ero electronic LFS - R Installation and operating instructions

r

ADDENDUM FOR REAR-OF-BOARD VERSION LFS - R

170.ADD.LFS.RB0 0,8.011-98/B

INDEX

ASSEMBLING..................................................... 1

Warning ....................................................... 1

General assembling information .................. 1

Wall mounting .............................................. 1

Omega din rail mounting ............................. 2

MECHANICAL DIMENSIONS............................. 3

CONNECTION DIAGRAMS................................ 4

Measuring inputs ......................................... 4

Outputs ........................................................ 7

Serial interface............................................. 9

Power line wiring ....................................... 10

1

GB

GENERAL ASSEMBLING INFORMATION

Select a cleaned location, easy to reach, where

minimum vibrations are present and the ambient

temperature is within 0 and 50 °C (32 and 122 °F).

These instruments can be mounted either on wall

or on OMEGA DIN rail.

For mechanical dimensions refer to Fig. 4.

WALL MOUNTING

For wall mounting, use the (A) holes.

In this case it is advisable to use four M4 screws

with a torque of 1Nm.

For mounting template and mechanical dimen-

sions, please refer to Fig. 4 drawing.

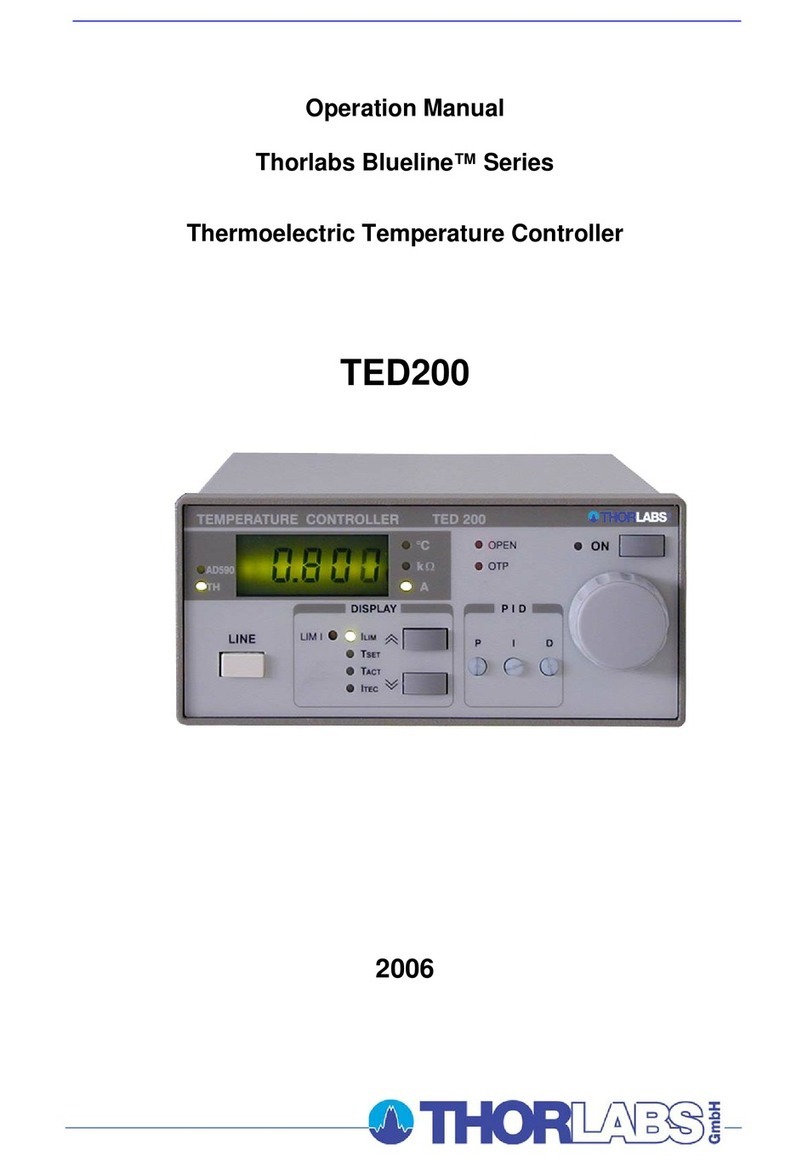

Fig. 1

ASSEMBLING

WARNING:

1) The correct functionality of these instruments

is guaranteed only if transport, storage,

installation, wiring, working condition and

maintenance are executed in compliance with

this manual.

2) The protection degree of these instruments is

equal to IP 20 (according to IEC529) and they

are connected to dangerous power lines, for

these reasons:

- installation, wiring and maintenance must be

executed by qualified personnel;

- all warnings contained in this manual must

be complied.

3) The safety requirements for Permanently

Connected Equipment say:

- a switch or circuit-breaker shall be included in

the building installation;

- It shall be in close proximity to the equipment

and easy to reach for the operator;

- it shall be marked as the disconnecting device

for the equipment.

NOTE: a single switch or circuit-breaker can

drive more than one instrument.

4) Before to execute any operation on the

connections, disconnect the instrument from

the power line by the circuit breaker.

(A)

(A)

(A)

(A)

2

GB

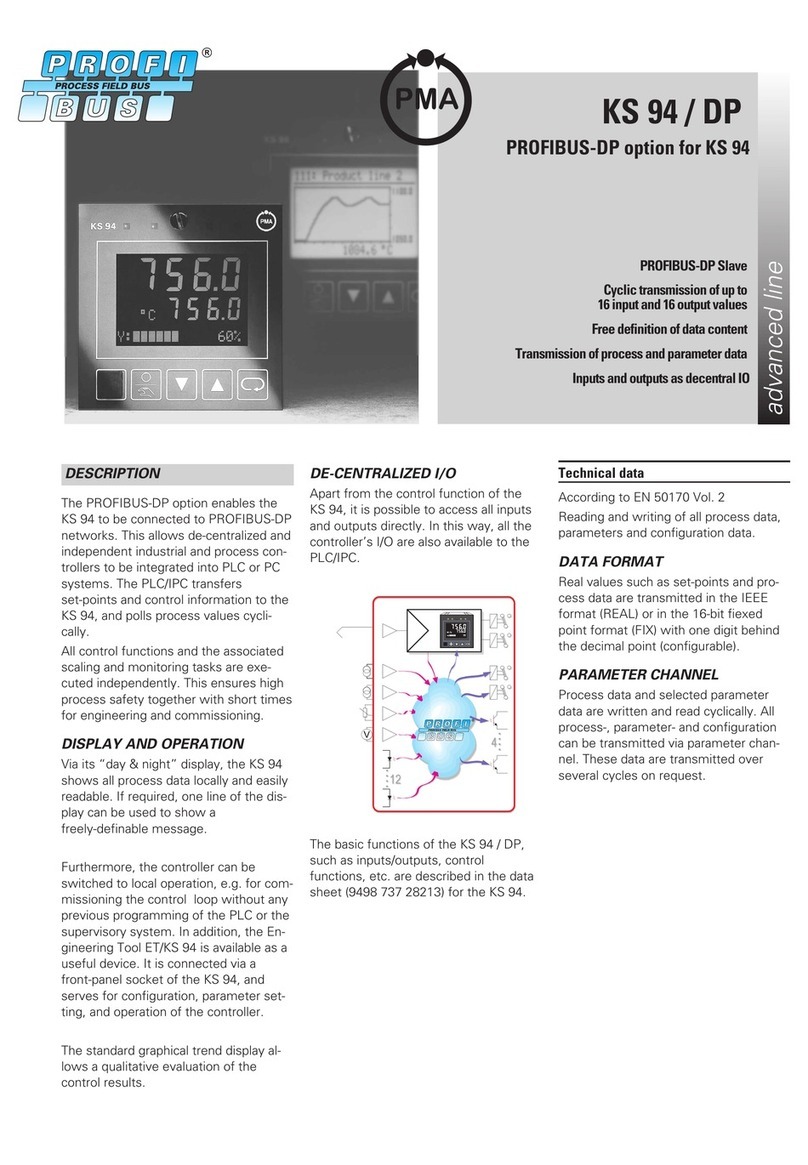

OMEGA DIN RAIL MOUNTING

For rail mounting use an OMEGA DIN rail in

accordance with EN 50 022 (35 x7.5 mm

or 35 x 15 mm) regulations.

Screwdriver

Fig. 3 REMOVING

Fig. 2 MOUNTING

3

GB

MECHANICAL DIMENSIONS

Fig. 4 MECHANICAL DIMENSIONS

4

GB

MEASURING INPUTS

NOTES:

1) Any external components (like zener barriers

etc.) connected between sensor and input

terminals may cause measurement errors due

to excessive and/or not balanced line

resistance or possible leakage currents.

2) The input accuracy is equal to + 0.2 % f.s.v.

(**) + 1 dgt. @ 25 °C of ambient temperature.

(**) For TC input, the f.s.v. should be referred

to the higher f.s.v. of the TC selected.

TC INPUT

TC type R and S

Fig. 6.A INPUT WIRING FOR TC TYPE R

AND S

CONNECTION DIAGRAMS

Connections have to be executed when the

instrument is placed in its proper location.

Fig 5.A LFS-RELAY TERMINAL BLOCK

Fig. 5.B LFS-mA TERMINAL BLOCK

14

+

_

Shield

14

+

_

Shield

15

15

5

GB

RTD INPUT

Fig. 7 RTD INPUT WIRING

NOTE:

1) Don’t run input wires together with power

cables.

2) Pay attention to the line resistance; an high

line resistance may cause measurement

errors.

3) When shielded cable is used, it should be

grounded at one side only to avoid ground loop

currents.

4) The resistance of the 3 wires must be the

same.

16

RTD

14

15 16

RTD

14

15

TC type J, K, L, N and T

Fig. 6.B INPUT WIRING FOR TC TYPE J, K, L,

N AND T

NOTE:

1) Do not run input wires with power cables.

2) For TC wiring use proper compensating cable

preferable shielded.

3) when a shielded cable is used, it should be

connected to one side only.

11

+

_

Shield

11

+

_

Shield

15

15

6

GB

LOGIC INPUT

NOTES:

1) Do not run logic input wiring together with

power cables.

2) Use an external dry contact capable of

switching 0.5 mA, 5 V DC.

3) The instrument needs 100 ms to recognize a

contact status variation.

4) The logic input is NOT isolated by the

measuring input.

5) This feature excludes the current transformer

input function.

Fig. 9- LOGIC INPUT WIRING

This input (connections 12 and 13) is used either

a current transformer input (for LFS-relay only) or

a logic input.

When the logic input is selected, it is used to

switch, by an external contact, from main set

point to second set point and viceversa.

logic input op. set point

open SP

close SP2

12

IN CT/SP-SP2 (for LFS-relay)

SP-SP2 (for LFS-mA)

13

LINEAR INPUT

Fig. 8 mA, mV AND V INPUTS WIRING

NOTE:

1) Do not run input wires together with power

cables.

2) Pay attention to the line resistance; a high line

resistance may cause measurement errors.

3) When shielded cable is used, it should be

grounded at one side only to avoid ground loop

currents.

4) The input impedance is equal to:

< 5 Ωfor 20 mA input

> 1 MΩfor 60 mV input

> 200 kΩfor 5 V input

> 400 kΩfor 10 V input

Shield

_

+mA,

mV

or

V

14

+

_

G

mA

mV

or

V

15

14

15

7

GB

OUTPUTS

LINEAR OUTPUT (For LFS-mA only)

This instrument is equipped with one linear output

(OUT 1) programmable as:

- main output (heating or cooling)

- secondary output (cooling)

- analog retransmission of the measured value

- analog retransmission of the operative set point.

Fig. 11 mA OUTPUT 1 WIRING

NOTE:

It is an isolated analog output.

Maximum load: 500 Ω.

CURRENT TRANSFORMER INPUT

(For LFS-relay only)

Safety note:

1) Do not run current transformer input wiring

together with AC power cables.

2) This feature excludes the logic input function.

3) The input impedance is equal to 10 Ω.

Fig. 10 - CURRENT TRANSFORMER INPUT

WIRING

This input allows to measure and display the

current running in the load driven by the

OUTPUT1 during the ON and OFF period of the

OUT 1 cycle time. By this feature it is also

available the "OUT 1 failure detection" function.

+

_

+

_

20 mA

7

8

OUT 1

12

13

Load

Current

transformer

8

GB

INDUCTIVE LOADS

High voltage transients may occur switching

inductive loads.

Through the internal contacts these transients

may introduce disturbances which can affect the

instrument performances .

For all outputs, the internal protection (varistor)

assures a correct protection up to 0.5 A of

inductive component.

The same problems may occur when a switch is

used in series with the internal contacts as shown

in Fig. 13.

Fig. 13 EXTERNAL SWITCH IN SERIES WITH

THE INTERNAL CONTACT

In this case it is recommended to install an

additional RC network across the external contact

as show in Fig. 13.

The value of capacitor (C) and resistor (R) are

shown in the following table.

Anyway the cable involved in relay output wiring

must be as far away as possible from input or

communication cables.

LOAD

(mA)

<40 mA

<150 mA

<0.5 A

C

(µF)

0.047

0.1

0.33

R

(Ω)

100

22

47

P.

(W)

1/2

2

2

OPERATING

VOLTAGE

260 V AC

260 V AC

260 V AC

RELAY OUTPUTS

Fig. 12 RELAY OUTPUTS WIRING

The contact rating of OUT 1 is 3A/250V AC on

resistive load.

The contact rating of OUT 2 and 3 is 2A/250V AC

on resistive load.

The number of operations is 1 x 105at specified

rating.

NOTES 1) Toavoid electricshock,connectpower

lineat theendofthewiringprocedure.

2) ForpowerconnectionsuseNo16AWG

or larger wires rated for at last 75 °C.

3) Use copper conductors only.

4) Do not run input wires with power

cables.

All relay contacts are protected by varistor against

inductiveloadwithinductivecomponentupto 0.5A.

The following are recommendations avoid serious

problems which may occur, when using relay

output for driving inductive loads.

OUT 1

(for LFS-relay

only)

OUT 2

(AL1)

OUT 3

(AL 2)

7

8

C

NO

1

2

3

NO - OUT 2

C - OUT 2/3

NO - OUT 3 R

C

LOAD

LINE

9

GB

SERIAL INTERFACE

RS-485 interface allows to connect up to 30

devices with one remote master unit.

Fig. 15 - RS-485 WIRING

The cable length must not exceed 1.5 km at 9600

BAUD.

NOTES:

1) This is an isolated RS 485 serial interface.

2)Thefollowingreportdescribesthesignalsenseof

the voltage appearing across the interconnec-

tion cable as defined by EIA for RS-485.

a) The ” A ” terminal of the generator shall be

negativewith respectto the ”B ”terminal for a

binary 1 (MARK or OFF) state.

b) The ” A ” terminal of the generator shall be

positive with respect to the ” B ” terminal for

a binary 0 (SPACE or ON).

VOLTAGE OUTPUTS FOR SSR DRIVE

(For LFS-relay only)

Fig. 14 SSR DRIVE OUTPUT WIRING

It is a time proportioning output.

Logic level 0: Vout < 0.5 V DC.

Logic level 1:

- 14 V + 20 % @ 20 mA

- 24 V + 20 % @ 1 mA.

Maximum current = 20 mA.

NOTE: This output is not isolated.

A double or reinforced isolation between

instrument output and power supply must be

assured by the external solid state relay.

+

__

+

7

8

OUT 1

SOLID STATE

RELAY 5

6COMMON

4

B'/B

B/B'

A/A' A'/A M

A

S

T

E

R

I

N

S

T

R

U

M

E

N

T

10

GB

equipmentand withineasyreachoftheoperator;

- it shall be marked as the disconnecting

device for the equipment.

NOTE: a single switch or circuit-breaker can

drive more than one instrument.

9) When neutral line is present, connect it to

terminal 9

10

9POWER LINE 100 V to 240 V A.C

(50/60Hz)

or 24 V AC/DC

POWER LINE WIRING

Fig. 16 POWER LINE WIRING

NOTES:

1) Before connecting the instrument to the power

line, make sure that line voltage corresponds to

the description on the identification label.

2) To avoid electric shock, connect power line at

the end of the wiring procedure.

3) Forsupply connectionsuseNo16AWGor larger

wires rated for at last 75 °C.

4) Use copper conductors only.

5) Do not run input wires with power cables.

6) For 24 V DC the polarity is not a care condition.

7) The power supply input is NOT fuse protected.

Please, provide it externally.

Power supply Type Current Voltage

24 V AC/DC T 500 mA 250 V

100/240 V AC T 125 mA 250 V

When fuse is damaged, it is advisable to verify

thepowersupply circuit, sothatit is necessaryto

send the instrument back to your supplier.

8) The safety requirements for Permanently

Connected Equipment say:

- a switch or circuit-breaker shall be included

in the building installation;

- It shall be in close proximity to the

P (L1)

P (L1)

N (L2)

N (L2)

Ero Electronic S.r.l.

Via E. Mattei, 21

28100 Novara

Italy

Tel. +39 0321481111

Fax +39 0321481112

BENELUX

ERO Electronic Benelux SA/NV

Rue Val Notre Dame 384

MOHA 4520 (WANZE)

Tel. 085-274080

Fax 085-274081

BRASIL

ERO ELECTRONIC DO BRASIL Industria

e Comercio Ltda.

Rua Garibaldi, 659 - Conj. 202

90035-050 PORTO ALEGRE

Tel. 051-2214888

Fax 051-2214734

CHINA

TIANJIN VEGA COMPANY Ltd

(TAIF)

Hebei District

300232 TIANJIN

Tel. 022-26273296

Fax 022-26273297

FRANCE

ERO Electronic SARL

Zac du Chêne

34, Rue du 35éme Régiment d’Aviation

69673 BRON CEDEX

Tel. 0478267979

Fax 0478267800

GERMANY

ERO Electronic GmbH

Ottostrasse 1

65549 LIMBURG A.D. LAHN

Tel. 06431-95680

Fax 06431-57493

NETHERLAND

ERO Electronic Nederland

Ganieelan 4

2404 CH Alphen a/d Rijn

Tel. 0172-420400

Fax. 0172-420395

SOUTH AFRICA

ERO Electronic S.A. Pty Ltd

Airgro House

1343, Spokeshave Avenue

Stormill Ext 2 ROODEPOORT

Tel. 011-4742278/9

Fax 011-4749404

P.O. Box 43112

Industria 2042

SPAIN

ERO ELECTRONIC IBERICA

Calle La granja, 74

Pol. Ind. Alcobendas

MADRID

Tel. 091-6618194

Fax. 091-6619093

U.K.

ERO U.K.

Unit 1, Cygnet Trading Estate

Faraday Close

Durrington, Worthing

WEST SUSSEX BN13 3RQ

Tel. 01903-693322

Fax. 01903-693377

U.S.A.

AMERICAN ERO Electronic Corp

BARRINGTON, ILL. 60010

Tel. 0847-382-0881

Fax 0847-382-0240

U.S.A.

BARBER COLMAN

Industrial Instruments Div.

P.O. BOX 2940

Loves Park, IL - 31132 - 2940

Tel. 0815-637-3000

Fax 0815-637-5341

Table of contents

Other ero electronic Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

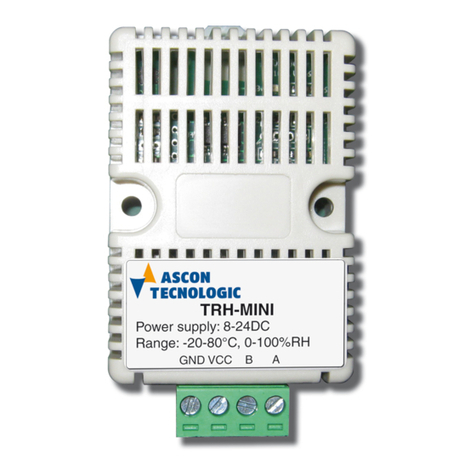

Ascon tecnologic

Ascon tecnologic TRH-MINI Engineering manual

Engineered Comfort

Engineered Comfort Fan Coil Controller EZstat Installation and operation manual

oventrop

oventrop Unibox E BV operating instructions

STIEBEL ELTRON

STIEBEL ELTRON SOM 9s Installation, operation, functions and options, troubleshooting

NetzHome

NetzHome WT14 quick start guide

Toss

Toss PIREG-D2 operating instructions