SERVICE MANUAL EIS 165.3 N/P KW (short version) inglese

Autori: Serralunga M. 14/10/2021

2

NO COPYING IN ANY FORM WITHOUT WRITTEN PERMISSION FROM EPTA QUALITY MANAGEMENT

TABLE OF CONTENTS

1. AMOUNT OF REFRIGERANT IN THE EQUIPMENT 3

2. REFRIGERATION SCHEMATICS FOR THE EQUIPMENT 4

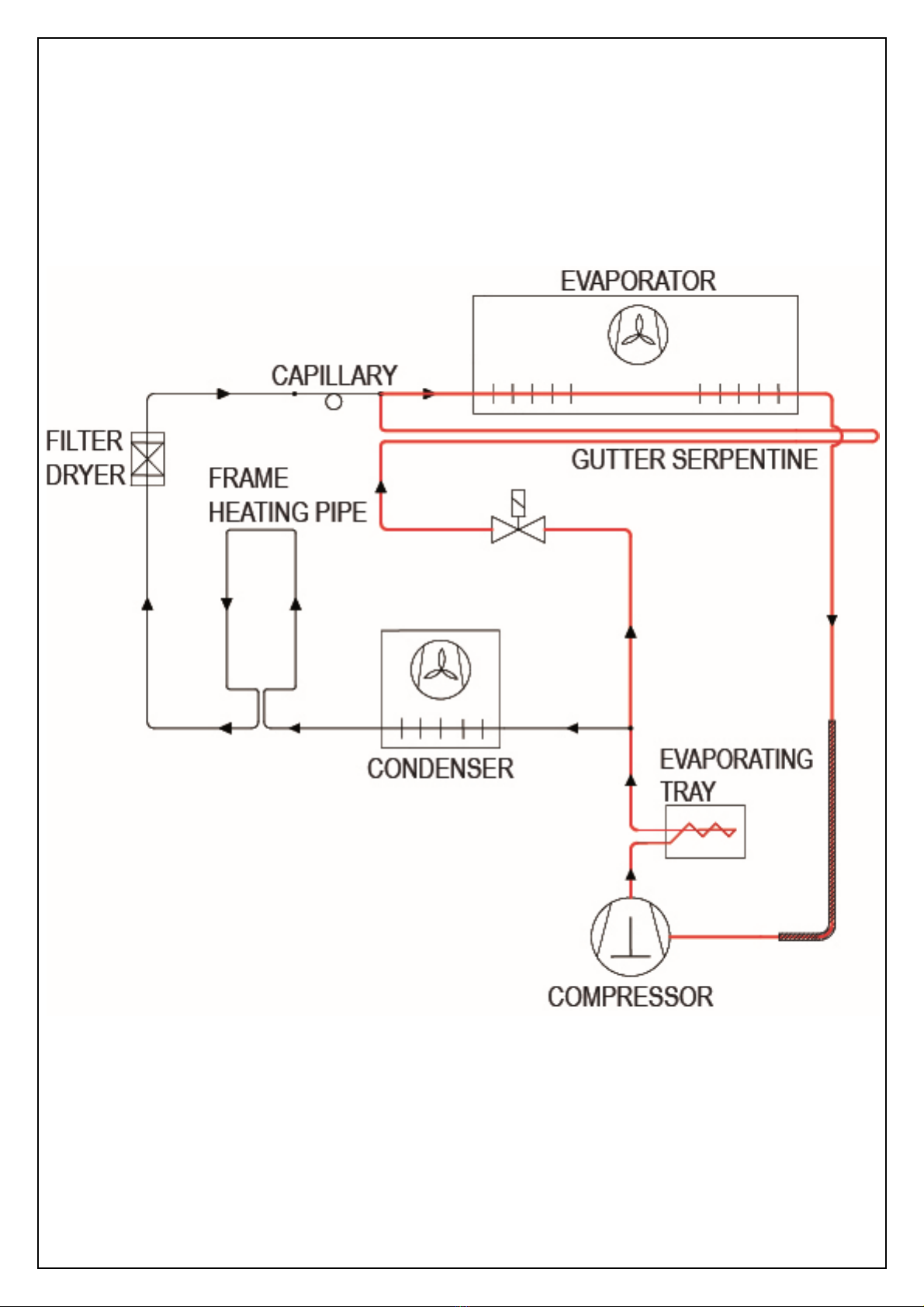

2.1. REFRIGERATION DIAGRAM FOR EIS 165.3 N/P KW 4

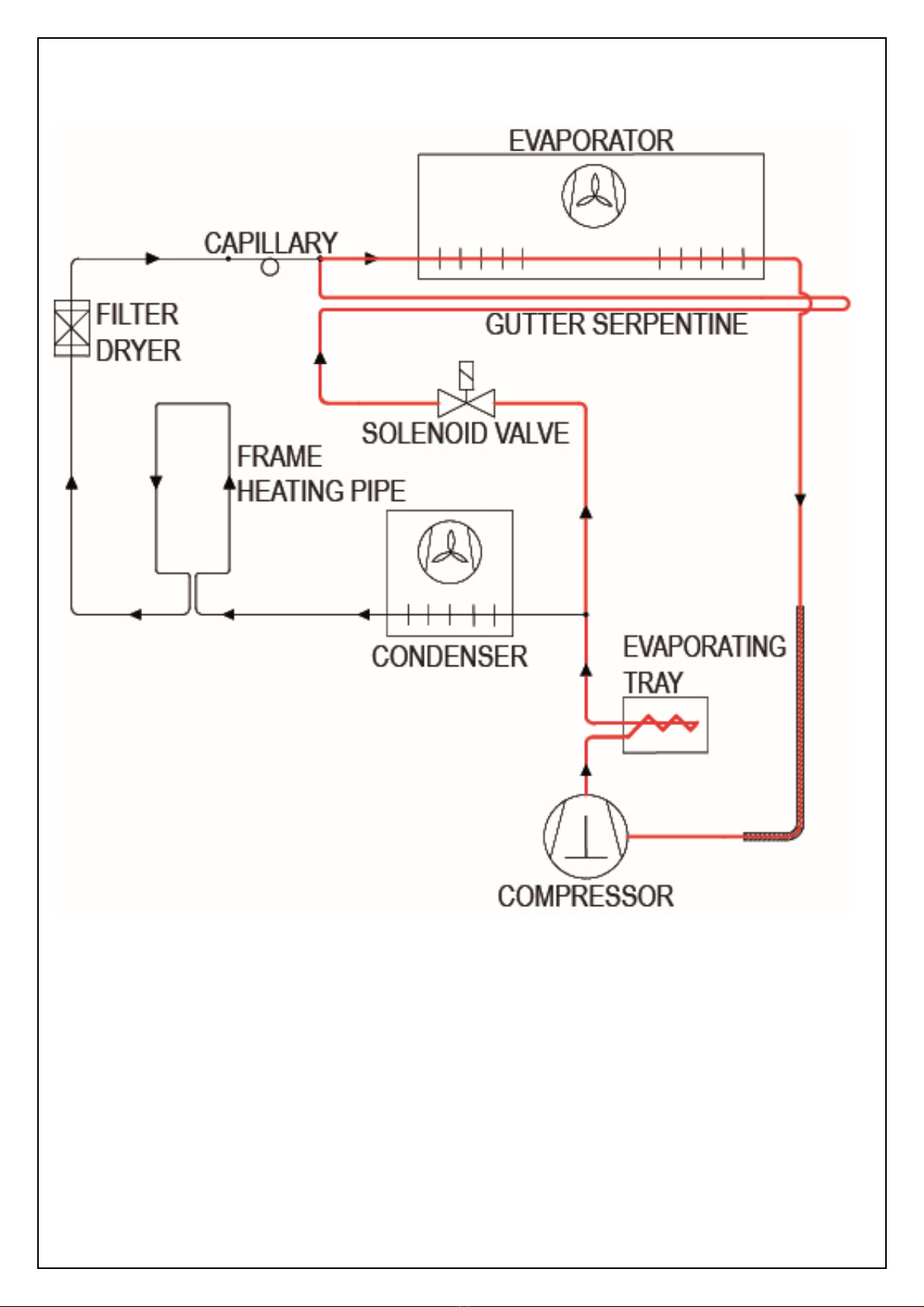

2.2. REFRIGERATION DIAGRAM FOR DEFROST CYRCLE EIS 165.3 N/P KW 6

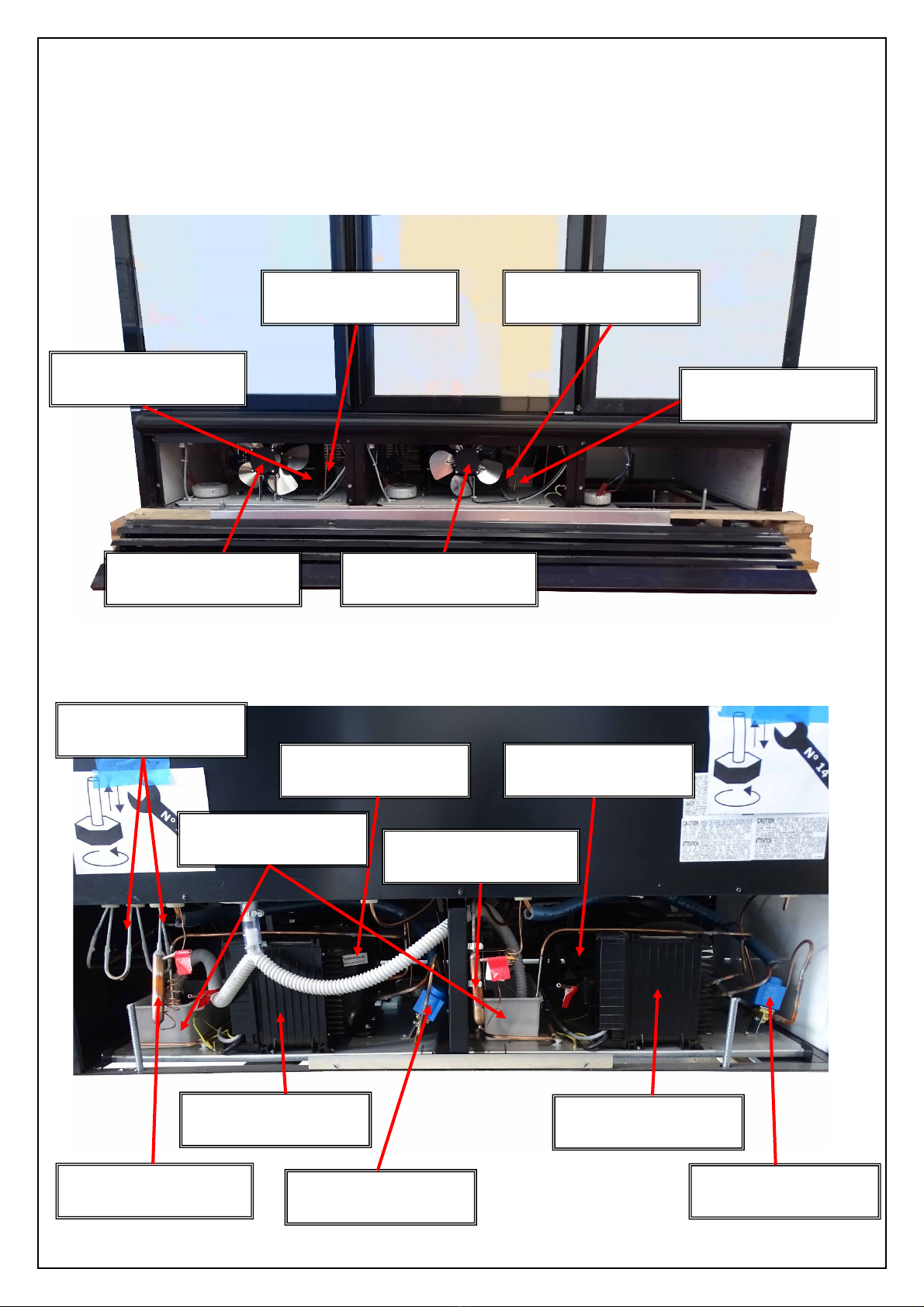

2.3. VIEW OF MOTOR COMPARTMENT – EIS 165.3 N/P KW 8

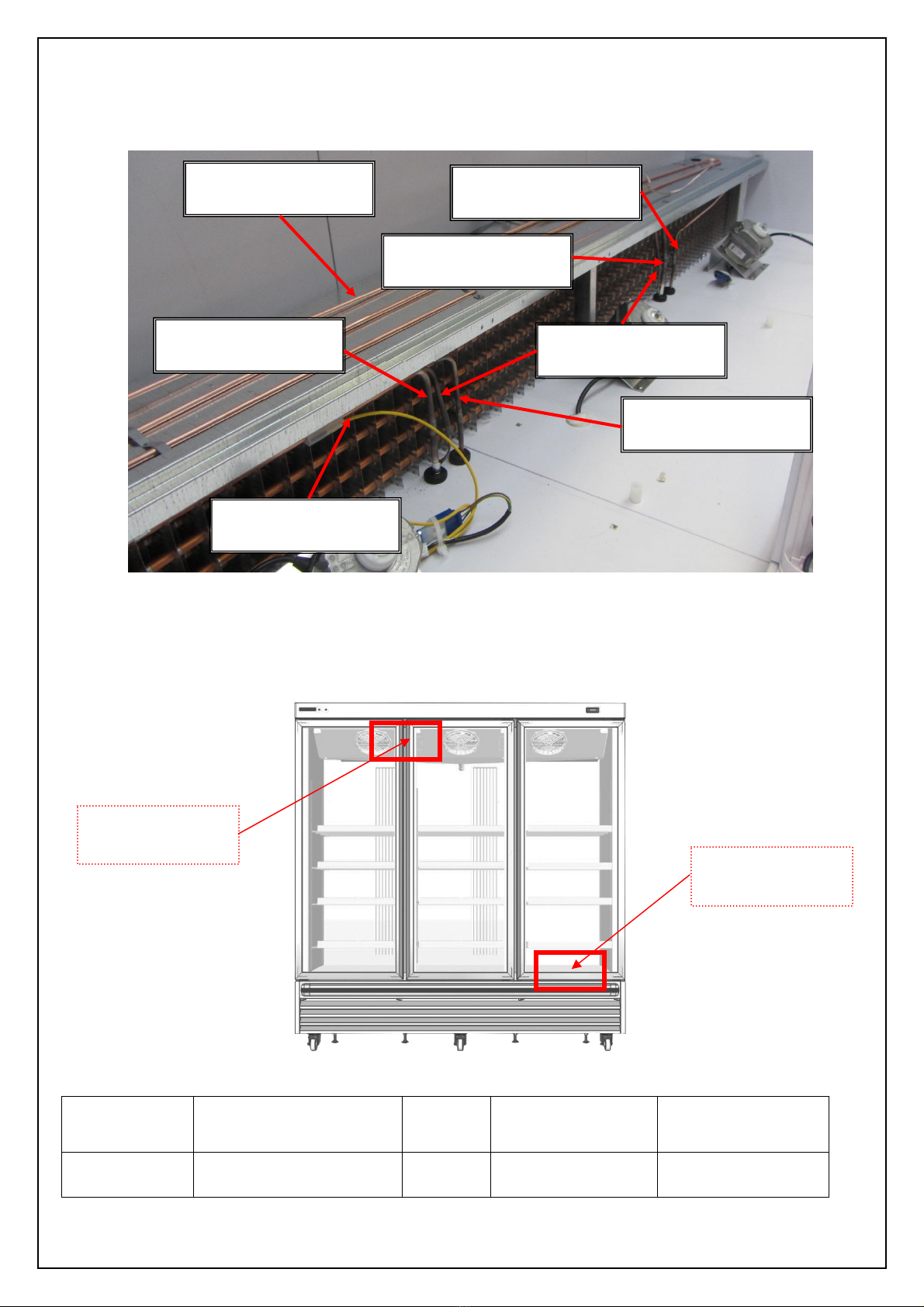

2.4. VIEW OF THE EVAPORATOR COMPARTMENT - EIS 165.3 N/P KW 9

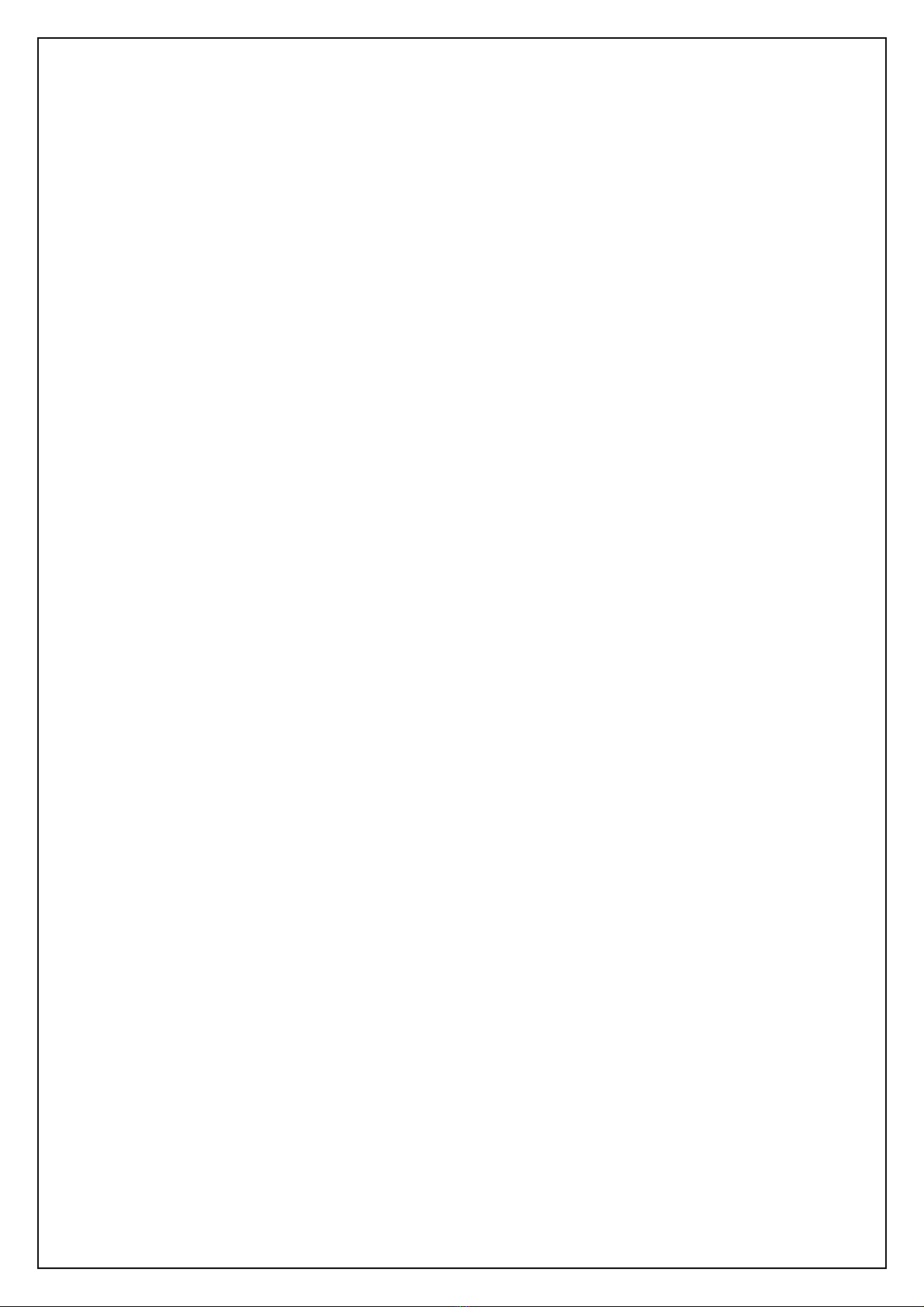

3. POSITION OF PROBE IN THE CABINET 9

4. ALARMS FOR EIS 165.3 N/P KW (Dixell Controller) 10

5. REPLACEMENT OF COMPONENTS 10

5.1. SAFE OPERATING PROCEDURES FOR REFRIGERAION UNIT USING R290 10

5.2. PROTECTION TOOLS AND DEVICES FOR SERVICEMENT 11

5.3. HOW TO EMPTY THE COOLING CIRCUIT AND PROVE IT BEFORE SERVICING 14

5.4. COMPRESSOR REPLACEMENT 15

5.5. UNSOLDER COPPER PIPE TUBE 15

5.6. COMPRESSOR REMOVING 16

5.7. NEW COMPRESSOR INSERTION 16

5.8. HIGH PRESSURE PIPE CLOSING 16

5.9. REFRIGERANT GAS CHARGING AND THERMODYNAMIC CIRCUIT CLOSING 18

5.10. CHECK THE CORRECT CLOSING OF THERMODYNAMIC CIRCUIT 20

5.11. REPLACEMENT OF CONDENSER MOTOR FAN 21

5.12. REPLACEMENT OF EVAPORATOR MOTOR FAN 21

5.13. REPLACEMENT OF POWER CORD 22

5.14. REPLACEMENT OF SOLENOID VAVE 22

5.15. REPLACEMENT OF ELECTRONIC CONTROLLER 23

5.16. REPLACEMENT OF LED BAR 23

5.17. REPLACEMENT OF TEMPERATURE SWITCH 23

5.18. REPLACEMENT OF TEMPERATURE YELLOW LIGHTS 24

5.19. REPLACEMENT OF DOOR AND DOOR GASKET 24

5.20. REPLACEMENT OF PROBS 30

5.21. REPLACEMENT OF DEFROST HEATER 31

5.22. REPLACEMENT OF DOOR HANDLE 31

5.23. REPLACEMENT OF FEET CASTORSLACEMENT OF SHELF RACK 32

5.24. REPLACEMENT OF SHELF RACK 33

6.MAINCABINETFUNCTIONS 34

6.1. DISPLAY UNIT AND MAIN PARAMETERS 34

6.2.USEOFLEDS 34

6.3. HOW TO CHANGE A PARAMETER VALUE 34

6.4. CONTROLLER PARAMETERS 35

6.5. TEMPERATURE SETTING 36

7.WIRINGDIAGRAM 37

7.1. WIRING DIAGRAM LEGEND 37

7.2. WIRING DIAGRAM 38

8. COMMON PROBLEM AND TROUBLESHOOTING 39

8.1. UNIT NOT IN TEMPERATURE 39

8.2. NOISY UNIT 41

8.3. PRESENCE OF WATER ON THE FLOOR OR ABNORMAL ICE INSIDE TANK 41

8.4. POSSIBLE PROBLEMS AFTER CIRCUIT REWORKS 43

8.5. INVERTER TROUBLESHOOTING 44