Erduro BTS ENGINEERING Fluid Solutions BTKF-I User manual

SINGLE STAGE

USER MANUAL

BTKF-I

https://prom-nasos.pro

https://bts.net.ua https://

prom-nasos.com.ua

+38 095 656-37-57,

+38 067 360-71-01,

+38 063 362-12-31,

- You should absolutely obey the followng safety nstructons.

- Never touch the pump and ppes havng temperature more than 80 ºC. Necessary

precautons should be taken for warnng users. (E.g Warnng sgns and sgnboards )

-

Never operate pump n reverse

drecton.

- Do not walk over pump pr ppes whch are connected to pump.

- Any operaton whch wll be done n pump should be performed by at least two

staffs.

- No works should certanly be done over wthout stoppng pump group.

-

Power comng to pumps should be off and you should be sure that t wll not operate

agan before you make any work

- Absolutely nstall the safety guards whch were dsmounted before after work n

pump has finshed.

- Tensons and crcks n ppe system absolutely should not reach to pump.

-

Do not make any operaton whle pump and ppes whch are connected to pump are

under pressure.

- Cloths of personnel who wll work over should be sutable and/or they should use

safety equpments.

-

Never do any operatons when pump s stll hot.

- Electrcal connecton related wth pump and auxlary equpments should be sutable

wth local rules and made by authorzed personnel.

- Operate pump wth only specfied condtons.

- Do not nsert your hand and fingers nto holes and spaces over pump body.

- Be always careful whle workng wth pumps dschargng hazardous lquds.

SAFETY INSTRUCTIONS

Fl uid

So lut ion s

2

BTKF-I Seres Pumps are centrfugal pumps havng horzontal shaft, separable radal

body, are sngle staged, scroll cased has closed mpellor, and can be connected to

straght ppe.

Usage Areas of Motor Water Pump

Pumps are sutable for dschargng lquds whch are low vscose, whose flow

temperature s up to 110ºC and whch are clean or a lttle drty. (Max20mg/dm³) . In

addton to others; man applcaton areas are:

- Heatng and Coolng Systems

- Water Supply

- Fre Extngushng Plants

- Water Supply and Crculaton Systems n Industral Plants

Explanaton of Pump Codes

BTKF-I 40/200

Pump Type

Rated Dameter of Dscharge Flange (DN-mm)

Number of Stages(pece)

Techncal nformaton

Speed : Up to3600 d/d rpm

Dscharge Flange :DN40 …DN200

Sucton

And Dscharge

Flange : TS EN 1092-2,EN 1092-2-EQV /PN16

Operatonal Temperature

:-10ºC…110ºC

Ambent Temperature (Maxmum) :+40ºC

Body Pressure :16 Bars

Isolaton Class

:F

Protecton Class

:IP55

Motor Connecton :3 Phase-380 V-50 Hz

Fl uid

So lut ion s

BTKF-1 SERİES PUMPS

3

Fl uid

So lut ion s

- Check whether all materals n delvery lst are sent. .

- If there s damage durng shppng please notfy ERDURO Shppng Department

and Transportaton company.

-

If there are mssng materals, mmedately nform ERDURO Shppng Department.

-.

Check whether packagng s damaged durng transportaton.

-

Please carefully take out packaged pump and accessores (f any). Check whether

they are damaged durng transportaton.

General warnngs.

Absolutely obey the followng rules durng transportaton.

-. Use proper wooden crane, forklft, or hostng mechansms For unloadng or

loadng wooden cases, packages, boxes and palettes dependng on ther weght and

volume.

-

Wear gloves, hard tp shoes and helmet durng carryng works.

-

Never stay under hostng mechansm whle loadng or unloadng pumps.

Pump and Motor Group Loadng/Unloadng

Before loadng/unloadng pump group please determned the followng propertes.

- Please find the lftng ponts.

- Please consder total weght and centre of gravty.

-

Please consder the packagng external dmensons

-

Durng loadng/unloadng make acceleratng and brakng operatons as t shall not

cause any damage for workng personnel.

- Load lftng capacty should be sutable wth pump and pump group weght.

- You should never stay under or near lfted load.

SHIPPING OF PUMPS

CARRYING

4

Fl uid

So lut ion s

- Pump should be hosted as t s ndcated n Fgure 1 -1 and Fgure 1 -2 for not

causng any damage n pumps. Motor hangng rng should absolutely

not be used

whle lftng complete group.

- Load should be kept n lfted poston more than requred tme.

- Pump and pump group should always be lfted and carred n horzontal poston

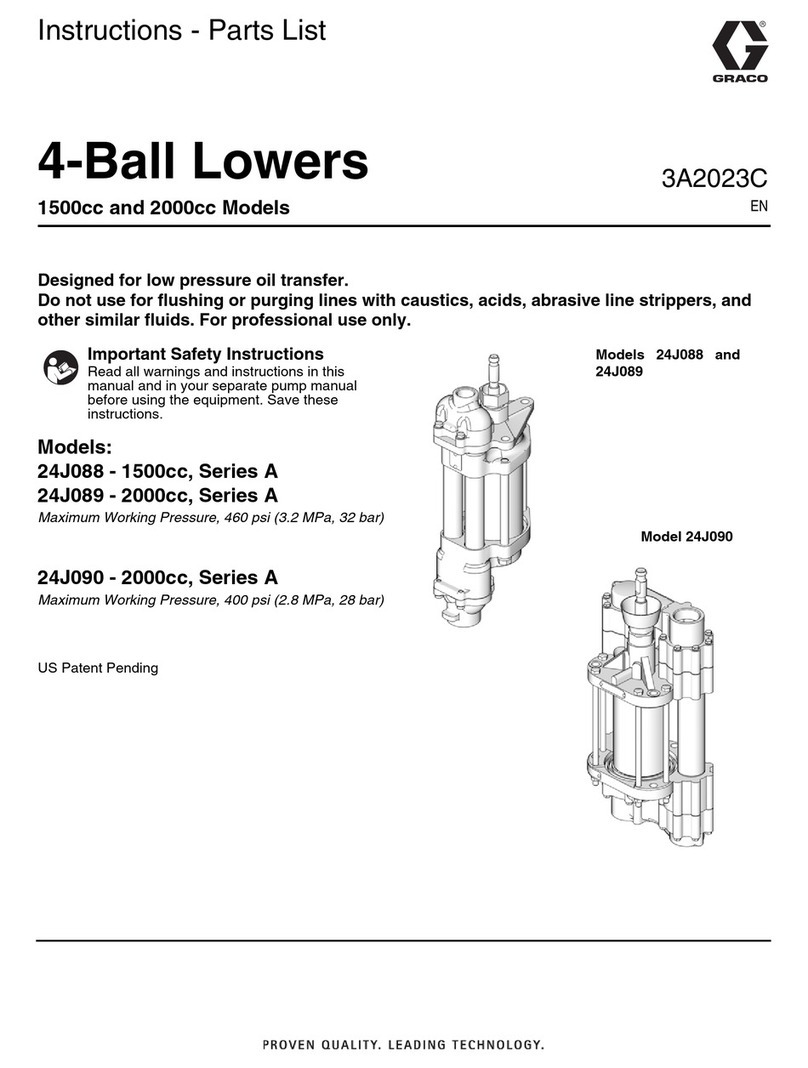

Fgure 1 Pump carryng

STORAGE

- If pump group s not mmedately nstalled, t should be stored n a place whch s

clean dry and does not nclude freezng and exploson rsk.

-

If pump bearng are type whch should be greased, they should be extra greased for

preventng entry of mosture to bearngs around shaft

- Pump should be protected from mosture, dust, drt and foregn objects by coverng

wth sutable materal.

- Pump shaft should be rotated a few turns (e.g once a week) for preventng pttng

around pump bearng surfaces and jammng of shaft.

INSTALLATION

Installaton of pump to ts place and connecton setup

and balance should only be

done by expert personnel. Faled nstallaton and pump ground may cause falures.

Ths stuatons are not covered wth warranty

5

Before nstallng the pump n ts place,

Sucton and dscharge flanges should properly be cleaned.

ATTENTION- Pump should be nstalled n a locaton where there s not exploson and

frost hazard and has good ar condtonng.

- There should be enough area around pump for reachng pump easly, for

mantenance and there should be enough space and heght to lft the pump f

necessary.

-Pump sucton ppe should be as short as possble.

If BTKF-I pumps are nstalled over a ppe whch s well supported or over ground by

means of base plate.

-BTKF-I pumps can be mounted to flat ppes vertcally or horzontally.

Flow can be from upwards to downwards or reverse n pumps whch are connected

vertcally. (Provded that pump flow drecton has been connected correct)

Motor axs can be n vertcal or horzontal poston n pumps whch are connected to

horzontal ppe motor should never reman below the horzontal plane.

Pump whch s nstalled over a pump ground can be mounted to a flexble ppe by

means of base plate.

ATTENTION:- You should be carefully work at pump nstallaton ground preparaton

and nstallaton of pump group nto ts place. Incorrect and careless nstallaton

causes early wearng of pump parts and falures.

- Pump ground should be so heavy to absorb vbratons and sturdy to prevent bends

and adjustments defects. Ground concrete should completely be soldfied,

completed ts plug tme and proper stud bolts are placed n pump frame fixng holes

and proper fixng lugs should be placed for usng n makng connectons wth weldng.

Concrete and plate upper surface should be horzontal and very smooth.

-Place the pump group over concrete ground and put or remove steel wedges under

frame and adjust the flanges. Provde that pump shaft completely n horzontal

poston.

-Tghten the anchorage stud bolts properly.

Installaton of Ppe Lne Installaton

-Nomnal dameter of pump dscharge and sucton pumps are not an ndcator for

correct dameters for dscharge and sucton ppes.

- It should be controlled that crcks and stresses and ppe weght do not effect pump.

GENERAL

Fl uid

So lut ion s

6

- Flow rates generally should not exceed 2m/s n sucton ppe and 3 m/s dscharge

ppe.

- Especally bottom backwater valve, slt trap,

filter and check valves and smlar

elements should be chosen to havng a larger passng area.

-

For ths reason, bolts of dscharge and sucton flanges should be loosen and t

should be controlled whether ppe system exerts a stress over pump.

--

Ppes and accessores havng dameter less than pump openng dameter should

absolutely not be used.

-

Never use

pumps as a support pont or carrer for a ppe nstallaton.

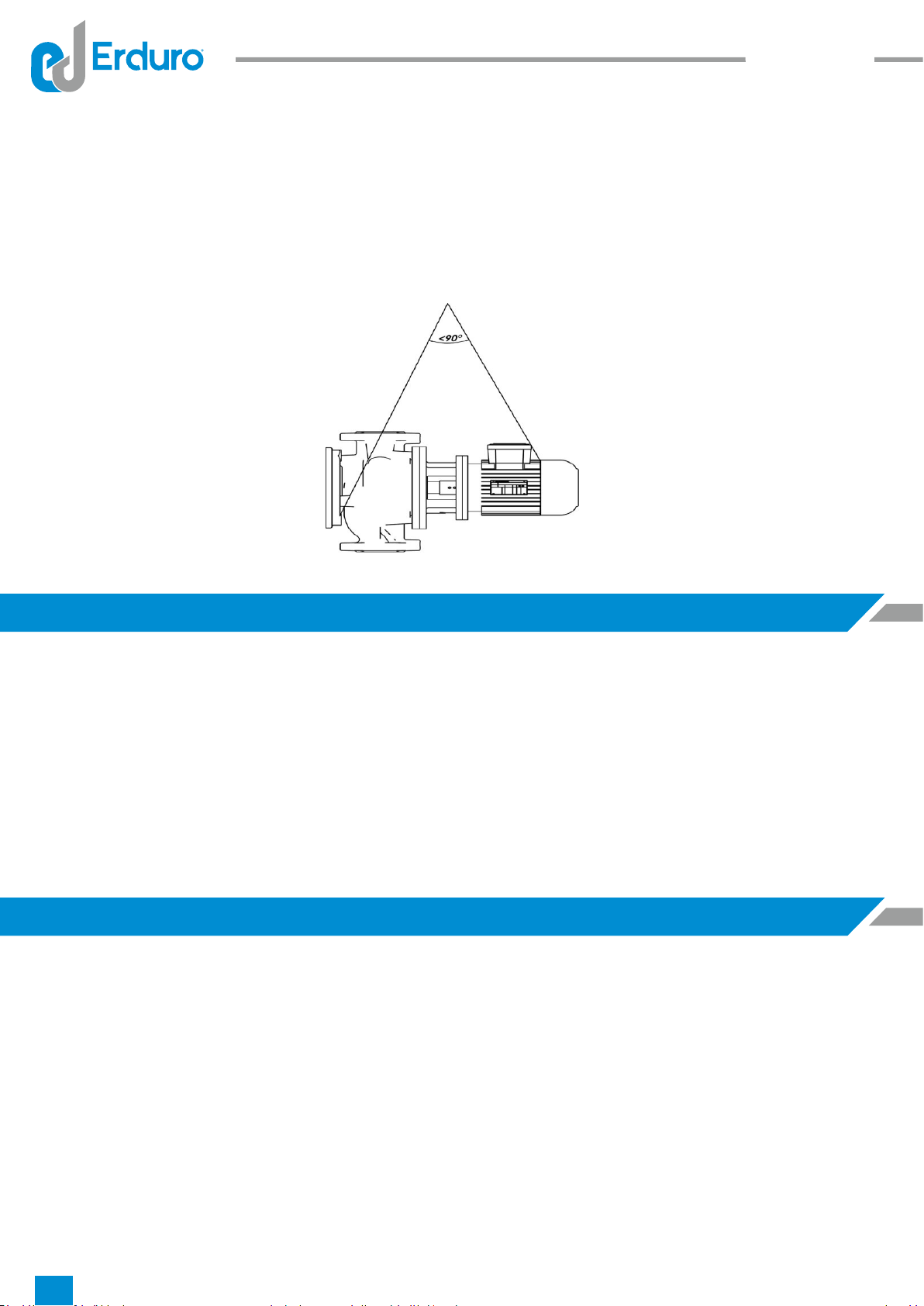

- Ppe system should be supported from ponts whch are close to pump. Fgure 2.

- Proper expanson equpments should be used for preventng addtonal forces to

pump whch may occur because of expanson n systems whch operate n over

vbrant and hot lquds.

-

Hgh speeds cause decrease n pressure

whch wll cause cavtatons condtons

and excess frcton losses n dscharge ppe.

- Weldng burrs, metal partcles, whch may occur durng ppe equpment producton

sand, and oakum and smlar foregn objects may present nsde pump. Sucton and

dscharge flanges should be closed wth gasket wthout hole for preventng those

materals enter nto pump durng nstallaton. At the end of nstallaton, all ppe parts

should be dsmounted, cleaned and dyed and nstalled agan. If drt retaned s used

at pump sucton lne, t should be removed and cleaned after first few days of

operaton and nstalled agan.

Fgure 2

Fl uid

So lut ion s

7

-

Ppe connectons should be made by flanges. Flanges gaskets should be produced

from sutable materal and should have sutable dmensons. Gaskets whch wll be

used between flanges should be centered for not preventng water flow.

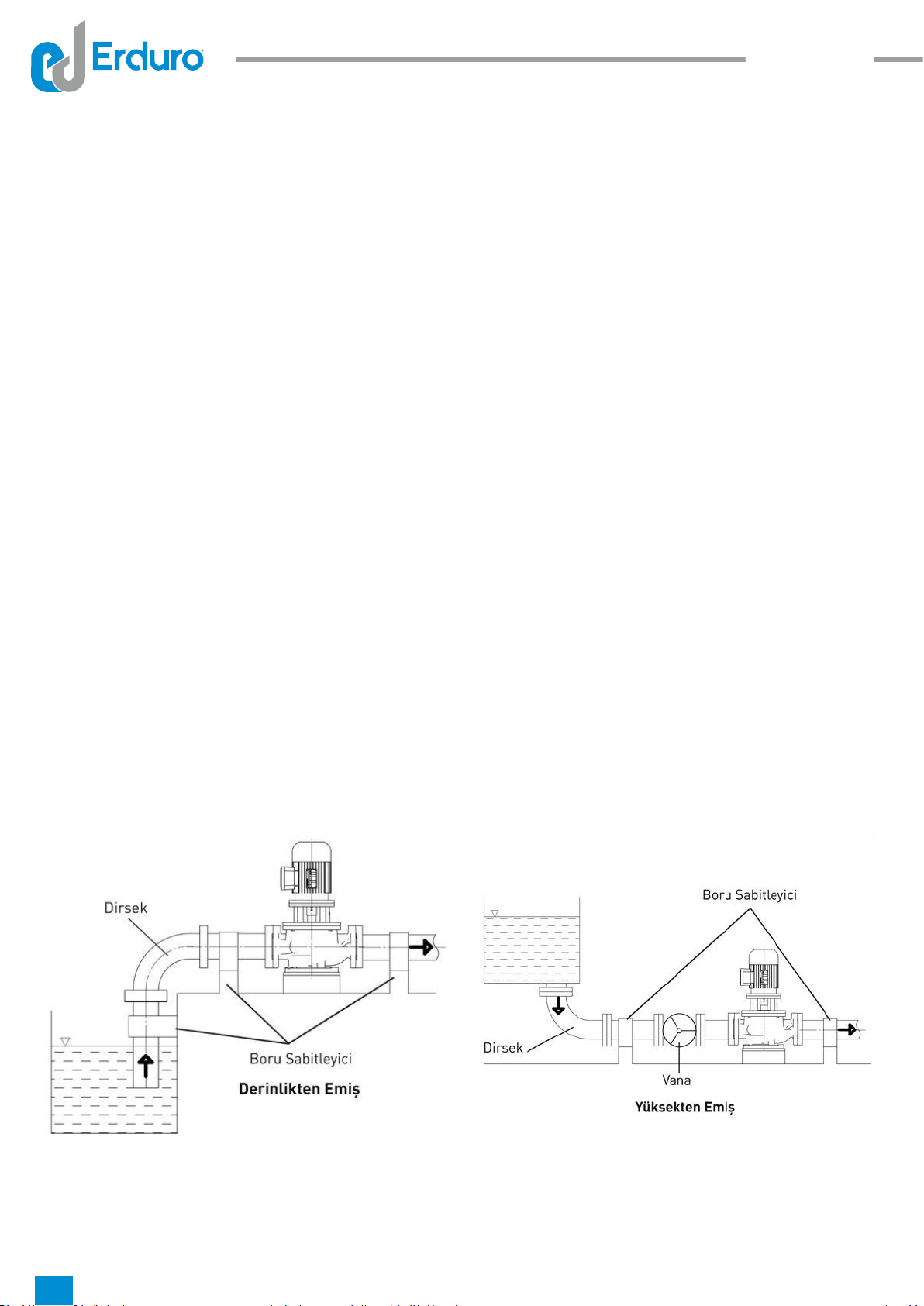

Fgure 3

Sucton and Dscharge Ppe Connectons

- If pump s suppled from a tank whch s hgher than pump, there should be an

solaton valve n sucton ppe whose axs wll be n horzontal poston. Ths valve

should

be completely open whle pump s n operaton and should never be used as

flow rate adjustment valve. (Attenton: Closng valve may cause pump operaton wth

cavtatons. )

-

Sucton ppe should absolutely be mpermeable and should not be arranged to

cause any ar wall. In ths case f a tank s suppled from a tank whch s hgher than

pump, (sucton hgh nstallaton) sucton ppe should be slghtly decreasng sloped

towards pump and suppled from a tank whch s lower than pump, sucton ppe

should be

slghtly ncreasng sloped towards pump.

-

Sharp bends should not be used, sudden drecton changes and cross secton

narrowng should be avoded and sucton ppe should be short as possble for

keepng pump frcton losses as low as possble. If there s need of cross secton

change n horzontal sucton ppe, an ntermedate eccentrc concal part whose flat

type s at upper sde should be used.

-. If pump dschargng heght s more than 10 m or dschargng lne s very long, a

check valve should be placed over dschargng ppe between pump and solaton

valve for protectng pump aganst water mpulses and reverse flows durng stop.

-

A control valve whch s close to pump should be connected for flow rate and

dscharge heght adjustment.

-

If pump dschargng heght s more than 10 m or dschargng lne s very long, a

check valve should be placed over dschargng ppe between pump and solaton

valve for protectng pump aganst water mpulses and reverse flows durng stop.

Fl uid

So lut ion s

8

d1: Sucon Opening Pressure

Meter Connecon

d2: Discharge Opening Pressure

Meter Connecon

By-Pass Valve Connecton

-.

A by-pass valve should be places over dscharge ppe just after pump and before

adjustment valve or outlet flange of pump f there s a case that pump wll operate n

condtons that pump dscharge valve s completely closed(that s wth zero flow rate)

or almost closed (that s wth very small flow rate). If such valve s not used and

pumps operates wth closed valve for a long tme, power whch s provded by motor

wll completely transform nto heat energy and pass nto dscharged lqud. Ths may

cause over heatng and abnormal falures n pump.

ELECTRICAL CONNECTIONS

- Electrcal connectons should be done by authorzed electrcans

Natonal nstructons, regulatons and nstructons of motor manufacturers should be

obeyed.

- Power cables should absolutely be nstalled as not

havng contact wth ppe

nstallaton, pump and motor body.

-

Motor shaft should be rotated by hand before makng electrcal condtons to control

whether t rotates easly.

-

It s recommended to use PTC(Passve Thermal Control-Thermstor) n motors.

However usage of those

depends on customer.

- Electrcal motors should be protected aganst overloadng by crcut breakers and/or

fuses. Crcut breakers and/or fuses should be selected wth respect to full load

values those are wrtten n nameplate on motor.

Fl uid

So lut ion s

9

Fl uid

So lut ion s

-

Compare and control voltage, ampere and frequency values whch are gven n

motor nameplate wth lne values.

-

Motor connecton scheme can be found n motor termnal box or n handbook.

- Motor electrcal connectons should be done accordng to local Electrcal

Regulatons and earthng connecton should absolutely be done.

-

Protecton class of motor body and control system cases n pump should be at least

EN 60529 IP 22. In addton to ths, protecton class of motor bodes and control

systems n pump group should be determned accordng to operatonal and

envronmental condtons.

-

Safety precautons whch are determned n "Safety Instructons" should be appled.

All power connectons should be dsconnected before startng to any work.

-However usage of those depends on customer. If PTC s used ends of those should

be connected to motor termnal box and later should be connected to PTC control

devce n motor control panel.

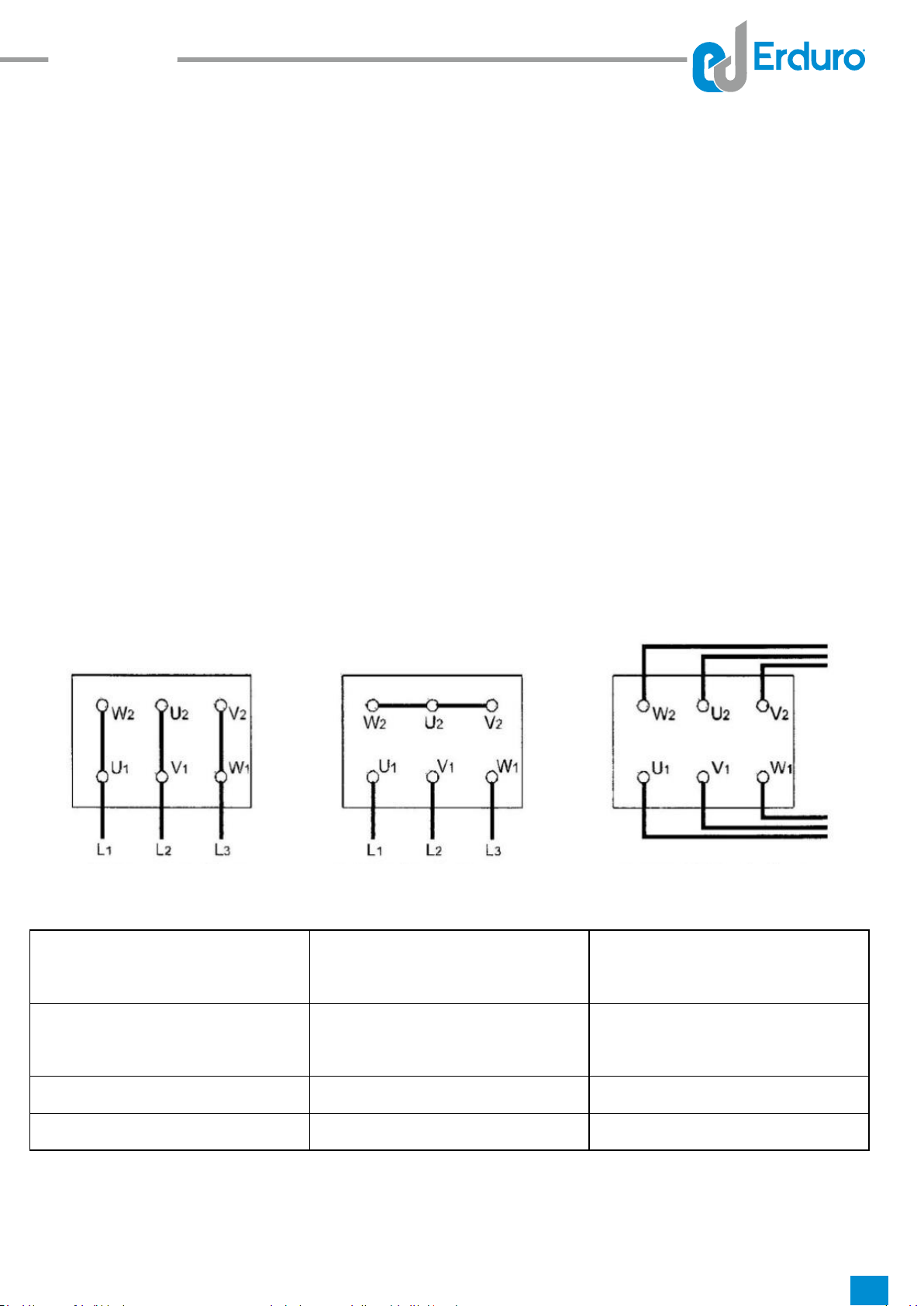

-

Motor connecton type changes accordng to motor mans power and connecton

type. Necessary connecton types of jumpers n termnal box are dsplayed n Table 1

and Scheme 1a -1b and 1c

Scheme 1a Scheme 1b Scheme 1c

Start Type Motor Power

PN<4kW

Motor Power

PN >4kW

Mans Power

3~400V

Mans Power

3~400V

Drect

Y-connecton (1b) Δ-connecton (1a)

Y/ Δ Star Delta Impossble

Remove Jumpers (1c)

Table 1

10

Fl uid

So lut ion s

Attenton! Transton tme from star to delta should be short n star-delta connected

motors. In case that t s long damages may occur n pump and motors.

Motor Power Y-

Setup tme

<30 kW

>30 kW

<3 seconds

<5 seconds

Table 2

- After all abovementoned operatons are completed, pump rotor should be rotated a

few turns for beng sure that t rotates easly.

-

All safety guards should be nstalled nto ther places. Pump should absolutely be

not operated after ths operaton s made. Ths s oblgatory for safety.

FIRST START

Controls Before Operaton

- If there s bottom back flow water valve n pump wth depth sucton; one of the plugs

n flanges s opened and sucton ppe and pump s filled wth water and ts ar s

taken.

-

Ths case does not cause problem n force feed pumps. Dscharge valve s closed

placement type of pump s consdered and one of the plugs n flanges s opened and

pumps sucton valve s slowly opened and pump s completely filled and ar s

completely removed.

-

If system ncludes vacuum pump, rse of water n sucton pump by means of

vacuum pump and fillng pump s provded. When water reaches the

hghest level

pump s started.

- Pump motor bearngs are "Lfetme Greased " bearngs so they do not need any

control.

-Be sure that there s water n water tank and/or source.

-Be sure that pump and sucton ppe s completely filled wth water.

-ATTENTION! Never let pump run n dry condtons.

11

Determnaton of Rotaton Drecton

- BTKF-I type pumps rotates n clockwse drecton when you look from motor towards

pump. Ths drecton s shown wth an arrow n pump body. Pump s operated for a

short whle and checked whether t rotates n correct drecton. If protecton guard s

unnstalled durng ths operaton, t should mmedately be nstalled after ths

operaton.

Startng Pump

- Check that sucton valve s open and dscharge valve s closed.

- Close the crcut breaker and start the motor.

- Wat motor to reach full speed. (Wat motor to pass delta n motors operaton wth

star-delta)

- Observe the ammeter n panel and slowly open dscharge valve. (If dscharge ppe

s empty n first start, do not open dscharge valve completely and open n controlled

way by controllng that value n ammeter s lower than motor rated values.)

-After valve s completely opened control the value whch s read from ammeter

whether t s same wth the value at operatonal pont. If the ammeter value s less

than operatonal value adjust t by closng the valve. If t s greater check the

nstallaton and statc heght.

ATTENTION: If any of followng problems occur whle pump operates n nomnal

speed; pump should mmedately be stopped and trouble should be elmnated.

1) Pump operates wth over vbraton.

2) Pump and motor connecton bearngs have over temperature.

3) Pressure s not enough.

4) Pump dscharges no water.

5) Flow rate contnuously decreases.

6) Motor operates overloaded

7) Pump operates wth very much nose.

8) Pump does not dscharge sufficent water.

Controls to be Made Whle Pump s Runnng

- Snce pumps have mechancal seal t does not need any mantenance. A few

amount of water may leak from mechancal seal but t s so small that t can not be

notced. If the amount of water comng from mechancal seal ths means that seal

surface s abraded and needs to be replaced. Lfetme of mechancal seal s manly

depends on cleanness of dscharged water.

Fl uid

So lut ion s

12

Fl uid

So lut ion s

- Motor current should sometmes be controlled from ammeter over electrcal panel

whch controls the motor. If current values are more than motor nameplate values

there may be frcton or squeezng n pump. Pump should mmedately be stopped

and mechancal and electrcal controls should be done.

- If there are spare pumps n system, ths type of pumps should be run for a short

whle at least once a week and controlled whether read for operaton. Control wth

auxlary elements f any.

-

Pump should absolutely be run n closed valve condton (zero flow rate) for a long

tme.

-

Pump should operate slent and wthout operaton.

- Bearng temperatures should never exceed ambent temperature (more than 50ºC

It should never exceed 80ºC

- Never operate pump wthout water.

LUBRICATION

- Snce motor bearngs ARE "Lfetme Greases" t does not need any mantenance.

DISMOUNTING PUMP AND REPAIR

ATTENTION!-Always dsconnect the electrcal connectons before start any operaton

over pump and be sure that you have taken necessary precautons to prevent to

operate mstakenly.

DISMOUNTING PUMPS

-

Close the solaton valves n sucton and dscharge

lnes.

-

Unnstall the safety guards.

-Separate the pump group from ppe system by unnstallng the pump sucton and

dscharge flange (and auxlary ppes f any) connectons.

-Separate scroll case from mechancal seal box. Be careful not to gve harm to

mechancal seal whle dong ths operaton.

-Unnstall the mpellor nuts and remove the mpellor wedge. Use rust solvent f

necessary.

-Take the ntermedate bushng.

-Carefully remove the rotatng parts of mechancal seal.

-Separate the mechancal seal box, and carefully remove the fixed elements of

mechancal seal.

-Unnstall the motor carrer.

13

Fl uid

So lut ion s

-Unnstall the pump shaft set screws and rgd couplng shaft bolts dependng on

connecton type.

-Separate pump shaft from motor shaft.

Installaton of Pump

-.

Pump nstallaton operaton s made by reverse order of pump dsmountng

process.

-

Before startng to nstallaton operaton, apply lubrcous materals such as graphte,

slcone or smlar slppery substances over contact surfaces or bolt surfaces. If you

can not find those substances use lqud ol. (drnkng water

pumps excludng)

-

Do not use gaskets whch you had removed. Use new ones havng same

dmensons. Be careful that new gaskets and O-rngs are n same dmensons.

-Place the motor as ts shaft end wll be upper sde and connect the motor carrer to

motor.

- Insert the pump shaft to the motor shaft by sldng.

-Place the seal box over motor carrer.

-Place the fixed elements of mechancal seal nto seal housng.

-Insert the rotatng parts of mechancal seal over pump shaft by sldng and place the

ntermedate bushng.

-Place the mpellor wedge and nsert the mpellor and connect the mpellor nuts.

-Connect the scroll case.

-Place the pump group over frame. Connect the sucton and dscharge ppes (and

auxlary ppes f any.)

-Connect the conductor plate f any.

14

Fl uid

So lut ion s

Fgure 5

Seals

-BTKF-I type pumps are always produced wth mechancal seal.

-Water leakage does not occur n a mechancal seal whch properly works. Generally

f there s not any vsble water leakage seals do not need mantenance. Besdes ths

mpermeablty of mechancal seals should regularly be controlled.

-Absolutely obey the nstructons of manufacturers where mechancal seals are used.

never operate the seal n dry condtons.

15

Fgure 6

1) Impellor

2) Carrer Foot

3) Scroll Case

4) Mechancal Seal

5) Dscharge Openng

6) Splash rubber

7) Pump Shaft

8) Motor

9) Sucton Openng

CROSS SECTION DRAWINGS

Fl uid

So lut ion s

16

Fl uid

So lut ion s

Table 3

1

There s ar n lqud Swrls occur snce depth of submerson ppe s

not enough and there fore ar can not be

absorbed. Control the lqud level n sucton tank

and ncrease the depth of bottom/sucton ppe

back water valve.

2

Ar pocket n sucton ppe Control the slope of sucton ppe and whether

there are sutable places for formaton of ar

pockets, f any make necessary correctons.

3

There may be ar n pump

and/or sucton lne

Fll pump or sucton ppe completely wth lqud

and repeat the start process

4

Ar s not

absorbed from

seal, sucton ppe, or

connectons. Pump absorbs

lqud whch s mxed wth ar

Control all connectons n sucton ppe. Check

seals. If necessary feed seals wth pressurzed

water. Check the submerson depth of sucton

ppe pr deep back water valve and ncrease

submerson depth f necessary.

FAILURES POSSIBLE REASONS

Started pumps never dscharges water 3-6-8-12-11-14

Flow rate decreases or no water s dscharged 4-2-7-15

Motor s overloadng

9-10-16-22

Bearngs have over temperature 17

There s vbraton n pump

13-18-21-19

Nose level s hgh

1-5-20

17

SPARE PARTS

- ERDURO warrants to provde the spare parts for BTKF-I Seres pumps for 5(five)

years begnnng from producton date. You can always easly obtan the spare parts

you need.

- In spare parts order, t wll be sufficent for you to nform the followng values whch

are wrtten n pump nameplate.

Pump Type : BTKF-I 40/200

Motor Power(P) and Revoluton(n) :5,5 kW - 2900 d/d

Producton Year and Seral No : 12/2011 - 201112-001

Flow rate(Q) and Manometrc Heght (Hm): 15 m³/h - 44 mSS

REASONS FOR FAILURES AND TROUBLE SHOOTING

type pumps, possble reasons

(Table 3 ) and trouble shootng methods (Table 4 ) are gven.

ATTENTION! Control the accuracy of all measurement gauges before startng to

elmnate the falure operaton.

In ths chapter falures which can be seen BTKF-I

Fl uid

So lut ion s

5

Pump operates wth

cavtatons

NPSH of plant s very low. Check the water level

n sucton tank. Check whether there are over

frcton losses n sucton lne. Check whether

solaton valve n sucton lne s completely open.

If necessary place the pump n low levels and

ncrease the load of pump at sucton sde

6Sucton depth s very much

If there s no obstacle whch may cause cloggng

control the frcton losses of sucton lne. If

necessary use a sucton ppe havng larger

dameter. If statc sucton depth s too much you

should rase the heght of water level n sucton

tank or pump should be places n lower levels.

7

Increase n dscharge heght Check whether valves are completely open. Check

whether there s an obstacle whch may cause

cloggng n dscharge ppe.

8

Pumps dscharge heght s

nsufficent

Actual dscharge heght of plant s hgher than gven

values. Check the total statc heght and frcton

losses of dscharge ppe. Usng ppes havng

greater dameter may be soluton. Check whether

valves are completely opened.

9

Pump s operatng at lower

dscharge heght

Dscharge heght of plant s lower than gven

values. Lathe the mpellor dameter accordng to

manufacturer suggestons

10

Speed very much Decrease the motor revoluton f possble or Lathe

the mpellor dameter accordng to manufacturer

suggestons

11

Pump rotates reverse Check rotaton drecton of motor whether t s

same wth the drecton whch s ndcated n pump

body or nameplate

12

Impellor partally clogged Clean the mpellor

13 Impellor, check valve or filter

clogged

Clean Impellor, check valve or filter

14 Impellor, partally filter clogged

Clean Impellor, or filter

15 Mechancal frcton n pump Check whether there are any obstacle or bend n

pump rotor

16 Flow rate s less than pumps

necessary flow rate

Increase the flow rate, use by pass valve or lne f

necessary

17 Worn or malfunctoned

mpellor

Replace the mpellor

18 Imbalanced rotatng parts Adjust the balance of rotatng parts

19

Pump operates out of ts

operaton regon

Check the operatonal regon values

20

Shaft s bend Check the shaft and replace f necessary

21

Motor Falure

Check the motor,. Motor s not sutable for ts ar

condtonng poston

Table 4

18

Fl uid

So lut ion s

INSTALLATION TYPES

Fgure 7

19

Fl uid

So lut ion s

SCREW DIAMETER

MAXIMUM TIGHTENING MOMENT(Nm)

CLASS PROPERTIES

8.8 10.9

M4 3 4,4

M5 5,9 8,7

M6

10 15

M8

25 36

M10 49 72

M12

85 125

M14

135

200

M16

210

310

M18 300 430

M20

425

610

M22

580

820

M24

730

1050

M27

1100

1550

M30

1450

2100

M33

1970

2770

M36 2530 3560

TIGHTENING MOMENT

20

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Zoeller

Zoeller 7008 owner's manual

Elmo Rietschle

Elmo Rietschle C-KLR 140 Original operating instructions

Wilo

Wilo Sub TWU 3-HS Series Installation and operating instructions

BUSCH

BUSCH DOLPHIN LA 0053-1111 A Installation and operating instructions

Pentair

Pentair SHURFLO PIRANHA 375-116-10 quick guide

FUXTEC

FUXTEC FX-WP152 Original user manual