RollMaster™5000

ALWAYSwearsafetygogglesorprotectiveeye‐wearwhenoperatingtheunit!

1700JasperSt.,UnitF,Aurora,CO80011T800.624.6706F303.364.7796•Newstripe.com

RollMaster™5000Manual/3068.1116

Page8

CLEANUP

Whenyouarefinishedstriping,removetherollerapplicator,tubeassembly,andhosefromthe

RollMaster™5000.ThisisdonebyopeningtheTroughasdescribedearlier.Removetheendof

thehoseattachedtothepaintpailtube.Makingsuretheendofthehoseiskeptuprightsonot

todripanypaint.Removethehosefromsideofeyeboltandlifthose,mandreltubeand

mandreltogetheroffmachine.Thispreventsanypaintcomingincontactwiththepumping

mechanism,whichassurestheowneroftheRollMaster™5000aclean,longlastingpieceof

equipment.HelpfulHint:Usea2lb.coffee‘can’orsimilarcontainertoplacethehose&

mandrelassemblyinfortransportingtoasinkforcleanup.

Themandrel,tubeassemblies,andtherollerthencanbewashedoutinasolvent,paintthinner

orwaterforfutureuse.Ifyoudesire,themandrelcanbewashed,andthehoseandrollermay

betossedawayandafresh,inexpensive,replacementkitcanbepurchasedfromyourdealeror

Newstripe.

OPERATIONALNOTES!

DONOTuselacquerbasedorFASTDRYpaints.Donotuseepoxypaintsexceptfortheones

listedunderthePAINTparagraphoftheOPERATIONsection.

Ourdefinitionof“FastDry”paintsisthosethatarereadyfortrafficin30minutes.

DONOToverthinthepaint.

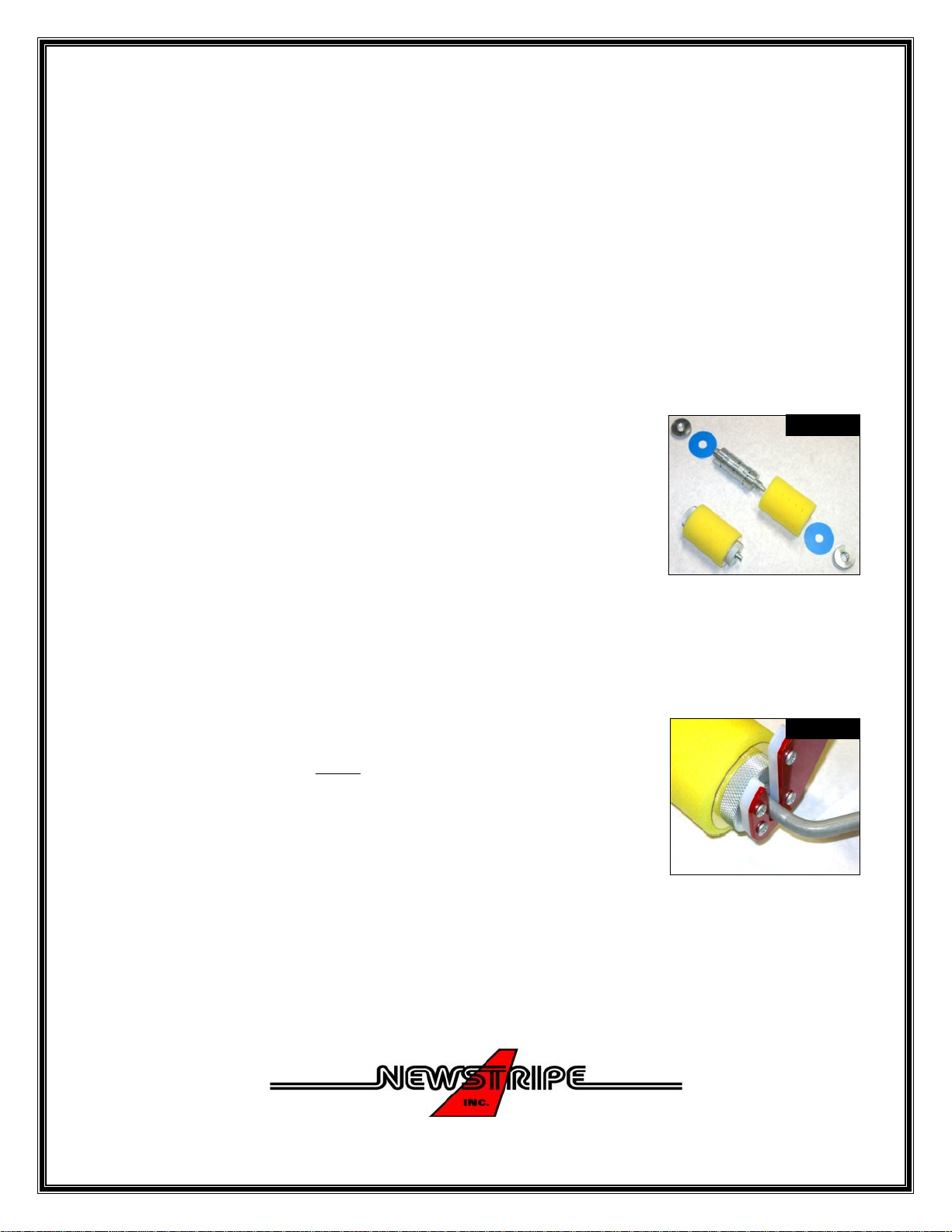

TheMandrelandRollerCovershouldslideupanddownfreelyinthe“J”Yokeswithside

clearanceofnotmorethan1/32".Properclearancewassetatthefactory,butitmaybe

necessarytospreadthesideplatesontheCarrierAssemblytoregainthisclearance.

TheMandrelandRollerCoverRollershouldrollfreelyinthe“J”Yokes.Ifnot,lightlyoiltheshort

endoftheMandrelTubeandthe“O”Ring.

Mostpaintscanbeusedwithoutthinning.However,somewill"flow"betterandmayneedto

bethinnedforeasieruse.

Coolertemperatures(50‐65degrees)willalsorequirepaintthinning.Normally,nomorethan4

oz(1/2cup)pergallonisrequired.FastDrypaintsarenotrecommended(FastDrypaintsare

thosethatare“nopickup”in30minutesorless)Also,onroughsurfacesthinningwillimprove

theappearanceoftheline.

Paintshouldbeatroomtemperatureforbestresults.

IfRollerCoverbecomesoversaturatedwithpaint,releasethePaintTriggerforashortperiodof

timeandcontinuerollingforwardtoallowexcesspainttotransferfromRollerCovertosurface

area.Squeezethetriggeragainwhenrollercoverrequiresadditionalpaint.Thispractice,called

feathering,willberequiredwhentheoperatorisstripinga2"or3"line.

Releasingthetriggerwhenyouare2‐3feetfromtheendofthelinewillallowyoutofinishwith

acleanandcrispendwithoutpuddling.