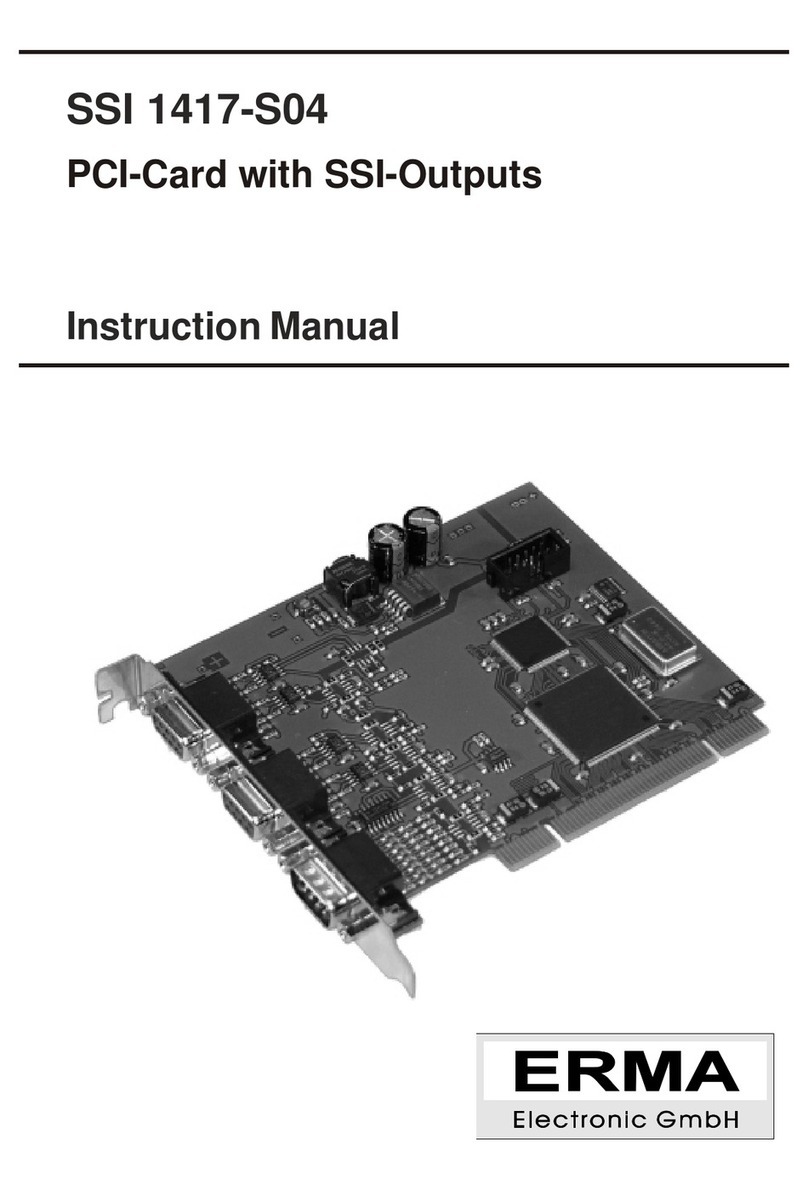

ERMA SSI 1417 User manual

Other ERMA PCI Card manuals

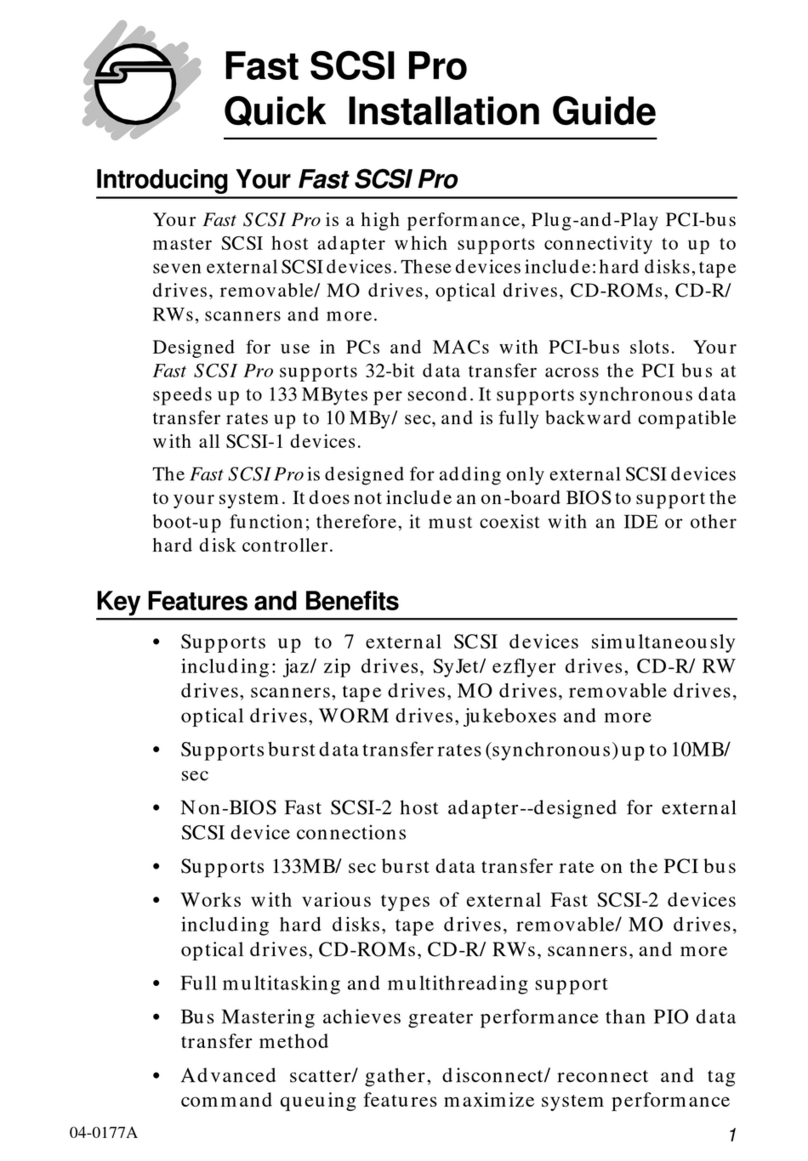

Popular PCI Card manuals by other brands

SIIG

SIIG CyberSerial Dual PCI Software installation

I-Bus

I-Bus IBC2602 user guide

Exsys

Exsys EX-60102 manual

Chelsio Communications

Chelsio Communications T5 Series Installation and user guide

Conrad Electronic

Conrad Electronic 97 46 71 operating instructions

Micro Innovations

Micro Innovations USB650A Quick installation guide

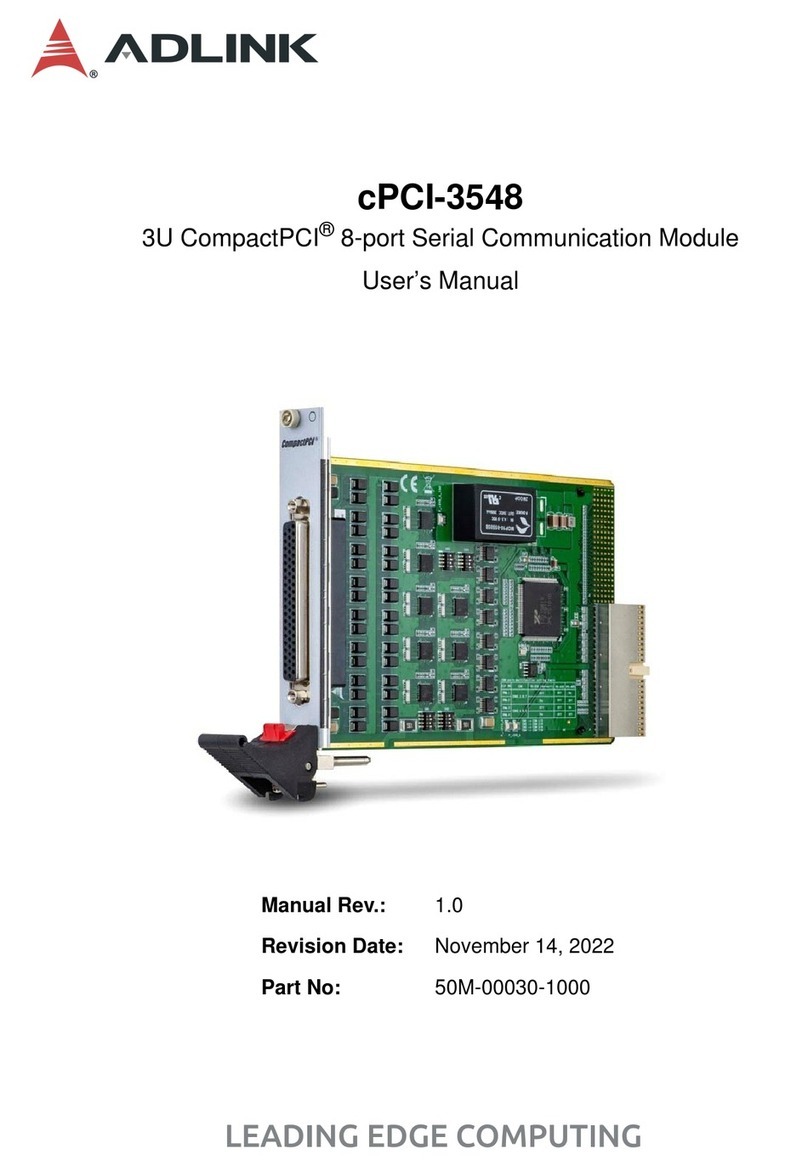

ADLINK Technology

ADLINK Technology cPCI-3548 user manual

Digium

Digium TE200 Series user manual

Allo.com

Allo.com 2nd Gen E1/T1/J1 Quick installation guide

Western Digital

Western Digital FireWire PCI Adapter installation guide

Pyle

Pyle Gamelink PLINK1 user guide

Alpha Networks

Alpha Networks WMP-A13V user manual