Noise Com UFX7000 Series User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the NoiseCom UFX7103 at our website: Click HERE

NOISE COM, INC.

TABLE OF CONTENTS

I. GENERAL INFORMATION

1-1 Special Instructions

1-2 Introduction

1-3 Description of the Basic Unit

1-4 Options and Optional Configurations

II. SPECIFICATIONS

2-1 Instrument Specification

2-2 Functional Specifications

2-3 Block Diagram

III. INSTALLATION

3-1 Initial Inspection

3-2 GPIB (IEEE 488 BUS) Interconnection

3-3 GPIB Address

3-4 RS 232, RS 422, RS 423 Interconnection

IV. OPERATION

4-1 Introduction

4-2 Front Panel Controls

4-3 Remote Operation

V. PERFORMANCE VERIFICATION

VI. ADJUSTMENT &CALIBRATION

VII. SERVICE

7-1 Common Parts

7-2 Parts List

7-3 Figures 1,2 and 3

VIII. WARRANTY

Document M016301 Pg 2 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

I. GENERAL INFORMATION

1-1 SPECIAL INSTRUCTIONS

Document M016301 Pg 3 Rev. 2 2/26/03

SELECTION OF LINE VOLTAGE AND FUSES

1. Remove Power Cord.

2. Open access door to power entry module with a small

screwdriver.

3. Pull fuse carrier out. Replace fuse with required one.

(Fuse size marked on rear panel).

4. Pull voltage select wheel out and rotate until correct

voltage appears in the window when access door is closed.

(DO NOT attempt to rotate wheel in place.)

5. Replace fuse carrier into right hand side slot (this is the

only active side) with the white arrow facing to the right.

Close access door.

THIS INSTRUMENT IS SUPPLIED WITH AFUSE FO

R

THE VOLTAGE SELECTED

A

LL SIGNAL AND CONTROL CABLES CONNECTED SHOULD NOT EXCEED 3

M

eters (9 Feet) IN LENGTH.

FOR PROPER OPERATION - THIS INSTRUMENT REQUIRES A 30

M

INUTE WARM-UP PERIOD PRIOR TO OPERATION.

IMPORTANT!

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

1-2 INTRODUCTION

This manual is the operation and maintenance manual for Series

UFX7000 & UFX9000 series Programmable Noise Generating

Instruments. It provides general information plus

installation and operation instructions.

Section I provides a description and option information for

the Programmable Noise Generating Instruments.

1-3 DESCRIPTION OF THE BASIC UNIT

Noise Com, Inc. Series UFX7000 and UFX9000 Noise Generating

Instruments represent the state of the art in noise

generators. Utilizing dedicated keys and a 4x20 LCD display

the UFX series is both user friendly and powerful. They can be

controlled manually by means of front panel controls, or,

alternately, they can be controlled remotely by means of a

controller via IEEE 488 (GPIB) BUS (RS-232, RS-422 or RS-423

option available). These Instruments operate remotely only in

the listen mode.

The case is 17" wide, 5.25" high and 12.5" deep. It is

equipped with front panel handles and fold down feet. Rack

mounting brackets for 19" rack mounting are available.

Brackets are mounted at the factory.

The RF circuit, without options, contains a noise generator

assembly, a standby switch, and a programmable attenuator

(Fig. #1). The above circuit with all options listed in the

following section (1-3) is depicted in Figure #2. The digital

interface for this unit, without options, is IEEE 488 BUS

(GPIB).

Document M016301 Pg 4 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

1-4 OPTIONS AND OPTIONAL CONFIGURATIONS

Programmable Noise Generating Instrument options include:

1. Fine resolution attenuator .1db steps 0 - 127.9DB.

2. Input Power 230V 50Hz.

3. Rack Mounting Brackets (19" x 5¼").

4. Switching bandwidth by means of band limiting filters.

Frequencies to be specified by customer.

4.1 Up to 6 filters and a filter bypass for full

band operation.

4.2 7 Filters.

5. Input connector and resistive combiner. This allows a

signal, externally supplied, to be combined with the

noise output. Noise output will be 6 dB below standard

output specified.

6. The following items may be added to Item 5: Option

Items 1, 4 and a 127 dB, 1 dB step attenuator. All of

the preceeding items are programmable. These option

items will be located in the input connector arm of the

RF circuit.

7. The marker input option permits injection of a signal

into the output line. The marker input is decoupled

approximately 23 dB. Decoupled noise output is

available at the marker input.

8. Noise Power Meter option provides the user with a real

time measurement of the output noise power.

Document M016301 Pg 5 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

2-2 FUNCTIONAL SPECIFICATIONS

Non Volatile memory to retain program parameters, GPIB

address, serial baud rate and user programmed control

sequences

Baud Rate : 0150,300,0600,1200,2400,4800 and

9600 to be used with optional serial

interface ports ( 8 data bits,no

parity 1 stop bit).

Time Delay: 0.1 to 999.9 seconds with 0.1 second

resolution.

Programmable Attenuator: Standard 0-127 dB in 1 dB steps.

Programmable Attenuator: Optional 127.9 dB in 0.1 dB steps.

Bandwidth selection: Optional band switching filter to

customer specification.

Consult Noise Com.

Standby Position: Power is switched into a dummy load.

Reset: A logic reset button is provided.

Second Output: Optional SPDT Switch to connect

either of two outputs.

Document M016301 Pg 7 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

III. INSTALLATION

3-1 INITIAL INSPECTION

Inspect the shipping container for damage. If the container

is damaged, retain until the contents of the shipment have

been checked against the packing list and the instrument has

been checked for mechanical and electrical operation.

If the instrument has been damaged in transit, notify the

carrier as well as Noise Com, Inc.

3-2 GPIB (IEEE 488 BUS Interconnection)

The only interconnection required for GPIB operation is

between the Programmable Noise Generating Instrument and the

controller. This is accomplished by means of a standard GPIB

24 wire interface cable.

Restrictions on use of GPIB interconnections are as follows:

1. No more than 15 Instruments may be installed on the

bus.

2. Total accumulative cable length in meters may not

exceed two times the number of bus instruments, or,

20 meters, whichever is less.

3-3 GPIB (IEEE 488 BUS) ADDRESS

The programmable noise generating instrument as shipped from

the factory is preset to address 5.

3-4 RS-232, RS-422, RS-423 INTERCONNECTION (optional)

RS-232, interconnections are made by means of a DB25S

connector mounted on the rear panel. It is wired as

DTE. Pin 3 is Receive, Pin 7 is Ground and Pins 4, 5

(RTS-CSD) and Pins 6, 8, 20 (DSR, DCD, DTR) are jumper

connected.

Interconnections for RS-422 and RS-423 are made as

follows: Use Pin 12 for positive data connection and in

13 for negative data connection.

Document M016301 Pg 9 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC

IV. OPERATION

4-1 INTRODUCTION

The NOISE/COM PNGI uses a powerful single-chip microprocessor

to accurately control the amplitude, bandwidth, and combining

of its internal broad-band noise source and an externally

applied user generated signal.

Commands to the PNGI can be entered via a front-panel

dedicated keypad. Alternately, commands can be down loaded

from any computer using the GPIB (HP-IB) IEEE-488

instrumentation bus (as a talker), or by the optional RS-232,

RS-422, or RS-423 adapters allowing connection to any

asynchronous serial interface. A front panel alphanumeric

display and lighting status indicators give the operator

visual verification of the programming process and functional

state of the device.

The PNGI includes a special non-volatile memory which will

retain various programmed parameters after the unit has been

powered-off, and restore them to the state they were in when

the instrument was last used. These preserved functions

include GPIB listener address and user programmed control

sequences specifying attenuation levels, signal bandwidth,

time delays and incremental attenuation step values.

A "Reset" button has been provided. Use of this button will

return the instrument to the power turn on state. At power

turn on, the programmable attenuator is at 127 dB and standby

is off.

When the instrument is powered up the LCD display will show

the following for several seconds:

NOISE COM, INC

PROGRAMMABLE NOISE

GENERATOR III

TYPE 2

The type code refers to the status of various factory

installed options.

Document M016301 Pg 10 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM INC

After a brief delay, the MAIN INFORMATION DISPLAY will

appear, similar to the display shown below:

MANUAL MODE, on the top line, indicates that the PNG is

ready to accept commands from the KEYPAD and has received

no commands from a Remote Interface (GPIB, RS-232, RS-

485). If the most recent command to the PNG were received

from a Remote Interface, rather than the Keypad, the top

line would indicate 'REMOTE MODE' to advise the user that

the PNG has most recently been under Remote Control, and

that a Keypad action (if not disabled by a remotely issued

Local Lockout Command) may interrupt a remotely controlled

operation.

If the basic unit was ordered without options then the

display would indicate the noise attenuation of 127 dB

(unless a >2 GHz unit then 79 dB is the maximum attenuation)

and the noise filter at position 1.

The internal Noise Attenuator, 'NA', and Signal Attenuator

(for an externally applied signal), 'SA' are each set to

the maximum attenuation permitted by the PNG Type. The

internal Noise Filter, 'NF', and Signal Filter, 'SF', are

set to position #1. Position #1 is a through path full

(bandwidth). The Step Size, 'ST', is set to the minimum

increment permitted by the PNG Type. If the PNG has

been internally configured to support a Power Meter, the

Noise Power delivered to the load will be displayed in this

position.

Document M016301 Pg 11 Rev. 2 2/26/03

MANUAL MODE

N

A=127.9dB NF=1

SA=127.9dB SF=1

ST=000.1 P=000.0dB

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

INITIAL PNG CONFIGURATION

The first time the PNG is used, and whenever the Remote

Communications requirements change, the 'LOCAL' Function should

be selected from the Keypad. By pressing this key as the

first in a sequence (key interpretations are sequence

dependent), the following information screen will be displayed:

The above display indicates that the PNG is set for remote

control via the GPIB (IEEE-488) interface, and that its GPIB

address is 5. The 'bar' underlining the New Setting '0000' is

a cursor, inviting the user to alter this parameter. A new

value may be entered from the keyboard, followed by 'ENTER'. If

only the 'ENTER'

key is pressed, without entering any new digits, the original

value will not be changed. When the 'ENTER' key is pressed,

the New Setting will be 'burned' into non-volatile memory,

replacing the previous value. The MAIN INFORMATION DISPLAY

will re-appear.

Permissible values for the GPIB/BAUD parameter are '0000' through

'0031', which represent GPIB addresses, and the discrete values

'0150', '0300', '0600', '1200', '2400', '4800', and '9600',

which represent Baud Rates for the optional RS- 232/485

Asynchronous Serial Interface. Selecting a valid GPIB address

will simultaneously enable the Serial interface at 9600 Baud.

The Serial ASCII character configuration is 8-Data Bits, NO-

Parity, 1-Stop Bit. Lower case characters are internally

converted to upper case by the PNG. The PNG will acknowledge each

Remote Command received by sending a Carriage Return (CR =

0D-hex or 13-decimal) character to the Serial Port.

Document M016301 Pg 12 Rev. 2 2/26/03

KEYBOARD SETUP

GPIB/BAUD :0005

N

EW SETTING :0000

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

4-2 FRONT PANEL CONTROLS

Programming via the keypad:

The PNGI can be directly programmed through the front panel

keypad (see Figure 3) using simple data entry sequences.

Internally the PNGI may have a maximum rf curcuit as follows:

two identical attenuation, filtering and standby circuits for

the internally generated noise source and for an externally

applied signal provided by the user. These three functions can

be independently programmed for each of the two signals (see

Circuit block diagram Fig 2). The two circuits then combine to

a single output.

Functions NOISE ATTEN and NOISE FILTER control the attenuation

and bandwidth of the noise source component of the output.

Functions SIGNAL ATTEN and SIGNAL FILTER control those same

functions as applied to the externaly introduced signal (if

this option was ordered). Programming details follow.

SETTING ATTENUATOR AND FILTER VALUES

To set the PNG's Attenuators and/or Filters to desired

values, press the first column key which corresponds to the

parameter to be changed. An Information Display similar to

one the samples below will be appear:

The 'bar' underlining the New Setting '000.0' or '0' is a

cursor, inviting the user to alter this parameter. A new

value may be entered from the keyboard, followed by 'ENTER'.

If only the 'ENTER' key is pressed, without entering any new

digits, the original value will not be changed. When the

'ENTER' key is pressed, the New Command will be executed,

setting the hardware appropriately. The new value will be

shown in the MAIN INFORMATION DISPLAY.

If the high resolution option was ordered then the noise

attenuator would display 127.9 dB instead. If the signal

side option was ordered then the signal atten key will fuction

when actualized. In either case maximum power is obtained at

the output when 0 dB of attenuation is keyed in and as the

attenuation level is increased the output noise or signal

decreases.

Document M016301 Pg 13 Rev. 2 2/26/03

KEYBOARD SETUP

NOISE ATTEN =127.0dB

NEW SETTING =000.0dB

KEYBOARD SETUP

NOISE FILTER = 1

NEW SETTING = 0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

As digits are pressed at the keypad, they enter the parameter

display from the right and displace previously entered digits to the

left. The parameter display may be reset to zero ('0000' or '0') by

pressing the 'CLEAR' key.

Invalid entries will not be accepted. The PNG will automatically

limit the Attenuation Value from '000.0' to the maximum value

permitted by the PNGI Type (typically 127 or'127.9' or '079.9').

Valid Filter settings range from '1' to '8', inclusive.

Filter setting 1 represents full bandwidth ie a through

path. Filter setting 2 terminates the noise into a load internally,

ie this is a standby state. These are the only valid settings unless

the unit has been configured with the filter option. In this case

Filter settings 3-8 represent either internal filters ordered by the

customer or back panel connections enabling the customer to connect

his own external filters. In this case the first filter is

actualized with filter setting 3, the second filter is setting 4,

etc.

INCREMENTING / DECREMENTING ATTENUATORS

The Noise and Signal Attenuators may be incremented or decremented

by the programmed STEP size using only two key strokes. To use this

feature, first set the Step Size to the appropriate value.

Pressing the 'STEP' key will cause the following Information

Display to appear:

The numeric and 'ENTER' keys are used, in the same manner as for

setting Attenuators, to set the Step Size. The selected value will

be added to or subtracted from the selected Attenuator when the INC

and DEC Function Keys are used first in a sequence.

To execute this function, press either the 'INC' or 'DEC' key, as

appropriate, followed by the 'NOISE ATTEN' or 'SIGNAL ATTEN'

key. The new Attenuator setting will be reflected in the MAIN

INFORMATION DISPLAY, and a Cursor Bar will call attention to the

most recent change.

Document M016301 Pg 14 Rev. 2 2/26/03

KEYBOARD SETUP

A

TTEN STEP =000.1dB

N

EW SETTING=000.0dB

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

Invalid entries will not be executed. The PNG will automatically

limit the Attenuation Value from '000.0' to themaximum value

permitted by the PNG Type (typically '127.9' or '079.9').

PROGRAMMING NOISE FUNCTION SEQUENCES

Through the Keypad, the PNG-III can be programmed with

operational sequences to be executed at a future time, and which

can be repeated as many times as necessary without re-keying the

commands. The PNG-III is capable of storing, in non-volatile

memory, ten (10) separate programs. The concepts associated with

Program use are described below.

A PROGRAM is a sequence of instructions which can be stored in

memory and called for execution when needed. The size of a

program (the number of instructions it may contain) is limited by

the amount of memory available for storage. Programs in the PNG-

III are organized like snippets of movie film, each having up to

sixteen (16) frames. As in a movie, each FRAME can describe a

different

piece of the action. FRAMES played in sequence show changes in

action, and Snippets of film spliced together can represent longer

action sequences.

To enter PROGRAM EDIT MODE, press 'PROG' on the Keypad.

PROG#0

FRAMES in a PNG PROGRAM appear thus:

Document M016301 Pg 15 Rev. 2 2/26/03

FR#00 FR#01 FR#02 FR#03 FR#13 FR#14

PROG#: 0 STEP#: 00

FUNCTION

VALUE

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

The number shown after 'PROG#:' defines the current PROGRAM Number

(Film snippet number) being edited. Valid PROGRAM numbers are '0'

through '9'. The number shown after 'STEP#:' defines the FRAME

Number being edited within the current PROGRAM. Valid FRAME Numbers

are '00' through '15'.

In place of the word 'FUNCTION' will be displayed the name of

the PNG component being controlled by the frame (such as

'NOISE_AT', 'SIG._AT', 'NOISE_FR', 'SIG._FR', 'SEL._AT',

'NOISE_ST' or 'SIG._ST'), or a Program Flow Command (such as

'DELAY', 'GOTO' or 'EXIT').

In place of the word 'VALUE' will be displayed the numeric

value being assigned to the PNG component or Program Flow Command

or the words 'INC.' or 'DEC.'

For each of the four parameters in the frame, the user may choose to

accept the current Program Step by keying 'ENTER', or key in an

alternate Command of appropriate composition. Once the first

edited frame is completed, the next sequential frame will

appear for editing. THE LAST FRAME IN A PROGRAMMED SEQUENCE MUST

HAVE THE 'EXIT' COMMAND. The 'EXIT' Command will be saved in

the PNG's non- volatile memory and terminate the Program Editing

Session. The session may be terminated prematurely by pressing the

'RESET' button,

however the currently displayed frame, if altered, will not be

posted to non-volatile memory.

Two new functions, available only in Program Edit Mode and Remote

Command Mode, are 'DELAY' and 'GOTO'. The DELAY function causes the

execution of a Time Delay of from '000.0' to '999.9' Seconds in the

program sequence. The GOTO Command causes a branch to a frame number

out of sequence, but within the same program.

The 'INC' and 'DEC' functions can also be used within a programmed

sequence. To use these functions, press either 'INC' or 'DEC' when

the Cursor Bar indicates the 'FUNCTION' part of the command. The

Program Edit Display will appear like this:

Document M016301 Pg 16 Rev. 2 2/26/03

PROG#:1 STEP#:09

SEL. AT

INC.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

The cursor will point to the 'SEL._AT' field, indicating that the

appropriate Attenuator, 'NOISE ATTEN' or 'SIG.ATTEN' must be

selected. Upon pressing the appropriate key, the Program Edit

Display will show:

At this time, the user may press 'ENTER' to accept the command, or

a numeric key which will change the command to assign a numeric

value to the selected attenuator.

Consider the following Program requirements:

The Noise Attenuator is to be incremented from 000.0 to 010.0dB in

steps of 002.0dB with the Noise Filter set at '2'. At each

attenuator setting, the state is to be held for 5-seconds before

advancing to the next. This sequence is to be repeated

indefinitely. The required programming steps are as follows:

PRG# STP# KEYSTROKES COMMENTS

0 00 [ENT] [ENT] PRG#0 STP#00

[STEP] [0] [0] [2] [0] [ENT] SET NS=002.0

0 01 [NOISE FILT] [2] [ENT] SET NF=2

0 02 [NA] [0] [0] [0] [0] [ENT] SET NA=0.000

0 03 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 04 [INC] [NOISE ATTEN] [ENT] NA=NA+NS =2.0

0 05 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 06 [INC] [NOISE ATTEN] [ENT] NA=NA+NS =4.0

0 07 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 08 [INC] [NOISE ATTEN] [ENT] NA=NA+NS =6.0

0 09 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 10 [INC] [NOISE ATTEN] [ENT] NA=NA+NS =8.0

0 11 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 12 [INC] [NOISE ATTEN] [ENT] NA=NA+NS =10.0

0 13 [DELY] [0] [0] [0] [5] [0] [ENT] DELAY 5.0 SEC.

0 14 [GOTO] [0] [2] [ENT] LOOP TO STEP#02

0 15 [EXIT] [ENT] [ENT] PROGRAM END

Document M016301 Pg 17 Rev. 2 2/26/03

PROG#:1 STEP#:09

N

OISE AT

INC.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

A graph of the Noise Attenuation resulting from the above program

would appear as follows:

ATTEN 10 │┌─┐ ┌─┐ ┌─┐

(dB) 8 │┌─┘ │┌─┘ │┌─┘ │

6 │┌─┘ │┌─┘ │┌─┘ │

4 │┌─┘ │┌─┘ │┌─┘ ││

2 │┌─┘ │┌─┘ │┌─┘ │┌─┘

0 └┴─────────┴─┴─────────┴─┴─────────┴─┘

0 5 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 Time

0 5 0 5 0 5 0 5 0 5 0 5 0 5 0 5 0 5 (Sec.)

For those programmers wishing to write and use programs longer than

16 steps, it is possible to take advantage of contiguous program

memory within the PNG. As there is space for ten programs of 16

steps each, a program starting at PRG#0 STP#00 could take advantage

of the complete 160 step program space. In the absence of an 'EXIT'

command instruction, the program will continue from PRG#0 STP#15 to

PRG#1 STP#00. By similar planning, a program starting at PRG#1 could

contain up to 16 X 9 = 144 program steps. Of course, writing

programs longer than 16 steps makes the used program space unusable

for programs that would normally fit into the over-flow space. Bear

in mind, too, that the GOTO command can only branch within the true

space of the current program, and that the programming 'language'

does not yet support conditional branch instructions.

EXECUTING A STORED PROGRAM SEQUENCE

To execute a previously stored program sequence, press the 'EXEC'

key on the PNG's Keypad. The following Information Display will

appear:

Enter the number of the program to be executed, followed by the

'ENTER' key. The selected program will be executed, beginning with

the first frame of the sequence. As the steps of the program are

executed, Information Displays of the following format will appear:

Pg 18

Document M016301 Pg 18 Rev. 2 2/26/03

EXECUTE

STORED PROGRAM

#0

PROGRAM

EXECUTING

PROG#0

FRAME#03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

As the above display will only be visible during execution of each

Program Step, only DELAY steps will appear for a duration sufficient

for viewing.

4-3 REMOTE CONTROL OF THE PROGRAMMABLE NOISE GENERATOR

All of the PNG Functions Programmable via the Front Panel Keypad

(with the exception of LOCAL) may also be controlled through a

remote Computer, Terminal, or Automatic Test Equipment (ATE) using

the GPIB or Asynchronous Interface Option Ports.

A 'language' has been developed for communicating with the PNG,

using simple ASCII character string Commands terminated by a CR

(Carriage Return) and optional LF (Line Feed). Space characters

may be inserted for clarity of reading, or may be deleted to improve

message throughput. When using the GPIB interface, the message may

be terminated by a LF, by the EOI hardware handshake line, or both.

The PNG, when powered on, is ready to accept commands and data from

a controlling device and respond with acceptance handshaking when

required.

Commands may be entered individually (1 command per line), or in

groups(several commands per line), with a maximum of 64 characters

(including CR/LF) per line. Commands not having proper syntax or

excessive length will be ignored. It is the user's responsibility to

insure that only valid and proper values are entered for selected

parameters.

Most Commands begin with a 2-character prefix, the first character

being 'N' or 'X' to indicate whether the Noise or external signal

channel of the PNG-III will be effected ['X' is used, rather than

'S' to avoid confusion with the Step Commands]. The second

character (A,F,S, or T) indicates whether the Command controls

Attenuation, Filters, Step Size or Time Delay (TD is also an

acceptable format for specifying a Time Delay). The following

characters, which may be 'I', 'D' or numbers indicate Increment,

Decrement or value assignment functions.

Document M016301 Pg 19 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

Numeric values for Attenuation, Step Size and Time parameters may be

entered in a 'free-format', and may include a decimal point where

appropriate. Thus, 012.5, 12.5 and 0125 are equivalent, as are

012.0, 12.0, 12 and 0120. Numeric values for Filter setting MUST be

entered as a 4-digit integer, with the most-significant three digits

being zero, and having a range from '0001' (Dummy Load on) through

'0008'. Alternately the Filter setting may be specified as a

decimal point '.' followed by a single digit. Thus, '0003', '0.3'

and '.3' are acceptable and equivalent; '3' alone is not

acceptable. The destination Step Number of a GOTO instruction, used

in Program Entry Mode, must also be entered as a 4-digit number,

with the most significant two digits being zero and having a range

from '0000' through '0015'.

When a Remote Command that directly addresses the Attenuators or

Filters is executed (NA, NF, XA, XF), the MAIN INFORMATION

DISPLAY will show the change to the most recently effected channel

(Noise or external).

COMMANDS:

NAnnnn or NAnnn.n Sets the Noise Attenuator to nnn.n dB.

NSnnnn or NSnnn.n Sets the Noise Step size to nnn.n dB.

NF000n or NF.n Sets the Noise Filter to position 'n'.

NAI Increments the Noise Attenuator by the

Noise Step size.

NAD Decrements the Noise Attenuator by the

Noise Step size.

XAnnnn or XAnnn.n Sets the external Signal Attenuator

to nnn.n dB.

XSnnnn or XSnnn.n Sets the eXternal Attenuator Step size

to nnn.n dB.

XF000n or XF.n Sets the external Filter to pos'n 'n'.

XAI Increments the external Attenuator by

the external Step size.

XAD Decrements the eXternal Attenuator by

the eXternal Step size.

TDnnnn or TDnnn.n Specifies a Time Delay (in seconds).

Pn Causes execution of stored Program #n.

Document M016301 Pg 20 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

Pn:mm NA12 Enters PROG#n FRAME#m into non-

Volatile memory. The specific

Command may be any that are

Permissible for Keypad entry of

Program Steps, plus the ability

to specify a Step Size for the

Signal Attenuator differs from

That of the Noise Attenuator Step.

T0nnnn or T0nnn.n Specifies the start of a TRIGGER

T1nnnn or T1nnn.n sequence.

QRequests PNG Status report to the

GPIB Port. and Async. Port. If the

Async baud Rate is not Set-up,

Default is 9600.

MSends Diagnostic Memory Dump to the

Async. Port.

REMOTE CONTROL EXAMPLES:

NA0123 cr Sets the Noise Attenuator to

‘012.3’

NA12.3 NF0007 cr Sets the Noise Attenuator to

‘012.3’

NA000.0 NS001.0 cr Sets the Noise Attenuator to

‘000.0’

NAI cr When following the above, sets the

Noise Attenuator to ‘001.0’ db.

NAI cr When following the above, sets the

Noise Attenuator to ‘002.0’ db.

NAD cr When following the above, sets the

Noise Attenuator back to ‘001.0’ db

NA0000 NS0010 TD0010 NAI TD0010 NAI TD0010 NAD cr

Performs the same functions as the

Group above, while inserting a 1-

Second Time Delay between each

Change.

Document M016301 Pg 21 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

NOISE COM, INC.

The following sequence of instructions enters the same sequence

of program steps described in the Keypad Programming example

above. Note that specific 2- character codes are used to

represent Program Functions, and that all such Program Entry

Commands must have the same opening format 'Pn:mm '

P0:00 NS002.0 cr P0:08 NAI cr

P0:01 NF0002 cr P0:09 TD 5 cr

P0:02 NA 0 cr P0:10 NAI cr

P0:03 TD 5 cr P0:11 TD 5 cr

P0:04 NAI cr P0:12 NAI cr

P0:05 TD 5 cr P0:13 TD 5 cr

P0:06 NAI cr P0:14 GO 0002 cr

P0:07 TD 5 cr P0:15 EX

Where cr is either a cr character for the RS-232 option

or for GPIB interface operation it is a LF or EOI hard-

ware or both.

Valid 2-character Function Codes for PNG-III Programs

are:

NA := Noise Attenuator

XA := eXternal signal Attenuator

NF := Noise Filter

XF := eXternal signal Filter

NS := Noise Step

XS := eXternal signal Step

TD := Time Delay

GO := GOTO

EX := EXIT

Note that it is possible to enter a Signal Step size that is

different than the Noise Step size, when programming via a

Remote Port. It is important to note that a Noise Step Command,

whether entered from the Keypad or a Remote Port, will set both

the Noise Step and Signal Step values. An 'XS' Command, entered

via a Remote Port, will set only the Signal Step value.

Therefore, to enable differing values for the two Step sizes,

the Signal Step value must be set AFTER setting the Noise Step

value.

Document M016301 Pg 22 Rev. 2 2/26/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Omron

Omron CP1E-E**D Series user manual

Grundfos

Grundfos Conex DIS-2Q Installation and operating instructions

ABB

ABB PME120 Operating instruction

Evco

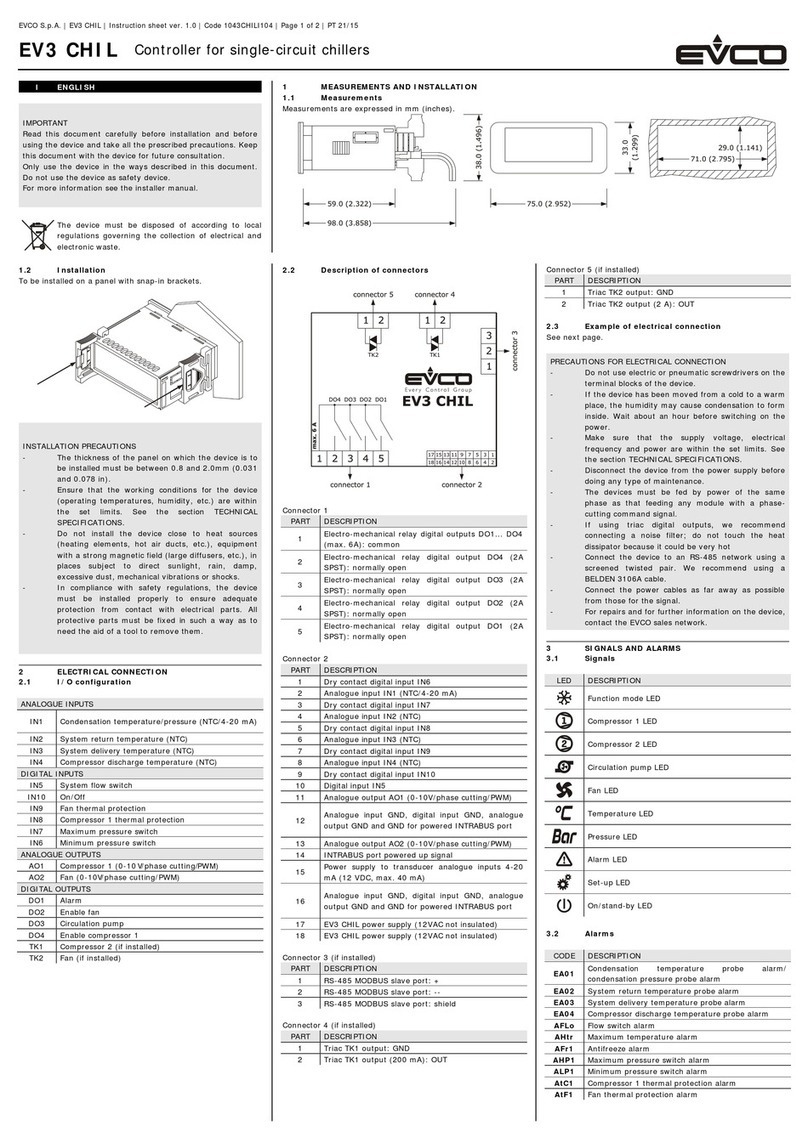

Evco EV3 CHIL instruction sheet

Shadow

Shadow QHC18MR 18kW QHC24MR 24kW Safety instructions and operation manual

Cypress

Cypress CapSense CY3280-24x94 user guide

BFI Automation

BFI Automation CFC 4000L Original operating instructions

AIMS Power

AIMS Power SCC-20A MPPT Installation and operation manual

Trinamic

Trinamic TMCM-3110 Hardware manual

Victron energy

Victron energy BlueSolar MPPT 100/30 user manual

GESTRA

GESTRA NRR 2-40 installation instructions

AfterBurner

AfterBurner GPIO CAPABILITY user manual