Equalizer System AUTO-LEVEL User manual

AUTO-LEVEL

Operation and Warranty Guide

TABLE

OF

CONTENTS

Precaution /Warnings ..................................................................................................................... 2

AUTO-LEVEL System Operation ...................................................................................................... 3-5

Helpful Hints .................................................................................................................................... 6

Maintenance .................................................................................................................................... 6

Override Procedures ..........................................................................................................................7

Equalizer Systems Warranty ........................................................................................................................End

Important

Warnings

and

Precautions

WARNING

READ

ENTIRE

INSTRUCTIONS

AND

ALL

PRECAUTIONS

PRIOR

TO

INSTALLING,

USING,

OR

TROUBLESHOOTING

THIS

EQUIPMENT

The

system

operates

using

hydraulic

fluid

under

high

pressure.

Extreme

fluid

pressure

can

be

present

even

if

the

system

is

not

operating.

System

forces

and

pressures

can

cause

severe

injury

or

death

if

used

improperly

or

modified.

Service

work

should

only

be

performed

by

trained

technicians.

Do

not

attempt

to

operate

any

portion

of

the

hydraulic

systems

when

the

vehicle

is

in

motion.

Visually

confirm

that

all

leveling

jacks

are

retracted

prior

to

travel.

Make

sure

there

are

no

obstructions

in

the

extend

or

retract

paths

of

the

jacks

or

slideouts.

Do

not

use

the

leveling

jacks

to

lift

the

unit

to

perform

any

kind

of

service

work

or

to

change

tires.

The

system

is

designed

as

a

leveling

and

stabilizing

system

and

is

not

meant

to

lift

the

coach

off

the

ground.

Do

not

go

under

vehicle

when

leveling

jacks

are

extended.

Do

not

operate

any

system

functions

while

anyone

is

under

the

coach.

Do

not

allow

excessive

motion

in

the

coach

during

the

AUTO-LEVEL

operation.

This

could

cause

the

system

to

level

improperly.

Modification

of

any

factory-supplied

item

may

result

in

the

denial

of

all

warranty

claims.

Call

Equalizer

Systems

Technical

Support

prior

to

any

modifications.

Do

not

attempt

any

technical

repairs

without

first

consulting

the

troubleshooting

guide

in

this

manual

and/or

calling

Equalizer

Systems

Technical

Support

at

(800)

845-9659.

Failure

to

do

so

may

result

in

denial

of

warranty

claims.

2.

AUTO-LEVEL Operation- Keypad # 3103

Starting Date- Approximately January 2012

• Power On: Press and release the POWER button to engage power. All LED’s on the

panel will come on then most will go out. The LED next to the POWER button should be lit

RED when power is on. The ignition key will need to be in the off position and the park

brake will need to be set to extend the jacks. If you attempt Auto-Level or manual extend

you will hear a “deny” tone if the key or park brake is in the improper position.

• AUTO-LEVEL: Press the AUTO-LEVEL button and release. The system will send

out a continuous series of beeps, the ‘OPERATING’ LED will flash RED to let you

know AUTO-LEVEL is operating and will automatically level the coach. When

completed, the keypad will signal a successful level with a dual-level tone. Press

and release the POWER button. Note: The keypad may be left on once level has

been achieved. The keypad will enter “sleep mode” after five minutes of inactivity.

Note: The jacks down LED lights must be off for Auto-Level to function.

If needed, press the ALL RETRACT button to clear and then Auto-Level

should function.

• Retracting the Jacks: To retract all jacks simultaneously, press and release

the All RETRACT button. All jacks will automatically retract and return to stowed

position. The pump will run in retract mode until all of the jacks are fully stowed

(plus an additional 5 seconds) up to a maximum of 60 or 90 seconds). This is the

proper method for retracting the jacks prior to travel. You may stop the ALL RETRACT

by pressing any button on the keypad. Jacks may be retracted in pairs by using the UP▲

button for each end or side for leveling purposes however the ALL RETRACT must be

used to fully stow the jacks prior to travel. The jacks down LED’s will turn off, indicating the

jacks are in the “stowed” position.

• Power OFF: Press and Release the Power Keypad Button

SETTING THE NULL, “LEVEL POSITION”

• Setting the Null: The Null or “level position” has been preset from the factory.

However, if the coach is not level following an attempt to AUTO-LEVEL, the Null is easy

to reprogram. To set the Null, push and release the POWER keypad button to engage

power. The LED next to the POWER button should be lit RED when power is on. Level

the coach by deploying jacks manually (using the DOWN ▼ keypad buttons, extend

jacks until the coach is level), or by simply parking the coach on a level site. You do not

need to have jacks deployed to set the Null. Use a bubble level on a flat surface in the

center of the coach as a reference. Once the coach is level, turn the POWER off at the

panel. Depress and hold the AUTO-LEVEL keypad button. Continue to hold the AUTO-

LEVEL button and press then release the POWER button, and listen for a series of beeps.

After the panel has beeped 5 to 6 times, release the AUTO-LEVEL button (the keypad

will continue to beep as long as the AUTO-LEVEL button is held). The new Null has been

set and the system will maintain this setting. Press and release the ALL RETRACT button

to retract the jacks to the stowed position.

*Visually confirm all jacks are retracted prior to travel.

Note: There are specific instances when manual extension of one (or more) jack is inhibited (deny tone when DOWN ▼ is depressed).

This situation is caused by the ‘anti-twist’ protocol in the software contained in the controller. Simply stated, the ‘anti-twist’ protocol

denies jack extension if the system senses that a specific corner of the coach is approximately 3 degrees higher than the rest. You will

be able to extend other jacks to overcome the slope. If the system incorrectly senses excessive slope, this can be overcome by re-

setting the Null. This will allow manual extension of all jacks. Remember to re-set the Null after manually leveling the coach.

3.

Manual Operation- Keypad # 3103

Starting Date- Approximately January 2012

• Power On: Press and release the POWER keypad button to engage power. All LED’s

will come on then most will go out. The LED next to the POWER button should be lit

RED when power is on. The ignition key will need to be in the off position and the park

brake will need to be set to extend the jacks. If you attempt to extend jacks by pressing

the DOWN▼ keypad buttons or all jacks with the AUTO-LEVEL button, you will hear a

“deny” tone from the keypad if the ignition key and or park brake is in the improper

position.

• Planting the Jacks: The jacks will be extended in pairs Fronts or Rears or Left

or Right Using the DOWN▼ (extend) keypad buttons, extend the jacks until they

contact the ground (this is referred to as “planting” the jacks). As you extend each pair

of jacks the corresponding LED jack status lights will come on to indicate jack(s) are out

of the “stowed” position. Jacks will be operated in pairs. Extend and plant the front jacks

first. Then extend and plant the rear jacks. Only after planting the fronts and then the

rears, should side to side corrections (leveling) be attempted. This process will stabilize

all four corners and minimize twist prior to the leveling process.

Do not manually over extend jacks. This may cause unwanted stress on the

coach or the jacks.

• Leveling the Coach: Use a bubble level on a flat surface in the center of the

coach as a reference. Level the vehicle by using DOWN▼ (extend) or UP▲ (retract)

keypad buttons until the vehicle is level. Front to rear then side to side. Jacks will

be operated in pairs. Do not attempt to lift the vehicle tires off of the ground. Only lift

(extend) enough to level and stabilize the unit. Once level, press and release the

POWER button to turn off the keypad. Note: The keypad may be left on once level

has been achieved. The keypad will enter “sleep mode” after five minutes of inactivity.

• Retracting the Jacks: To retract all jacks simultaneously, press and release

the ALL RETRACT button. All jacks will automatically retract and return to stowed

position. The pump will run in retract mode until all of the jacks are fully stowed

(plus an additional 5 seconds- up to a maximum of 60 or 90 seconds). This is the proper

method for retracting the jacks prior to travel. You may stop the ALL RETRACT by

pressing any button on the keypad. Jacks may be retracted in pairs by using the UP▲

button for each end or side for leveling purposes. However, the ALL RETRACT must be

used to fully stow the jacks prior to travel. The jacks down status LED lights will turn off,

indicating the jacks are in the stowed position.

• Power OFF: Press and release the POWER keypad button.

Visually Confirm all Jacks are Retracted Prior to Travel

There are ten (10) LED indicators on the AUTO-LEVEL keypad. The functions of these LED’s are detailed below.

4.

Keypad Indicator LED’s

During

typical

operation,

the

LED’s

on

the

bottom

left

hand

corner

of

the

keypad

should

NOT

be

illuminated.

The

only

LED

that

should

light

is

the

‘OPERATING’

LED,

which

should

flash

during

operation.

‘POWER’

LED .......................................... ON Red when power is ON

OFF when power is OFF

FLASH every 5sec. In Sleep Mode

‘JACK’

LED (4 each) ............................. ON Red when jack(s) are deployed

OFF when jack(s) are stowed

‘OPERATING’

LED ................................. ON Red w/ Auto Level or All Retract

OFF when keypad is idle or ‘sleeping’

‘LOW

VOLTAGE’

LED .......................... ON Red when voltage is below 10.5 volts dc

OFF when voltage is above 10.5 volts dc

‘ENGAGE

PARK

BRAKE’

LED........... ON Red when park brake is not set

OFF when park brake is set.

‘IGNITION

ON’

LED ............................... ON Red when ignition is in the ON position

OFF when ignition is OFF

‘EXCESS

SLOPE’

LED .......................... ON Red

following

an Auto Level attempt, if

system cannot overcome slope

OFF when slope is not excessive

Note: If the LOW VOLTAGE, ENGAGE PARK BRAKE< IGNITION ON or EXCESS SLOPE

LED’s illuminate, an “error” condition is present and must be corrected prior to operating

the jacks.

5.

Helpful Hints

Your coach is equipped with an air suspension.

The air suspension is deflated when the auto-level button is pressed and re-inflated when the all retract button is pressed.

The re-inflation requires that there is air pressure available to inflate the air suspension when the all retract button is

pressed. So it is recommended that the engine be started and air pressure allowed to build prior to pressing all retract to

assure that air is available to inflate the air suspension.

Your leveling system is equipped with an override option.

See the section on override. This is to allow you to get the jacks retracted in the event of electrical failure. It is

recommended that you review and understand this procedure prior to its need rather than to learn the procedure in

difficult environments.

Automatic functions.

You may stop automatic functions (auto level or all retract) at any time by pressing any button on the keypad. If auto

level is in process and the ignition key is turned to the engine run position or the park brake is released auto level will stop

and the warning beeper will come on and the jacks down status lights will flash.

Movement during auto level.

Excessive movement in or of the coach during the auto level process may result in the system not leveling properly.

Examples of this are strong winds that rock the coach during the auto level process or getting out of the coach causing a

rocking during the leveling process.

Proper Voltage.

The auto level system is a micro processer controlled system that requires adequate voltage and a permanent chassis

ground. Low voltage and or poor connections can prevent the operation or stop the operation in process.

Unit storage.

If the unit is stored for more than 24 hrs. with the jacks retracted it is possible that the jacks down status lights will come

on when the key is turned to the engine run position. Simply press the all retract button to clear the lights and the warning

buzzer.

Maintenance Items

Maintain the reservoir fluid level to a minimum ¾ full when the jacks are fully retracted. Use automatic transmission fluid

that meets a Dexron specification, the use of the “multipurpose” automatic transmission fluid is fine.

Change the fluid in the reservoir if it shows signs of contamination, debris or water.

The cylinder rods may be cleaned and protected by using WD-40 or equivalent.

Proper maintenance of the vehicles batteries and electrical system is important for proper system operation. Proper

voltage and grounding is critical. Follow the battery and coach manufactures guidelines for proper care and maintenance.

Additional Maintenance items and Troubleshooting items may be found on the web site

www.equalizersystems.com

6.

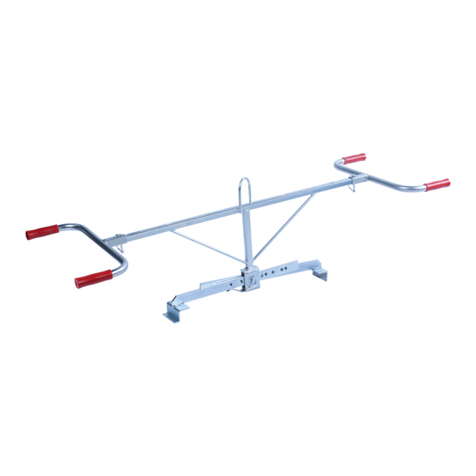

Override procedure

The leveling system is equipped with an override option to allow for the retraction of the jacks if the electrical system has

faulted. Generally if the fault is week or dead batteries it is best to charge the batteries and operate the system normally.

The procedure requires a 1/8 inch Allen wrench and an electric drill (recommended 2000 rpm) with a 7/16 hex driver.

1. Locate and access the pump/manifold assembly. Generally it will be located behind a plastic shield in one of the

forward storage compartments.

2. On the side of the manifold there are 4 individual cartridge valves (one for each jack leg). There is an Allen (1/8

inch) screw recessed in the center of the end of the valve stem. Using a 1/8 inch Allen wrench turn the screw(s) in

Clockwise approximately 2 turns until they stop. All 4 may be selected or just the ones that are for the jack(s) that

are needing to have the override performed on. (See Drawing)

Note: some units may have a single valve on the opposite side (retract) of the manifold, if so it must have the

screw turned in as above.

3. Locate the plastic plug at the end of the motor use a small screw driver to pry out the plug. This will expose the

motor override hex. Using a drill with a 7/16 hex drive bit run the drill in the Counter-Clockwise direction to

retract the jack(s) until they are fully retracted. Re-install the plug when completed. (See Drawing)

Hint: If the pump motor will run from the Keypad using the drill may not be needed. Simply press the all

retract after step 2.

4. When the jack(s) are fully retracted return all of the override screws (item 2 above) to their original out counter-

clockwise position.

Important failure to return the valves to the out (counter-clockwise) position may result in the jacks

“Drifting” from the stowed position.

7.

Equalizer Systems Limited Warranty Policy

March 2017

1. Only warranty claims with prior written or verbal authorization from Equalizer Systems will be recognized, all other claims will

be denied.

2. Equalizer Systems warrants slide out and leveling system components for a period of two years from the date of original sale of

the vehicle. This warranty covers defects in material and workmanship only. Equalizer Systems is not liable for any damage due to

abuse, neglect, misuse, negligence, misapplication, error of operation, accidental or purposeful damage or damage due to an “act of

God” such as, wind or rain damage, flood, lightning or other natural occurrence of the like. Equalizer Systems limited warranty is

applicable to the Equalizer Systems components only and does not apply to the vehicle, apparatus or property to which it is

attached. Warranty parts will be shipped at no charge if the repair is authorized by an Equalizer Systems representative. Purchased

components used in authorized warranty repairs will be reimbursed at the original purchase price.

3. Labor and freight expenses due to warrantable parts defects or workmanship will be reimbursed for a period of one year from the

date of original sale of the vehicle. Freight expenses will either be prepaid by Equalizer Systems or reimbursed at the UPS Ground

rate only. Any additional shipping charges or requirements are the obligation of the vehicle owner or service center performing the

warranty repair. The owner or service center’s obligation may include overseas shipping charges, border fees, brokerage fees and

any other additional fee of the like.

4. Warranty labor will be reimbursed only for claims that have prior written or verbal authorization from an Equalizer Systems

representative. Warranty labor compensation is required to correspond with the “Warranty Parts Replacement Time Guideline”

published by Equalizer Systems. Any warranty repair not listed on this guideline will require prior authorization from an Equalizer

Systems representative. A reasonable time allowance will be determined by the Equalizer Systems representative. Any warranty

repair that is not listed on this guideline that is performed without prior authorization will be denied without exception. Time

associated with learning about the repair or excessive diagnostic and installation time will not be reimbursed. Warranty labor will be

reimbursed at the authorized service center’s published shop rate if the rate is reasonable for that region. Overtime labor will not be

reimbursed without exception.

5. Labor, parts and freight credit (if applicable) will be sent after the parts are tested and the warranty claim is validated. Returned

parts that are found to be in normal operating condition are not warrantable and will be charged to the owner or service center.

Equalizer Systems reserves the right to charge back the service center for labor claim payments previously submitted if the

installation of the warranted part is found to be inadequate at a later date.

6. Claims will be denied if the date submitted is greater than 30 days from the repair date.

7. Prior authorization is required before parts may be sent back to Equalizer Systems. A Return Authorization Number is required

for items to be accepted.

8. Complete systems are not warranted unless authorized by an Equalizer Systems representative. There are absolutely no

exceptions to this clause.

9. Warranty coverage for parts or systems sold by non-authorized resellers (such as live or internet auctions) will be at the discretion

of Equalizer Systems.

10. Equalizer Systems is not liable for loss of time, manufacturing costs, labor, material, loss of profits, direct or indirect damages

incurred by the vehicle manufacturer.

11. Excessive warranty labor resulting from inadequate access to the Equalizer Systems product will not be reimbursed.

12. Equalizer Systems will not pay a markup on warranty parts unless required by law.

13. Travel expenses, hotel, telephone, fuel or any other expenses of the like are not covered under warranty.

Replacement Parts:

1. Replacement parts are warranted under the same guidelines listed above for the remainder of the original warranty or 90 days,

whichever is longer. Proof of warranty repair date and original vehicle purchase date are required.

No additional warranties, expressed or implied, are authorized by Equalizer Systems

This warranty voids all previous issues.

Questions concerning this warranty should be directed to:

Equalizer Systems

55169 CR 3 North

Elkhart, IN 46515

1-(800) 846-9659

1-(574) 266-6083 fax

To activate your warranty, please visit our website at http://equalizersystems.com/service/activate-warranty

OM001-ER1

This manual suits for next models

1

Table of contents