Equipment Technologies APACHE AS740 User manual

TM

2019 Operator’s Manual

AS740

DO NOT OPERATE THIS EQUIPMENT UNTIL THIS MANUAL HAS BEEN READ AND UNDERSTOOD.

ONLY PROPERLY TRAINED PERSONS SHOULD OPERATE THIS MACHINE.

FORM # 580510004

COPYRIGHT 2018

EQUIPMENT TECHNOLOGIES

ApacheSprayerInformation

Dealer: _________________________

Main Phone # _______________

Service Contact: __________________

Phone # ___________________

Parts Contact:____________________

Phone# ___________________

Shop Contact: ____________________

Phone #___________________

Sales Rep:_______________________

Phone # ___________________

Precision Rep: ____________________

Phone # ___________________

ET / Apache Phone #: _______________

Machine Model: ________________________

Machine Serial #:________________________

Engine Serial #: _________________________

Rate Controller Model:_____________________

Aux Controller/Display:____________________

GPS Antenna Model:______________________

GPS Source:_________ GPS Satellite:_______

Height Control:__________________________

Software Version:________________________

Offset: LH Outer:______ LH Inner:______

Center:________ RH Inner:______

RH Outer:______

Sensitivity:______ Speed:______ Stability:_____

Autosteer: ____________ Module Orientation:____

Software Version:_________________________

Guidance Width/Inches:_______________

# of Sections:__________________

Boom 1 Cal:___________________

Boom 2 Cal:___________________

Boom 3 Cal:___________________

Boom 4 Cal:___________________

Boom 5 Cal:___________________

Boom 6 Cal:___________________

Boom 7 Cal:___________________

Boom 8 Cal:___________________

Boom 9 Cal:___________________

Implement Offsets:

Fore/Aft:______ Height:______

Wheelbase:_________________

Product Control:

Speed Cal#:__________________

Valve Cal#:__________________

Meter Cal#:__________________

Valve Advance:_______________

Valve Delay:_________________

Section Control:

On Look Ahead:_______________

Off Look Ahead:_______________

Low Limit/ Minimum Flow:

Nozzle Size/Color/Rate_______=_______

Nozzle Size/Color/Rate_______=_______

Nozzle Size/Color/Rate_______=_______

Nozzle Size/Color/Rate_______=_______

*To maintain minimum spray pattern adjust when

changing nozzle size.

The password for the locked screens on the ET Pilot Touchscreen is “2201”.

TM

AS740 Operator’s Manual i

Dear Valued Customer,

Congratulations on the purchase of your new Apache Sprayer, and welcome to the Apache

family of owners! We hope that your new Apache Sprayer exceeds your expectations, and

gives you years of satisfaction. We invite you to visit us at www.etsprayers.com or in

person at our plant in Mooresville, Indiana.

On behalf of all of our employees, we thank you for your business!

Yours Faithfully,

Matthew F. Hays

Chief Executive Officer

TM

AS740 Operator’s Manual

ii

NOTICE

Before operating your Apache Sprayer, please check and calibrate the following precision agricultural

equipment depending on the machine configuration. Always operate the Apache within the state and local

guidelines and regulations.

1. Check all settings and calibrations in your Viper® 4+, field computers:

• Swath Width

• Boom Section Calibration

• Receiver Fore/Aft Settings

• Valve Calibration

• Flow Meter Calibration

• Rate Calibration

• Low Limit Setting

2. Please review your AutoBoom® and AccuBoom™ settings, if equipped.

3. Calibrate the RS1®autosteer if equipped. RS1®autosteer calibration must be performed on a large,

flat, and open area. Make sure all settings are entered properly, and that calibration is performed in its

entirety. This includes driving on an A-B line for roughly 20 minutes after automatic calibration is complet-

ed to allow the yaw sensor to learn how to acquire the line properly.

TrademarkInformation

Caterpillar®

• Cat® TDTO 30

Cummins®

Raven Industries

• AccuBoom™

• AutoBoom®

• FlowMax™

• RS1® Autosteer

• Viper® 4+

Equipment Technologies (ET)

• Apache™

Lucas® Oil Products

SiriusXM™

Michelin®

Goodyear®

John Deere®

• Autotrac™

AS740 Operator’s Manual iii

TM

TABLE OF CONTENTS

Chapter 1: General Information

2019 AS740 Specifications 1-1

Apache AS740 Fluids, Filters and Capacities 1-2

Chapter 2: Safety

Safety Symbols, Signal Word and Statements 2-1

Safety Precautions 2-2

Pre-Operation Hazards 2-2

Fire and Explosion Hazards 2-2

Burn Hazards 2-3

Lifting Hazards 2-3

Exposure Hazard 2-3

Entanglement / Sever Hazard 2-3

Alcohol and Drug Hazard 2-3

Exhaust Emissions Safety 2-4

Environmental Precautions 2-4

Safety Belt 2-4

Safety Decals 2-5

Exterior Decal Locations 2-6

Chapter 3: Operation

Pre-Operation Checks 3-1

Cab Overview 3-2

Cab Access Ladder 3-3

Steering Column 3-3

ET Pilot System 3-4

ET Pilot System Touch Screen 3-6

Diagnostics Page 1 3-8

Fault History 3-9

Diagnostics Page 2 and 3 3-10

Diagnostics Page 4 3-11

Scheduled Maintenance App 3-15

Vehicle Settings Page 1 and 2 3-17

Vehicle Settings Page 3 and 4 3-18

Vehicle Settings Page 4 3-19

Light Buttons 3-19

Apache Sprayer Lighting 3-20

AM/FM Radio with Weather Band 3-20

SiriusXM Satellite Radio Activation Information 3-21

Seat Adjustment 3-22

Joystick and Viper® 4+ 3-23

Starting and Stopping Engine 3-24

Warm-up 3-25

Stopping 3-25

Apache Sprayer Direction and Speed 3-26

Neutral 3-26

Forward 3-27

Shifting Forward Gears 3-27

Reverse 3-28

Foot Throttle/ Decelerator 3-29

Exhaust Braking 3-29

Cruise Control 3-30

Towing 3-31

Hood Tilt Latch 3-31

Battery 3-32

Cabin Power Distribution Module 3-32

Chassis Distribution Module 3-32

Axle Adjustment (Manual) 3-33

Front 3-33

Rear 3-33

Axle Adjustment (Optional)

(Adjust-On-The-Go) 3-34

Adjust-On-The-Go Calibration 3-34

Front 3-35

Rear 3-36

Vehicle Dynamics 3-36

Climate Controls 3-37

Precision Equipment 3-38

Antenna Mounting Plate 3-38

Rear Camera 3-39

Jumpstarting The Engine 3-40

Exhaust Cleaning 3-42

Automatic Cleaning 3-42

Disabled Mode 3-43

Manual Cleaning 3-44

Low DEF Fluid 3-45

Chapter 4: Wet System Operation

Wet System Overview 4-1

Fill Station 4-2

Product Pump and Valves 4-2

Sump Valve 4-3

Flow Control 4-3

Electronic Boom Valves 4-4

Viper® 4+ Monitor 4-4

Side Console 4-5

Joystick 4-6

Filling Product Tank 4-6

Tank Fill Monitor 4-7

Product Tank Sight Gauge 4-9

Filling Rinse Tank 4-9

Operating Booms 4-10

Tilt to Remove Boom from Cradle 4-10

Unfold Boom Wings 4-10

Unfold Boom Tips 4-10

TM

AS740 Operator’s Manual

iv

Height Adjustment 4-11

Tilt to Level Boom 4-11

Fold Boom Tips 4-11

Fold Boom Wings 4-12

Tilt to Return Boom to Cradle 4-12

Spraying 4-12

Optional Fence Row Nozzle 4-15

Flushing Product Tank 4-15

Flushing Booms 4-16

Cleanload Chemical Eductor 4-17

Startup 4-17

Loading Liquid or Powdered Chemical into Hopper 4-17

Chapter 5: Lubrication and Maintenance

Maintenance Precautions 5-1

Environmental Precautions 5-3

Non-Apache Equipment Maintenance 5-3

Cleaning Guidelines 5-4

Mechanical Parts 5-4

Electrical Parts 5-4

Body and Cab Exterior 5-4

Apache Sprayer Service Interval Chart 5-5

Before Initial Use 5-6

After First 10 Hours 5-6

Adjust Boom 5-6

As Required 5-9

Daily 5-9

Boom Fold Cylinder 5-9

Grease Pommier Boom 5-10

Flush Wet System 5-12

Check Tire Pressure 5-12

Check Engine Oil Level 5-13

Check Cooling System 5-14

Cycle Fan Reverser 5-14

Check Transmission Fluid Level 5-15

Check Hydraulic Fluid Level 5-15

Adjust Poly Tank Straps 5-16

Every 40 Hours 5-16

Torque Lug Nuts 5-16

Grease Rear Suspension 5-16

Grease Front Axle Assembly 5-17

Grease Axle Components 5-18

Check Differential Fluid Level 5-18

Check Rear Differential for Leaks 5-18

After First 100 Hours 5-19

Every 100 Hours 5-20

Grease Driveline Components 5-20

Torque Axle Extension Brace Bolts 5-21

Change Fuel Filter 5-22

Change Fuel Separator Filter 5-22

Clean Fuel Tank Strainer 5-23

Every 500 Hours or Yearly 5-24

Clean or Change Engine Primary Air Filter 5-24

Change Differential Fluid 5-25

Change Hydraulic Fluid Filter 5-25

Clean Hydraulic Fluid Strainer 5-25

Inspect Front Accumulator and Suspension Cylinder 5-27

Check Front Suspension Cylinder Fluid Level 5-27

Check Accumulator Charge 5-27

Change Engine Oil and Filter 5-28

Change Transmission Fluid and Filter and Clean Strainer 5-29

Inspect and Repack Wheel and Inter-Flex Bearings 5-30

Change Final Drive Fluid 5-31

Change Cab Charcoal Filter 5-32

Every Year 5-33

Adjust Toe-In

(Standard 120” Axles) 5-33

Adjust Toe-In

(120” to 160” Adjustable Axles) 5-34

Change Engine Safety Air Filter 5-35

Winterize Wet System 5-36

Every 1000 Hours or Yearly 5-38

Change Hydraulic Fluid 5-38

Change DEF Suction Strainer 5-38

Every 2000 Hours 5-39

Change Crankcase Ventilation Filter 5-39

Every 4500 Hours or 3 Years 5-39

Change DEF Supply Module Filter 5-39

Chapter 6: Torque Value Charts

Fittings 6-1

Torque Value Chart 6-1

Bolts 6-2

Metric Bolts 6-2

Chapter 7: Troubleshooting

Apache Sprayer Troubleshooting

Symptoms and Solutions 7-1

Chapter 8: Electrical System

Chassis Power Distribution Module Chart 8-1

Cabin Power Distribution Module 8-2

Boom Power Distribution Module 8-3

Chapter 9: Warranty

Equipment Technologies Warranty Policy

For all 2019 Model Year Apaches 9-1

Chapter 10: Maintenance Log

AS740 Operator’s Manual 1-1

TM

CHAPTER 1

GENERAL INFORMATION

The graphics and text in this manual generally describe the AS740 Apache Sprayer. Apache Sprayers differ by model and by optionally

installed equipment. Your Apache Sprayer may not exactly match the graphics and/or text descriptions in this manual. Please contact

your dealer or Equipment Technologies with any questions regarding this manual, or the instructions within it.

2019 AS740 Specifications

AS740

Tank Capacity 750 gallons [2839 liters]

Engine 173 hp T4-F QSB6.7 Cummins

Transmission JCB Power shift 4-speed, torque converted

Speed Ranges 1st 0-5 mph [0-8.04 km/h], 2nd 0-9 mph [0-14.5 km/h],

3rd 0-16 mph [0-25.7 km/h], 4th 0-28 mph [0-45 km/h]

Brakes Internal, wet disc, self adjusting

Suspension Front Axle: Center oscillating with independent hydraulic, accumulated struts.

Rear Axle: Patented hydraulic load suspension with compensating anti-sway

control, self-adjusting for diminishing/increasing load.

Cab ET custom pressurized cab

Crop Clearance 42 in. [106.6 cm] or 50 in. [127 cm]

Axles 120 in. [304.8 cm] Fixed Width Axle (Standard)

120 to 160 in. [304.8 to 406.4 cm] Adjustable Axle Width with Optional

Hydraulic Adjust (50 in. clearance only)

Final Drive JCB planetary gearset

(42 in. [106.6 cm] CC);

JCB all gear drop box

(50 in. [127 cm] CC)

Weight 19,200 lb [7892.5 kg] dry weight

Fuel Capacity 90 gallons [340.69 liters]

Width 12 ft [3.6 m]

Length 24 ft [7.3 m]

Height 144 in. [365.7 cm]

Wheel Base 15 ft [4.6 m]

Turning Radius 17 ft [5.1 m]

Standard Tires Front: 380/80R38 and Rear: 380/90R46

Booms 90 ft [27.4 m], 100 ft [30.4 m], 120 ft [36.6 m], 132 ft [40.2 m], 60 / 90 ft [18.2 / 27.4 m]

Boom Height 18 to 89 in. [45.6 to 226.1 cm]

(42 in. CC [106.6 cm] CC):

26 to 97 in. [66 to 246.4 cm]

(50 in. CC [127 cm] CC)

Product Pump Hypro 9306C HM1C, hydraulically driven centrifugal pump

Roto-Flush Pump pressured

TM

AS740 Operator’s Manual

GENERAL INFORMATION

1-2

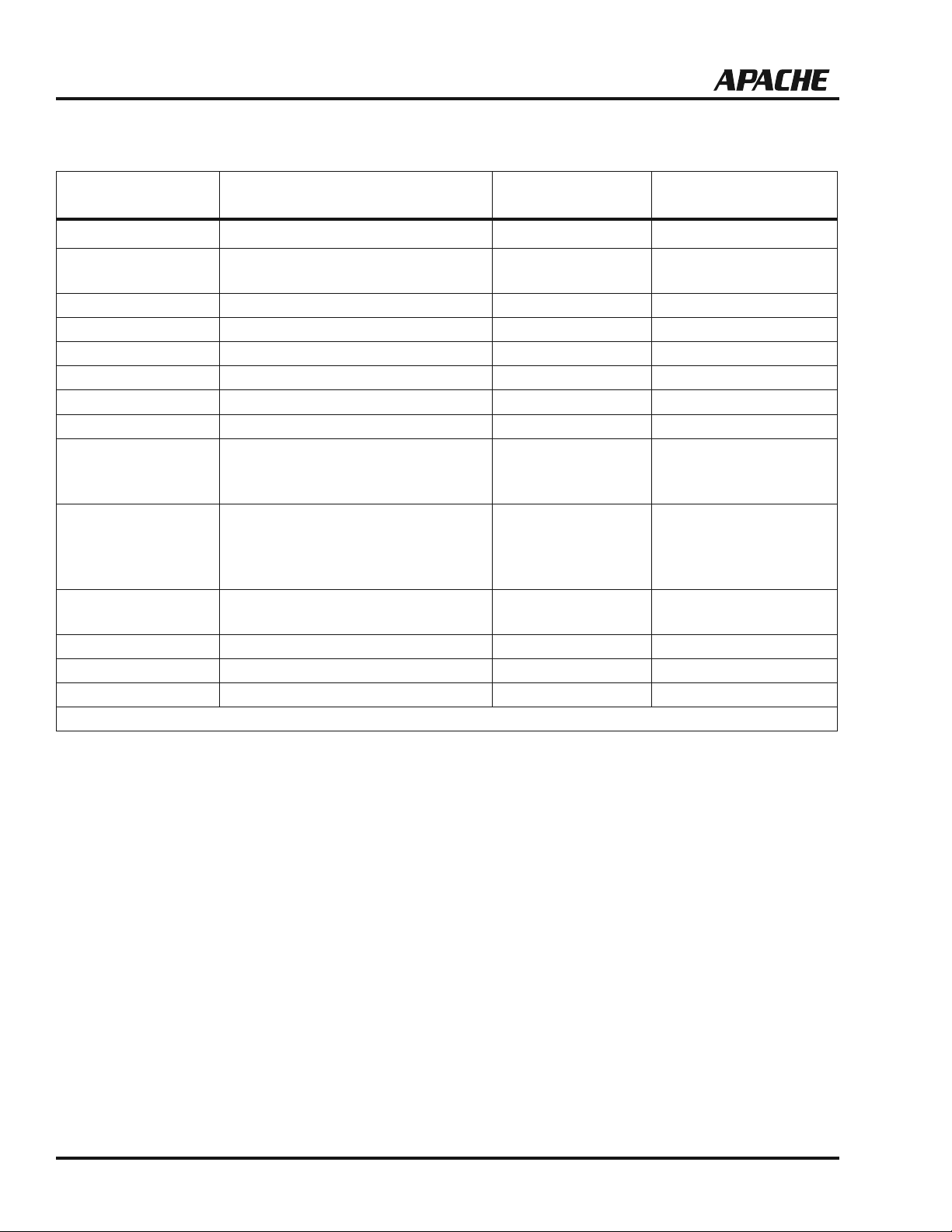

Apache AS740 Fluids, Filters

and Capacities

Component Lubrication Capacity

Quarts [Liters] Filter Part Number

Engine Oil Lucas 15W-40 Magnum Motor Oil 16 [15] 201450241

Engine Coolant KostGuard Universal

Antifreeze 50/50 24 [22.7] ----

Engine Primary Air Filter ---- ---- 230000001

Engine Safety Air Filter ---- ---- 230000002

Transmission Lucas Universal Hydraulic Fluid 16 [15] 300000101

Differential (Rear Axle) Lucas Universal Hydraulic Fluid 11.9 [11.26] ----

Planetary Lucas 80/90 Gear Oil 2.9 [2.7] ----

Rear Drop Box Lucas 80/90 Gear Oil 21 [20] ----

Engine Fuel Diesel 90 Gallons

[340.69 Liters]

Filter: 261000003

Separator/Filter: 211000000

Tank Strainer: 201450001

Diesel Exhaust Fluid (DEF) ...... 5 Gallons [19 Liters]

DEF Supply

Module Filter: 241000009

DEF Tank

Suction Screen: 241000008

Hydraulic System Lucas Universal Hydraulic Fluid 40 Gallons

[151.42]

Filter: 880000026

Strainer: 840000010

Front Suspension Lucas Universal Hydraulic Fluid as required ----

A/C System R134a 2.8 lbs ----

Cab Filter ---- ---- Charcoal Filter: 490003651

NOTE: Any oil and fluid substitutions must meet or exceed recommended fluid specifications.

Michelin Tire Pressure (Cold)

380/80R38...................................29 psi [2.0 bar]

380/90R46...................................42 psi [2.9 bar]

480/70R34...................................20 psi [1.38 bar]

620/70R42...................................35 psi [2.83 bar]

800/65R32...................................23 psi [1.59 bar]

Lug Nut Torque

All Wheels.................................................................................................................................................420 lb-ft [570 N•m]

Wet System Capacities

Product Tank AS740..........................................................................................................................750 gallons [2839 liters]

Rinse Tank...........................................................................................................................................100 gallons [379 liters]

Hydraulic Pump Output...............................................................................................................................................2400 psi [165 bar]

Goodyear Tire Pressure (Cold)

320/85R38 ..............................................35 psi [ 2.41 bar]

320/90R50 ..............................................75 psi [ 5.17 bar]

TM

AS740 Operator’s Manual 2-1

CHAPTER 2

SAFETY

Apache is committed to the safe design and operation of

its products. This Apache Sprayer has been designed and

manufactured with your personal safety while operating

the Apache Sprayer as a primary concern.

Safety, Symbols, Signal Words and

Statements

Safety symbols, signal words, and statements, are used

in this manual and on the Apache Sprayer to identify

and alert you of potential hazards where personal safety

precautions are required.

The safety alert symbol is used to

alert you of potential personal injury

hazards. Carefully read the safety

message associated with safety

symbol and follow any instructions

provided to ensure your safety.

Safety signal words are used to alert you of the potential

personal injury hazards. Carefully read the safety message

associated with safety signal word and follow any instruc-

tions provided to ensure your safety.

Safety statements are used to explain and inform you of

potential personal injury hazards and provide precaution-

ary instructions. Read, understand and follow all safety

messages and information contained in this manual and

on the Apache Sprayer to prevent personal injury and

ensure safe reliable Apache Sprayer operation.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

The italicized NOTICE, indicates a potentially hazardous

situation which, if not avoided, may result in improper

Apache Sprayer operation and/or damage to equipment,

property and the environment.

TM

AS740 Operator’s Manual

Safety

2-2

Safety Precautions

There is no substitute for common sense and following careful operation and service practices. Improper practices and carelessness

can cause personal injury or even death.

The following safety precautions and guidelines must be followed in addition to the specific safety precautions listed throughout this

manual and on the Apache Sprayer to reduce the risk of personal injury.

Keep this manual and all included literature in a safe and convenient location. Contact your Apache dealer or Apache at (800) 861-

2142 to obtain replacement owner’s manuals and safety decals.

To ensure your safety, the safety of others, and the safe operation of the sprayer, read, follow and practice the following:

The safety messages that follow have

WARNING level hazards.

Pre-Operation Hazards

Read and understand this Owner’s Manual before operating or servicing the Apache Sprayer to

ensure that safe operating practices and maintenance procedures are followed. If you do not

understand any part of this manual and need assistance, see your Apache dealer for assis-

tance.

• NEVER permit anyone to operate the Apache Sprayer without proper training. Obtain

proper knowledge and training before attempting to perform any operation or service

procedure in this manual.

• This Apache Sprayer and its attachments are designed to spray liquid product. Use of

this Apache Sprayer in any other manner other than its intended use is prohibited.

• Remove or clean contaminated clothing before entering the cab.

• Some components and systems of Apache Sprayers are manufactured by companies

other than Apache and have specific safety, inspection, adjustment and maintenance

procedures outlined by their manufacturer. Carefully read and understand all non-

Apache Sprayer and sprayer manufacturer instructions and manuals supplied with

the Apache Sprayer. These include, but are not limited to the Engine Owner’s Manual,

Sprayer Monitor System Manual, Radio Manual, Chemical Eductor Manual, Product

Pump Instructions and other optional equipment.

Fire and Explosion Hazards

Diesel fuel is flammable and explosive under certain conditions. Store any containers containing

fuel in a well-ventilated area, away from any combustibles or sources of ignition.

• NEVER use a shop rag to catch spilling fuel.

• Wipe up all fuel spills immediately.

• NEVER refuel with the engine running.

• ALWAYS have appropriate safety equipment available. Have all fire extinguishers

checked periodically for proper certification, operation and/or charge capacity.

• ALWAYS read and follow safety-related precautions found on containers of hazardous

substances like parts cleaners, primers, sealants and sealant removers.

TM

AS740 Operator’s Manual

Safety

2-3

Burn Hazards

Some of the engine surfaces become very hot during operation and shortly after shut-down. Keep

hands and other body parts away from hot engine surfaces.

Lifting Hazards

• ALWAYS use lifting equipment with sufficient capacity to lift the Apache Sprayer or equipment.

• If transport is needed for repair, acquire assistance when using a hoist and when loading and unloading.

ALWAYS wear the appropriate personal protective equipment as required by the task at

hand, including but not limited to:

• Relatively tight and belted clothing

• Safety gloves

• Safety shoes/boots

• Safety eye glasses/goggles/shields

• Hearing protection, ear plugs

• Head protection, hard hats

• ALWAYS wear a respirator, goggles and gloves in addition to wearing long shirt sleeves

and long pants when handling chemicals. Read the chemical safety label or instructions

before usage.

Entanglement / Sever Hazard

NEVER wear jewelry, watches, unbuttoned cuffs, ties or loose-fitting clothing and ALWAYS

tie long hair back when working near moving/rotating parts.

• ALWAYS Keep hands, feet, hair and clothing away from all moving/rotating parts.

• NEVER operate the engine without the guards in place.

Alcohol and Drug Hazard

• DO NOT operate or service the Apache Sprayer while under the influence of alcohol, awareness-altering drugs or

medications that would affect your ability to operate or maintain the sprayer safely.

Exposure Hazard

TM

AS740 Operator’s Manual

Safety

2-4

Exhaust Emissions Safety

Carefully read all safety information and observe any exhaust or pollution safety instructions. Be aware of and follow all regulations

and policies as outlined by the engine OEM to maintain exhaust emission compliance with the Environmental Protection Agency (EPA),

California Air Resources Board (CARB) and Environment Canada where applicable.

It is the owner’s responsibility to keep the Apache Sprayer maintained and within compliance.

The state of California, U.S., has special regulations that may exceed the EPA regulations. If the Apache Sprayer is operated or ser-

viced in the state of California, observe all exhaust and pollution regulations.

WARNING! Exhaust Gas Exposure Hazards

• All internal combustion engines create carbon monoxide gas during operation and special precautions

are required to avoid carbon monoxide poisoning. Prolonged exposure to carbon monoxide will cause

brain damage or death.

• ALWAYS operate the engine outside in a well-ventilated area.

• NEVER block windows, vents or other means of ventilation if the engine is operating in an enclosed

area.

• ALWAYS ensure that all connections are tightened to specifications after repair is made to the exhaust

system.

Environmental Precautions

The safety messages that follow have NOTICE level hazards.

• Thoroughly clean any spilled fluids from the equipment and/or ground after service is completed. Dispose of used fluids

and filters as required by law.

• ALWAYS be environmentally responsible. Follow the guidelines of the EPA or other governmental agencies for the

proper disposal of hazardous materials such as engine oil, diesel fuel and engine coolant. Consult the local authorities or

reclamation facility.

• NEVER dispose of hazardous materials by dumping them into a sewer, on the ground, or into ground water or water-

ways.

Safety Belt

WARNING! Impact Hazards

• ALWAYS fasten your seat belt when operating the Apache Sprayer. The safety belt must be worn

properly by the driver anytime the Apache Sprayer is in motion.

• NEVER alter or tamper with any safety belt system components.

Safety belt systems are designed to limit occupant motion by restraining occupants’ bodies within the cab and prevent, or reduce

the severity of, injuries during most types of collisions. When safety belts are used properly, they are effective in reducing the risk of

injury.

Inspect the safety belt system regularly for cuts, frays, wear, discoloration or abrasion. The hardware, mounts, retractor and belt

should work freely. The belt and/or components must not show signs of deterioration. If you suspect any part of the system is in need

of repair, have the system repaired or replaced immediately and use only parts designed for the safety system.

Safety belt systems are designed to limit occupant motion by restraining occupants’ bodies within the cab and prevent, or reduce

the severity of, injuries during most types of collisions. When safety belts are used properly, they are effective in reducing the risk of

injury.

Inspect the safety belt system regularly for cuts, frays, wear, discoloration or abrasion. The hardware, mounts, retractor and belt

should work freely. The belt and/or components must not show signs of deterioration. If you suspect any part of the system is in need

of repair, have the system repaired or replaced immediately and use only parts designed for the safety system.

TM

AS740 Operator’s Manual

Safety

2-5

WARNING! Impact Hazard

DO NOT operate the Apache Sprayer if any part of the seat belt system is damaged. The system must be

repaired or replaced before operating the Apache Sprayer.

Safety Belt (ctnd.)

NOTICE: DO NOT use harsh cleaners, bleach or any products which could cause the safety belt material to deteriorate.

Safety Decals

CAUTION!

ALWAYS read and follow the safety decals on the Apache Sprayer. Safety decals are additional

reminders for safe operating and maintenance techniques.

Safety decals are used to explain and inform you of potential personal injury hazards and provide precautionary instructions. Read,

understand and follow all safety decals on the Apache Sprayer to prevent personal injury and ensure safe reliable Apache Sprayer

operation.

NOTICE: Prevent safety decals from becoming dirty or damaged and replace them immediately should they become damaged or are

missing. Should an Apache Sprayer part that has a decal attached to it need replacement, obtain a new decal with the new part.

Contact your Apache dealer or Apache at (800) 861-2142 to obtain replacement safety decals.

To ensure your safety, the safety of others and the safe operation of the sprayer, read, follow and observe the following safety decals

shown on subsequent pages.

TM

AS740 Operator’s Manual

Safety

2-6

ExteriorDecalLocations

1.

2.

3.

4.

5.

TM

AS740 Operator’s Manual

Safety

2-7

6.

7.

8.

9.

ExteriorDecalLocations(continued)

TM

AS740 Operator’s Manual

Safety

2-8

ExteriorDecalLocations(continued)

10.

11.

12.

13.

14.

(Not shown in the picture)

TM

AS740 Operator’s Manual 3-1

CHAPTER 3

OPERATION

Before performing any operation procedures, read the following

safety messages and read the Safety Section.

WARNING! Control Hazard. DO NOT operate

the Apache Sprayer while wearing a headset

to listen to music or radio because it will be

difficult to hear the warning signals.

WARNING! Impact Hazard. Secure any loose

items in cab. Items that are unsecured may

cause injury in case of a roll-over.

WARNING! Roll-Over Hazards

• DO NOT operate on steep slopes.

• DO NOT drive across a slope. Drive up

and down slopes.

• DO NOT turn down a slope.

• Slow down when turning.

• Keep booms as close to the ground as

possible.

• Drive slowly across rough ground.

• DO NOT operate on public roads or high-

ways with product in the product tank.

• ALWAYS use 4 way flashers on public

roads or highways

• ALWAYS come to a complete stop before

reversing directions.

Pre-Operation Checks

Before operating the Apache Sprayer, perform the following

safety and equipment checks.

• Read and understand this manual before operating the

Apache Sprayer.

• Read and follow all safety messages and safety decal in-

structions in this section. See “Safety” on page 2-1. Check

the condition of all safety decals. Replace if damaged.

• Check that all shields and guards are properly installed and

in good working condition. Replace if damaged.

• Check all hardware for proper installation and torque. See

”Torque Value Charts” on page 6-1.

• Check the operating area for bystanders and obstruction

before operating.

• Check that all hydraulic hoses and fittings are in good con-

dition and not leaking. Make sure the hoses are routed to

prevent damage, not twisted, sharply bent, kinked, frayed,

or pulled tight or rubbing, before starting the Apache Spray-

er. Replace any damaged hoses or fittings immediately.

• Check the operation and condition of the seat belt. Immedi-

ately repair or replace the seat belt if damaged or if it does

not operate properly.

• Check tires for proper inflation pressure according to tire

manufacturer’s recommendations. Specifications are also

provided on the back cover of this manual. See ”Check Tire

Pressure” on page 5-12.

• Check engine oil level and add oil as needed. See ”Check

Engine Oil Level” on page 5-13.

• Check transmission fluid level and add fluid as needed. See

”Check Transmission Fluid Level” on page 5-15.

• Check differential, gearboxes and/or planetaries fluid levels

and add fluid as needed. See ”Check Differential Fluid

Level” on page 5-18.

• Check coolant level and add coolant as needed. See the

engine manufacturer’s manual for details.

• Check hydraulic reservoir fluid level and add fluid as need-

ed. See ”Check Hydraulic Fluid Level” on page 5-15.

TM

AS740 Operator’s Manual

OPERATION

3-2

CabOverview

6. Arm Rest

7. Brake Pedal

8. Air Seat

9. Fire Extinguisher

(left of seat)

1. Air Vents (multiple points in the steering

column - not shown)

2. Steering Column

3. Steering Wheel

4. Joystick

5. ET Pilot System

TM

AS740 Operator’s Manual

OPERATION

3-3

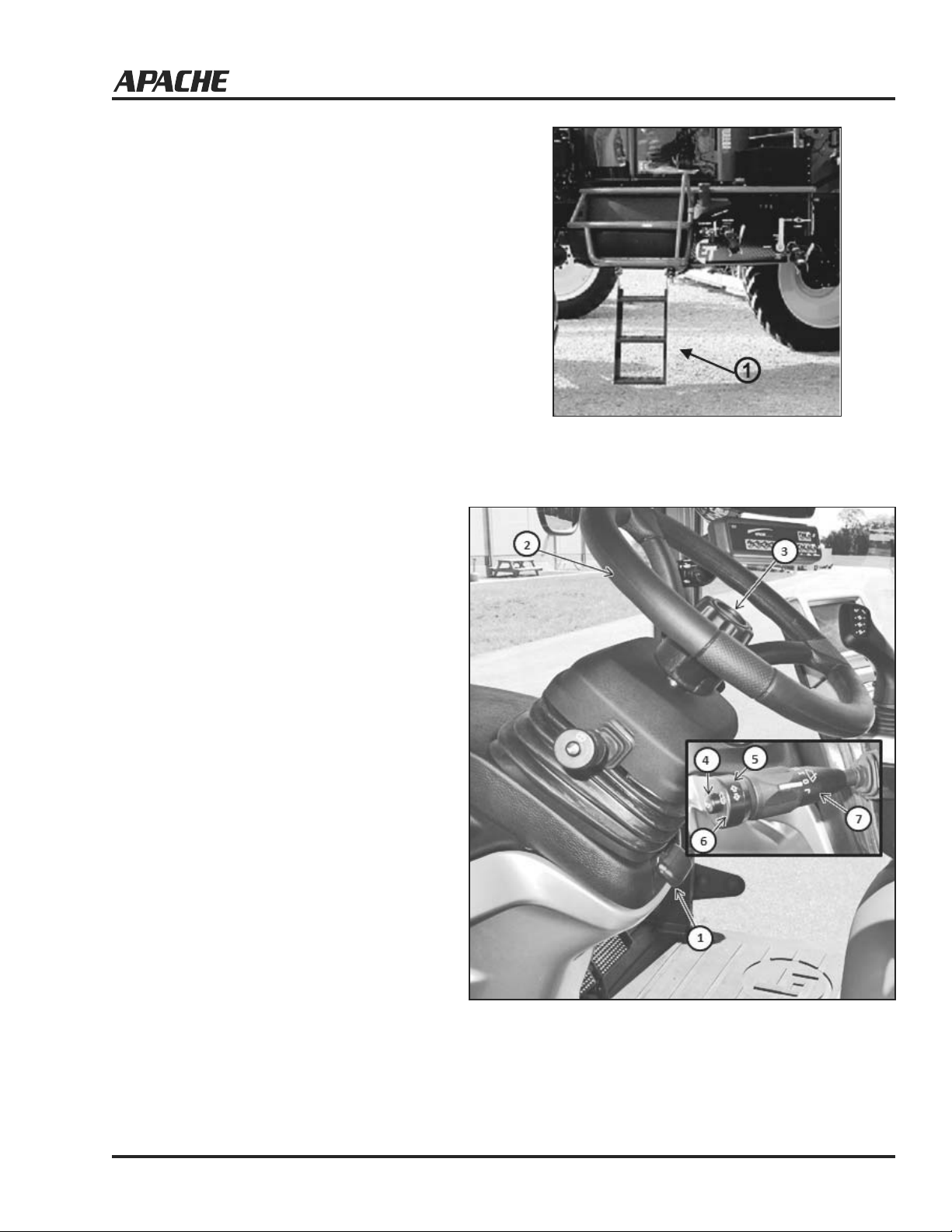

CabAccessLadder

1. Access Ladder

The cab access ladder is automatically actuated by

the parking brake switch.

• When the parking brake is applied, the ladder

folds down.

• When the parking brake is released, the ladder

folds up.

SteeringColumn

NOTE: DO NOT drill the plastic of the steering column, or alter in any way.

1. Steering Column Tilt Adjustment Lever

• Lift up on the lever.

• Adjust the tilt to the desired position.

• Release the lever to lock the column.

2. Steering Wheel

3. Steering Wheel Telescope Adjustment Knob

• Turn center knob counterclockwise to unlock.

• Position steering wheel to desired height.

• Turn center knob clockwise to lock.

4. Horn Button

• Push to sound horn.

5. Turn Signal Lever

• Push lever up for right turn signal.

• Push lever down for left turn signal.

6. Windshield Washer

• Push ring to operate washer.

7. Windshield Wiper Switch

• Turn lever to the “I” position for low-speed

wiper.

• Turn lever to the “II” position for high-speed

wiper

• Turn lever to the “J” position for delay wiper.

TM

AS740 Operator’s Manual

OPERATION

3-4

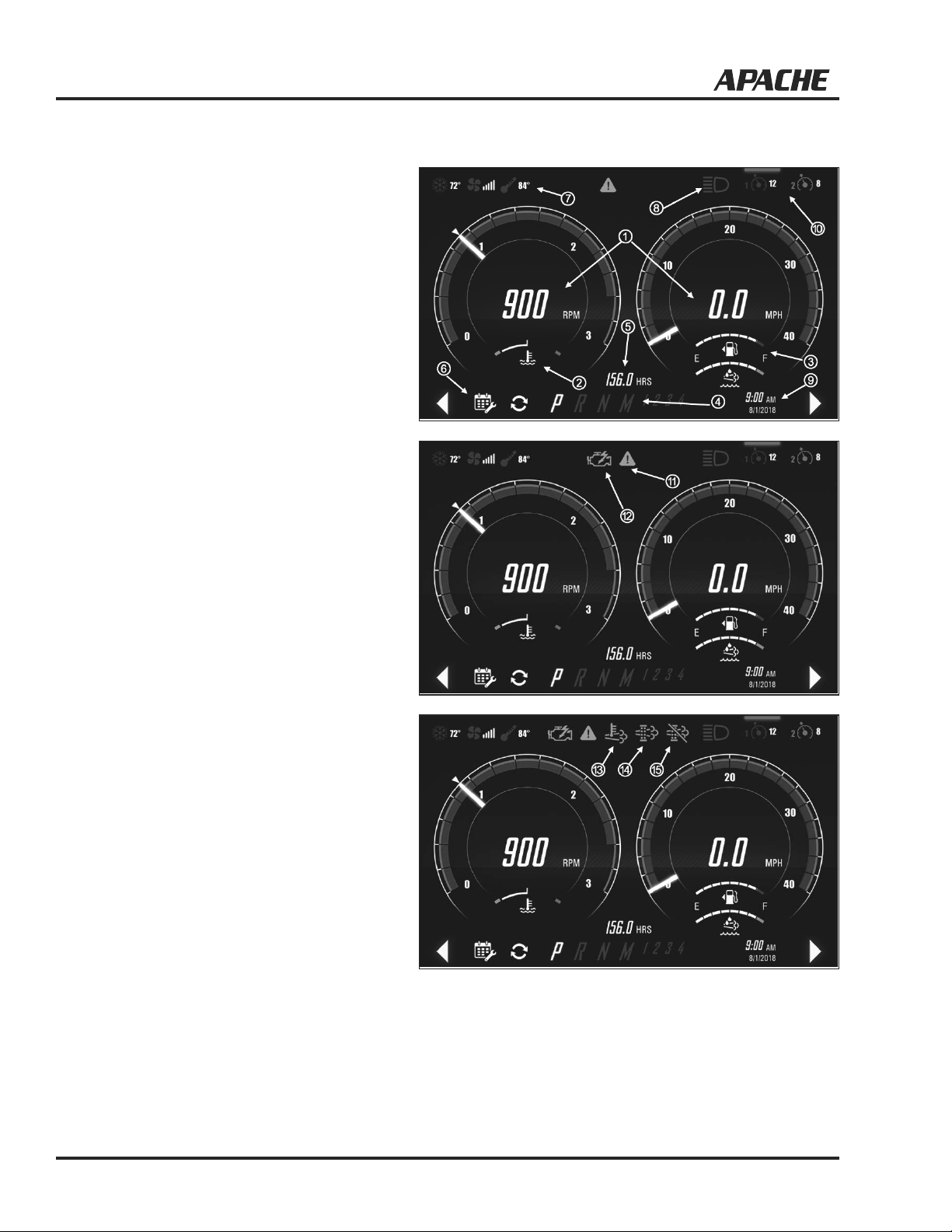

1. Engine RPM and MPH Readout

2. Temperature Gauge

3. Fuel Gauge

4. Direction and Gear Indicator

(The gear indicator will remain solid when

torque converter is locked in.)

5. Engine Hours

6. Scheduled Maintenance Icon

(Appears only when there is Scheduled

Maintenance required.)

7. Climate Control Readout

8. High Beams Indicator

9. Date and Time Indicator

10.Cruise Control Indicators

11.General Warning Indicator

12.Engine Fault Indicator

13.High Exhaust Temperature Lamp

14.Exhaust System Cleaning in Progress

15.Exhaust Cleaning Disabled

ETPilotSystem

Table of contents