epur OAKBOT EOX 4.2 Series User manual

DOCUMENT

epur

User’s Manual

OAKBOT EOX series 4.2

Original Manual

epur | USER’S MANUAL

www.epur.io - - | 2 | - - contact@epur.io

Contents

Contents........................................................................2

After-Sales Service.........................................................3

General Conditions of use and important warnings................................4

Items Supplied..................................................................6

Clamping Module.............................................................6

Machining Module............................................................7

Control Unit................................................................8

Toolbox.....................................................................8

General Specifications.....................................................11

General Recommendations........................................................12

General....................................................................12

Handling...................................................................12

Environment................................................................13

Test Conditions............................................................14

Warning about dimensioning assemblies......................................15

Safety.....................................................................15

Instructions for use...........................................................21

#1 - Aim...................................................................21

#2 - Starting up the OAKBOT................................................21

#3 - Shutting down the machine.............................................23

#4 - Milling Tools.........................................................24

#5 - Calibration...........................................................30

#6 – Preparing the pieces of wood..........................................38

#7 – Putting the Clamping Module in place..................................39

#8 - Use...................................................................43

#9 – Using the device for prohibiting access to the machining zone.........48

#9 – Using the user interface..............................................52

#10 – Extraction unit......................................................66

#11 - Maintenance..........................................................67

#12 – Safety Pictograms....................................................71

#13 – Personal Protective Equipment........................................72

Warranty.......................................................................73

Warranty Period............................................................73

Scope of the Warranty......................................................73

Conditions of application of products......................................74

epur | USER’S MANUAL

www.epur.io - - | 3 | - - contact@epur.io

Introduction

Thank you for purchasing an EPUR OAKBOT digital milling machine.

In order to ensure use in optimum conditions, get the best results possible and

be familiar with safety measures, please familiarize yourself with this manual

from A to Z.

/!\ CAUTION /!\

Read this manual in its entirety before beginning to use the OAKBOT.

Please read the instructions for use and warnings carefully so as to use your

digital milling machine in complete safety.

After-Sales Service

You can contact the After-Sales Service:

by e-mail at the following address:

by surface mail at the following address:

EPUR SAS

Hameau de Caillens - 11140 - Rodome - France

or by telephone at: +33(0)4 68 31 29 11

The photographs in this manual are not contractually binding.

All rights reserved, in particular the right to reproduce, disseminate and translate.

Reproduction in any form whatsoever, as well as recording, processing, duplication and

dissemination hereof, even in part, by any means whatsoever are prohibited unless the EPUR SAS

Company authorizes such in writing.

epur | USER’S MANUAL

www.epur.io - - | 4 | - - contact@epur.io

General conditions of use and important

warnings

/!\ CAUTION /!\

Respecting the following precautions is essential. Failure to comply with this

may result in irreversible material damage to the product and/or its environment

and cause serious bodily injury, risk of fire and/or death. These precautions are

not exhaustive and in no way substitute the elementary rules of safety concerning

an item of professional equipment intended for machining work.

The machine has inbuilt safety systems. Do not remove them and see that they

stay in place and remain in good working order.

For your own safety, wearing personal protective equipment is mandatory. This

includes ear defenders, protective eyewear and safety footwear. Wear suitable

clothing when using the machine.

Never carry out any work on the milling machine or insert anything, when it is

powered up or operating, as this would risk causing serious injury.

Do not place anything on your milling machine, either externally or internally,

keep it clean and clear it regularly of all deposits and waste resulting from

machining operations. Do not use alcohol-based cleaning products or solvents

for cleaning your machine.

Machine just wood. Any other material machined using the OAKBOT would release

the EPUR SAS Company from all liability in the event of damage to people or

property.

epur | USER’S MANUAL

www.epur.io - - | 5 | - - contact@epur.io

Only use milling tools supplied by EPUR with the OAKBOT.

Do not cover your milling machine during operations as this might lead to

overheating.

Connect the control unit to the milling machine via the dedicated cable.

Connect your milling machine to the power supply with the cable supplied to a

suitable socket and check the status of the power supply cable. A single, direct

connection is preferable to accumulating with other plugs.

Do not use the machine in a dangerous environment, as it is an electrically-

powered system. It must be connected to the mains power supply or an electrical

generator. It runs on 220 volts. Do not use in damp places or places exposed

to rain.

Do not use or leave electrical tools near flammable liquids or in gaseous or

explosive atmospheres. The motors may generate sparks and catch fire.

When changing accessories, only use those tools that we have supplied for this

purpose.

Do not force tools or accessories if they do not work properly, as it is certain

that there is a problem. Check out what could be causing this.

It is prohibited to disassemble and/or modify your digital milling machine. Any

part that has been disassembled or modified will no longer be covered by the

manufacturer’s warranty, unless the latter expressly agrees to such.

When changing milling cutters and before using again, check that you have

removed any tool, spanner or similar items from the machine and its area of

use.

Before starting up the Oakbot, check that any object in the machining zone is

removed that might come into collision with the milling cutter and possibly

injure the operator, disrupt your machine or even seriously damage it.

Place your milling machine on stable wooden blocks that can take its weight.

Vibrations from the milling machine may unbalance any inadequate support and

cause the unit to fall over, which may result in serious injuries and damage

to machine and environment, and possibly cause fires.

Use the clamping system as recommended in this manual and do not use in any

other way. Poor clamping may lead to the machine falling over, causing serious

injuries and damage to the system and its environment.

epur | USER’S MANUAL

www.epur.io - - | 6 | - - contact@epur.io

The machine must be kept under supervision during the first few seconds of the

milling process. If clamping is not properly ensured, this often leads to

uncoupling at the beginning of the machining process.

Wait for the machine and the spindle to stop completely before handling

workpieces or the machine.

The OAKBOT which comes with its clamping system and handling trolley is a unit.

No machining must be carried out or movement made without the robot being

engaged on the clamping system and suspended on its trolley.

Items Supplied

Clamping Module

Mass: 18 kg

epur | USER’S MANUAL

www.epur.io - - | 7 | - - contact@epur.io

Machining Module

Mass: 35 kg

epur | USER’S MANUAL

www.epur.io - - | 8 | - - contact@epur.io

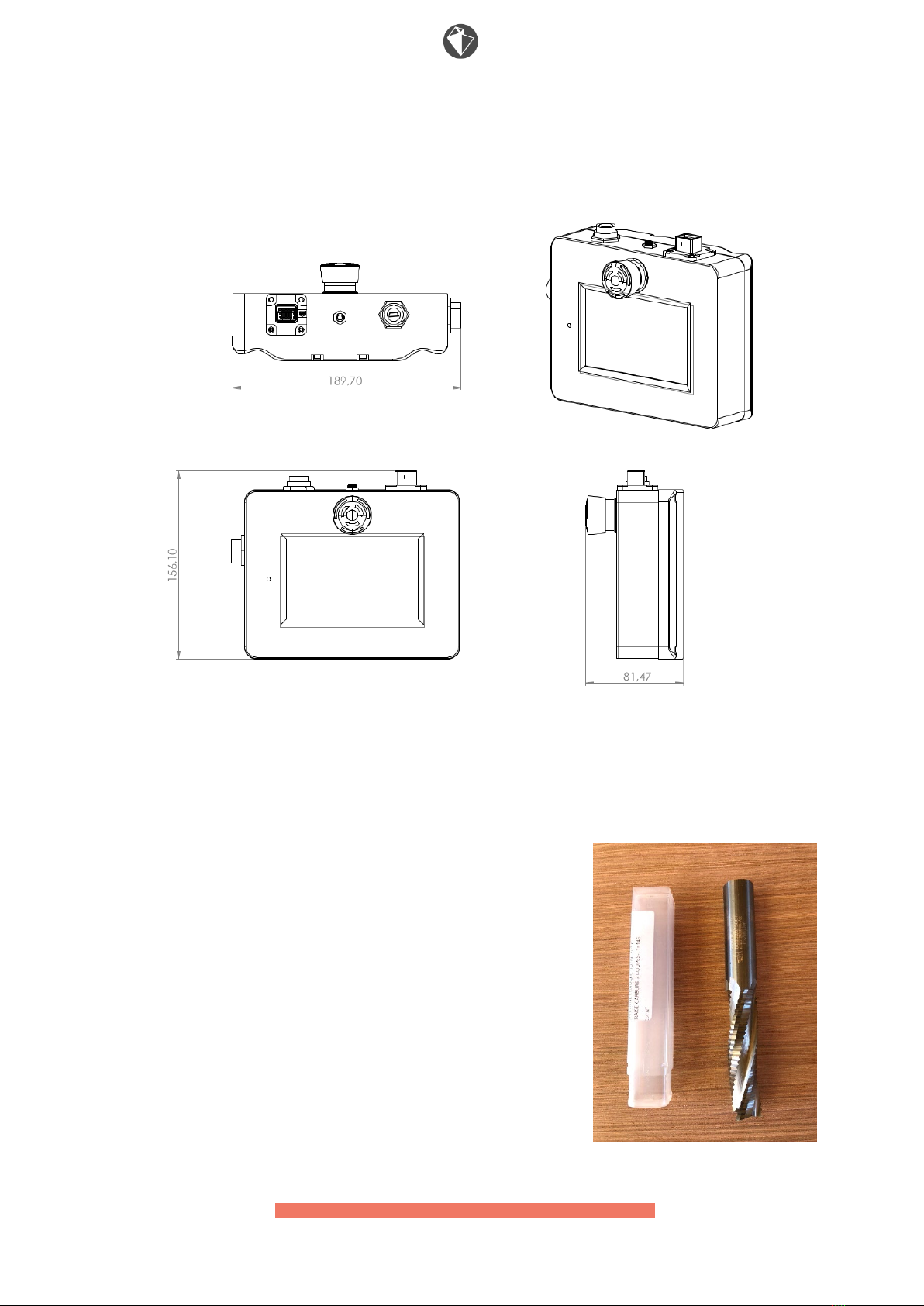

Control Unit

Toolbox

Systainer toolbox

Tenon milling cutter – Cylindrical mortise Ø20mm

epur | USER’S MANUAL

www.epur.io - - | 9 | - - contact@epur.io

Conical dovetail milling cutter Ø max 40 mm

ER32 spanner wrench & #32 flat spanner

ER32 collet chuck - 20 mm + nut

epur | USER’S MANUAL

www.epur.io - - | 11 | - - contac[email protected]o

General Specifications

Total assembly dimensions: clamping module + machining module:

Height: 641 mm

Width: 844 mm

Length: 825 mm

Mass: 53 kg

Energy: 220-240 volts AC ~ 50 Hz

Maximum sound level: 92dB

X travel: 353 mm

Y travel: 247 mm

Z travel: 100 mm

epur | USER’S MANUAL

www.epur.io - - | 12 | - - contac[email protected]o

General Recommendations

General

Your OAKBOT is a portable cutting robot for structural timber assemblies and joints

of all sorts, including tenons, mortises, dovetail joints... positioning itself at

the ends and edges of a beam. Using the OAKBOT will require a trolley for handling

the robot as well as a clamp between the robot and the workpiece to be machined.

Implementing this stage properly, as described below, is essential for ensuring

your own safety and achieving the smooth unit operation. Once clamping is carried

out, machining configuration is easy using your remote control which features a

touch-control interface to guide you throughout the process. Machining will then

be automatic and require no personal intervention during the assembly.

Handling

For your own safety, wearing safety footwear is mandatory when handling your

robot. If the robot falls over during handling, this may result in serious

injury to the operator.

Avoid placing the unit on the ground, so as not to have to lift it into the

suspension position. We recommend using the handling trolley which enables you

to place your machine at the correct handling height at any time. At all times

during machining cycles, the machine must be suspended from the handling trolley.

If you have to lift your milling machine cutter from the ground, use correct

postures and gestures. The same goes when transporting your machine.

epur | USER’S MANUAL

www.epur.io - - | 13 | - - contac[email protected]o

ADOPT CORRECT POSTURES

CARRYING

Environment

To work in complete safety, your work environment must be adapted to OAKBOT use.

Your OAKBOT is a robot: when being used, some parts are fixed, while others are

mobile and will enter into movement:

As a result, its centre of gravity may change during use. Consequently, you

must check permanently that instructions for use of the mobile trolley are

respected (particularly with cants and slopes) – see the OAKBOT handling trolley

user’s manual.

When being moved, your robot will also assume variable dimensions. Consequently,

you must check that the robot’s moving part is totally free to move and that

the environment around your support is sufficiently uncluttered to avoid any

risk of collision and any risk of the operator being crushed throughout the

whole of the robot’s travel. Keep the workspace clean and uncluttered, as

congested places contribute to accidents.

/!\ CAUTION /!\

Taking all possible positions of the robot into consideration, the OAKBOT’s maximum

width is 1400 mm.

epur | USER’S MANUAL

www.epur.io - - | 14 | - - contac[email protected]o

Test Conditions

In order to use your OAKBOT in the best safety conditions, respect the following

rules:

Only mill wood.

Only use milling tools supplied by EPUR.

Check that no foreign body other than wood be present in the part to be machined.

Always place the beam to be machined with its largest width in a sectional

position, parallel to the jaws of the clamping module.

Ensure that whenever the robot is operating (simply moving or during a machining

cycle):

The robot is suspended from its handling trolley

The robot is snapped into place and locked onto the clamping system

The devices for confining off the machining zone are deployed.

/!\ CAUTION /!\

The user is fully responsible for checking that no operation is requested to be

carried out by the OAKBOT if the latter is not snapped into place and locked

properly in its clamping system with the devices for confining off the machining

zone deployed. The OAKBOT must also be suspended correctly from its handling trolley.

Failure to respect this rule of use shall release the EPUR SAS Company from any

liability whatsoever.

/!\ CAUTION /!\

The user shall be fully responsible for positioning the OAKBOT on the workpiece to

be machined. In the event of the device tipping over, falling or colliding as a

result of the OAKBOT being used, the EPUR SAS Company shall not be held liable in

any way whatsoever.

epur | USER’S MANUAL

www.epur.io - - | 15 | - - contac[email protected]o

Warning about dimensioning assemblies

/!\ CAUTION/!\

Although a digital tool, the OAKBOT is only a milling cutter and, as such, it is

up to the user to calculate machining dimensions. In no way can EPUR guarantee the

dimensioning of assemblies or joints carried out using the OAKBOT, for any assembly

whatsoever. Consequently, the EPUR SAS Company shall not be held liable for any

damages or financial losses caused by faulty assemblies.

Safety

Machine status indicator light

Lights indicating machine status (green and red) are located on the robot’s

electrical control unit.

If the green light is on, the machine is ready to be configured.

If the red light is on, the robot is machining or moving (even if the user

cannot perceive any movement) and the operator must stand aside in the zone

situated at the rear of the robot and respect a minimum distance of 1 metre

between him/her and the machine.

epur | USER’S MANUAL

www.epur.io - - | 16 | - - contac[email protected]o

/!\ CAUTION /!\

Before initiating any action, check that no one is present in the side areas of

the machine, regardless of the distance. Also check that no one is present in the

front zone, less than 3 metres away from the machine.

If the red light is flashing, this is because the machine has placed itself in

safety status (motor power supplies cut off), which may happen in 2 cases:

The emergency stop button has been actuated.

The machine has detected an obstacle in its path.

Whatever the case, the procedure to be followed will be indicated on the screen.

Device prohibiting access to the machining zone

In order to prevent any risk to the user, the device confining off the machining

zone must be deployed for any action requested of the machine. This device prohibits

access to the machining zone, makes it possible to contain any shavings from

Side Area

Front Area

Side Area

Rear Area

/!\

Minimum

distance 1

metre

epur | USER’S MANUAL

www.epur.io - - | 17 | - - contac[email protected]o

machining and also contain dust and wood chips which the device will make it easier

to expel by directing them to the extractor unit. (See user’s guide #9).

epur | USER’S MANUAL

www.epur.io - - | 18 | - - contac[email protected]o

Emergency stop button

The emergency stop button is situated on the remote control.

When the button is actuated, the following message is displayed on the screen:

CAUTION

CAUTION

/!\ THE EMERGENCY STOP BUTTON HAS

BEEN ACTUATED /!\

To begin use again, disengage the

emergency stop button

epur | USER’S MANUAL

www.epur.io - - | 19 | - - contac[email protected]o

The reset button

The reset button enables the machine’s power supply circuits to be actuated after

the machine has been started up or the emergency stop button pressed. This button

is located next to the machine’s on/off button. The button’s contour will flash

(orange) if resetting is required and the indication will also be relayed by the

user interface.

CAUTION

#1 - MACHINE

Before launching the machining

process, press the reset button.

OK

epur | USER’S MANUAL

www.epur.io - - | 20 | - - contac[email protected]o

Positioning errors

If the machine detects a positioning error, the following message will be displayed:

CAUTION

/!\ A POSITIONING ERROR HAS OCCURRED

/!\

To start using again, initiate the

emergency stop button

Clamping detection device

In order to prevent any risk to the user, a built-in safety system makes it possible

to inhibit all operations (movement, motor start-up) until the robot is properly

snapped into place in its clamping system. Relevant information messages will be

displayed on the interface if needs be.

CAUTION

CAUTION CLAMPING

Check that the machine is correctly

positioned on the clamp.

OK

Table of contents

Popular Power Tools manuals by other brands

Makita

Makita JN3201 instruction manual

blue photon

blue photon BlueCure Mini user guide

Gluefast

Gluefast Adjutant-JR instructions

SPERO

SPERO SP 52 Translation from the original instruction manual

Dremel

Dremel 6800 Operating/safety instructions

Master Appliance

Master Appliance ECOHEAT EC-100 instruction manual