Erie water treatment SOF-WHF series User manual

© 2017erie watertreatment TM-EN-SOF-WHF-Rev2017.01

Technical Manual

WHOLEHOUSE WATER FILTER

Models:

SOF-WHF-

TABLE OF CONTENT

Page 2

Table ofcontent...................................................................................................................Page 2

Warning & Safety instructions..............................................................................................Page 3

Operating conditions & Requirements.................................................................................Page 4

Installation...........................................................................................................................Page 5

Commissioning.....................................................................................................................Page 6

Electronic control panel.......................................................................................................Page 7

Maintenance........................................................................................................................Page 10

Troubleshooting...................................................................................................................Page 12

Electrical wiring diagram......................................................................................................Page 13

Default configuration parameter settings.............................................................................Page 14

Exploded view - System........................................................................................................Page 15

Exploded view - Timer assembly ..........................................................................................Page 17

Exploded view - Valve body..................................................................................................Page 19

Technical data......................................................................................................................Page 21

WARNING & SAFETY INSTRUCTIONS

Page 3

Before you begin the installation of the appliance, we advise you read

andcarefully follow the instructions contained in this manual. It contains

importantinformationaboutsafety,installation,useandmaintenance of

the product. The actual system that you have received, may differ from

the pictures/illustrations/descriptions in this Technical Manual.

Failure to follow the instructions could cause personal injury or damage

to the appliance or property. Only when installed, commissioned and

servicedcorrectly,theappliancewillofferyoumanyyearsoftrouble-free

operation.

The appliance is intended to 'filter' the water, meaning it will remove

specific undesired substances; it will not necessarily remove other

contaminants present in thewater. Theappliance willnot purify polluted

water or make it safe to drink!

Installation of the appliance should only be undertaken by a competent

person, aware of the local codes in force. All plumbing and electrical

connections must be done in accordance with local codes.

Before setting up the appliance, make sure to check it for any externally

visible damage; do not install or use when damaged.

Use a hand truck to transport the appliance. To prevent accident or

injury, do not hoist the appliance over your shoulder. Do not lay the

appliance on its side.

Keep this Technical Manual in a safe place and ensure that new usersare

familiar with the content.

The appliance is designed and manufactured in accordance with current

safety requirements and regulations. Incorrect repairs can result in

unforeseen danger for the user, for which the manufacturer cannot be

held responsible. Therefore repairs should only be undertaken by a

competent technician, familiar and trained for this product.

In respect of the environment, the appliance should be disposed of in

accordance with Waste Electrical and Electronic Equipment

requirements.Refertonational/locallawsandcodesforcorrectrecycling

of this appliance.

OPERATING CONDITIONS & REQUIREMENTS

Page 4

OPERATING PRESSURE MIN-MAX: 2,0-8,3 bar / 29-120 psi

check water pressure regularly; it may fluctuate severely

depending on the time of day, the day of the week oreven the

season of the year.

take into account that night time water pressure may be

considerably higher than day time water pressure.

install a pressure reducer ahead of the appliance if necessary.

install a pressure booster, if it is likely that water pressure may

drop below the minimum.

OPERATING TEMPERATURE MIN-MAX: 2-48 °C / 36-120 °F

do not install the appliance in an environment where high

ambient temperatures (e.g. unvented boiler house) or freezing

temperatures can occur.

the appliance cannot be exposed to outdoor elements, such as

direct sunlight or atmospheric precipitation.

do not install the appliance too close to awater heater; keep at

least 3 m (10 ft) of piping between the outlet of the appliance

andtheinletofthewaterheater;water heaterscansometimes

transmit heat back down the cold pipe into the appliance;

always install a check valve at the outlet of the appliance.

ELECTRICAL CONNECTION:

the appliance only works on 24 VAC; always use it in

combination with the supplied transformer.

makesuretoplugthe transformer intoa poweroutlet,whichis

installed in a dry location, with the proper rating and over-

current protection.

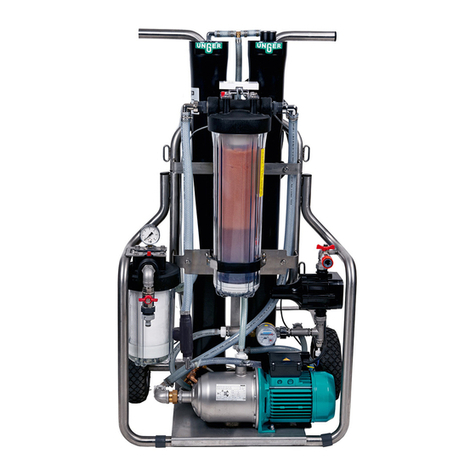

INSTALLATION

Page 5

INLET & OUTLET

We strongly recommend the use of flexible hoses to

connect the appliance to the water distribution system; use

hoses with a large diameter in order to limit the pressure

loss.

If the appliance is not equipped with the factory bypass

(optional), we strongly recommend to install a 3-valve

bypasssystem(notincludedwiththisproduct!)toisolatethe

appliance from the water distribution system in case of

repairs.Itallowstoturnoffthewatertotheappliance,while

maintaining (untreated) water supply to theuser.

WITH FACTORY BYPASS (optional)

Picture 1

= mains water supply (untreated water)

= inlet of appliance (untreated water)

= outlet of appliance (treated water)

= house/application (treated water)

1. Screw the factory bypass onto the in/out ports on the

control valve (&); make sure to install the gasket

seals. Tighten the nuts firmly by hand.

2. Screw the connection kit with nuts onto the factory

bypass (&); make sure to install the gasket seals.

Tighten the nuts firmly by hand.

3. Connect the mains water supply to the adaptor on the

inlet port of the factory bypass ().

4. Connect the house/application to the adaptor on the

outlet port of thefactory bypass ().

WITH 3-VALVE BYPASS SYSTEM (notincluded)

Picture 2

= inlet of appliance (untreated water)

= outlet of appliance (treated water)

1. Install the 3-valve bypass system.

2. Screw the connection kit with nuts onto the in/out ports

on the control valve (&); make sure to install the

gasket seals. Tighten the nuts firmly by hand.

3. Connectthe3-valvebypasssystemtotheadaptorsonthe

in () and out () port of the control valve.

4. Connectthemainswatersupplytotheinletofthe3-valve

bypass system.

5. Connectthehouse/applicationtotheoutletofthe3-valve

bypass system.

DRAIN

We recommend the use of a stand pipe with P-trap.

To prevent backflow from the sewerage system into the

appliance,always install and use the included drainadaptor

withairgapanddoublehosebarb,toconnectthedrainhose

to the sewerage system.

Lay-out the drain hose in such a way that pressure loss

is minimized; avoid kinks and unnecessary elevations.

Make sure that the sewerage system is suitable for the

rinse water flow rateof the appliance.

Picture 3

1. Install the drain adaptor to the sewerage system; it fits

overa32mmpipeorinsidea40mmpipeadaptor.Ensure

a permanent and watertight connection.

2. Connect a 13 mm hose to the drain connection of the

control valve (); secure it by means of a clamp.

3. Run the drain hose to the drain adaptor and connect it to

one ofthe hosebarbs;secure itby means of aclamp.This

drain line operates under pressure, so it may be installed

higher than the appliance.

COMMISSIONING

Page 6

ELECTRICAL

Picture 4

1. Plug the transformers output lead into the socket on the

control valves power cord; secure it by means of the

TwistLock clamp.

2. Plug the transformer into an electrical outlet.

PRESSURIZING

1. Make sure the bypass system is in 'bypass' position.

2. Make sure the electronic controller of the appliance is in

service mode.

3. Open the mains water supply.

4. Open a cold treated water faucet nearby the appliance

and let the water run for a few minutes until all air is

purged and all foreign material that may have resulted

from the installation is washed out; close the tap.

5. Gently pressurizethe appliance, by putting it intoservice:

factorybypass:

1. open the 'outlet' valve;

2. slowly open the 'inlet' valve.

3-valvebypass:

1. close the 'bypass' valve;

2. open the 'outlet' valve;

3. slowly open the 'inlet' valve.

6. After 2-3 minutes, open a cold treated water faucet

nearby the appliance and let the water run until all air is

purged from the installation and the filter media is

properly rinsed (it is normal for the rinse water to show

some discoloration!); let the water run until the rinse

water is clear; close the tap.

7. Check the appliance and all hydraulic connections for

leaks.

ELECTRONIC CONTROL PANEL

1. Program the electronic controller.

PERFORM REGENERATION

1. Manuallyinitiate a regeneration, bypressing the scroll

button; the display will show:

2. Leavethe appliance inthis position; the countdown timer

will countdown to 0 sec and start a regeneration.

Regen in 10 sec

ELECTRONIC CONTROL PANEL

Page 7

Picture 5

POWER-UP

After power-up the display will show the installed software

version for a period of 5 seconds.

POWER FAILURE

In the event of a power failure, the program will remain

stored in the NOVRAM®duringan undefined period, while an

incorporated SuperCap will maintain the correct time of day

during a period of several hours; consequently, in case of

prolonged power failure, the time of day might not be

maintained; if this happens, the time of day will be reset to

8:00 when the power supply is re-established, while the

indication will flash, indicating that the time of day needs to

be set.

When the power failure occurs during the execution of an

automatic regeneration, the control valve will remain in its

last position; when the power supply is re-established, the

control valve will return to the service position, stay there for

60 sec. and restart a complete regeneration from the

beginning.

TIMER FAILURE

In the event of a timer failure, the display will show the

message:

If powering off/on the appliance doesn’t solve this problem,

professional service is required.

MAINTENANCE REMINDER

Onlyavailableifthe maintenance reminder functionhas

been activated and programmed by your supplier!

Once the maintenance interval is reached, the display will

intermittently show the message:

While the appliance will continue to operate normally, it is

recommended to have preventive maintenance performed

by a professional.

SERVICE MODE

In service mode the display shows the time of day and the

number of days remaining until the next regeneration:

REGENERATION MODE

In regeneration mode the display shows the remaining

regeneration time and the remaining cycle time:

The appliance can be reset to service mode at any time by

pressing the scroll button, as such manually advancing it

through the regeneration cycles.

MANUAL REGENERATION

It is possible to manually initiate an immediate regeneration

or a delayed regeneration (at the preprogrammed time of

regeneration).

1. Press the scroll button; the display will show:

If the control panel is left in this position, the

countdowntimerwillcountdownto0secandstartan

immediate regeneration.

To cancel this mode, press the scrollbuttonbefore

the countdown timer has reached 0 sec; the display

will show:

If the control panel is left in this position, a delayed

regeneration will be started at the indicated

preprogrammed time of regeneration.

To cancel this mode, press the scroll button; the

control panel will return to the service mode.

HOLIDAY MODE

It is possible to put the appliance in holiday mode; this will

prevent automatic regeneration from taking place, yet will

ensure the appliance is automatically regenerated atthe end

of the holiday cycle.

1. Press the scroll button repeatedly until the display

shows:

Press the up or down button to activate the

holiday mode bysetting the number of full days away

fromhome,ordeactivatethe holiday mode (OFF).

Once the control panel is back in service mode, the display

will show:

The holiday mode is automatically cancelled when a

regeneration is manually initiated!

symbol

button

function

SCROLL

to advance to the next

parameter

UP

to increase the value of the

parameter

DOWN

to decrease the value of the

parameter

Service Required

Rgn:XXX CycY:ZZZ

8:01 7 DAY REM

Maintenance Now

Regen in 10 sec

Regen @ 2:00

Holiday: OFF

8:01 Holiday

ELECTRONIC CONTROL PANEL

Page 8

PROGRAMMING INSTRUCTIONS -

BASIC SETTINGS

Beforeenteringthe programming mode, makesurethat

the appliance is in the service mode.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode;

any changes made willNOT be saved!

1. Press the scroll button and hold it for 2 sec until the

displayshows:

Press the up or down button to set the

language.

2. Press the scroll button again; the display will show:

Press the up or down button to set the time of

day.

3. Press the scroll button again; the display will show:

Press the up or down button to set thenumber

of days between regenerations.

4. Press the scroll button again; the display will show:

Presstheupordownbuttontosavethesettings

into the NOVRAM® and exit the programming mode.

The regeneration cycle is necessary to wash out

impurities that are captured in the filter media during the

service cycle, and to prevent ‘caking’ of the filter media,

which may result in an increase of pressure drop over the

appliance. Typically a regeneration every 7 days should be

sufficient. In case of high flow rates, excessive water usage

or ahigh concentration of impurities in the incoming water,

it may be necessary to lower the number of days between

regenerations.

PROGRAMMING INSTRUCTIONS -

CONFIGURATION PARAMETERS

Beforeenteringthe programming mode, makesurethat

the appliance is in service mode.

All configuration parameters on this appliance have

been pre-programmed in the factory, to offer optimal

performance in a wide range of applications and situations.

Neverthelessitmaybenecessaryordesirable tochangeany

of these parameters, to further optimize the appliances

performance or to adapt it to the specific requirements of

the installation.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode;

any changes made willNOT be saved!

1. Press the scroll button and hold it for 6 sec until the

displayshows:

2. Within 10 sec, press the up button; the display will

show:

Press the up or down button to set the units of

measure(Metric or US).

3. Press the scroll button again; the display will show:

Press the up or down button to activate the

maintenance reminder function by setting the

maintenance interval, or deactivate the maintenance

reminderfunction.

4. Press the scroll button again; the display will show:

Press the up or down button to set the length

of the regeneration cycle.

Pressthescrollbuttonagaintoadvancetothenext

regeneration cycle.

Cycle 1

Backwash

Cycle 2

N

ofunction

Cycle 3

Fast rinse

5. Press the scroll button again; the display will show:

Press the up or down button to set the time of

regeneration.

6. Press the scroll button again; the display will show:

Presstheupordownbuttontosavethesettings

into the NOVRAM® and exit the programming mode.

Regen @ 0:00

Exit

Language:English

Set time: 8:01

Interval:7 Days

Exit

Cycle 1: XX min

System Check

MaintInt: OFF

Units:Metric

ELECTRONIC CONTROL PANEL

Page 9

DIAGNOSTICS MODE

In the Diagnostics mode several operating parameters

can be consulted; particularly during a service intervention,

these parameters can be helpful to identify the cause of a

problemor malfunction.

Before entering the Diagnostics mode, make sure that

the appliance is in service mode.

In case no button is pressed in a period of 5 min, the

control panel will automatically return to the service mode!

Accessing the Diagnostics mode

1. Press the scroll button and hold it for 6 sec until the

displayshows:

2. Within 10 sec, press the down button; the display will

show:

You are now in the Diagnostics mode.

Press the scroll button to advance to the next

diagnostics parameter.

Available diagnostics parameters

Regen X days ago: number of days since last

regeneration.

In Srvc: total number of days in service.

# of Regens: numberof regenerations since installation.

Regen @: setting of time of regeneration.

Interval: setting of number of days between

regenerations.

Cycle X: setting of length of corresponding regeneration

cycle.

Units: control is programmed for Metric units.

Regen: setting of the regeneration mode.

Valve Type: setting of valve type.

MP Resets: number of resets of microprocessor (for

factorypurposeonly).

Memory Reset: number of corrupt memory start-ups (for

factorypurposeonly).

EZRFTg EZDRV r02:software version.

Exiting the Diagnostics mode

1. Press the scroll button repeatedly until the display

shows:

Press the up or down button to exit the

Diagnostics mode.

Exit

Regen XXdays ago

System Check

MAINTENANCE

Page 10

RECOMMENDATION

Notwithstanding the reliability of the appliance, we strongly

recommend to have it serviced and maintained on a regular

basis by a competent and duly trained technician. He will be

able to determine the appropriate maintenance interval for

the appliance, depending on yourspecificapplication and the

local operating conditions. The advantages of performing

regularmaintenance are:

regular check of the local operating conditions (water

quality, pressure, etc);

regular control and adjustment of the settings of the

appliance, to guarantee it operates at maximum

efficiency;

minimize the risk of unexpected break-down.

Contact your dealer or installer for more information, or visit

our website.

ROUTINE CHECKS

Regularlytheusershouldperformabasicchecktoverifyifthe

appliance is functioning correctly, on the basis of the

following control points:

1. Check settings of electronic control panel.

2. Check water composition before/after appliance.

3. Check drain line from control valve; there shouldn’t be

any water flow(unless appliance is in regeneration).

4. Checkapplianceandsurroundingarea;thereshouldn’tbe

any water leakages.

BYPASSING THE APPLIANCE

Occasionally it may be necessary to put the appliance

hydraulically in bypass, i.e. to isolate it from the water

distribution system; f.e.:

in case of an urgent technical problem;

when it is not necessary to supply treated water to the

house/application (refill swimming pool, irrigation,...).

WITH FACTORY BYPASS (optional)

Picture 6.a

SERVICE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is OPEN

Picture 6.b

BYPASSPOSITION

= inlet valve to appliance is CLOSED

= outlet valve from appliance is CLOSED

Picture 6.c

MAINTENANCE POSITION

= inlet valve to appliance is OPEN

= outlet valve from appliance is CLOSED

WITH 3-VALVE BYPASS SYSTEM (notincluded)

Picture 7.a

SERVICE POSITION

= bypass valve is CLOSED

= inlet valve to appliance is OPEN

= outlet valve from appliance is OPEN

Picture 7.b

BYPASSPOSITION

= bypass valve is OPEN

= inlet valve to appliance is CLOSED

= outlet valve from appliance is CLOSED

Picture 7.c

MAINTENANCE POSITION

= bypass valve is OPEN

= inlet valve to appliance is OPEN

= outlet valve from appliance is CLOSED

SANITIZING THE APPLIANCE

This appliance is manufactured from premium quality

material and assembled insafeconditions toassureit is clean

and sanitary. If installed andserviced correctly, this appliance

willnotinfectorcontaminateyourwatersupply.However,as

in any 'device' plumbed-in in your water distribution system,

a proliferation of bacteria is possible, especially in case of

'stagnant water'. Therefore this appliance will automatically

rinse the filter media periodically.

If the power supply to the appliance is disconnected for a

longer period of time, we recommend, when the power

supply is re-established, to manually initiate a complete

regeneration.

TROUBLESHOOTING

Page 11

PROBLEM

C

AUSE

S

OLUTION

U

ntreated water to

service

Open or defective bypass

C

lose

orreplace

bypass

Appliance

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

Excessive water usage

Initiate regeneration manually

Change in raw water hardness

Verify

composition

of

i

ncoming

untreated

water

and adjust regeneration frequency accordingly

Appliance

fails to

r

egenerat

e

Referto problem“

Appliance

fails to

regenerate

”

Appliance

fails to backwash properly

Refer to problem “

Appliance

fails to

backwash

properly”

V

alve bodyand timer out of synchronisation

Synchronize valve body and timer

Decreasing

filter

capacityof

filter media

Clean or replace filter media

Loss of

filtermedia

Refer to problem “Loss of

filtermedia

”

Leak at risertube

Verify that riser tube is seated correctly and is not

cracked

Low levels of

contaminant in treated

water

Bypass not completely closed

Close bypass

Excessive service flow rate

Lower service flow rate

Increasefiltercapacitybyincreasingvolumeoffilter

media

Leak at risertube

Verify that riser tube is seated correctly and is not

cracked

Appliance

fails to

regenerate

Faulty electrical supply

Verify electrical service (fuse, transformer,...)

Defective PCB

Replace PCB

Defective

drive motor

Replace

drive motor

Regeneration frequency not programmed

Program regeneration frequency

Loss of water pressure

Mineral or iron build

-

up in resin tank

Clean resin bed and control valve; increase

regeneration frequency

Plugged lowerand/or upperdistributor

Verify that distributors are free of debris

Crushed lower and/or upper distributor

Replace distributor(s)

Drain line from control

valve flows

continuously

Appliance

in regeneration

Wait until regeneration finishes or

manually

advance regeneration to end

Faulty electrical supply

Verify electrical service (fuse, transformer,...)

Defective drive motor

Replace drive motor

Defective microswitch

Replace micro switches

Defective PCB

Replace PCB

V

alve bodyand timer out of synchronisation

Synchronize valve body and timer

Loss of

filter media

Lower and/or upper distributor damaged

Replace distributor(s)

Leak between riser tube and upper distributor

Verify that riser tube is seated correctly and is not

cracked

Appliance fails to

backwash properly

Low operating pressure

C

heck operating pressure; must be higher than

2

,

0

bar

Insufficient water supply

Check water supply(flow rate/dynamicpressure)

Restricted drain line

Verify drain linefor kinks or restrictions

Excessiveb

uild

-

up

ofimpurities

in

pressure

tank

Clean

or replace

filter media

and control valve;

increase regeneration frequency

Plugged backwash flow control

Clean

or replace backwash flow control

Plugged top or bottom distributor

Verifythattop and bottom

distributorarecleanand

slots are not clogged by iron or other impurities

Filter media is completely ‘caked’ (solid block)

Replace filter media and reduce regeneration

interval

Control valve cycles

continuously

Defective microswitch

Replace micro

switches

ELECTRICAL WIRING DIAGRAM

Page 12

= position switches

= powerlead

= drive motor

= auxilliary contact (24 VAC, max. 500mA)

= key pad

DEFAULT CONFIGURATION PARAMETER SETTINGS

Page 13

Model SOF-WHF-

Filter media 12 26

44

Units

Metric Metric Metric

MaintInt(mths) OFF OFF OFF

Cycle 1: BACKWASH (min) 5 5 5

Cycle 2: SLOW RINSE (min) 0 0 0

Cycle 3:PURGE (min) 2 2 2

Regen @ 0:00 0:00 0:00

EXPLODED VIEW - SYSTEM

Page 14

EXPLODED VIEW - SYSTEM

Page 15

Item PN Description Remark (*)

1 PT/1018/BA Pressure tank, 10x18 12L

PT/1035/BA Pressure tank, 10x35 26L

PT/1054/BA Pressure tank, 10x54 44L

2 A1100(BB) Coconut Granular Activated Carbon (GAC) multiple of 1 cuft

3 A2000 Quartz sand multiple of 25 kg (=17 ltr)

4 A1000 Gravel multiple of 25 kg (=17 ltr)

5 39004 Dome label ‘erie water treatment’

6 39099 Label ‘Softena’ (mini) 12L

39100 Label ‘Softena’ (midi) 26L

39101 Label ‘Softena’ (maxi) 44L

7 J/1018(W) Tank jacket 10x18, white 12L

J/1035(W) Tank jacket 10x35, white 26L

J/1054(W) Tank jacket 10x54, white 44L

8 38534 Riser tube assembly to be cut to length

9 287/166/LS Top distributor

10 J/10 Tack cover

11 568/303/1 Connection kit 1” BSP male

12 2400TF/JM/AUX/MAX Control valve

13 28/298/11 Transformer 230/24V - 50 Hz, 24VA, EuroT plug

14 38522 Drain hose to be ordered per meter

15 74163 Air gap with double hose barb

16 38521 Clamp, drain hose (2x)

(*) Recommended Spare Part

EXPLODED VIEW - TIMER ASSEMBLY

Page 16

EXPLODED VIEW - TIMER ASSEMBLY

Page 17

(*) Recommended Spare Part

Item PN Description Remark (*)

1 70971 Power lead with plug

2 72263 Clamp

3 28/244/1 Plug (large)

4 71502 Screw, timer cover (3x)

5 15/222 Screw, back plate (2x)

6 70962 Back plate

7 75157 Worm coupling

8 15/222 Screw, drive motor assembly (2x)

9 74267 Cable clamp

10 70312 Strain relief, power lead

11 75158 Retaining ring, worm drive shaft

12 72261 Drive motor

13 75156 Worm driveshaft

14 70965 Switch cam

15 568/386 Bracket, micro switches

16 568/310 Gear, switch cam

17 15/184/7 Locking screw, switch cam

18 15/173/12 Screw, micro switches (2x)

19 72451 Micro switch assy

20 71679 Cable set, drive motor

21 15/102 Screw, PCB (2x)

22 72703 Printed Circuit Board

23 74274 Timer cover assembly ‘Softena’

EXPLODED VIEW - VALVE BODY

Page 18

EXPLODED VIEW - VALVE BODY

Page 19

Item PN Description Remark (*)

1 21/83 Drainconnection

2 568/271/M Backwash flow control M (18,9 ltr/min)

3 72678 Bolt, valve cover (6x)

4 568/254/3 Valve cover

5 185/154/1 O-ring, valve cover

6 186/112 O-ring, Teflon

7 72327 Washer, PE

8 568/260 Worm gear

9 568/259 Rotor cam

10 185/041/1 O-ring, rotor

11 568/345/2 Rotor plate

12 568/256 Seal disk

13 568/383 Insert plate

14 568/384 Gasket

15 51/5/105 Spring, float valve

16 568/270/4 Float valve

17 568/274/5 Injector (green)

18 186/118 O-ring, plug (small)

19 541/273 Plug (small)

20 541/254 Spring clip, plug (small)

21 570/251 Gasket, riser

22 568/334 Riser insert

23 185/214/1 O-ring, riser tube

24 185/337/1 O-ring, tank

25 541/232 Adapter ring

26 15/207/12 Screw, adapter ring (2x)

27 72772 Packing gland nut (plastic)

28 185/211/1 O-ring, packing gland nut

29 186/115 O-ring, worm drive shaft (2x)

30 568/208/2 Worm driveshaft

31 14/43 Washer, worm drive shaft

32 185/208/1 O-ring, plug (large)

33 21/72/3 Plug (large)

34 72800 Valvebody

A RK/568/259/2 Repair kit rotor

B RK/75154 Repair kit packing gland nut

(*) Recommended Spare Part

TECHNICAL DATA

Page 20

Technical specifications:

Model SOF-WHF-

Filter media (cuft) 12 26 44

Operating pressure min/max(bar) 2,0/8,3

Operating temperature min/max (°C) 2/48

Electrical connection (V/Hz) 230/50(1)

Max. power consumption (VA) 12

Hydraulic connection inlet/outlet 1” BSP Male

Hydraulic connection drain 13 mm hose barb

Pressure tank 10x18 10x35 10x54

(1) Supplied with 24V transformer

Performances @ 3 bar operating pressure(2):

Model SOF-WHF-

Filter media (cuft) 12 26 44

Service flow rate @∆p 1 bar (m³/hr)(3) 3,6 3,4 3,2

Recomm. max. service flow (m³/hr) (4) 1,0 1,2 1,4

Rinse water usage per regeneration (ltr) 132 132 132

Backwash flow rate(ltr/min) 19 19 19

(2) Indicative numbers, performances depending on operating conditions and water quality

(3) Based on clean filter bed operation

(4) Flow rate at which filtration process is still executed adequately, higher (up to x2) intermittent flow rates are possible

Dimensions:

Model SOF-WHF-

Filter media (cuft) 12 26 44

Width(mm)(W) 264 264 264

Depth (mm) (D) 282 282 282

Depth,incl. factorybypass(mm)(D) 371 371 371

Height(mm)(H) 629 1.065 1.554

Table of contents

Popular Water Filtration System manuals by other brands

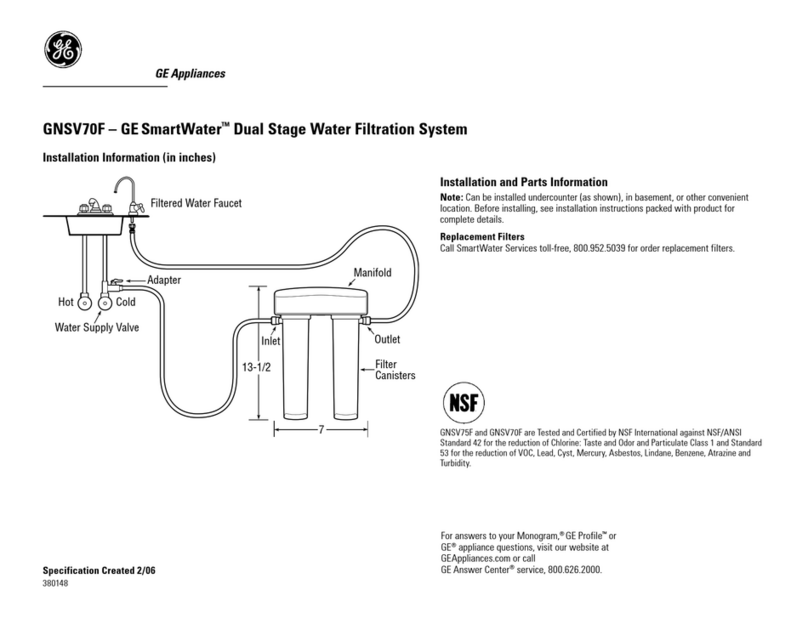

GE

GE SmartWater GNSV70FBL Installation information

Kohler

Kohler KT001-MF installation guide

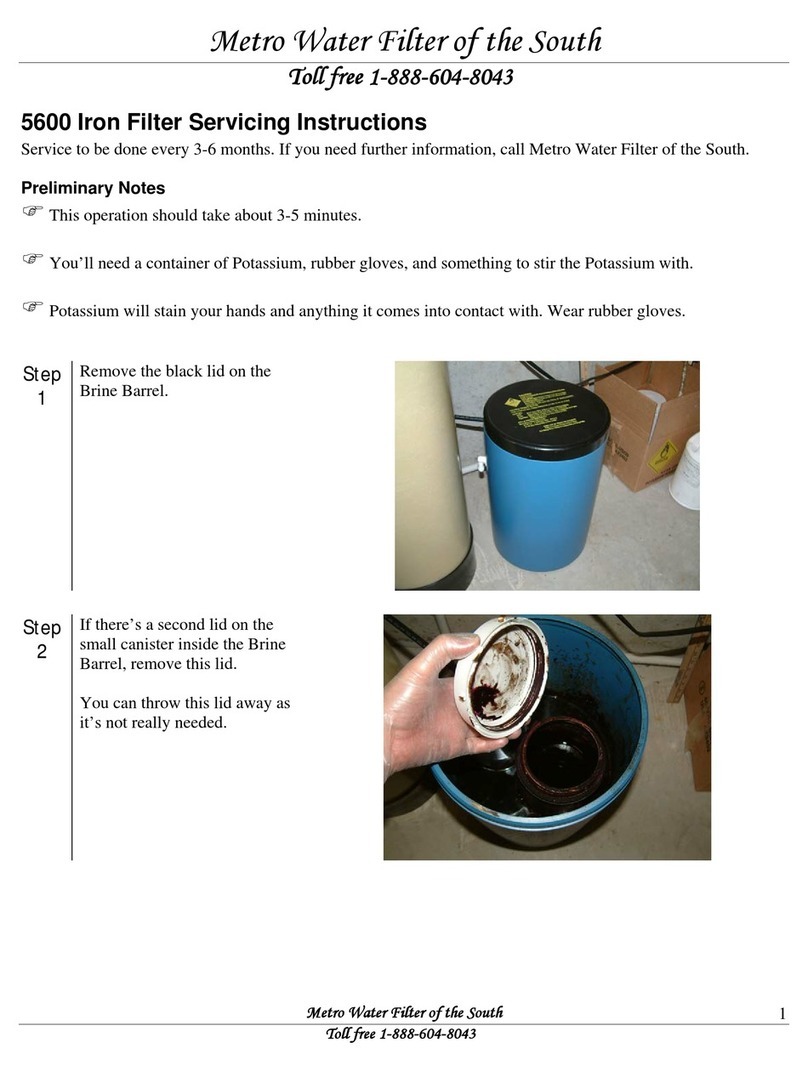

Metro Water Filter of the South

Metro Water Filter of the South 5600 Servicing instructions

Hahn

Hahn HF-RO3-RO Replacement instructions

Judo

Judo SPEEDYMAT-LF Installation and operating instructions

Kinetico

Kinetico Pacifica manual

WaterStep

WaterStep M-100 instruction manual

Watts

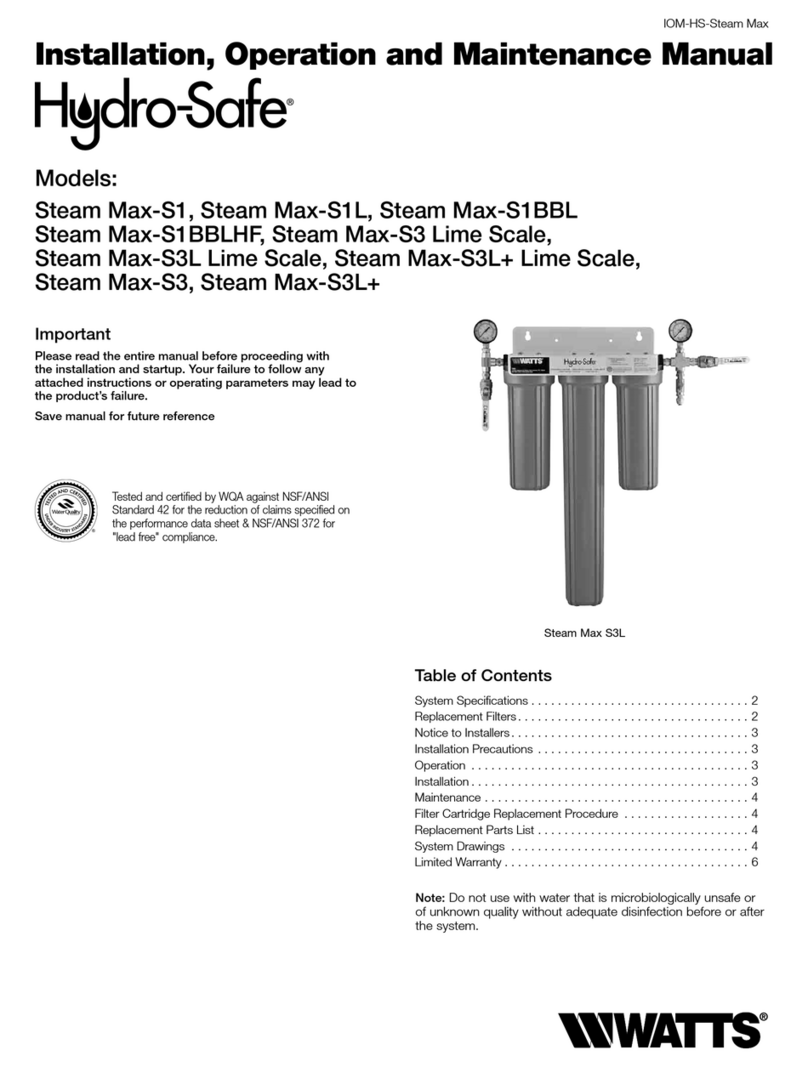

Watts Hydro-Safe Steam Max-S1 Installation, operation and maintenance manual

KENT

KENT Grand Plus Instruction handbook

AquaticLife

AquaticLife 540565 Installation, operation, maintenance guide

EHEIM

EHEIM ecco pro 300 manual

Beckett

Beckett RFPG Specifications