Ergonomic products D1 Workstation User manual

198 Airport Road, Fall River, MA 02720

www.ergonomic-products.com 1-866-ERGO-4-US

Assembly & Installation Guide

950-007 rev F

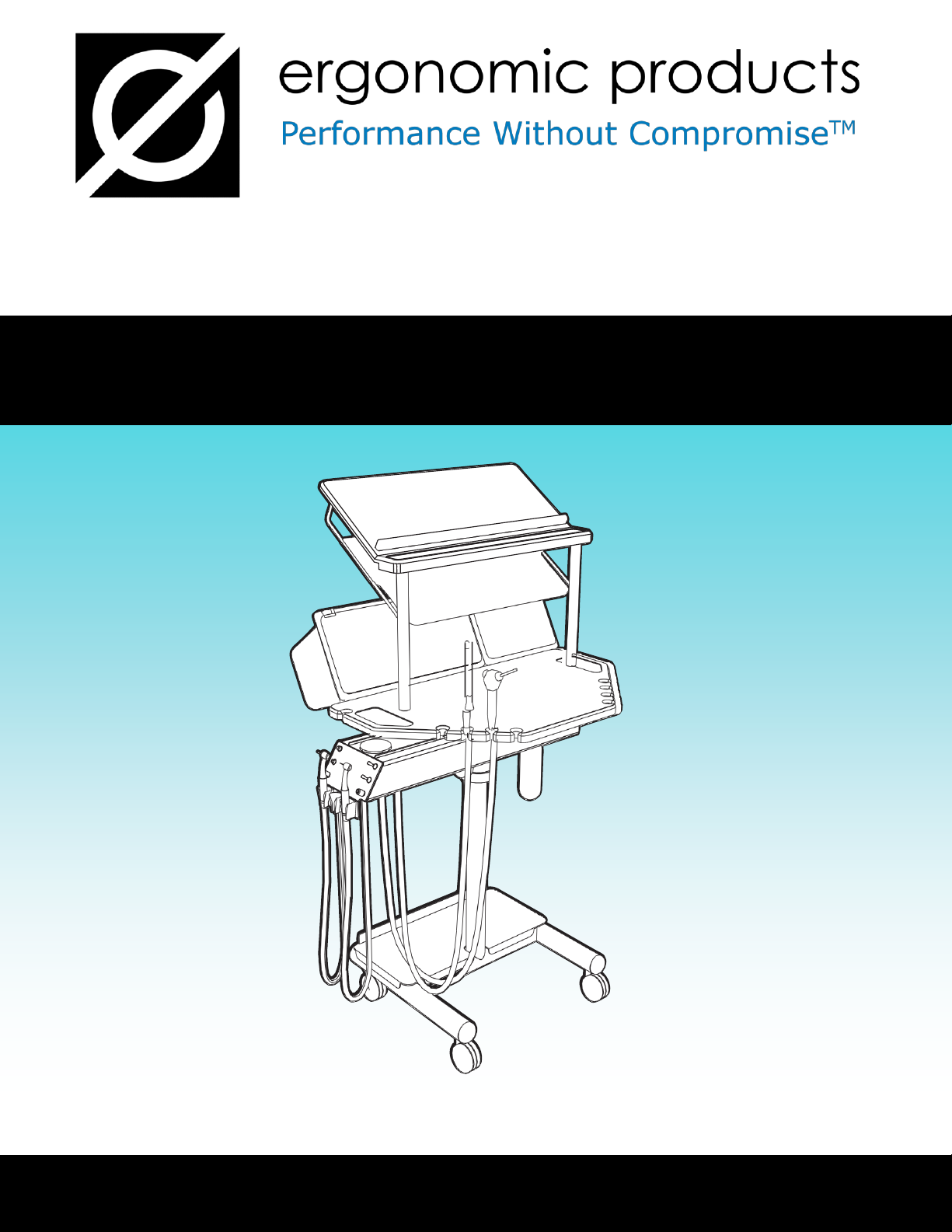

D1: Ergonomic Products Workstation

®

1

Introduction

In this manual you will find complete assembly & installation instructions for your new Ergonomic Products

Workstation. There are sections nine (9) sections:

1.

Receiving your workstation

2.

Unpacking & Assembly

3.

Installation

4.

Connecting a USB Keyboard

5.

Height Adjustment

6.

Accessing the Power Channel Interior

7.

Utility Connections

8.

Basic Anatomy of an Ergonomic Products Workstation

9.

Technical Specifications

Section 1 - Receiving your workstation

Prior to assemble your Ergonomic Products Workstation, carefully follow the instructions in the following

subsections. Doing this will facilitate the actual assembly process.

Shipping Configuration

Your Ergonomic Products Workstation is carefully packed at the factory for safe shipment. During unpacking

and assembly, please refer to the table below for the Packing/Shipping checklist. In the event that your

shipment was damaged and/or missing, contact Ergonomic Products customer service and the shipping

insurance

company.

Description

Notes

Ergonomic Products Workstation Base assembly

Shipped on Pallet

Ergonomic Products Top Tier assembly

(if applicable)

Shipped on Pallet

Accessories Box

Packed on Workstation Base, Please refer to

shipping checklist on box for complete list of

contents.

Inspection

After unpacking your Workstation, carefully check that the configuration/options for your product(s) are

correct. Inspect the shipping cartons immediately for evidence of in-transit damage. If you see any

indication of external damage, call us at the toll-free number listed above. This will simplify making a

claim against the shipping company.

QUESTIONS? Contact Customer Service At: 1-866-ERGO-4-US

For answers to your technical questions.

In the event you need to use our voice mail system, a technical service representative will return your

call promptly.

2

Required Tools

Description

Notes

Utility knife

For box and packing removal

Water Pump Pliers

Top Tier Assembly

Phillips screwdriver

5/32” Allen wrench

Supplied

1/8” Allen wrench

Supplied

3/32” Allen wrench

Supplied

Electric drill

For umbilical plate mounting

2 inch hole saw

Pilot bit for No. 8 screws

3

Section 2 -

Unpacking & Assembly

Your Ergonomic Products Workstation is carefully packed at the factory for safe shipment. The following

section describes the steps for safe unpacking and assembly.

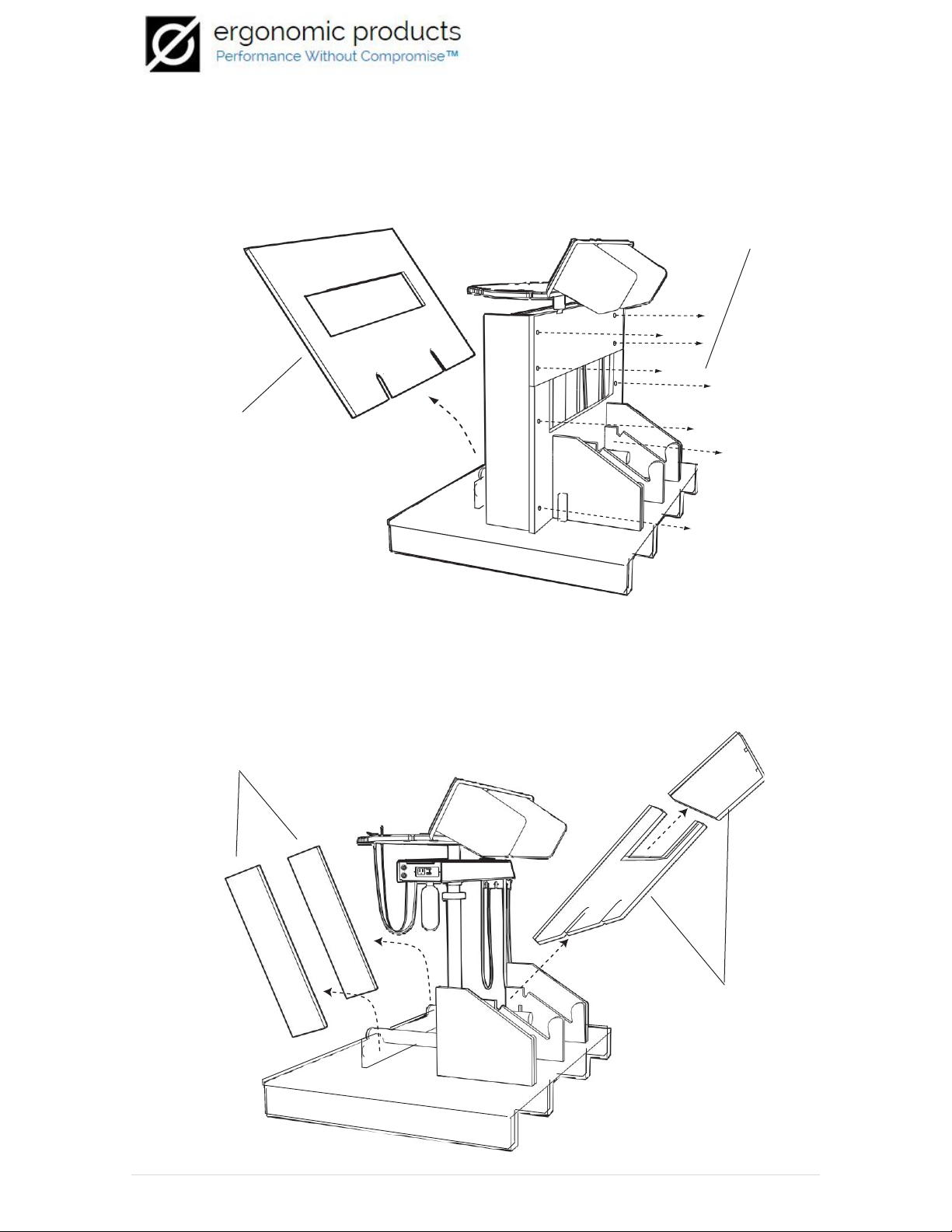

1.

Remove all packing material from the Ergonomic Products Shipping container.

(Fig 1.)

Fig. 1

2.

Remove Top Tier Assembly from rear of container and set aside. Using a Phillips

screwdriver, remove the six (6) screws from the front face of the container. (Fig. 2)

top tier

assembly

six (6) phillips screws

Fig. 2

4

3.

Remove the front face plate and set aside. Proceed to the rear of container and

remove the eight (8) Phillips screws from the upper and lower sections of the rear

face plate. (Fig.3)

Eight (8) Phillips Screws

Front Face Plate

Fig. 3

4.

Remove the rear face plate sections & side supports and set aside. (Fig. 4)

Side Panels

Rear Panels

Fig. 4

5

5.

Safely lift Workstation Assembly from container base and place on floor. (Fig. 5)

Important: Practice safe lifting procedures & use a partner to remove

workstation from container base.

Fig. 5

6.

Retrieve Top Tier Assembly (if applicable) and align the Top Tier Support Shafts

with the holes in the Workstation Assembly worksurface. Once in place, fasten the

Top Tier Assembly in place with the Support Shaft Lock Nuts. (Fig. 6)

Top Tier Assembly

Workstation Assembly

Top Tier Support Shafts

Support Shaft Lock Nuts

Fig. 6

Congratulations! Your Ergonomic Products Workstation is now fully assembled!

6

Section 3 - installation

Umbilical Installation

All of the utilities required by your Workstation are supplied via the Umbilical Tube. Installation simply involves

plugging in tubing and electrical connectors. After connections are made, install hose clamp and umbilical

cover.

1.

Plug in 9 pin power connector and tubing connector. (See fig. 7)

Be Careful not to cut or damage any of the tubes and wires inside the umbilical tube.

9 Pin Power connector

Black, yellow, red wires on top

Tubing Connector:

Move lever clockwise to install or

remove; Move counter

clockwise to lock

Fig 7

2.

Plug suction hose onto copper tube. Run USB cord through hole and make appropriate

connections. (See fig. 8)

USB Port

120 V Outlet

Fig. 8

7

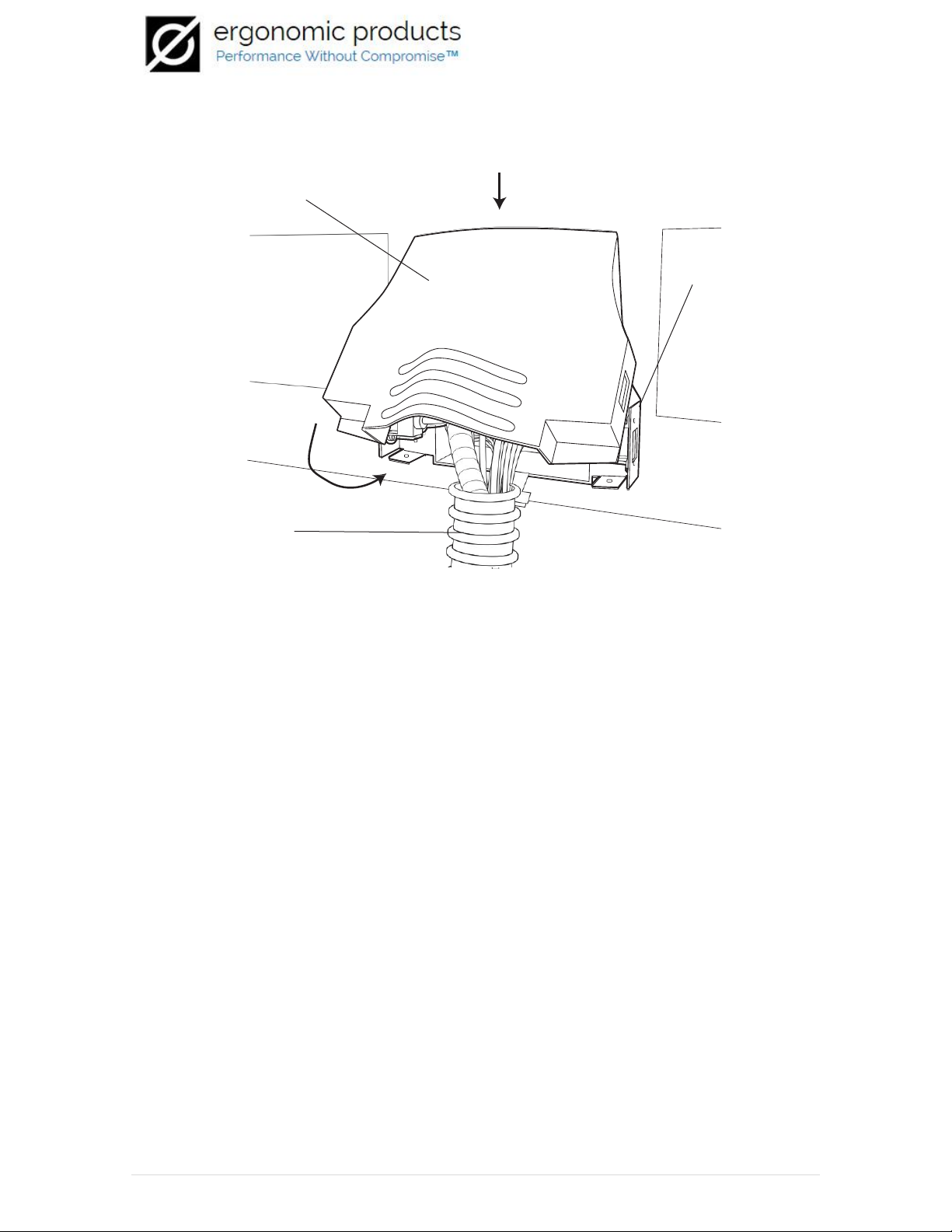

3.

Securely attach umbilical hose to chassis with hose clamp. Hook cover on tab at

top and fasten with the 2 screws on bottom corners. (See fig. 9)

Umbilical Cover

Umbilical chassis

Umbilical

hose

Fig. 9

8

Section 4 - USB Keyboard connection

Your Ergonomic Products Workstation supports USB (Universal Serial Bus) for connections to a Mac or PC computer

keyboard (not supplied). The following section describes the connection process.

1.

Remove both Keyboard Slide Bracket Screws with a 1/8” Allen wrench (supplied). Locate both

Top Tier Set Screws and loosen with the supplied 5/32” Allen wrench (supplied) until Top Tier can

be lifted away from posts. (Fig. 10)

Top tier set screw (detail)

Keyboard

slide bracket

screws

(2)

Top tier set screws (2)

Fig. 10

2.

Lifting the Top Tier Worksurface away, run USB cable from a USB Keyboard (not supplied)

down the length of the slotted support shaft and replace the Top Tier Worksurface. Re-tighten

the Top Tier Set Screws and replace the Keyboard Slide Bracket Screws. (Fig. 11)

Top tier work surface

USB cable (from USB keyboard)

Top tier support shaft

w/slot

Fig. 11

9

3.

Under the Lower Worksurface, plug the male end of the USB cable (from Key-

board) into the female USB receptor on the Power Channel® and the keyboard

connection is complete. (Fig. 12)

Lower work surface

Top tier support shaft

Power Channel®

USB Cable

(From USB Keyboard)

Fig. 12

Section 5 - Worksurface height adjustment

Your Ergonomic Products Workstation is height adjustable. To adjust the worksurface height to your personal

preference, read the following section.

To Adjust: Loosen the Height Adjust Set Screw on the Workstation Support Post Coupler

and raise or lower the worksurface (in one inch increments) to the desired height and then

re-tighten the set screw. (Fig. 13)

Workstation

support Post

coupler

Workstation support

Post

Height adjust set screw

Height adjustment detent(s)

Fig. 13

Important: The height adjustment is only complete when the set screw is in contact with a

height adjustment detent.

10

Section 6 - Accessing the Power Channel® Interior

Only a licensed dental service technician should attempt to service your Ergonomic Products Workstation. This

section is to show the proper way to gain access to the interior of the Power Channel® on your workstation.

1. Depress Saliva Trap Canister until it slips under Power Channel® chassis. (Fig. 14)

note: If vac is shut off, removing canister cover allows for more clear

Saliva trap canister

Power channel®

Chassis

Fig. 14

2. Remove Chassis Thumb Screw & water bottle from the rear of the Power Channel® and set

aside. (Fig. 15)

Chassis thumb

screw

Water bottle

Fig. 15

11

3. Slide the Power Channel® Chassis forward until the six (6) alignment tabs are

aligned with the Power Channel® Cover. (Fig. 16)

Power channel®

Cover

Power Channel® Chassis

Alignment tab(s)

Fig. 16

4. When tabs are aligned, the Power Channel® Chassis can be lowered to disengage it

from the Power Channel® Cover. (Fig.17)

Note: Sliding Power Channel® cover upwards facilitates Power Channel® Chassis removal.

Power Channel®

Cover

Power Channel® Chassis

Fig. 17

NOTE: Reverse steps 1-3 to re-install

12

Section 7 - Utility Connections

13

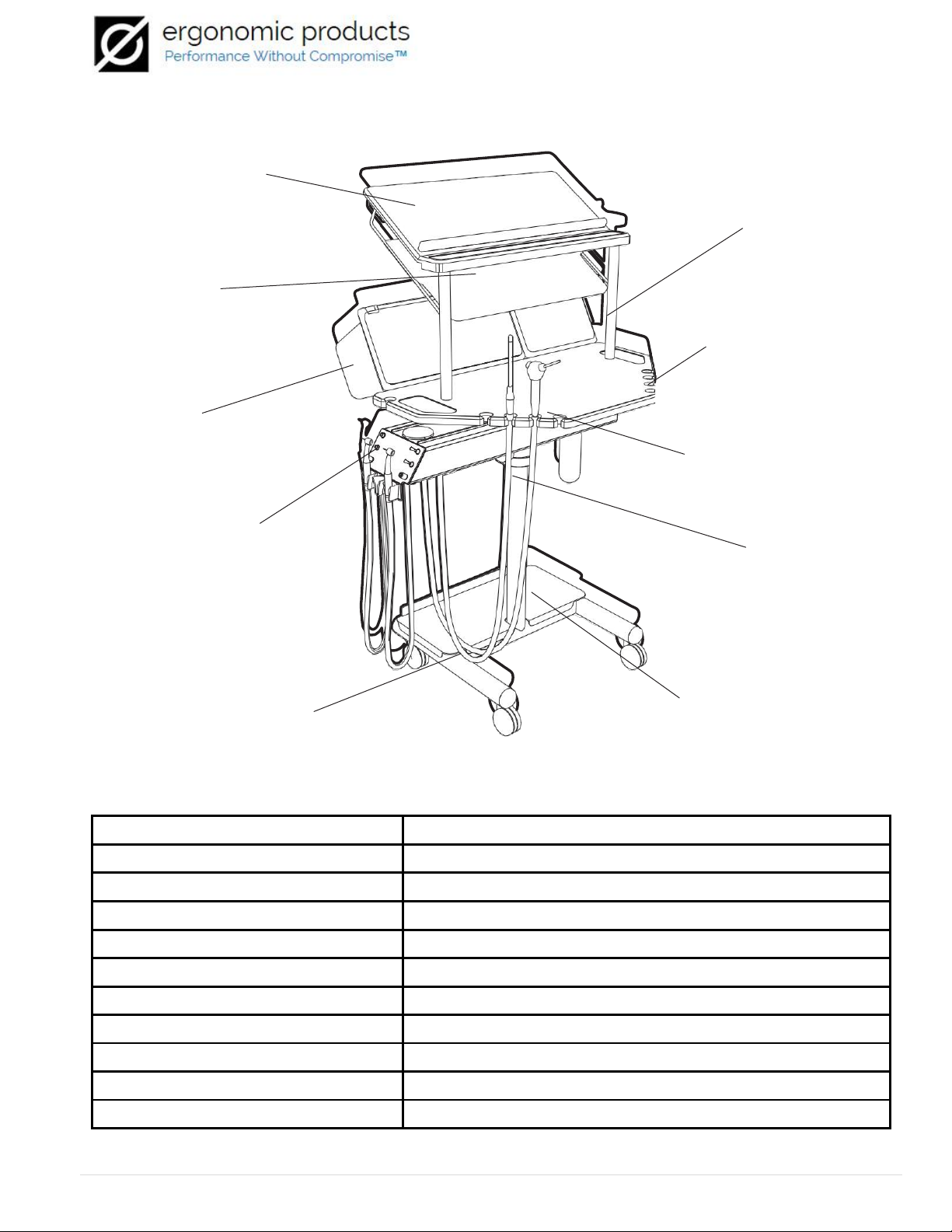

Section 8 - Basic anatomy of an Ergonomic Products Workstation

Top tier

worksurface

Top tier

support post

Keyboard slide

Lower worksurface

Consumable bins

Power channel®

Power channel®

faceplate

Worksurface

support post

H-Frame

Base

Trash shelf

Section 9 - Technical Specifications

Dimensions (Single Tier)

30”w, 25

1/2

”d, 30”h

Dimensions (Two Tier)

30”w, 25

1/2

”d, 48 1/2”h

Weight

88 lbs

Plumbing Requirements (general)

1/2” copper pipe stub for vacuum

Plumbing Requirements (air)

3/8” Compression fitting w/valve

Plumbing Requirements (water)

3/8” Compression fitting w/valve

Electrical Requirements (general)

(1) 120V 15A - GFI outlet (quad)

Cure Light Info (standard)

120V, 0.5A

UltraSonic Info (optional)

120V, 1.5A

Electric Handpieces (optional)

120V,1.25A

Handpiece illumination (Standard)

120V, 0.6A

14

A PROMISE FROM THE EMPLOYEES AT ERGONOMIC PRODUCTS, INC.

At Ergonomic Products, Inc., we understand that placing a dental equipment order, whether it be with a

local distributor, one of the big names in the industry or a specialty firm like ours, can be difficult. We

understand your fears in making such an investment. Whether your order is large or small, we promise

to treat every customer with the same level of complete honesty and courtesy. We know you won’t get

this kind of commitment everywhere you go.

We promise to give you answers to your technical questions as quickly as possible. Our technical people

are working diligently every day to deliver the finest equipment. When a service need does occur, we

will take full responsibility and do everything in our power to correct the problem.

We promise to always truthfully describe our products and the technology they provide you with. We

are sure that our equipment is absolutely the best available. Period. We believe that it will tell its own

story. We will never sell you more than our equipment can deliver. Life is too short for that.

We promise to offer you a significant warranty on our products that we will unequivocally stand behind.

• 10-year limited warranty on all Corian®surfaces*

• 5-year warranty on all RapidCarts®**

•

• 3-year warranty on all Workstations®

• 1-year warranty on all storage tubs and bins

• 3rd party components carry the original manufacturer’s warranty:

o 1-year warranty on scalers

o 1-year warranty on curing lights

o

o 1-year warranty on BienAir Electric Motors

* Limited to manufacturer’s defects only

** Excludes powder coated RapidCarts®tops (1 year warranty)

**** Excludes bulbs

We promise to offer you prompt, inexpensive repairs. Products under warranty will, of course, be fixed

as quickly as possible and service will be done on site if feasible. If it must be returned to our technical

center, it will be returned to you without additional shipping charges. If the time needed to repair it will

affect your practice schedule, we will try to provide a loaner so as to not interrupt your service to your

patients. In an emergency, our Doctor Delivery Power Channels® will ship overnight. The entire new

unit can be placed in service in 45 minutes or less. No one else in the industry can come close to this

level of response. Further, if a warranty does not apply, we will quickly repair your product and promise

that our repair costs are very modest.

Should your office damage equipment, due to improper use or inadequate installation or maintenance,

we’ll still make sure to fix your problem, promptly and without complaint.

We promise to continuously satisfy you with our products and services. We think of our customers as

friends. We want to hear from you and help you improve your practice.

Sincerely,

The Staff at Ergonomic Products, Inc. 1-866-ERGO-4-US

Table of contents