Equipter RB4000 User manual

Catalog No. E4000OM-0416

April 13, 2016

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

Equipter

Operators Manual

Model RB4000

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 i 04/13/16

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior

written permission of New Heights, LLC.

Additional manuals can be ordered for a fee from New Heights, LLC. Toll Free 717-768-0070.

COPYRIGHT 2011 by

New Heights, LLC

DISCLAIMER

The information in this manual is provided to promote the safe use of, and assist the operator in achieving the

best performance from Equipter described herein, for their intended applications.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 ii CAT E4000OM-0416

Figure 1. Operating and Maintenance Positions .................................................................................. 2

Figure 2. Decals ....................................................................................................................................... 3

Figure 3. Danger Decal, Electrocution Hazard...................................................................................... 5

Figure 4. Equipter Positioned Under Roof. ........................................................................................... 8

Figure 5. Equipter dumping into truck................................................................................................... 8

Figure 6. VIN Label, Tire and Loading Information Placard................................................................. 9

Figure 7. Connection to Tow Vehicle. .................................................................................................... 9

Figure 8. Wheel Lift Lever. .................................................................................................................... 10

Figure 9. Chains, Latch, Break-Away Cable........................................................................................ 10

Figure 10. Platform Latch and Wheel Lift Safety Lock........................................................................11

Figure 11. Parking Brake Lever. ........................................................................................................... 12

Figure 12. Parking Brake Adjustment. ................................................................................................. 12

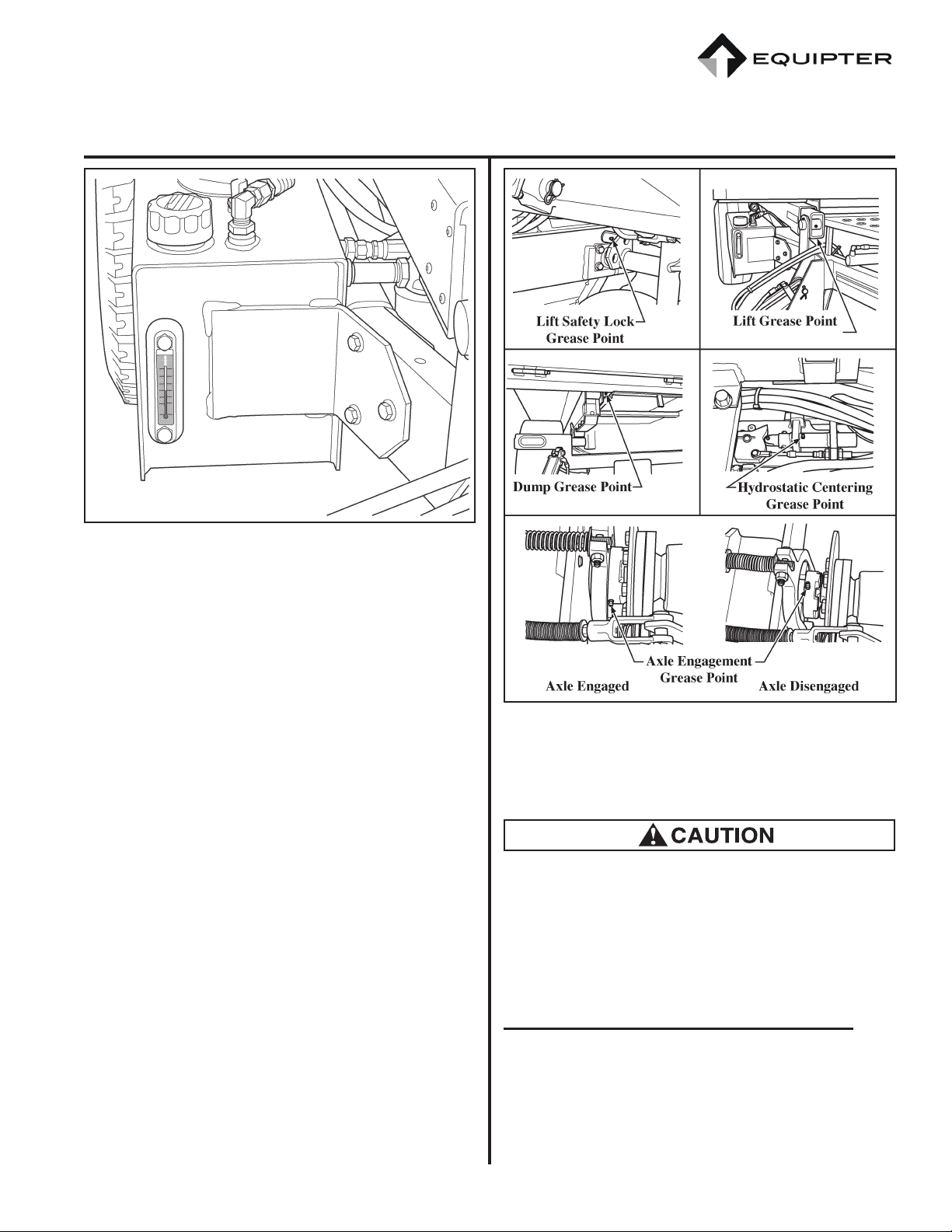

Figure 13. Fluid Levels. ......................................................................................................................... 12

Figure 14. Grease Fittings Locations................................................................................................... 13

Figure 15. Ignition Switch, Choke, Fuel Shutoff and Pull Start. ........................................................ 14

Figure 16. Throttle at Operator Station................................................................................................ 14

Figure 17. Forward/Reverse and Steering Levers. ............................................................................ 16

Figure 18. Bubble Level Indicator. ....................................................................................................... 16

Figure 19. Outrigger Levers.................................................................................................................. 16

Figure 20. Decal-Raise or Lower Steering Wheels. ............................................................................ 16

Figure 21. Front Outriggers with blocking. ......................................................................................... 17

Figure 22. Rear Outriggers with blocking. .......................................................................................... 17

Figure 23. Decal-Operator Contact Possible....................................................................................... 17

Figure 24. Flaps Open Under Roof....................................................................................................... 18

Figure 25. Roll Back, Lift, Dump and Tailgate Levers. ....................................................................... 19

Figure 26. Dumping debris from Dump Box. ...................................................................................... 19

Figure 27. Preparing to Store the Mats................................................................................................ 19

Figure 28. Mat Storage. ......................................................................................................................... 19

Figure 29. VIN Label, Tire and Loading Information Placard............................................................. 21

IllustratIons

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 iii 04/13/16

INTRODUCTION............................................................................................................................................ 1

REPORTING SAFETY DEFECTS ................................................................................................................. 1

WARRANTY ................................................................................................................................................... 2

GENERAL INFORMATION............................................................................................................................. 4

SAFETY PRECAUTION DEFINITIONS ......................................................................................................... 4

PRECAUTIONS.............................................................................................................................................. 4

Safety Requirements ................................................................................................................................ 5

Before You Start ....................................................................................................................................... 6

Operating Precautions.............................................................................................................................. 6

Load Handling Precautions ...................................................................................................................... 6

Transport Precautions .............................................................................................................................. 7

OVERVIEW .................................................................................................................................................... 8

TRANSPORTING ........................................................................................................................................... 8

Steps for Determining Correct Load Limit ................................................................................................ 8

Tow Vehicle............................................................................................................................................... 9

Trailer Connection .................................................................................................................................... 9

Disconnecting the Trailer .........................................................................................................................11

OPERATION..................................................................................................................................................11

Maintenance ............................................................................................................................................11

Engine Operation.................................................................................................................................... 14

DRIVING THE EQUIPTER ........................................................................................................................... 15

Loading and Unloading........................................................................................................................... 15

Outrigger Operation................................................................................................................................ 16

DUMP BOX .................................................................................................................................................. 17

Emptying the Dump Box......................................................................................................................... 19

Optional Mats ......................................................................................................................................... 20

TIRE SAFETY INFORMATION .................................................................................................................... 21

Steps for Determining Correct Load Limit – Trailer ................................................................................ 21

Steps For Determining Correct Load Limit – Tow Vehicle ...................................................................... 23

Glossary of Tire Terminology .................................................................................................................. 23

Tire Safety - Everything Rides On It ....................................................................................................... 26

Tire Safety Tips....................................................................................................................................... 31

VENDOR PARTS LIST................................................................................................................................. 31

SPECIFICATIONS........................................................................................................................................ 32

OPERATIONS CHECKLIST ......................................................................................................................... 33

table of Contents

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 iv CAT E4000OM-0416

table of Contents

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 1 04/13/16

INTRODUCTION

This manual is furnished to you, the owner/opera-

tor, as a guide to get the greatest benet from your

Equipter. New Heights, LLC wants you to be able

to get the most use out of your machine through

safe and efcient operation.

Before attempting to operate this machine, carefully

read all sections of this manual. Be sure that you

thoroughly understand all of the safety information

and operating procedures.

Pay special attention to the Safety Precautions and

Requirements, particularly all DANGER, WARN-

ING, and CAUTION notices included in this man-

ual. These items combined, form the guidelines for

promoting a safe and efcient operating environ-

ment, along with continuous, reliable service and

minimum down time.

NOTE: Directional reference is as follows: the

front is toward the hitch, back is the

tailgate, the operator platform is on

the left, hydraulic tank on the right.

Throughout this manual reference

is made to the Transport Position,

Dump Position, Rollback Position

and Lift Position (See Illustration).

NOTE: Some equipment depicted in illustra-

tions may not reect exact production

model congurations.

NOTE: All safety, operating, and servicing

information reects current produc-

tion models at the time of publication

of this manual.

NOTE: New Heights, LLC, reserves the right

to discontinue models at any time,

change specications, and improve

design without notice and without

incurring obligation on goods previ-

ously purchased and to discontinue

supplying any part listed, when the

demand does not warrant production.

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or death,

you should immediately inform the National High-

way Trafc Safety Administration (NHTSA) in

addition to notifying New Heights, LLC.

If NHTSA receives similar complaints, it may open

an investigation, and if it nds that a safety defect

exists in a group of vehicles, it may order a recall

and remedy campaign. However, NHTSA cannot

become involved in individual problems between

you, your dealer, or New Heights, LLC.

To contact NHTSA, you may either call

the Vehicle Safety Hotline toll-free at

1-888-327-4236 (TTY: 1-800-424-9153), go to

http://www.safecar.gov or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain other information about motor

vehicle safety from http://www.safecar.gov.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 2 CAT E4000OM-0416

WARRANTY

This Equipter is designed and manufactured to high

quality standards. New Heights, LLC, therefore,

guarantees this machine to be free from defects in

workmanship and materials for one year from pur-

chase date. Warranty provides for replacement parts

but does not include the labor to replace defective

parts.

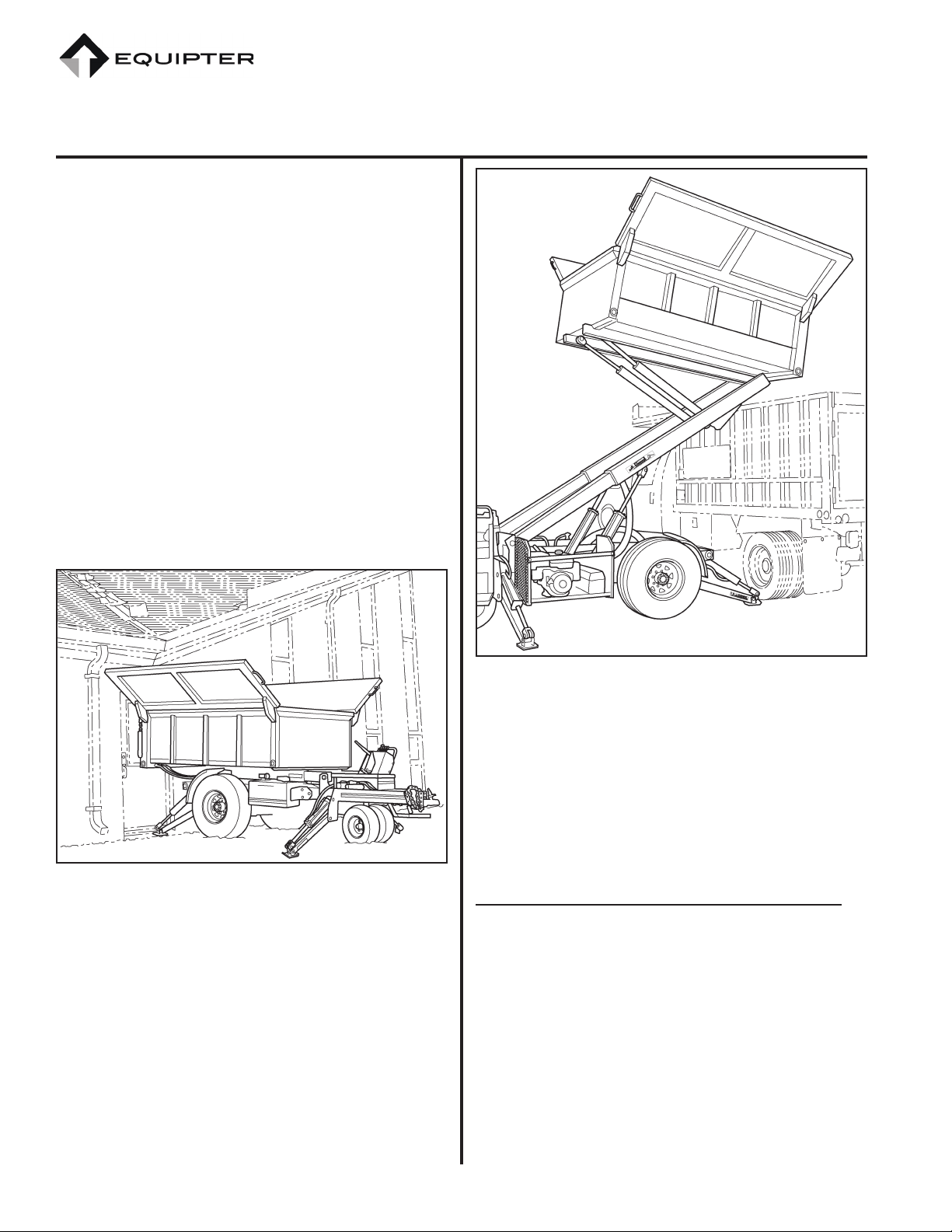

Figure 1. Operating and Maintenance Positions

Vendor components are warranted separately by

their specic manufacturer.

Warranty does not cover normal wear or failure due

to hydraulic oil contamination.

Misuse, abuse, misapplication, and unauthorized

alterations will void this warranty.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 3 04/13/16

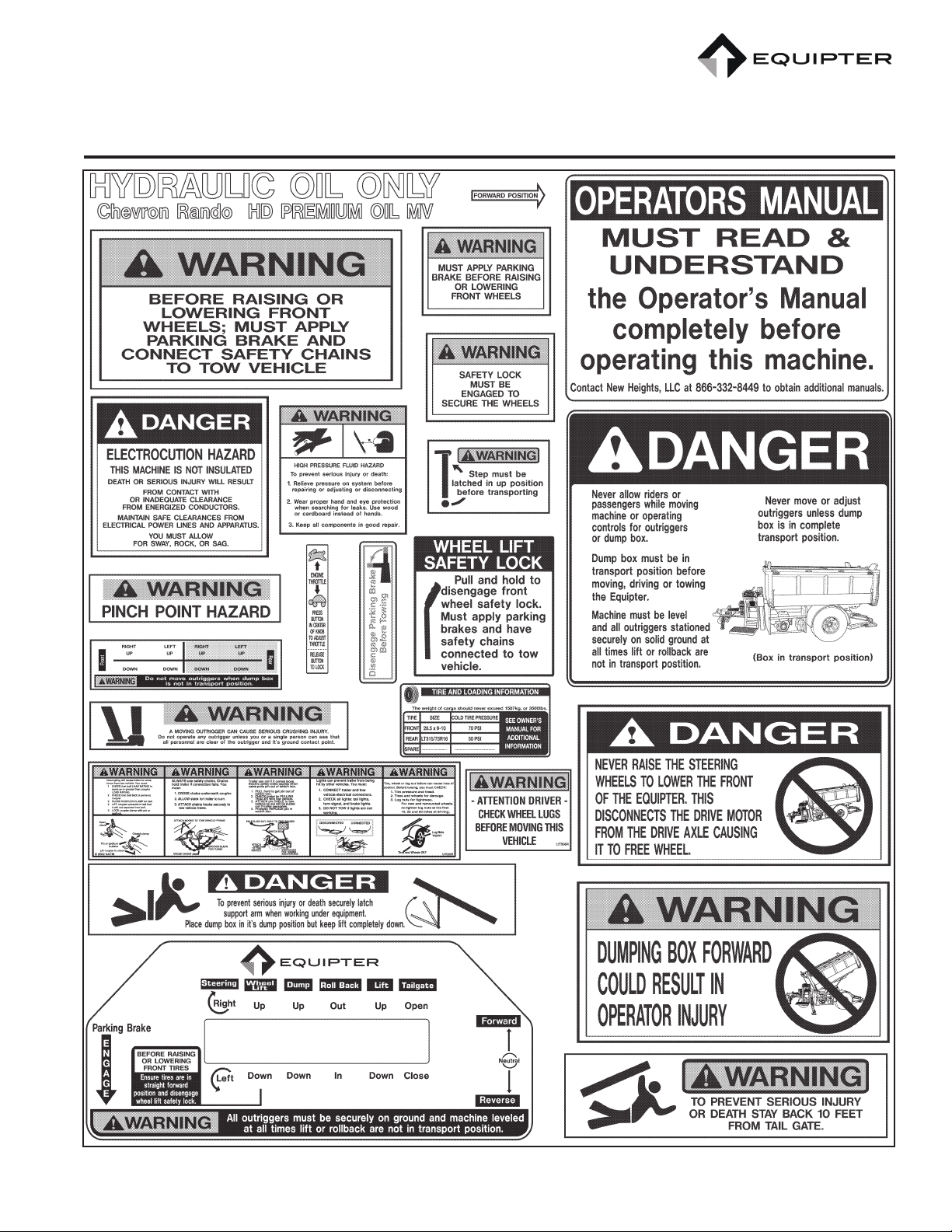

Figure 2. Decals

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 4 CAT E4000OM-0416

GENERAL INFORMATION

The purpose of this manual is to provide safe oper-

ating and maintenance procedures for the intended

use of this machine. It is important that all informa-

tion in this manual is READ and UNDERSTOOD

before operating the Equipter.

Since the manufacturer has no direct control over

machine application and operation, it is the respon-

sibility of the operator to conform to good safety

practices in the implementation of this machine.

This section is composed of various warnings and

safety tips which must be followed.

SAFETY PRECAUTION DEFINITIONS

Dangers, Warnings, Cautions, and Notes are stra-

tegically placed throughout this manual to further

emphasize the importance of personal safety, qual-

ications of operating personnel, and proper use of

this machine in its intended application.

These precautions supplement and/or complement

the safety information decals afxed to the unit and

include headings that are dened as follows:

Indicates an imminently hazardous situation

which, if not avoided, will result in death or seri-

ous injury.

Indicates a potentially hazardous situation or

practice which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation or

practice which, if not avoided, will result in dam-

age to equipment and/or minor injury.

Notes are also found in this manual.

NOTE: Provides information which may be

of special interest.

PRECAUTIONS

The primary responsibility for safety with the

equipment falls to the operator. It is the skill, care,

common sense, and good judgement of the operator

that determines how efciently and safely the job is

performed. Know the equipment before you start.

Know the capabilities, dimensions, and how to op-

erate all the controls. Visually inspect the equipment

before starting and never operate equipment that is

not in proper working order with all safety devices

in place and operating.

Modication of the equipment, including remov-

al or modication of safety and identication

decals, without the written consent of the manu-

facturer is a safety violation and is strictly pro-

hibited.

This machine is not insulated and does not pro-

vide protection from contact with or proximity to

an electrically charged conductor.

Working in the vicinity of power lines is a very seri-

ous hazard and special precautions must be taken.

Any overhead wire shall be considered to be an

energized line until the owner of the line or the

electrical utility authorities indicate that it is not an

energized line and it has been visibly grounded.

Contact with power lines is not required for electri-

cal power to arc between the line and equipment.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 5 04/13/16

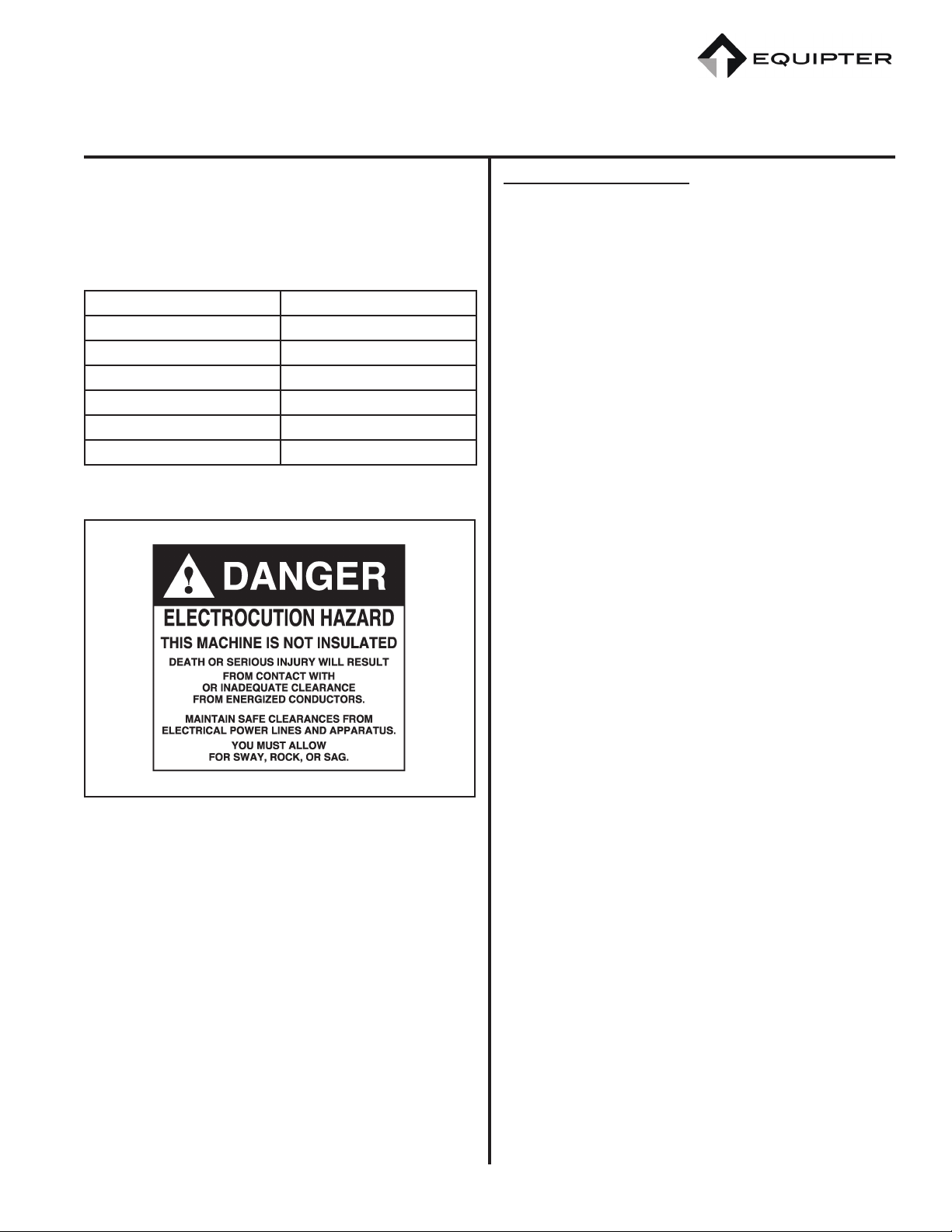

Always be aware of the power carried by the power

lines. Allow sufcient time and distance to react

to swaying or sagging power lines. The following

table provides the minimum distances which should

be maintained.

0 volts to 300 volts Avoid Contact

300 volts to 50 kv 10 ft.(3.05 m)

50 kv to 200 kv 15 ft.(4.6 m)

200 kv to 350 kv 20 ft.(6.1 m)

350 kv to 500 kv 25 ft.(7.6 m)

500 kv to 750 kv 20 ft.(9.2 m)

750 kv to 1000 kv 45 ft.(13.7 m)

Figure 3. Danger Decal, Electrocution Hazard

Safety Requirements

All operators must be 18 years of age or older and

must have the ability to securely engage the parking

brakes.

The parking brakes must always be securely en-

gaged unless the equipment is attached to a tow

vehicle or it is being driven by its own drive system.

The equipment freewheels unless the hydraulic mo-

tor is engaged to the rear axle or the parking brake

is engaged.

Always connect and disconnect the Equipter to the

tow vehicle in a level area. Never lower or raise the

front wheels unless the parking brake is applied and

the safety chains are attached to the tow vehicle.

Never disengage the front wheel safety lock unless

the parking brake is securely applied and the safety

chains are attached to the tow vehicle.

Raising the front wheels for road transportation also

disengages the hydraulic motor from the rear axle

causing it to freewheel for highway towing. When

equipment is secured to tow vehicle hitch, slightly

engage the reverse drive lever to ensure the hydrau-

lic motor has disengaged from the rear axle.

Lowering the front wheels allows the hydraulic mo-

tor to engage to the rear axle. Before releasing the

parking brake and disconnecting the safety chains,

slightly engage the reverse drive lever to ensure the

rear axle has engaged for jobsite use.

Before lifting or extending the dump box out of

transport position always lower all outriggers and

ensure that the Equipter is completely level with all

outriggers rmly stationed on secure footing. Never

lift, lower or adjust outriggers while dump box is

not in the transport position. If any adjustments

need to be made to level the Equipter, always have

the dump box in transport position before moving

the outriggers.

The dump box cannot be dumped without the out-

riggers lowered but never lift or extend the dump

box without the outriggers supporting the Equipter.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 6 CAT E4000OM-0416

Always use the bubble level to help conrm that the

Equipter is completely level any time the dump box

is not in the transport position.

The dump box must be in the transport position

(fully forward and down on the frame) before driv-

ing or towing the Equipter.

Always wear a hard hat when operating machine.

Before You Start

Know your equipment. Know how to operate all

controls and know emergency shut down proce-

dures. Make sure all safety devices are in place.

Do not wear loose clothing or items such as rings

and watches around the equipment. They could get

caught in moving parts and lead to serious injury or

death.

Inspect the equipment. Check for missing shields,

loose bolts, twisted or damaged hydraulic hoses. Be

sure all operational decals are in place and legible.

Never operate a damaged or unsafe machine.

Keep all step plates, grab bars, pedals and controls

free of dirt, grease, oil, and water. Keep area clear

of tools, rags, and extra parts. Keep equipment clean

to help avoid injury from a fall when getting on or

off equipment.

Operating Precautions

Know the work area before you begin. Observe any

potential hazard areas such as soft ground, drop-

offs, rocks, and other obstacles.

Do not drive on hills above a 5% grade. Be aware of

wet conditions which may allow the machine to lose

traction and slide on a hill.

Always lower outriggers before raising or extending

the dump box.

Observe overhead electrical and phone lines. Be

sure equipment will safely clear them.

Be aware of others in the work area. Be sure others

know when and where you will be working. Make

sure no one is underneath or behind equipment.

Never try to board equipment while its moving.

Never allow riders or passengers while driving

machine or operating the outrigger controls or dump

box.

This machine is NOT to be used for personnel lift.

Be aware of what is going on around you. Watch for

others who may not be watching out for themselves.

Load Handling Precautions

Ensure machine is level and stabilized and that the

brakes are properly set prior to operating the dump

box.

Check clearance on both sides before outriggers are

lowered. Make sure personnel are clear of outrig-

gers.

Use blocking or cribbing underneath the outriggers

to assist in securely leveling the machine.

Never allow riders or passengers in the dump box

when raising or lowering.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 7 04/13/16

Transport Precautions

Always use a tow vehicle with a GVWR capacity

greater than that of the combined Equipter and tow

vehicle weight. The hitch must also be of a rating

greater than that of the Equipter.

Always connect the break-away brake cable to the

tow vehicle. Do not connect to the safety chains or

slide-in.

Always disconnect and park Equipter on level

ground. If disconnecting or parking on level ground

is not possible, use blocking in front and behind rear

wheels to prevent the machine from rolling.

Always use a snap pin or lock to secure the latch in

the locked position over the ball.

Ensure that the dump box is down against the frame

and fully retracted in “transport position” before

transporting.

Ensure that the outriggers are fully raised before

transporting.

Ensure that the front steering assembly is raised and

securely latched before transporting.

Do not transport the unit with the dump bed “aps”

open. This would cause the unit to be over-width.

Do not overload the unit. Be aware of the maximum

load capacity of the Equipter.

Check all lights before transporting the equipment

on public roads. Have an assistant verify brake light

operation.

Conrm trailer brakes work.

Being sure wheel mounting nuts (lug nuts) on trailer

rear wheels are tight and properly torqued.

Lug nuts are prone to loosen right after a wheel is

mounted to a hub. When driving on a new or re-

mounted wheel, check the lug nut tightness often

during the rst few hundred miles of the trailer’s

use, especially after the rst 10, 25 and 50 miles of

driving, before each tow, and at least twice per year

thereafter.

Maintenance Precautions

Replace all safety shields and guards when nished

performing maintenance. Do not operate the equip-

ment with protective equipment removed.

Never perform maintenance or adjustments while

the equipment is operating. Turn off the engine

when performing maintenance to prevent accidental

movement.

Never perform maintenance on this machine un-

less the lift is completely in the down position. The

dump box can be tilted in the dump position secured

with the support arm but never with the dump box

lifted.

Make sure all operating and residual pressures are

relieved before working on a hydraulic system.

Shut engine off and operate all the controls to re-

lieve any pressure.

Use only manufacturer recommended replacement

parts. Other parts may be substandard in t and quality.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 8 CAT E4000OM-0416

OVERVIEW

The Equipter is designed for contractors to simplify

a difcult job - cleanup. It takes this labor intensive,

time-consuming job to a level of automation not

found previously. This ingenious machine will not

only simplify your work, it reduces trafc through

carefully manicured ower beds, around fences, and

over shrubbery. Your customers will quickly see the

benets of less wear and tear through their yard.

The Equipter is a simple and durable time saver. It

can be towed to the jobsite by most pickup trucks.

At the jobsite, it is disconnected from the tow ve-

hicle and becomes a self-propelled vehicle. It can

be driven into place across yards and the dump bed

extended and/or raised over fences, shrubbery, and

ower beds.

Figure 4. Equipter Positioned Under Roof.

At about 6 feet wide the Equipter ts places where

trucks and trailers do not. Once in position, panels

on the dump bed open to provide nearly 11 feet of

“collection” coverage. The dump bed can be posi-

tioned just under a roof’s overhang to prevent debris

from falling on the ground or driveway.

Figure 5. Equipter dumping into truck.

When the job is done, the Equipter is driven to the

desired location and the debris dumped into a wait-

ing container or truck. The Equipter can clear 11

feet allowing most standard dump trucks to be used

to haul away debris.

TRANSPORTING

Steps for Determining Correct Load Limit

1. Locate the statement “The weight of cargo

should never exceed 1587 kg or 3500 pounds”

on your vehicle’s placard.

2. The gure equals the available amount of

cargo and luggage load capacity.

3. Determine the combined weight of luggage

and cargo being loaded on the vehicle. That

weight may not safely exceed the available

cargo and luggage load capacity calculated in

Step 2.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 9 04/13/16

Figure 6. VIN Label, Tire and Loading Information

Placard.

4. If your vehicle will be towing a trailer, load

from your trailer will be transferred to your

vehicle. Consult this manual to determine

how this reduces the available cargo and lug-

gage load capacity of your vehicle.

Tow Vehicle

The tow vehicle must have a tow rating greater than

the GVWR of the Equipter (see specications). In

addition, the vehicle must be equipped with a trailer

hitch. A Class IV hitch is the minimum recommen-

dation.

NOTE: Some Class III hitches are rated for

greater than 5,000 lbs. with a 500 lb.

tongue weight. Most Class IV hitches

are rated for 10,000 lbs. and a 1,000

lb. tongue weight.

The standard hitch on the trailer utilizes a 2-5/16

inch hitch ball and 7 RV trailer plug.

NOTE: An electronic brake controller is

needed.

Hitch balls have ratings similar to hitches. Typ-

ically, a 2-5/16 inch hitch ball with a 1-1/4 inch

shaft is required for towing the Equipter.

Trailer Connection

To connect the Equipter to the tow vehicle it is

easiest to drive it into position although the tow

vehicle can also be backed under the hitch similar to

a standard trailer hook-up.

The outriggers must be fully raised before driving

or towing the Equipter.

Always connect Equipter on level ground. If

connecting on level ground is not possible, use

blocking in front of and behind rear wheels to

prevent the machine from rolling.

1. Using all applicable safety procedures, start

the engine. Refer to the section on Engine

Operation.

2. Drive the Equipter into a position with the

hitch coupler over the hitch ball. Refer to the

section on Driving the Equipter.

3. Engage Parking Brake.

4. Place steering wheels in straight forward posi-

tion.

5. Attach the safety chains to the tow vehicle.

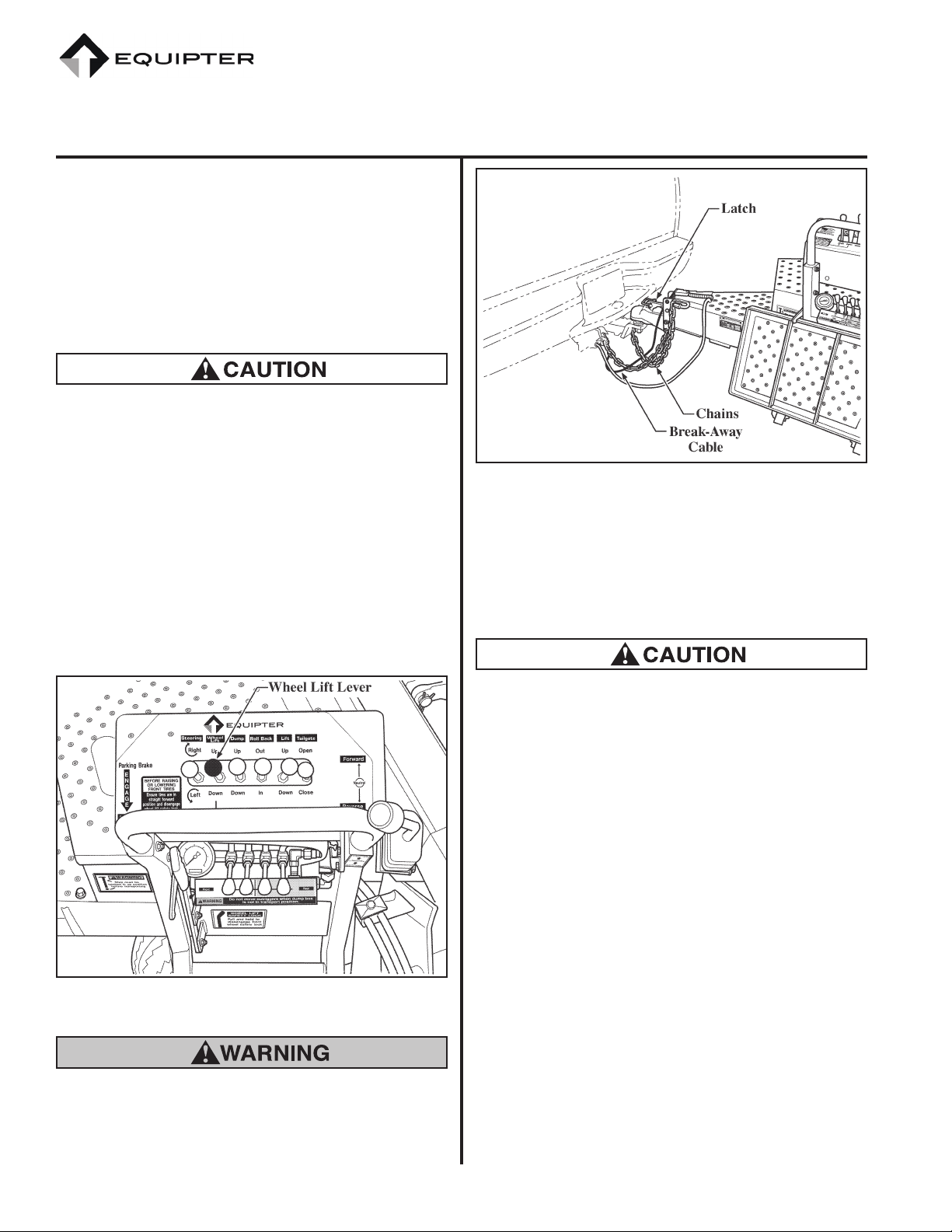

Figure 7. Connection to Tow Vehicle.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 10 CAT E4000OM-0416

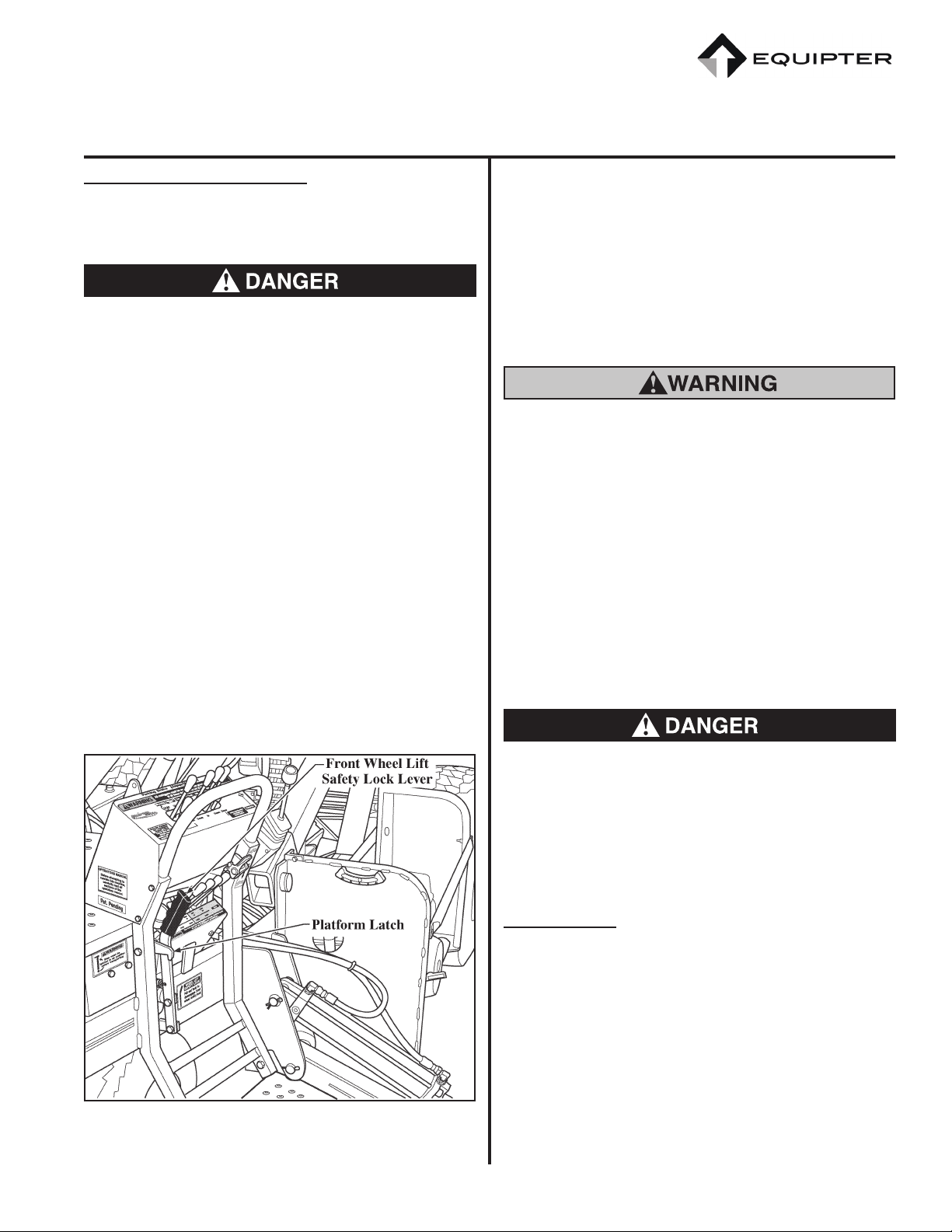

6. Lower the hitch by disengaging the “wheel

lift safety lock” and moving the “Wheel Lift”

control lever in the “Up” direction. This

lowers the trailer hitch by raising the steering

wheels.

7. Secure the trailer to the ball using the latch

mechanism.

The steering wheels, when completely raised,

t inside the frame. They must be in a straight

forward direction for the wheels to properly t

within the frame. Failure to do so will result in

failure to securely lock the steering wheels for

transport.

8. After the weight of the trailer is securely on

the tow vehicle, raise the steering wheels

completely. Ensure the wheels are latched by

trying to lower the wheels without releasing

the safety lock lever.

Figure 8. Wheel Lift Lever.

The parking brake on the Equipter must be

engaged. After the steering wheels are completely

raised, the drive system is disengaged and the

axle will freewheel.

Figure 9. Chains, Latch, Break-Away Cable.

9. To ensure that the drive system has disen-

gaged, slightly engage the drive lever in

reverse.

10. Turn off the engine.

Never transport the Equipter with the engine

running.

11. Raise the operator’s platform and secure using

the latch provided.

NOTE: If the platform does not latch, check

that the front wheels are fully raised

and safety lock is locked in position.

12. Attach the break-away brake cable and elec-

trical plug to the tow vehicle. Place a padlock

or hairpin clip through the latch. Verify that

the safety chains are securely attached to the

tow vehicle.

13. Disengage Parking Brake.

14. Test trailer brakes with brake controller in the

tow vehicle.

15. Test the brake, signal, tail, and clearance

lights on the trailer.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 11 04/13/16

Disconnecting the Trailer

After being towed to the job site, the Equipter can

be disconnected from the tow vehicle.

Always disconnect Equipter on level ground. If

disconnecting on level ground is not possible, use

blocking in front of and behind rear wheels to

prevent the machine from rolling.

1. Engage Parking Brake.

2. Lower the operator’s platform by releasing

the latch.

3. Start the engine using all applicable safety

procedures. Refer to the section on Engine

Operation.

4. Lower the steering wheels until they contact

the ground.

NOTE: Pull and hold to engage front wheel

safety lock. Must apply parking

brakes and have safety chains con-

nected to tow vehicle.

Figure 10. Platform Latch and Wheel Lift Safety Lock.

5. Release the latch that secures the trailer to the

hitch ball.

6. Continue lowering the steering wheels until

the trailer is clear of the hitch ball and the

front wheel safety lock is securely engaged.

7. Slightly engage the drive lever in reverse to

ensure that the drive system is engaged.

Never disengage the Parking Brake or safety

chains unless the drive system is engaged.

8. Disconnect the electrical plug and break-away

brake cable from the tow vehicle. Secure them

to the trailer to prevent dragging or interfer-

ence with operation of the Equipter.

9. Disconnect the safety chains from the tow

vehicle.

10. Disengage Parking Brake.

11. Drive the Equipter away from the tow vehicle.

Always engage the parking brake when parking

the Equipter. Do not park the Equipter on hills

or steep inclines unless blocking is placed in front

of and behind the rear wheels.

OPERATION

Maintenance

While every effort has been made to build a high

quality product, it is important that the Equipter be

maintained and serviced on a regular basis. This

contributes to ensuring reliable equipment that can

be depended on when its needed. Replace all worn

or damaged parts with original manufactured parts.

Never perform maintenance on this machine unless

the lift is in complete transport position. For main-

tenance under the dump box it can be tilted in the

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 12 CAT E4000OM-0416

dump position and must be secured with the support

arm in place but never have the dump box in the

lifted position.

All personnel must stay off and all body parts out

from under the dump box at all times the lift is not

in the transport position.

Every 8 hours of operation or daily the following

should be checked:

• Check Engine Oil Level - Refer to Engine

Operation Manual.

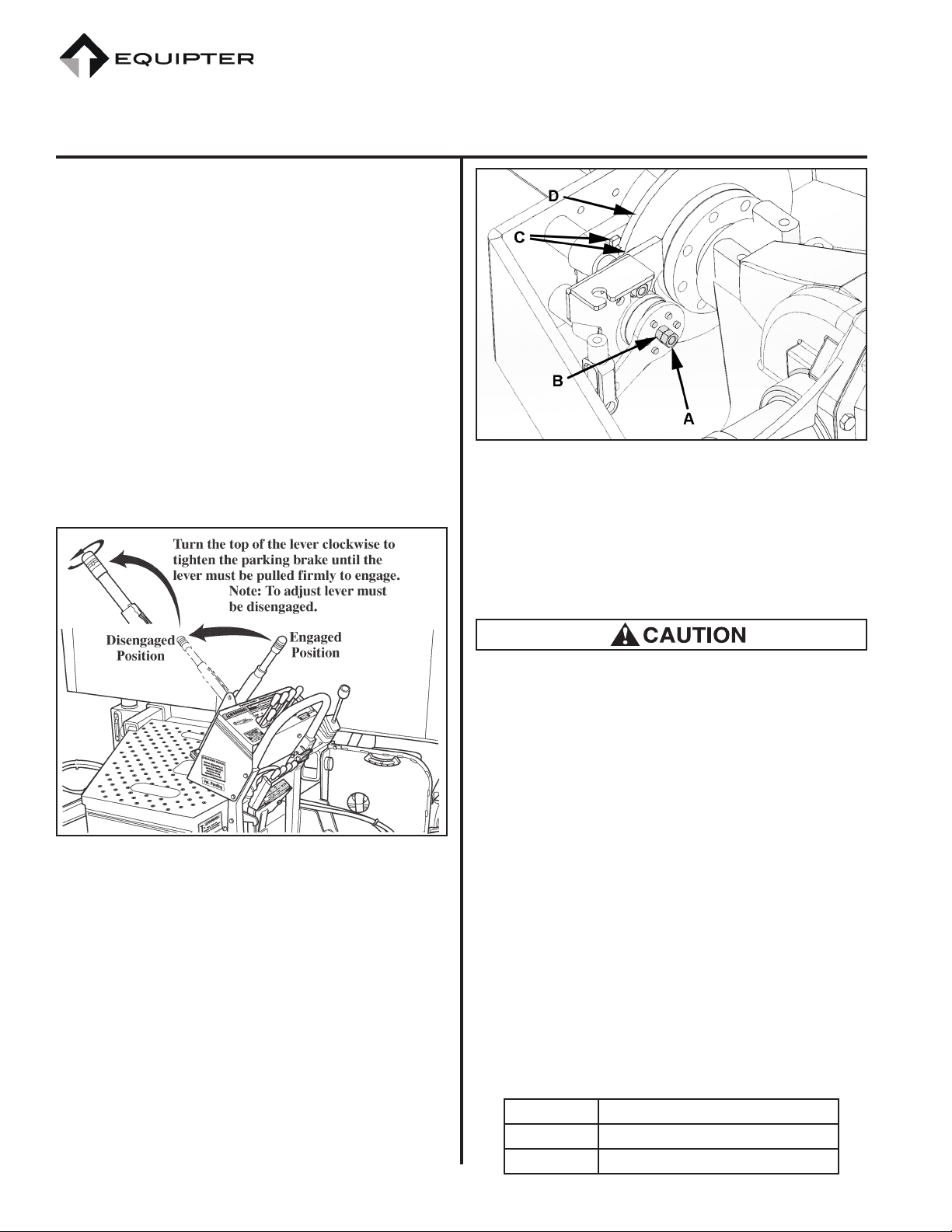

• Check and adjust parking brake. (See illus-

tration). Ensure that the Parking Brake is

working properly.

Figure 11. Parking Brake Lever.

• If parking brake does not hold trailer

and lever adjustment is at the maximum,

chock trailer tires and turn knob on top

of lever fully counter clockwise. Loosen

jam nut (A). Tighten nut (B) until there is

approximately a business card clearance

between brake pads (C) and rotor (D)

on each side. Tighten jam nut (A). Adjust

parking brake as shown in gure 11.

Figure 12. Parking Brake Adjustment.

• Check Tire Ination Pressure with tires cold

(not been driven for at least 3 hours). Rec-

ommended ination pressure is on the “Tire

and Loading Information” placard located

on the hitch.

If tires are replaced, be sure they are sized for

the rim and meet or exceed the load capacity of

the original tires supplied by the factory.

• Check Hydraulic Fluid Level - With the

Equipter on level ground, the dump bed

down and retracted, the outriggers raised,

and the steering wheels down, the hydraulic

oil level should be visible in the sight gauge

in between the top and bottom of the tem-

perature gauge (normal reading should be

between 1/4 and 1/2 on the gauge). If nec-

essary to rell, use only approved SAE 5W

hydraulic oil.

New Heights, LLC recommends changing the

hydraulic oil lter every year and the hydraulic oil

every 2 years.

The following are approved oil sources:

Chevron Rando HD Prem MV Hyd Oil

Mobil Mobil DTE 12 or 12M

Castrol Aerial Lift

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

CAT E4000OM-0416 13 04/13/16

Figure 13. Fluid Levels.

NOTE: Maximum recommended hydraulic

oil operating temperature is 160° F

(71° C).

Every 40 hours of operation or weekly the follow-

ing should be checked:

• Check Tire Ination Pressure - Refer to

“Tire and Loading Information” placard

located on the hitch.

• Check that all wheel lugs nuts are tight. If

not, they must be torqued to the proper spec-

ication.

• Lubricate rollback slide rails - Apply grease

to frame rails where dump box slides. Use

Molybdenum grease (NLGI #2).

• Check rear axle oil level.

Figure 14. Grease Fittings Locations.

• Lubricate all Grease Fittings - Grease t-

tings are located at most pivot areas.

Be sure to lubricate like items on the opposite

sides of the Equipter.

Worn grease ttings that will not hold the grease

gun, and ttings with a stuck ball, must be re-

placed.

Lubricate the Axle Engagement System

In the drive system is a grease tting. This tting

should be lubricated every 40 hours to ensure prop-

er operation. To access the grease tting:

1. Engage Parking Brake.

New Heights LLC

11 Township Drive

Paradise, PA 17562

Phone: 717-768-0070 • Fax: 717-768-8910

Web: www.equipter.com

04/13/16 14 CAT E4000OM-0416

2. Lower the outriggers.

3. Release the safety latch and raise the front

steering wheels completely.

Place the support arm under the dump box to

provide extra safety while lubricating the axle

engagement system.

4. Tilt the dump box to gain access to the top of

the drive axle. Place the support arm under

the dump box before entering the area under

the dump box.

NOTE: If the grease tting is rotated away

and cannot be accessed, the drive sys-

tem can be operated to spin the drive

shaft. Use the drive control lever to

“bump” the system until the grease

tting is accessible.

5. Apply lubricant as needed.

Engine Operation

This manual is intended to provide an overview of

how the engine works within the Equipter. Addi-

tional information regarding engine operation and

maintenance is available within the Engine Manual

supplied with the machine.

The engine is used to drive a hydraulic pump. The

hydraulic pump then powers various cylinders

and the drive motor. Engine controls consist of a

keyed ignition switch, choke, remote throttle, and

fuel shut-off valve. The ignition switch has three

positions: OFF, RUN, and START. The engine has

a rope pull-start in the event that the battery is not

operational (ignition switch must be in the RUN

position to pull-start).

Figure 15. Ignition Switch, Choke, Fuel Shutoff and Pull

Start.

The throttle is located at the operator station next

to the directional control lever. Press red button in

center of knob to adjust throttle, release button to

lock. More gradual adjustment of throttle can be

made by turning black knob. When starting a cold

engine,pull throttle part way out, slide choke lever

toward the front of the Equipter. After the engine is

running, slowly move the choke into the run posi-

tion. If the engine is warm, choke operation should

not be necessary.

Figure 16. Throttle at Operator Station.

Other manuals for RB4000

2

Table of contents

Other Equipter Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Roketa

Roketa GK-19 Owners manual, assembly instructions, and parts manual

Rick's Specialty Vehicles

Rick's Specialty Vehicles Cricket ESV owner's manual

Cushman

Cushman 646442 owner's manual

HAUL MASTER

HAUL MASTER 62645 Owner's manual & safety instructions

Seizmik

Seizmik 06016 Installation & operation manual

Westward

Westward GO-4 EV INTERCEPTOR IV Operator's manual