6

Operation & Maintenance (cont.)

IMPORTANT

Both ends of the motor must be adjusted

to the same setting.

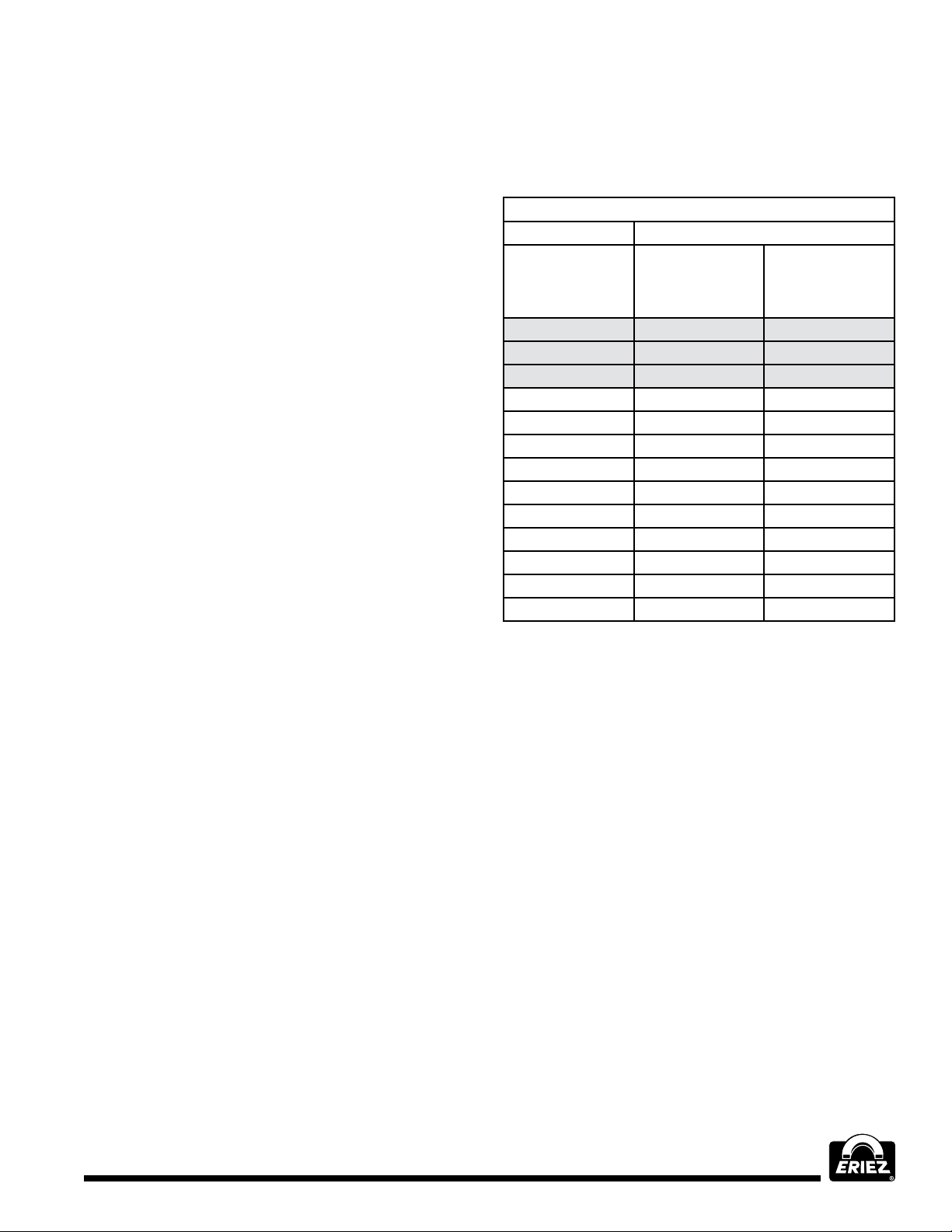

FIGURE 4

Adjustable weights set at 50%.

Fixed weight shaded.

Adjustment of Force Output

To decrease the centrifugal force output, a quick

and easy adjustment can be made to the eccentric

weight position at each of the motors.

1. Disconnect all power to the unit.

2. Remove both end covers, exposing the eccentric

weights. Each end of the shaft has a percentage

calibration from zero to 100%. See photo illustration.

3. Loosen only the outer eccentric weight at each

end of the motor (use a metric wrench). Rotate

the dot (punch mark or similar indicator) to

the desired force output percentage position.

Do the same at both ends of the motor.

4.

Be certain weights have been retightened securely

and replace motor and end covers back to their

proper position.

Motor vibrations are easily adjusted by setting

the indicator on the eccentric weight to the proper

(% of maximum force) output.

For more information on reading tray displacement,

see Eriez' YouTube channel and look for "How to

Read Eriez Vibratory Displacement Stickers."

IMPORTANT

• Never loosen the inside eccentric weights

closest to the motor.

• Never operate the motor vibrator while the

weights at opposite ends are set at different

settings.

• Be certain eccentric weights are retightened

securely.

Adjustment by Adding/Removing Springs

Deflection may also be adjusted by adding or

removing leaf springs.

Adding springs will decrease deflection at the

same speed, and removing springs will increase

deflection at the same shaft speed. Refer to

Repairs-Spring Replacement in this manual

for instruction on placing or adjusting springs.

NOTE: Material build-up on pan may increase pan

deflection and cause tuning spring failure or cracks

in tray and base.

If material build-up on the tray is anticipated,

consult Eriez to discuss an over deflection monitor.

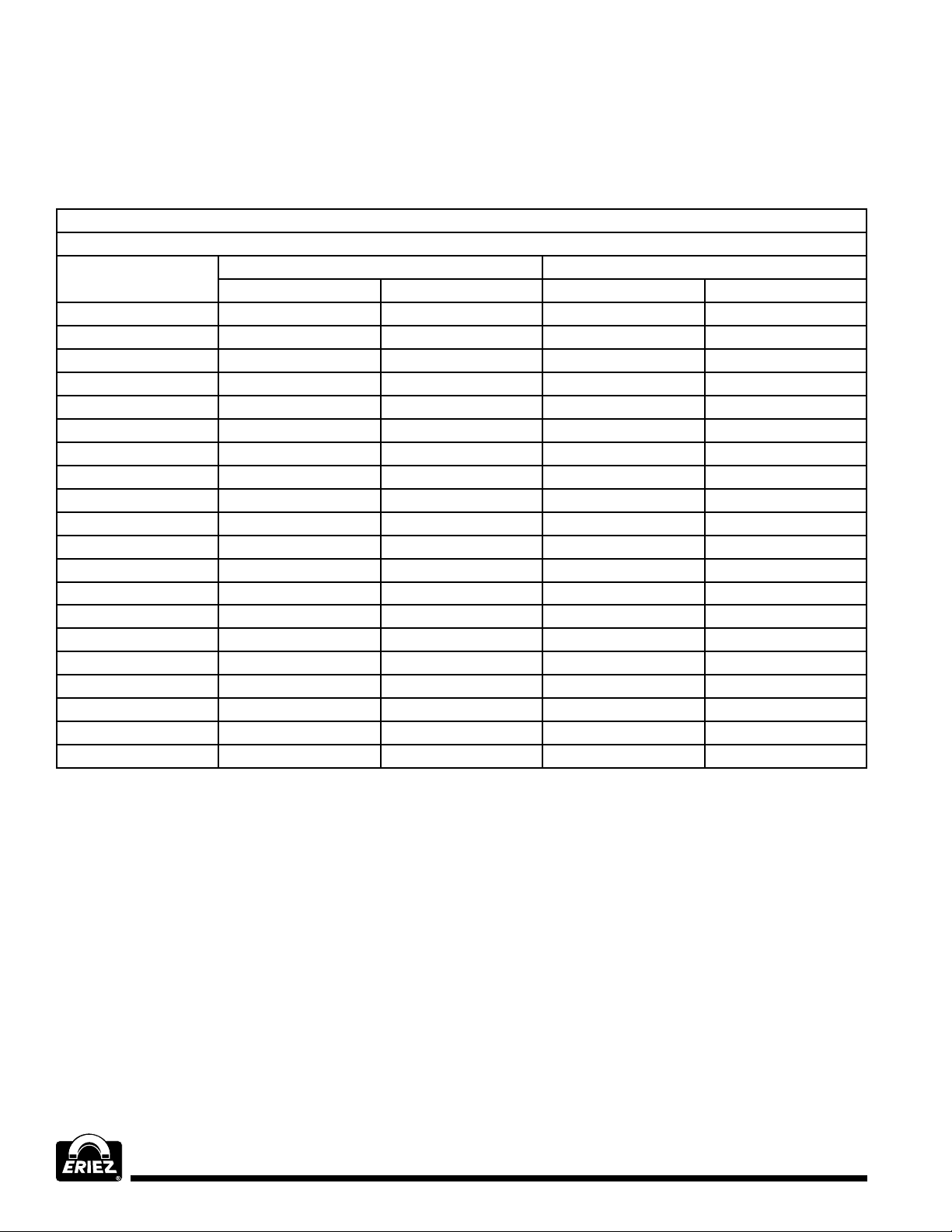

Spring Replacement

Before disassembling springs, note how the clamps,

springs and spacers are arranged. They must be

reassembled in the same order. There must always

be a plastic spacer on both sides of the leaf springs.

Torque spring bolts to 78 ft. lbs. (106 Nm)

CAUTION

Do not operate unit with any associated equipment

in direct contact with any part of the vibratory

unit. Cracks can occur in the tray and base.

FIGURE 5

Typical

spring

arrangement