices according to the electrical regulations of the respective country.

Proper Use:

炴This MPPT controller is designed solely for solar power generation. Connecting it to any

other power sources, such as wind turbines or generators, may void the warranty.

炴There are no user-serviceable parts inside the MPPT. Do not disassemble or attempt to

repair the MPPT controller.

炴A disconnect or isolation device must be available for safely and conveniently disconnecting

the MPPT from the system.

15

2.2 Installation

Step 1: Unpack and Check

Check the MPPT controller for any transportation damage or impact and ensure the

specifications match the order.

Step 2: Check MPPT controller Parameter Limits

Ensure that, under maximum temperature compensation, the open-circuit voltage (Voc) of the

solar panel array does not exceed the rated voltage of the MPPT (refer to chapter 1.5 for details).

Multiple MPPT controllers can be installed in parallel on the same battery bank to obtain higher

charging current. Each parallel MPPT must be connected to an independent solar panel.

Step 3: Determine Installation Space

To ensure air circulation, leave at least 15 cm (6 inches) of space above and below the MPPT

controller and 10 cm (3.97 inches) on the sides. Do not install the MPPT controller inside a

closed enclosure.

Note: The rear heat sink must be installed in a vertical direction (allowing for vertical

airflow).

Step 4: Assemble and Install Mounting Bracket

Align the mounting bracket with the accessory mounting holes on the MPPT controller and

secure them using M4 countersunk screws.

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fuse breaker / fuse

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fuse

breaker / fus e terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fuse

breaker / fus e terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / f use breaker / f use

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / f use breaker / f use

terminal terminal

PV

BAT

Solar panel

BAT

breaker / f use

breaker / fuse terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / f use

breaker / fuse terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

Figure 2-2

Figure 2-1

16

Step 5: Drill Mounting Holes on the Installation Position

Measure and mark the distance on the installation position, drill four 6mm diameter holes (if

using composite material bulkheads, insert plastic expansion particles into the holes).

Step 6: Secure the MPPT Controller to the Installation Position

Align the MPPT controller's mounting holes with the holes created in Step 5 and secure the

MPPT controller to the installation position using M4 self-tapping screws or M4 bolts, then

tighten the screws.

Step 7: Connect the Cables

1瀭

Before connecting, distinguish between input and output wires (see 1.2 Parts and

Diagrams). The wire core definition is as follows: Red wire core is positive (+), and black

wire core is negative (-).

2瀭

Install a circuit breaker or fuse with a rating equal to or greater than the charging current

between the cables at No. 滦and 滧, and keep it in the OFF state.

3瀭

Connect the terminals at No. 滨and 滩according to the corresponding positive and

negative positions (see 1.6.2 Battery Connector Definitions).

4瀭

Connect the RJ45 communication cable and temperature sensor at No. 滪(see 1.6.1 6P

Connector Definitions).

This MPPT controller can prevent reverse current leakage at night, so there is no need

to add diodes in the system.

Avoid connecting the photovoltaic input to the MPPT controller's output power cable to

prevent damage to the MPPT controller's internal circuitry and invalidate the warranty.

The installation must comply with electrical specifications. Select appropriate specifications

for circuit breakers and fuses based on application requirements.

Ensure secure and stable connections, use cable clamps to secure cables to prevent

movement in mobile applications, and maintain tight connections to avoid overheating due to

loose connections.

There is a risk of electric shock. Before connecting, test the impedance between all terminal

connections and ground.

1

23

4

56

8

77

5

6

2

6in(15cm)

6in(15cm)

4in

(10cm)

Red(PV+)

Blue(PV-)

Red(BAT+)

Blue(BAT-)

breaker / fuse breaker / fuse

PV BAT

Solar panel

220濠Öî澱溨潻溦溦濡

290濠Öî潽溡溡潻溤溡濡 290濠Öî潽溡溡潻溤溡濡

溣溨溠濠in:15濡

30MM 205MM

⛈ㄉⴖ䣶⥗

⥗⦐ⶾ㛵䣶

9

10

8

77

5

6

2

1

23

4

56

910

breaker / fus e breaker / fus e

terminal terminal

PV

BAT

Solar panel

PC / router Temperature sensor

breaker / fus e breaker / fus e

terminal terminal

PV

BAT

Solar panel

BAT

breaker / fus e

breaker / fus e terminal terminal

PV

Solar panel

PC / router Temperature sensor

BAT

breaker / fus e

breaker / fus e terminal terminal

PV

Solar panel

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

㔐帡妶䳆工ㆬ㫜 ㏧帡妶䳆工ㆬ㫜

溨溦濠Öî潽溣潻溣溩濽

90濠Öî潽溣潻溥溤濽

Figure 2-3

17

The negative terminal of the MPPT should be connected (common negative). If necessary,

ground the MPPT controller according to instructions, local specifications, and regulatory

requirements.

Step 8: Power On

Before powering on, ensure all cable connections are secure.

1瀭

Close the breaker at No. 滦(Battery). If there is power in the battery, the MPPT controller

will run automatically.

2瀭

After the MPPT controller is powered on normally, close the breaker at No. 滧, and the

solar panels will start functioning normally.

If the MPPT controller does not start after closing the No. 滦breaker, it may be due to the

battery being depleted. Closing the No. 滧breaker will enable the MPPT controller to be

powered on properly using solar panel input.

Minimum system - Single product

CAN bus

CAN bus

Figure 2-4

18

Maximum system - six products

Figure 2-5

CAN bus

CAN bus

Table of contents

Other ePropulsion Controllers manuals

Popular Controllers manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC RGK900 manual

Conotec

Conotec FOX-2003SJ-1 instruction manual

WILSON AUDIO

WILSON AUDIO Activ XO Installation and care guide

Hawker

Hawker FLEXILEVEL 3 Operating and installation instructions

cashco

cashco DA0 Installation, operation & maintenance manual

Balboa

Balboa Mach 2.1 EL Series Installation and configuration guide

AMCOL

AMCOL 3500-ETC Technical description

FlowCon

FlowCon SM.3 Installation and operation instruction

Siemens

Siemens SQM5 Series Technical instructions

LEGRAND

LEGRAND Wattstopper DCLV2 installation instructions

Fisher

Fisher ED Safety manual

Lattice Semiconductor

Lattice Semiconductor MachXO2 Series Usage Guide