Ergo 50 Series Operating manual

Preventive Maintenance

Swiss Egro 50 Series

V 2.2

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 2

Index

1. Preventive Maintenance.....................................................................3

2. Programming manual ........................................................................3

3. Service table..................................................................................5

4. Maintenance table ...........................................................................6

5. Lubricant table ...............................................................................8

6. PM Service kits................................................................................8

7. PM service kits content......................................................................9

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 3

1. Preventive Maintenance

Preventive maintenance (PM) ensures a continuous good quality of coffee products and reduces the

unscheduled break downs of the coffee machine. During preventive maintenance recommended services

will be done and necessary spare parts will be exchanged. Moreover it simplifies the organisation of the

maintenance and the spare parts logistics.

The bases for preventing maintenance are our service kits, along with all necessary spare parts. These

are available as “PM Service kit” and “PM Extension kit”.

The preventive maintenance is controlled by the number of brewing cycles, counted in the coffee

machine. Reaching the number of cycles, the coffee machine is indicating following message in the

display "PM Service Req.".

Egro Coffee System AG recommends adjusting the maximum brewing cycles for preventive maintenance

to 15’000 cycles. For coffee machines with the brewing unit “NBUP” (New Brewing Unit Project) the

number of cycles will be with 25’000.

The brewing cycles depend on various criteria as regularity of brewing, composition of water, cleaning

product, climatic conditions, etc. Egro Coffee System AG recommend, in case of unfavorable conditions,

to adjust the number of brewing cycles.

2. Programming manual

Put the machine in programming mode (mode 4).

Readout the brewing cycles: The parameter "P-Serv" informs how many brewing cycles the coffee

machine has done, since the last maintenance.

Choose menu „Service“Enter Pin 1849 Display shows

„Product Total..“

Pin ....

Press Enter Choose „P-Serv“ Disp. „P-Serv 12’789“ 12’789 corresponds to

the cycles since the last

maintenance

Turn

k

ey bac

k

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 4

Adjust the maximum cycles: By entering the maximum number of brewing cycles the service counter is

activated. The input of the value 15 corresponds with 15'000 brewing cycles.

With reaching of this 15'000 brewing cycles the display shows the message "PM Service Req." and the

customer has to inform the service organization.

The number of brewing cycles has to be adapted depending upon application and environment of the

coffee machine.

Reset the brewing cycles: After preventive maintenance was accomplished, the cycle counter will be

reset to zero and activated again.

Choose menu „Service“

Press enter Choose „Max. Cycles“ Press enter Enter the value 15 for

15’000 cycles

Pin .... Enter Pin 1849 Display shows

„Product Total..“

Press enter Turn key back

Press Enter. Choose „CLR P.Serv” Press Enter.

Pin .... Enter Pin 1849 Display shows

„Product Total..“

Press Enter.

Choose menu „Service“

„CLR P Serv?“

„P Serv. Cleared” Turn Key back

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 5

3. Service table

There are service kits for all types of the series 50. Additional there are extension kits available. Both

kits contain the requested exchange and spare parts.

In the following table you can see which kit has to be used with appropriate brewing cycles or years.

15'000 cycles or

after 1 year 30'000 cycles or

after 2 years 45'000 cycles or

after 3 years 60'000 cycles or

after 4 years 75'000 cycles or

after 5 years 90'000 cycles or

after 6 years

PM service kit PM service kit PM service kit &

PM extension kit PM service kit PM service kit PM service kit &

PM extension kit

With brewing unit “NBUP”

25'000 cycles or

after 1 year 50'000 cycles or

after 2 years 75'000 cycles or

after 3 years 100'000 cycles or

after 4 years 125'000 cycles or

after 5 years 150'000 cycles or

after 6 years

PM service kit PM service kit PM service kit

PM extension kit PM service kit PM service kit PM service kit

PM extension kit

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 6

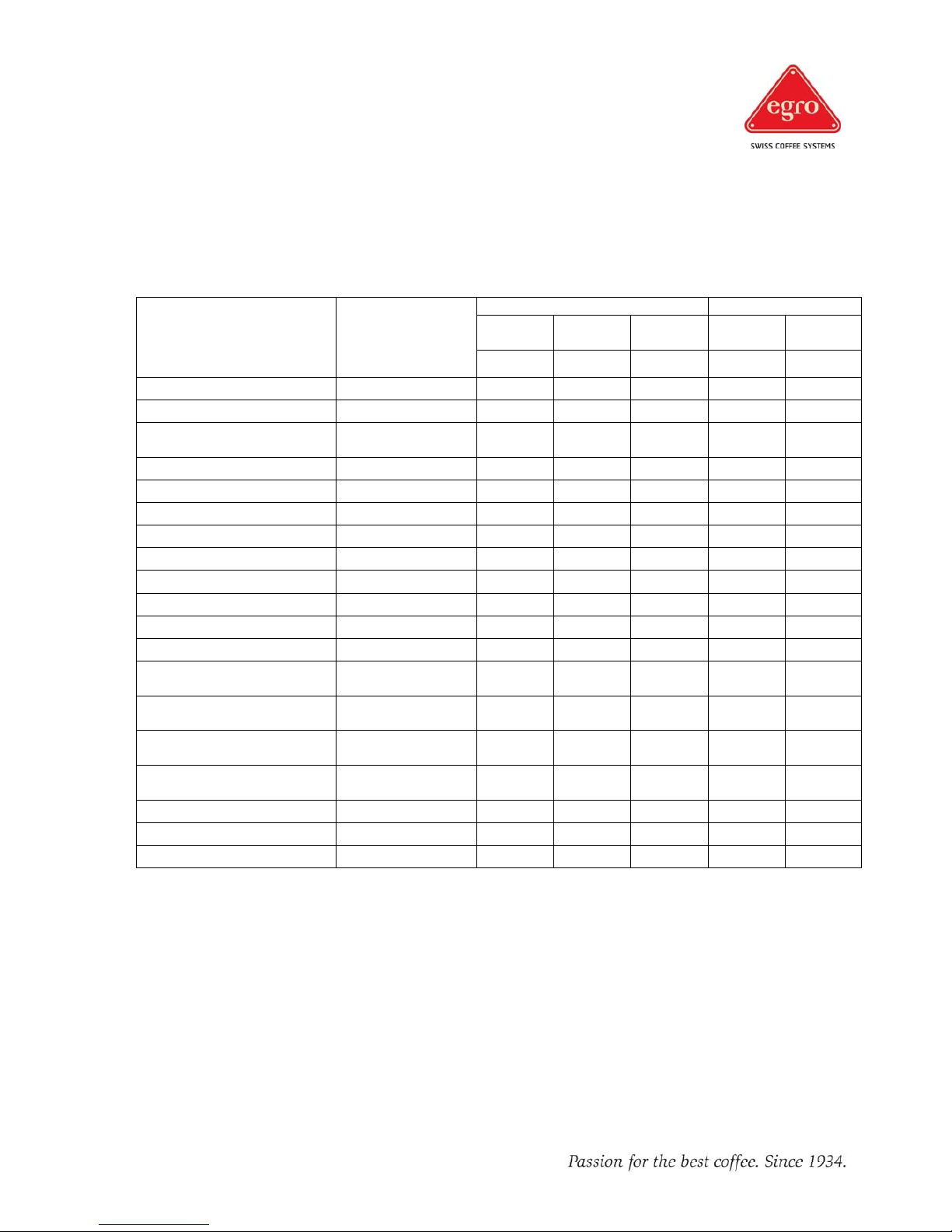

4. Maintenance table

Assembly Description

Control

Clean

Decalcify if

necessary

Lubricate*

Replace

PM service kit Every PM

Housing Cover •

Bean hopper •

Grounds drawer •

Trip tray •

Brewing unit Brewing unit •

Upper piston motor Spindel ••(1)

Upper piston •

Brewing sieve •

O-Ring for piston •

Turcon gasket •

Piston motor sensors •

Ejector •

Lower piston motor Spindel ••(1)

Brewing piston •

Brewing sieve •

O-Rings for brewing piston •(3) •

Turcon gasket (NBUP) •

Piston motor sensors •

Boiler coffee / tea Boiler ••

Expansion valve •

Brewing valve •••

Brewing valve plunger •

O-Ring for brewing valve housing •(2)

O-Ring for the connection brewing valve - boiler •(2) •

Tea valve ••

Tea valve plunger •

O-Ring for tea valve housing •(2)

Non return valve boiler inlet •

Boiler steam Boiler gasket •

Heating element •

Non return valve boiler inlet •

Level sensor

•

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 7

Assembly Description

Control

Clean

Decalcify if

necessary

Lubricate*

Replace

Steam valve block O-Ring for vacuum valve •

Pressure switch •

Pressure relief valve •

Steam valves •

Grinder Grinder ••

Cold water block Water pump •

Cold water valves •

Tubes and connections •

Milk system Milk frother ••

Silikon tubes

•

Teflon tubes

•

Refrigerator Milk sensor ••

Milk pumps ••

Air foam valve

•

Air pump •

Switch valve •

Non return valve •

PM extension kit Every third PM

The following maintenance actions have to be done additionally.

Steam valve block Plunger for steam valve •

O-Ring for steam valve block •

Pressure switch

•

Gasket for pressure relief valve •

Pressure relief valve •

Threaded male connector

•

Steam boiler Boiler inlet •

Steam boiler gasket

•

O-Ring for steam boiler •

Level sensor

•

Milk system Milk foamer •

* see Lubricant table

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 8

5. Lubricant table

The lubricant table informs which lubricant has to be used where. By the use of not specified lubricants,

you can shorten the life time extremely.

Type Description Declaration

ID-No. Thermal

Range Area of application

1 High performance lubricant Berulub

FG-H 2 SL 059246

-45 to

+160°C

All connections:

Boiler fittings, tea- and steam

wand, piston motors

Non Food Area

2 High performance lubricant Berulub

SIHAF 2 059245

-45 to

+160°C

For all rubber seals like:

NBR, EPDM, Viton

Inapplicable for Silicon O-Ring!

3 Synth. Assembly Grease Klübersynht

UH1

64-2403 054567

-30 to

+140°C Lower Piston O-Ring

Do not use with EPDM rubbers!

6. PM Service kits

The service and extension kit are available in the spare parts catalogue of our Webshop.

Serie PM service kit PM extension kit

5011 / 5031 ID 060942

5021 / 5023 / 5033 ID 060943 ID 060944

5025 / 5035 ID 060945 ID 060946

5012P / 5031P ID 060947 ID 060948

5021P / 5023P / 5033P ID 060949 ID 060950

5025P / 5035P ID 060951 ID 060952

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 9

7. PM Service kits content

Series 50

Service kit Extension kit

ID 060942 ID 060943 ID 060945 ID 060944 ID 060946

Description Assembley group 5011 5023 5025 5023 5025

2 way plunger T22 Tea / steam valve 1 3 2

3 way plunger T22 Brewing valve 1 1 1

3 way plunger low tension

spring Steam valve 1

Copper gasket Relief valve 1 1

Expansion valve 11 bar Coffee boiler 1 1 1

Gasket kit brewing unit Brewing unit 1 1 1

Level sensor 180 mm Steam boiler 1 1

Milk foamer Milk system 1 1

Non return valve Boiler 2 2

O-Ring seal Vacuum valve Vacuum valve 1 1

Pressure switch 1.3 bar Steam boiler 1 1

Relief valve Steam valve block 1 1

Silicon hose 6,0 x 3,0 mm,

rosa Milk system 1 1

Silicon hose 6,0 x 3,0 mm,

white Air foam valve 1 1

Silicon hose 7,0 x 3,0 mm

white Milk system KS 1

Silicon hose 7,0 x 4,0 mm

blue Milk system 1

T Hose connector 12-6-12 Drain system 2 2

T Hose connector 6-6-6 Drain system 1

Teflon pipe 4,0 x 2,5 mm Milk system KS 2

Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf 15.05.09

Page 10

Series 50P

Service kit Extension kit

ID

060947 ID

060949 ID

060951 ID

060948 ID

060950 ID

060952

Description Assembley group 5012P 5023P 5025P 5012P 5023P

5025P

2 way plunger T30 Tea valve 1 1 1

2 way plunger Steam T30 Steam valve block 1 1 1

3 way plunger Steam T30 Steam valve block 2 2

3 way plunger T30 Brewing valve 1 1 1

Copper gasket Relief valve 1 1 1

Expansion valve Coffee boiler 1 1 1

Gasket kit brewing unit Brewing unit 1 1 1

Level sensor 140 mm Steam boiler 1 1 1

Milk foamer Milk system 2 2

Non return valve Boiler 2 2 2

O Ring seal Steam valve block 2 2 2

O-Ring seal Brewing valve 2 2 2

O-Ring seal Vacuum valve Vacuum valve 1 1 1

Pressure switch 1.5 bar Steam valve block 1 1 1

Relief valve, steam Steam valve block 1 1 1

Silicon hose 6,0 x 3,0 mm,

rosa Milk system 2 2

Silicon hose 6,0 x 3,0 mm,

white Air foam valve 1 1

Silicon hose 7,0 x 3,0 mm

white Milk system KS 2

Silicon hose 7,0 x 4,0 mm

blue Milk system 2

Steam boiler gasket Steam boiler 1 1 1

T Hose connector 12-6-12 Drain system 1 2 2

T Hose connector 6-6-6 Drain system 1 1

Teflon pipe 4,0 x 2,5 mm Milk system KS 3

Threaded male nipple

6 x G1/8 Steam valve block 2 2 2

Table of contents

Popular Coffee Maker manuals by other brands

Philips

Philips HD7864 instruction manual

Philips

Philips 1200 Series user manual

Tchibo

Tchibo Cafissimo CLASSIC Original instructions for use and warranty

Espressotoria

Espressotoria System ADESSO quick start guide

Swiss

Swiss Egro 50 Series operating instructions

Oster

Oster PRIMALATTE II TOUCH instruction manual