INTRODUCTION ................................................................................................................................................................................................1

REPORTING SAFETY DEFECTS..................................................................................................................................................................1

WARRANTY..........................................................................................................................................................................................................2

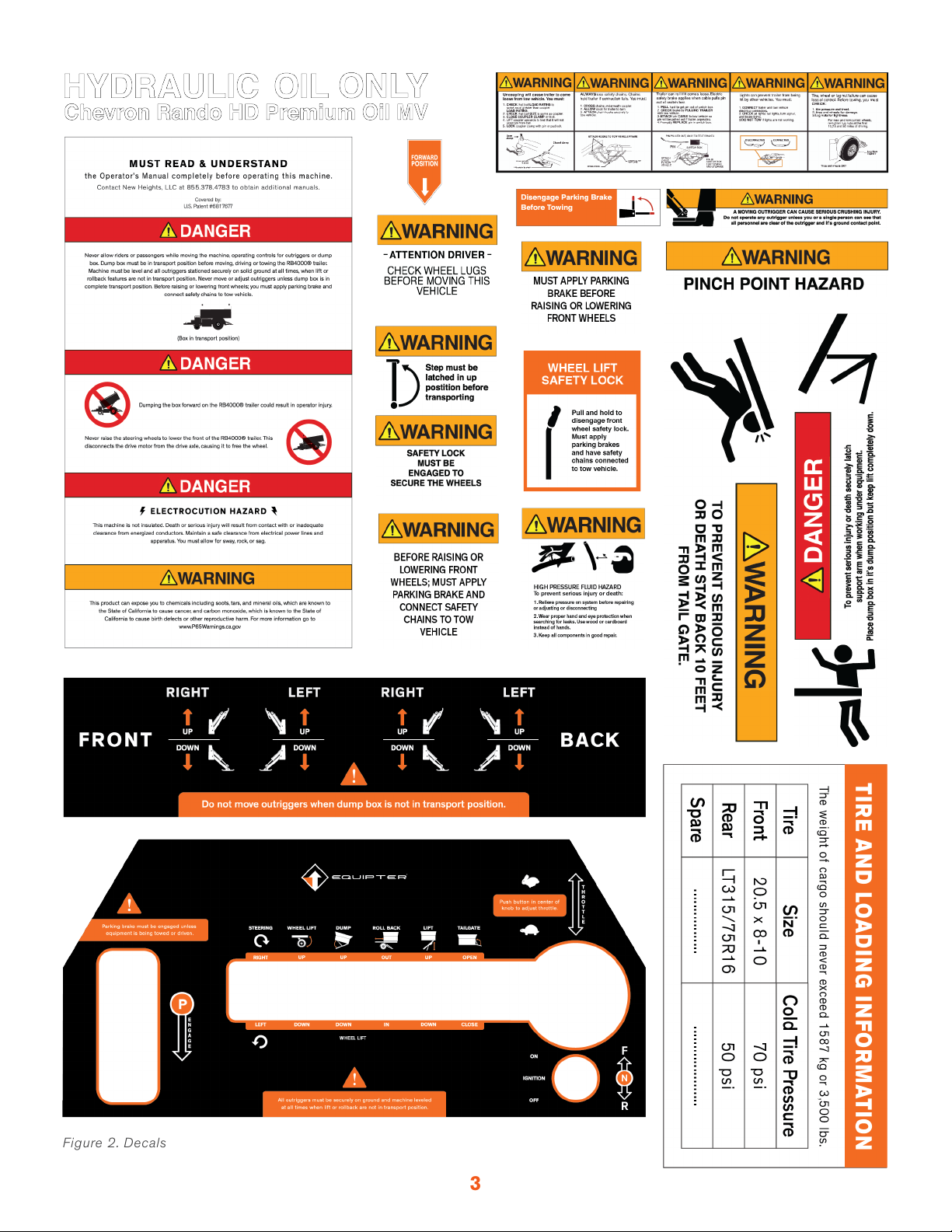

GENERAL INFORMATION..............................................................................................................................................................................4

SAFETY PRECAUTION DEFINITIONS.......................................................................................................................................................4

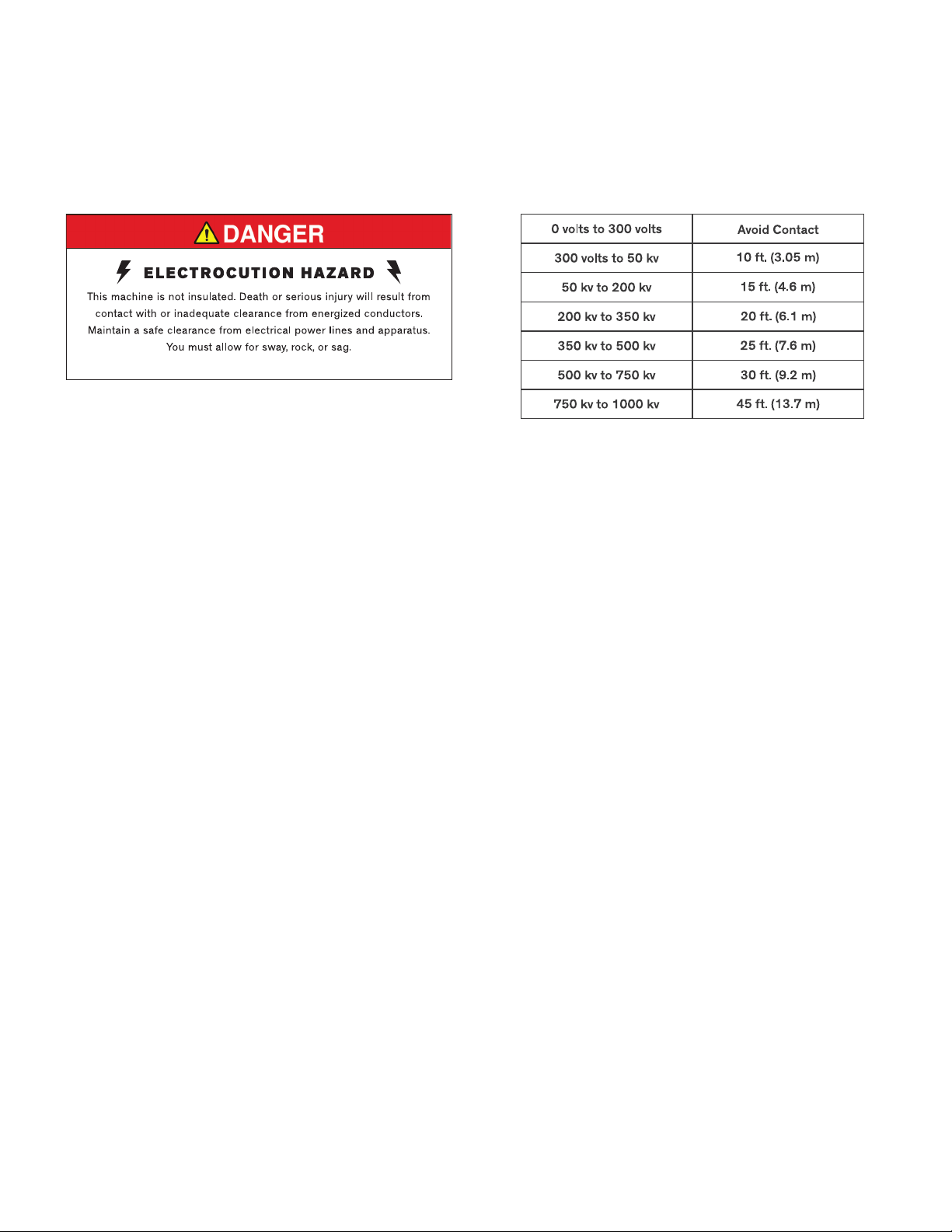

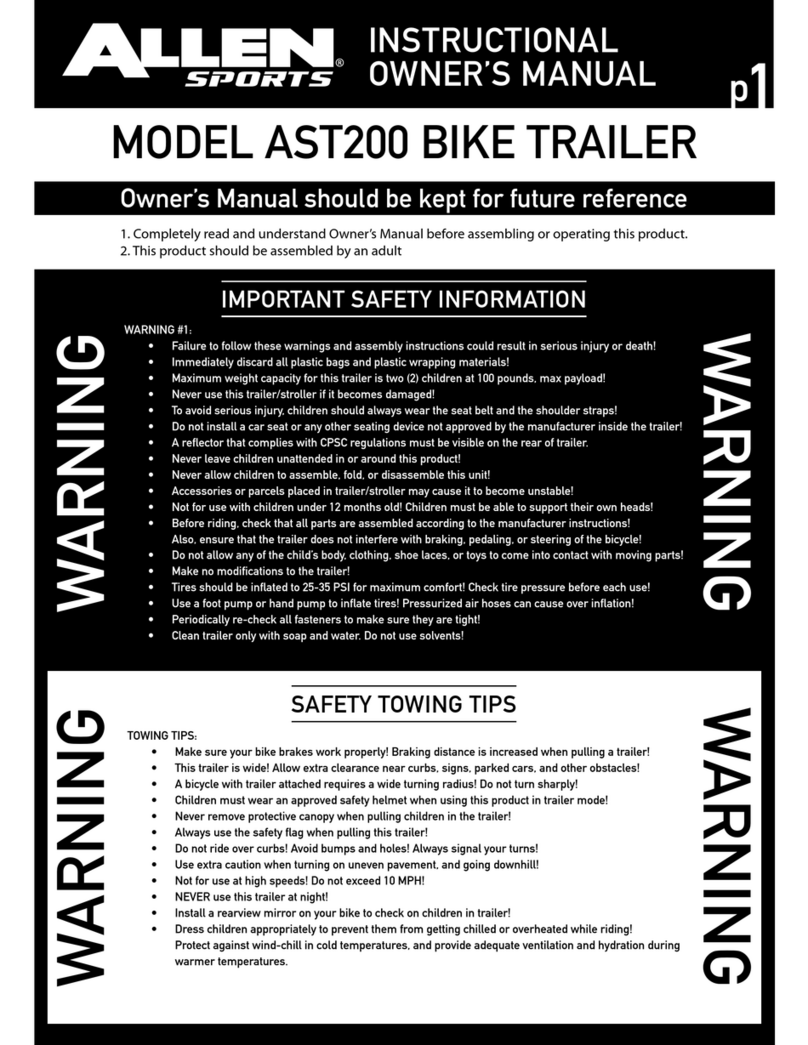

PRECAUTIONS...................................................................................................................................................................................................4

Safety Requirements................................................................................................................................................................................5

Before You Start ........................................................................................................................................................................................6

Operating Precautions.............................................................................................................................................................................6

Load Handling Precautions ...................................................................................................................................................................6

Transport Precautions...............................................................................................................................................................................7

Maintainance Precautions.......................................................................................................................................................................7

OVERVIEW ...........................................................................................................................................................................................................8

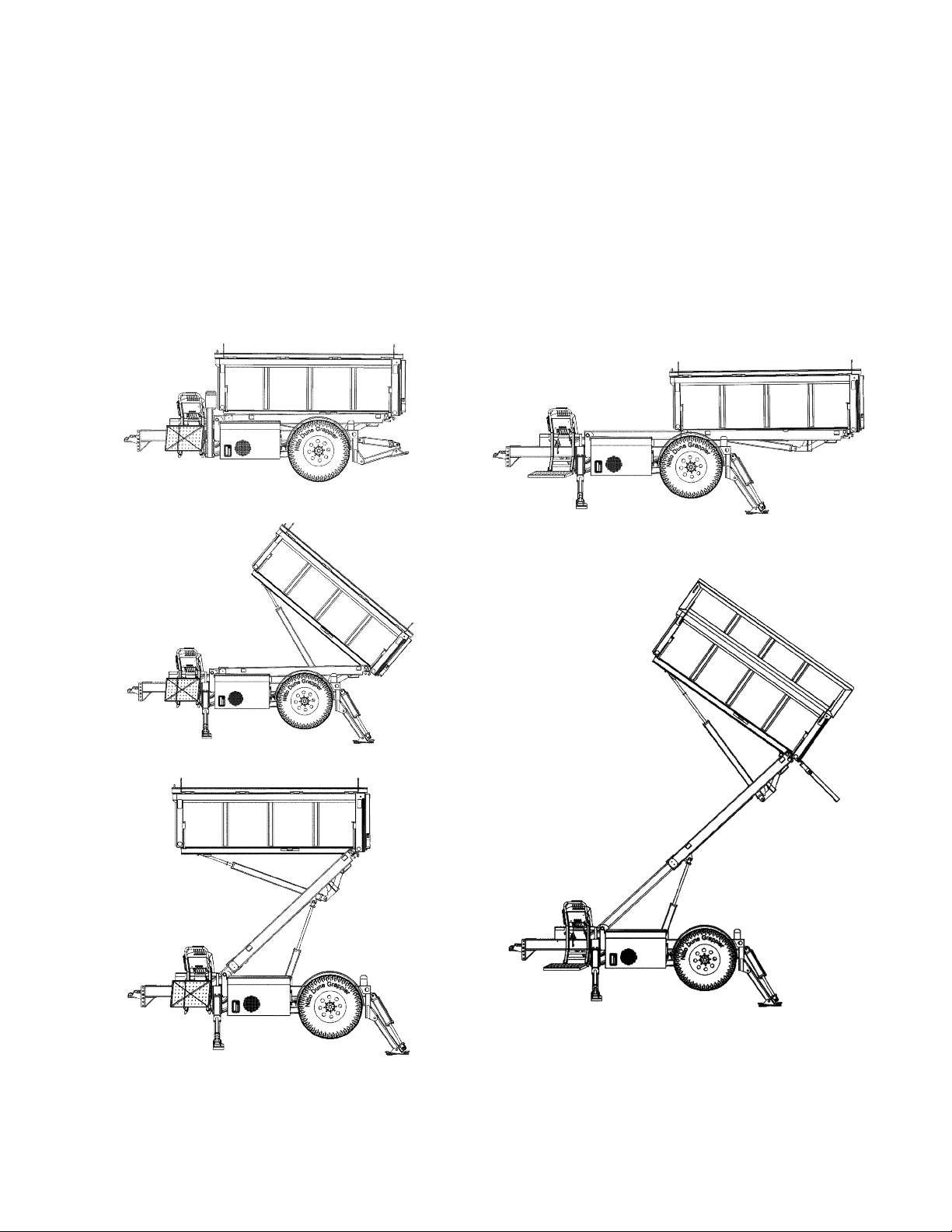

TRANSPORTING................................................................................................................................................................................................9

Steps for Determining Correct Load Limit ......................................................................................................................................9

Tow Vehicle ..................................................................................................................................................................................................9

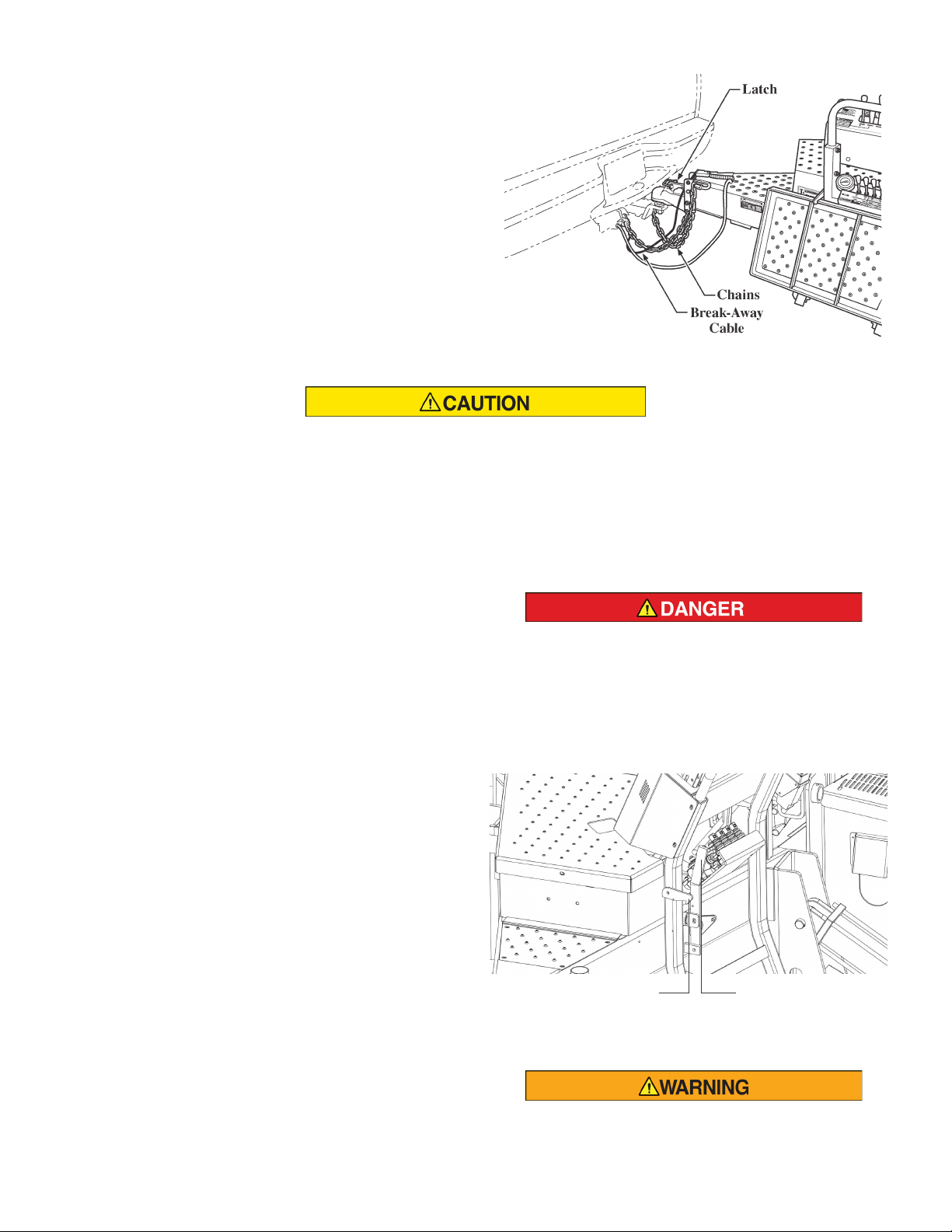

Trailer Connection.................................................................................................................................................................................. 10

Disconnecting the Trailer .................................................................................................................................................................... 11

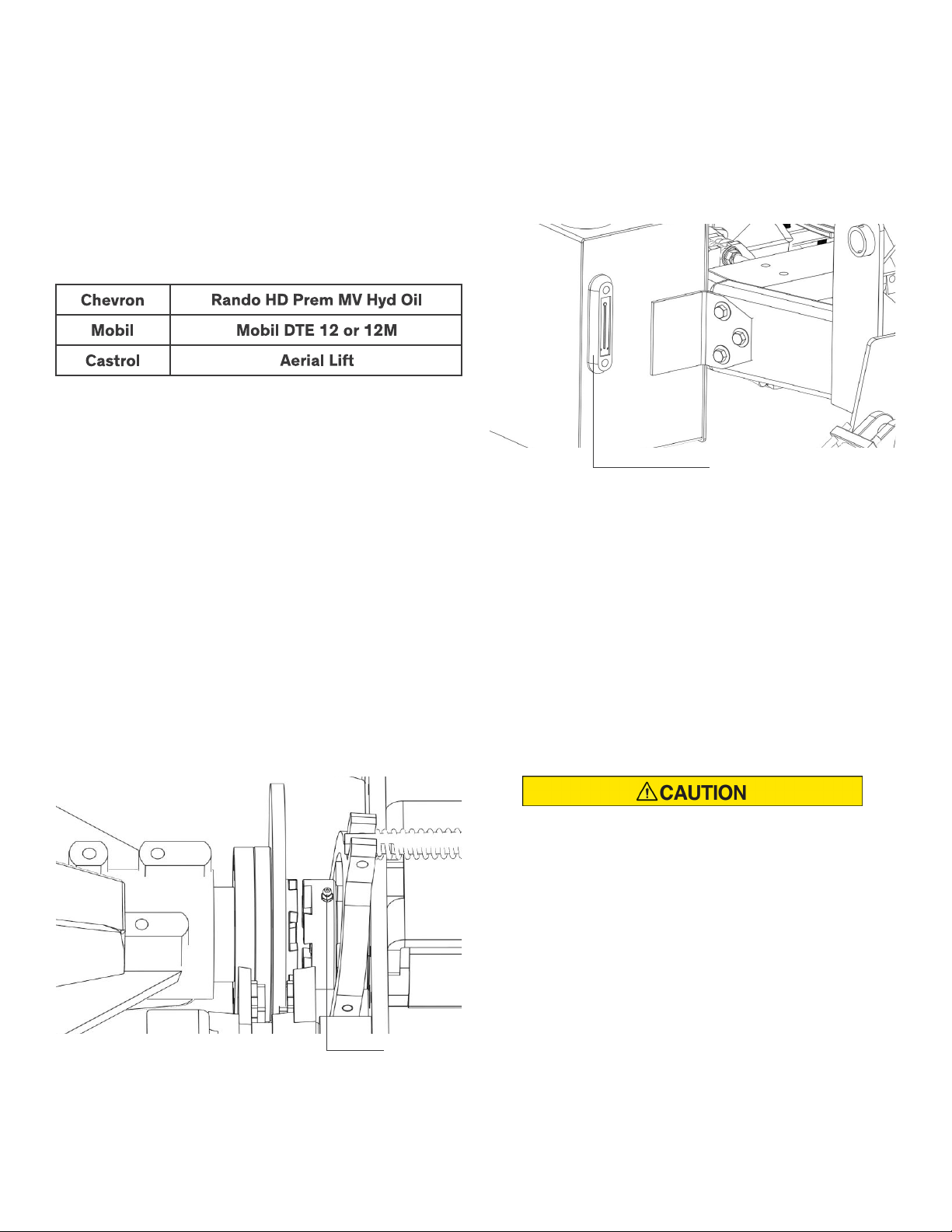

OPERATION...................................................................................................................................................................................................... 12

Maintenance............................................................................................................................................................................................. 12

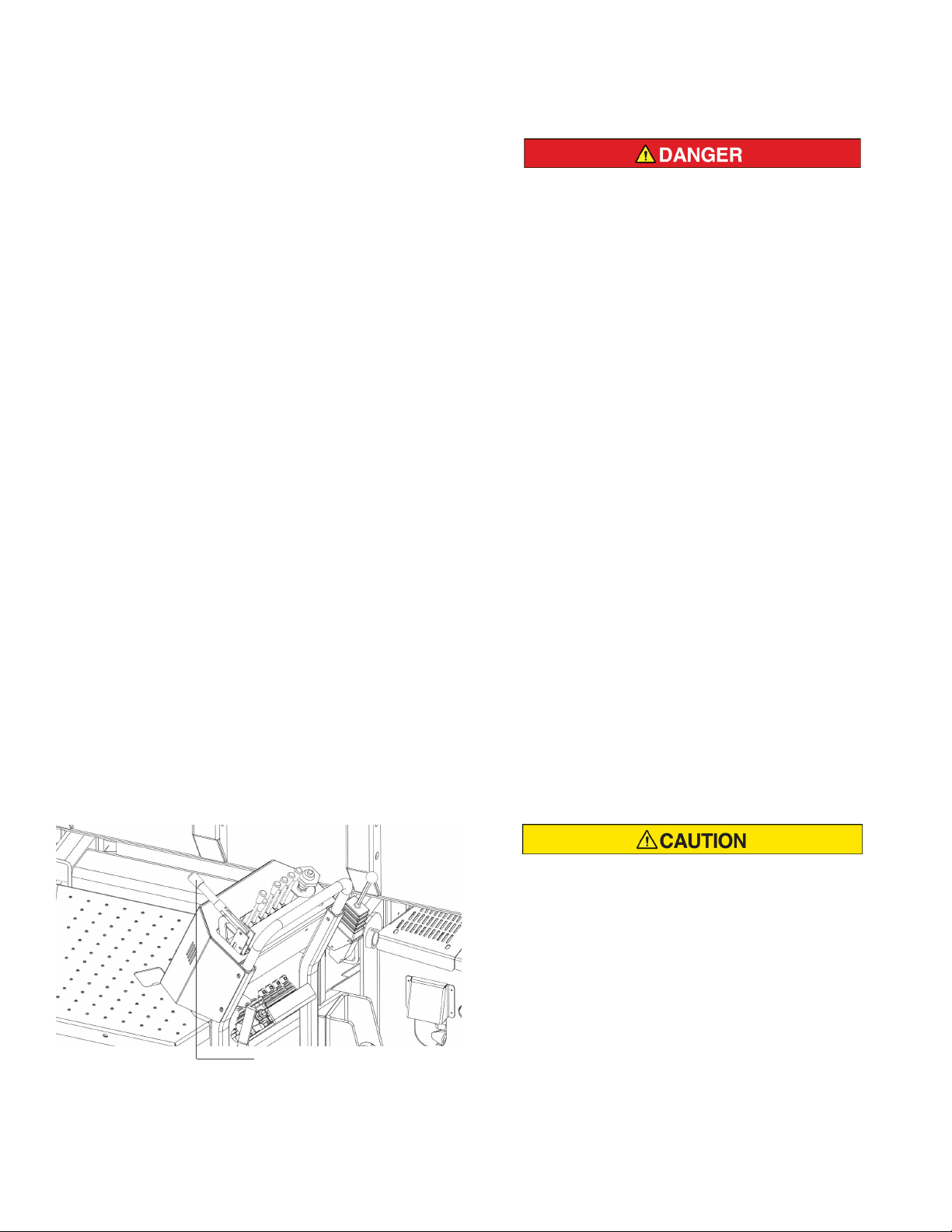

Engine Operation ................................................................................................................................................................................... 14

DRIVING THE EQUIPTER ........................................................................................................................................................................... 15

Loading and Unloading........................................................................................................................................................................ 16

Outrigger Operation .............................................................................................................................................................................. 16

DUMP BOX ....................................................................................................................................................................................................... 18

Emptying the Dump Box...................................................................................................................................................................... 19

EXTENSION RAILS........................................................................................................................................................................................ 20

OPTIONAL MATS............................................................................................................................................................................................ 21

CHUTES............................................................................................................................................................................................................. 21

SPOUTING GUARD ....................................................................................................................................................................................... 22

CHUTE AND SPOUTING GUARD STORAGE....................................................................................................................................... 22

CONTOL PANEL COVER ............................................................................................................................................................................. 22

SPARE TIRE MOUNT AND OUTRIGGER PAD STORAGE............................................................................................................... 22

TIRE SAFETY INFORMATION.................................................................................................................................................................... 23

Steps for Determining Correct Load Limit – Trailer................................................................................................................. 24

Steps For Determining Correct Load Limit – Tow Vehicle..................................................................................................... 25

Glossary of Tire Terminology ............................................................................................................................................................. 26

Tire Safety - Everything Rides On It............................................................................................................................................... 29

Tire Safety Tips ....................................................................................................................................................................................... 34

SPECIFICATIONS........................................................................................................................................................................................... 36

OPERATIONS CHECKLIST ..........................................................................................................................................................................37

TABLE OF CONTENTS

ii