- 2 -

INDEX

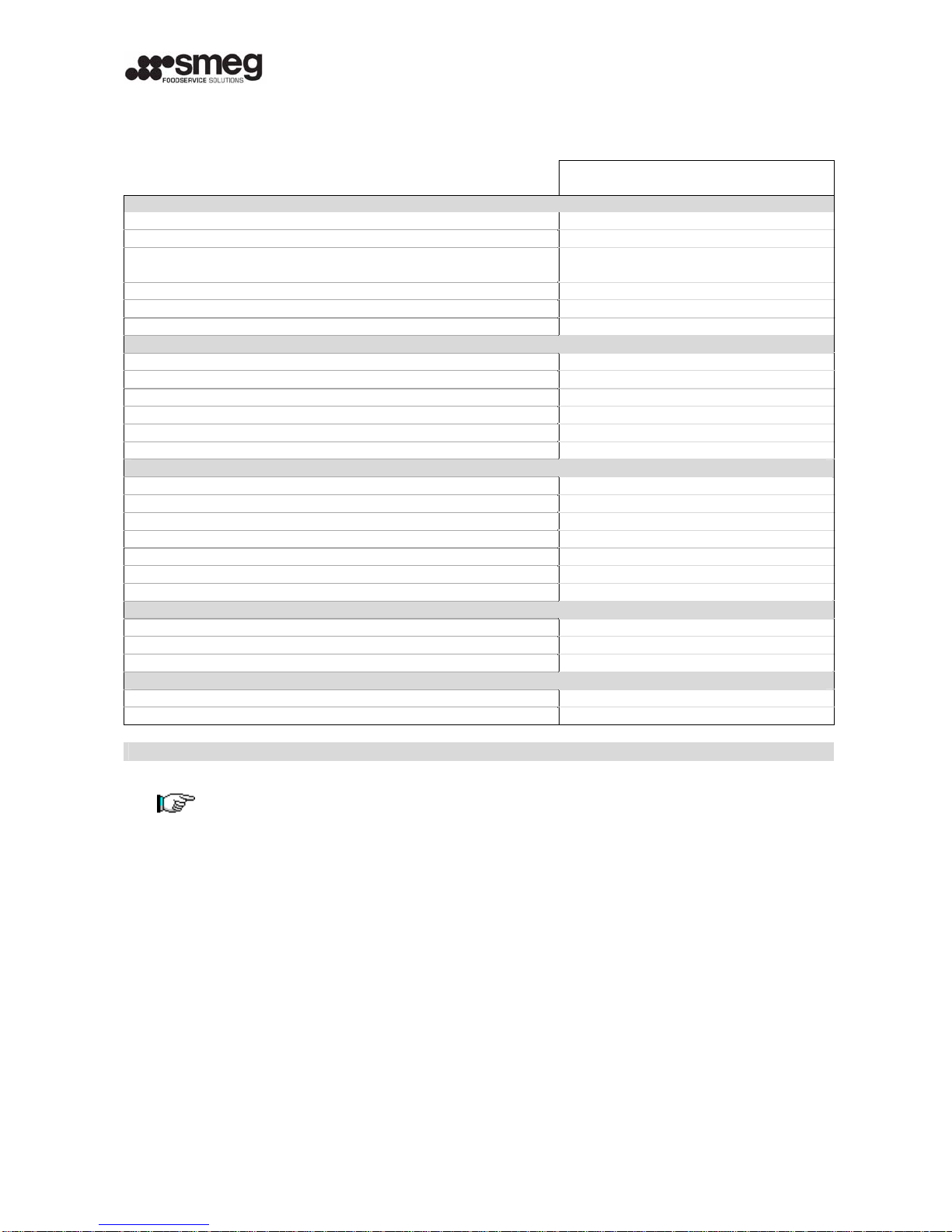

1GENERAL INFORMATIONS ....................................................................................................................................3

1.1MANUFACTURER / ASSISTANCE ............................................................................................... 3

1.2CERTIFICATION .................................................................................................................. 3

1.3AIM AND CONTENTS............................................................................................................. 3

1.4CONSERVATION.................................................................................................................. 3

1.5SYMBOLS USED................................................................................................................... 3

2EQUIPMENT FEATURES.........................................................................................................................................4

2.1USE............................................................................................................................... 4

2.2PARTS THAT MAKE UP THE MACHINE......................................................................................... 4

2.3COMPONENTS.................................................................................................................... 5

2.4DESCRIPTION..................................................................................................................... 5

2.5TECHNICAL SPECIFICATIONS................................................................................................... 7

3INSTALLATION ........................................................................................................................................................8

4FUNCTIONING........................................................................................................................................................10

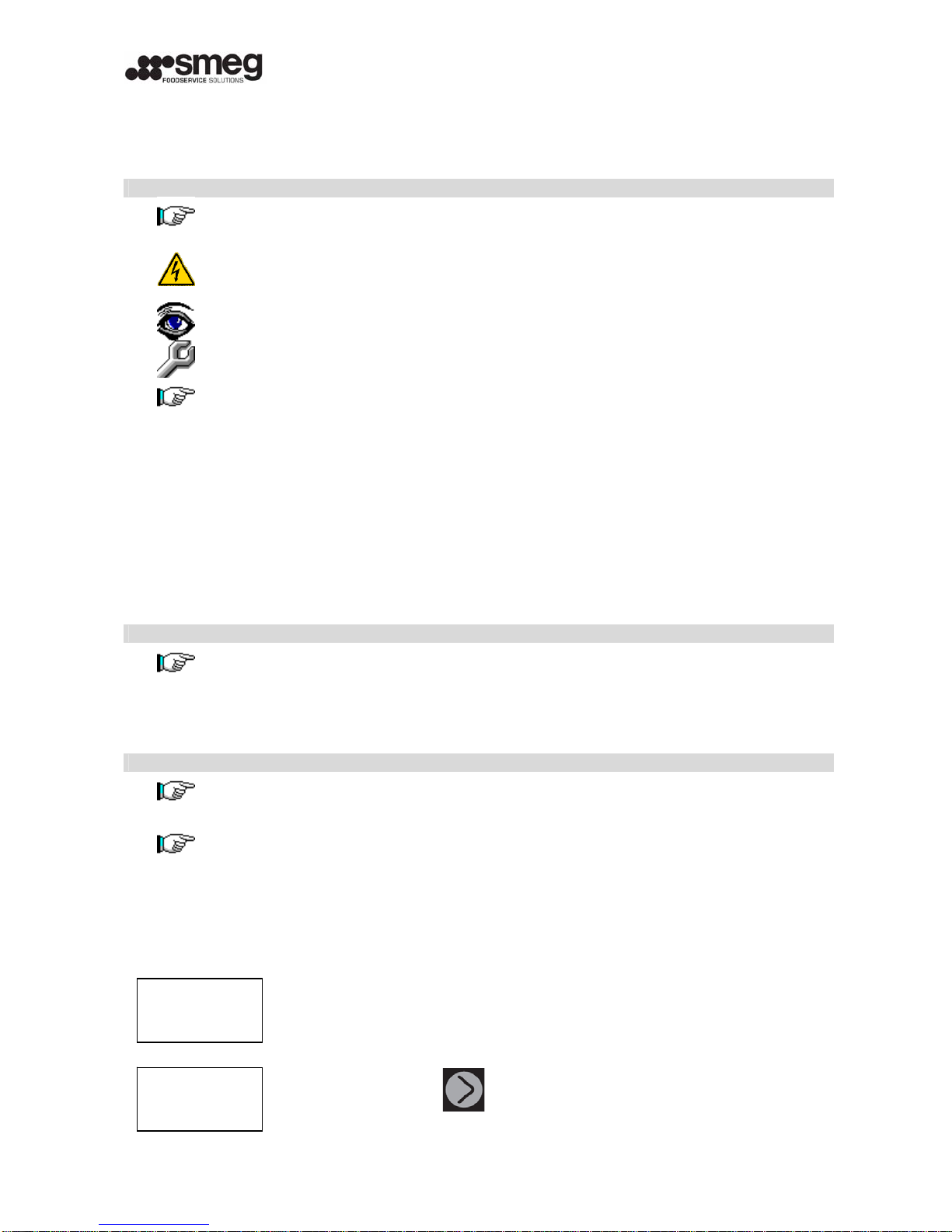

4.1FIRST START UP ................................................................................................................10

4.2NORMAL USE ....................................................................................................................10

4.3INACTIVITY ......................................................................................................................10

4.4ELECTRONIC BOARD OPERATING.............................................................................................10

5ROUTINE MAINTENANCE.....................................................................................................................................13

5.1MAINTENANCE PERSONNEL QUALIFICATIONS ..............................................................................13

5.2MAINTENANCE PERSONNEL TASKS ...........................................................................................13

5.3REPLACING FILTER CARTRIDGE ..............................................................................................14

5.4PRELOAD EXPANSION TANK...................................................................................................14

5.5VERIFICATION OF THE SETTING..............................................................................................15

5.6CLEANING CONDUCTIVITY PROBE CONNECTORS ..........................................................................15

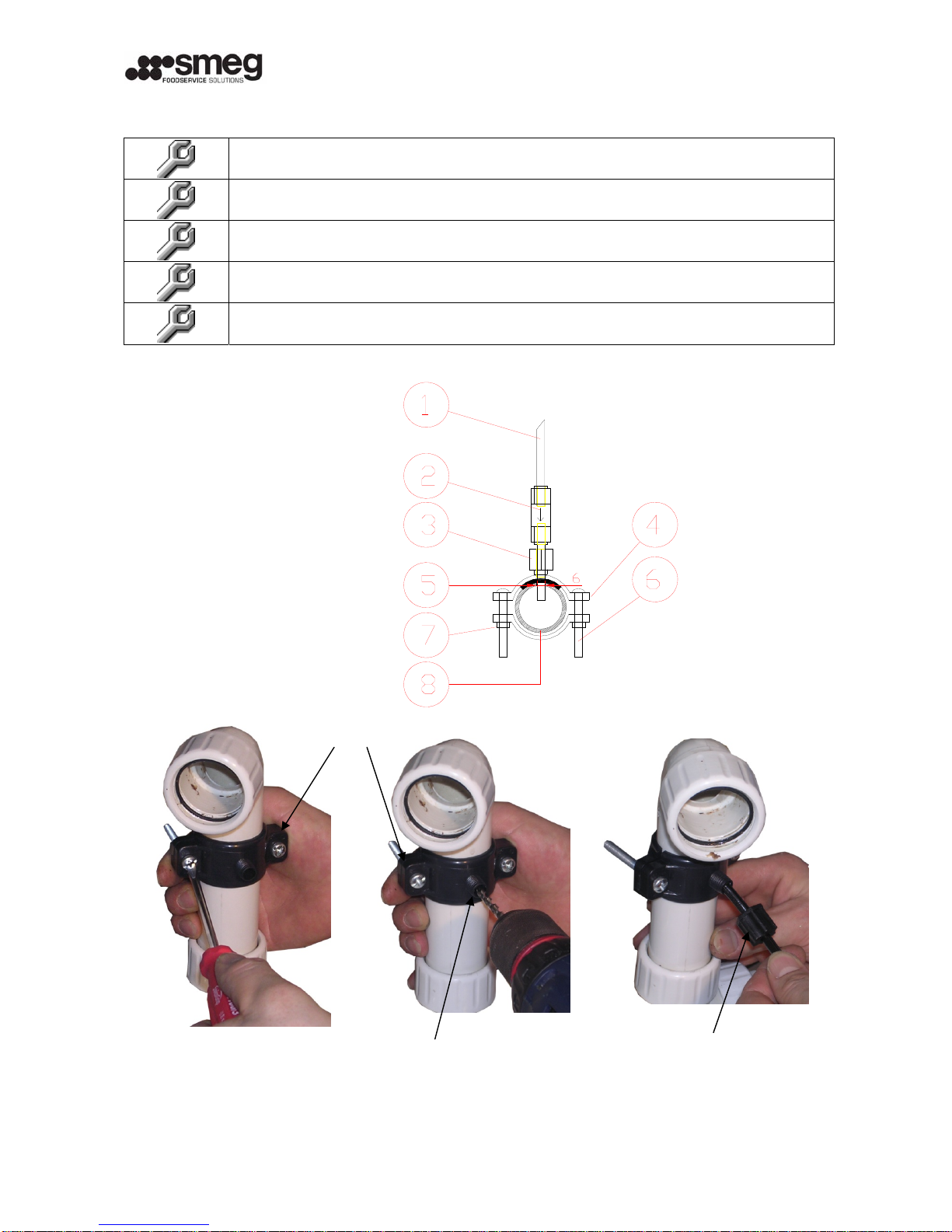

5.7CLEANING SOLENOID VALVES FILTER........................................................................................16

5.8MACHINE SANITATION .........................................................................................................16

6EXTRAORDINARY MAINTENANCE......................................................................................................................17

6.1ELECTRONIC BOARD WHIT DISPLAY REPLACEMENT .......................................................................17

6.2PROTECTION FUSE REPLACEMENT ...........................................................................................17

6.3PUMP REPLACEMENT ..........................................................................................................18

6.4CHECK/REPLACEMENT OF OSMOTIC MEMBRANES .........................................................................19

7TROUBLE-SHOOTING...........................................................................................................................................20