Installation & Operation Manual

Proven Quality since 1892

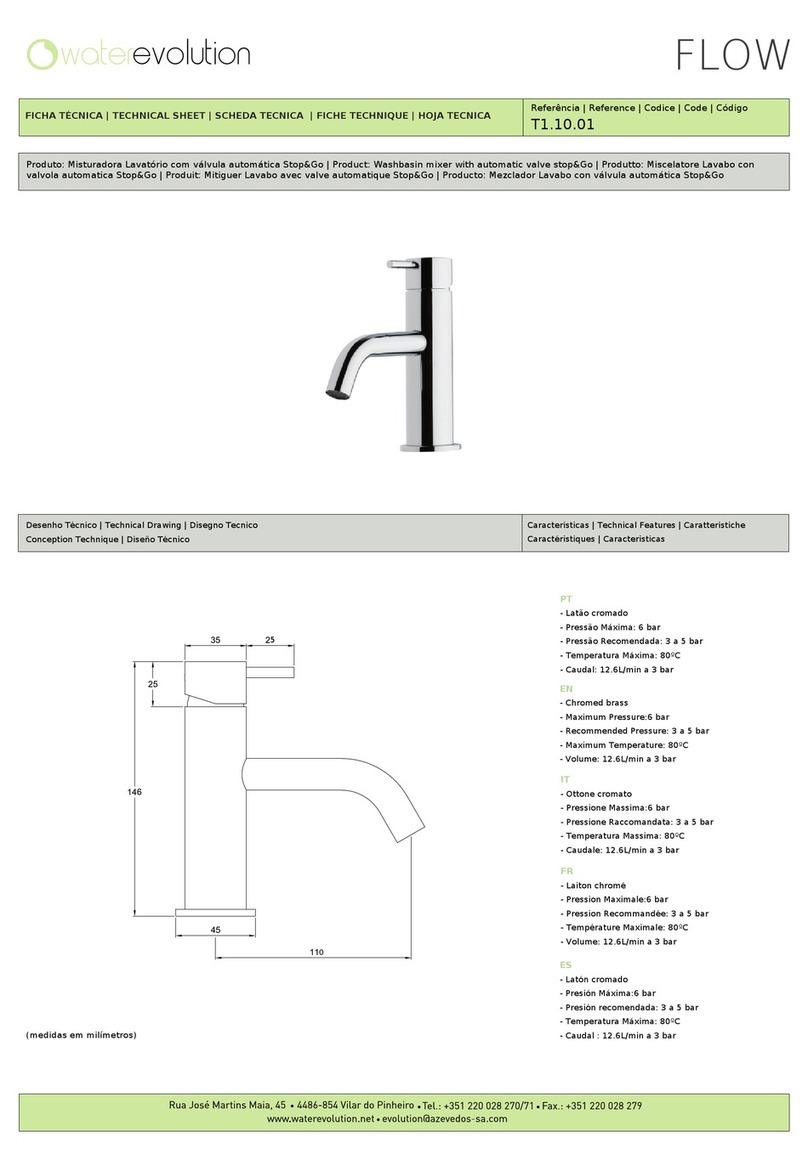

ECON Noise Diffuser fig. 1054X www.eriks.com

Rev. 2

5. Function

ECON Noise Diffusers are designed to decrease the level of noise associated with steam or

compressed air trap cycles. By installing a Noise Diffuser a reduction of about 80% of the noise

can be expected, measured at 1 meter form the application. Also due to its simple and small

design the ECON noise Diffuser is easy to install and uses little space.

6. Application

The ECON Noise Diffuser dampens the sound caused by steam or compressed air trap cycles.

The Noise Diffusers are designed for standard operating conditions. For the use of extreme

conditions e.g. aggressive or abrasive media, it is recommended to mention this at the ordering

stage, to verify whether the Noise Diffuser is suitable. The installation designer is responsible for

the Noise Diffuser selection suitable for the working conditions. The Noise Diffusers are

unsuitable, without written permission of an ERIKS company, to apply for hazardous media as

referred into Regulation (EC) no 1272/2008.

7. Installation

During the assembly of the Noise Diffusers, the following rules should be observed:

- make sure, before assembly, that the Noise Diffusers were not damaged during the

transport or storage, are according request and are suitable for the job.

- before installing the Noise Diffuser remove the plastic covers placed on the connection

ends.

- make sure that the thread on the pipe are from the same standard as the Noise Diffusers

and also free from pollution.

- check materials, pressure and temperature and their maximum values.

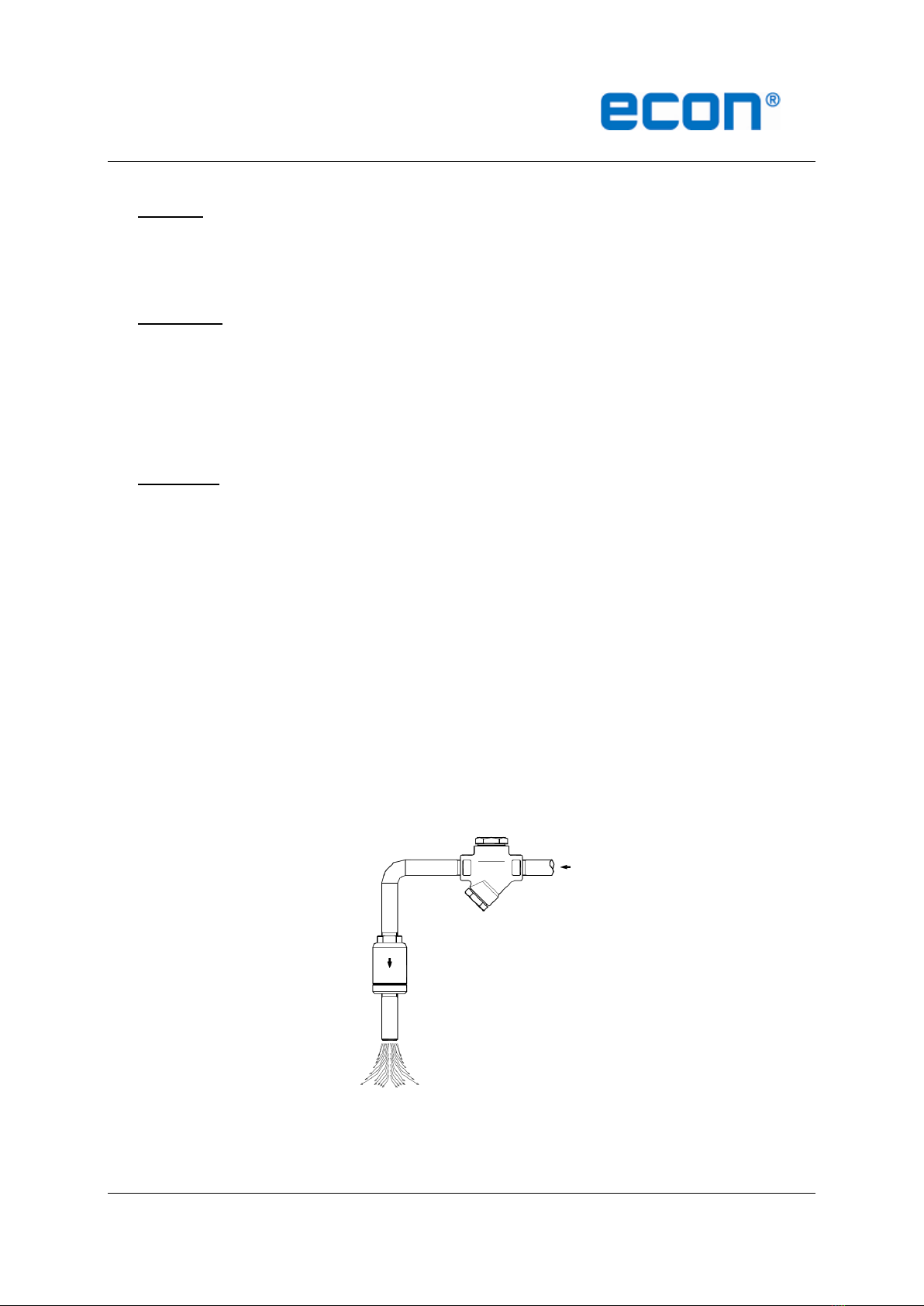

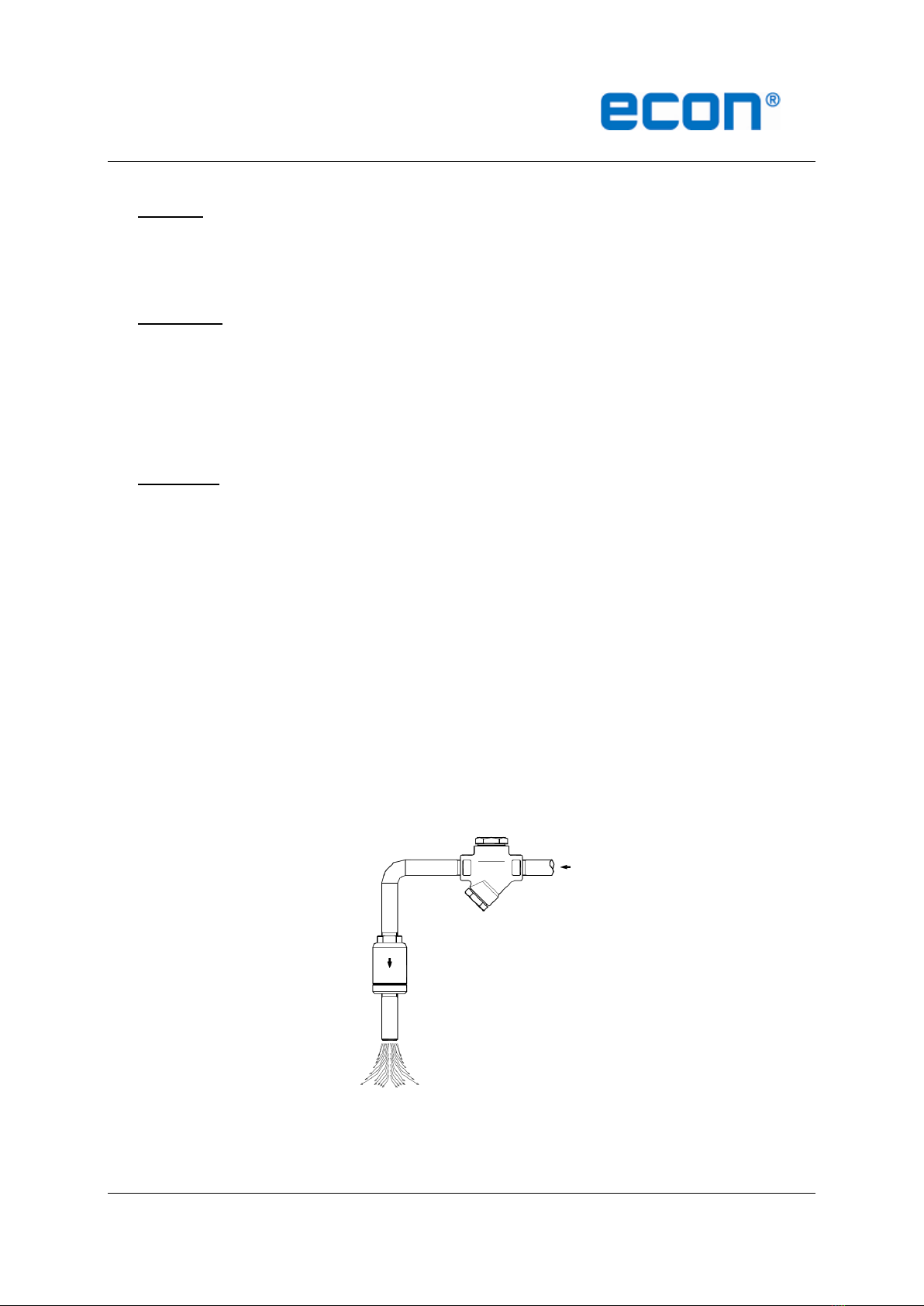

- the equipment has an arrow or inlet/outlet designations. Be sure that the Noise Diffuser is

installed with the arrow pointing in the same direction as the flow. See for an example the

figure below.

- the Noise Diffusers should be fitted in such a way that the outlet is pointed at the floor or

other suitable enclosure. Do not install the Noise Diffuser in such a way that it may cause

an accidental exposure to the discharge.

- the installation area should have easy access and provide enough space for maintenance

and removing operations.

- the installation area should have the necessary fire extinguishing system to prevent

damage to the equipment due to over temperature/pressure cause by fire.