Toss PIREG-D2 User manual

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

1

Opera ing Ins ruc ions

Temperature Controller PIREG®-D

2

Wi h kind regards

GmbH & Co. KG

-Verpackungssys eme-

Danziger S raße 15

D-35418 Al en-Buseck

Tel.: +49 (0) 64 08 - 90 91

- 0

Fax: +49 (0) 64 08 - 43 55

E-Mail: info@ oss-gmbh.de

In erne : www. oss-gmbh.de

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

2

PIREG-D

2

Device description:

Resistance Temperature Controller

Applications:

Packaging machine for sealing

plas ic films.

Con roller PIREG-D2

Curren ransformer PIREG-CT-50

Contents:

1. General, safety and warning instructions 3

1.1. ote on the device description 3

1.2. Icons and symbols 3

1.3. General safety instructions 4

1.4. Application 4

1.5. ote on the heating conductor 4

1.6. ote on the sealing transformer 4

1.7. ote on the current transformer 5

1.8. General assembly instructions 5

1.9. Maintenance 5

1.10. Validity 5

2. Short description 5

3. Functions 6

3.1. Control 6

3.1.1. Hea -up ramp 6

3.1.2. Se ing empera ure coefficien s 7

3.1.3. Calibra ion reference ime 7

3.1.4. Tempera ure range 7

3.1.5. Calibra ion mode 7

3.1.6. Transformer ype 7

3.1.7. Reference empera ure 7

3.1.8. Tempera ure coefficien correc ion 7

3.2. Calibration 7

3.2.1. Ini ialisa ion 8

3.2.2. Calibra e inpu amplifier 8

3.2.3. De ermining he phase shif 8

3.2.4. De ermine reference resis ance 8

3.2.5. Tempera ure comparison ime 8

3.2.6. Check reference resis ance 8

3.2.7. De ermine he P-fac or 8

3.2.8. Se ini ialising remanence 9

3.2.9. Tempera ure-coefficien correc ion 9

3.2.10. Single-poin c correc ion 10

3.2.11. P-fac or correc ion 11

3.3. Off-state 11

3.2.1. Measuremen pulse-pause 11

3.2.2. Calibra ion swi ching 11

3.4. On state 12

3.5. Sequence control 12

3.5.1. Prehea ing 12

3.5.2. S ar delay 12

3.5.3. Sealing ime 12

3.5.4. Cooling phase 12

3.6. Monitoring 12

3.6.1. Tempera ure moni or 12

3.6.2. Hea ing moni or 12

3.6.3. S ar moni or 12

3.6.4. Communica ion moni or 12

3.7. Error state 12

3.7.1. Possible errors 13

3.8. Relay functions 14

3.8.1. Tempera ure func ion 14

3.8.2. Sequence func ion 14

3.8.3. Time pulse func ion 14

3.9. Display functions 14

3.9.1. Languages 14

3.9.2. Brigh ness 14

3.9.3. Hold mode 14

3.9.4. Cycle coun er 14

3.9.5. Saving 14

3.9.6. Releases 14

3.9.7. Tempera ure uni 15

4. Operation 15

4.1. Keys 15

4.1.1. Cursor 15

4.1.2. Se ing numerical values 15

4.1.3. Selec ing func ions 15

4.1.4. Accep ance of he se ings 15

4.1.5. Menu change 15

4.1.6. Menu re urn 15

4.1.7. Locking 15

4.1.8. Execu ion preven ion 16

4.2. Leuchtdioden 16

4.2.1. Power 16

4.2.2. Hea 16

4.2.3. Alarm 16

4.3. Inputs 16

4.3.1. S ar inpu s 16

4.3.2. Prehea inpu s 16

4.3.3. Calibra ion S ar Inpu 16

4.3.4. Rese Inpu 16

4.3.5. Measuremen pause 16

4.3.6. Calibra ion swi ching 16

4.3.8. Se value inpu 16

4.4. Outputs 17

4.4.1. Ac ual Value Ou pu 17

4.4.2. Message relay ou pu 17

4.4.3. Con rol relay ou pu s 17

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

3

4.4.4. Alarm ou pu 17

4.4.5. ELR ou pu 17

4.5. Interfaces 17

5. Menu structure 18

5.1. Switching on 18

5.2. Working menu 18

5.2.1. Working menu wi hou sequence con r. 18

5.2.2. Working menu wi h sequence con rol 18

5.2.3. Symbols for he opera ing s a us 19

5.2.4. Error menu 19

5.2.5. Kalibrierungs-Auswahlmenü 20

5.2.5.1. Calibra ion Informa ion menu 20

5.3. Selection menu 20

5.4. Sequence Control menu 21

5.4.1. Prehea menu 21

5.4.2. S ar Func ion menu 21

5.4.3. S ar Delay menu 21

5.4.4. Welding Time menu 22

5.4.5. Cooling Phase menu 22

5.5. Monitoring menu 22

5.5.1. Tempera ure moni oring menu 23

5.5.2. Hea ing moni oring menu 23

5.6. In-/Output settings menu 23

5.6.1. Relais se ing menu 23

5.6.1.1. Message Relay se ings menu 23

5.6.1.1.1. Message Relay Temp. func. menu 24

5.6.1.1.2. Message Relay Seq. func. menu 24

5.6.1.1.3. Message Relay Time P. func. m. 24

5.6.1.2. Con rol Relay se ings menu 24

5.6.1.2.1. Con rol Relay Temp. func. menu 25

5.6.1.2.2. Con rol Relay Seq. func. menu 25

5.6.1.2.3. Con rol Relay Time P. func ion m. 25

5.6.1.3. Alarm Relay se ings menu 25

5.6.1.4. Relay Ou pu s s a us menu 26

5.6.2. Inpu se ing menu 26

5.6.2.1. Prehea ing inpu se ing menu 26

5.6.2.2. S ar inpu se ing menu 26

5.6.2.3. Calibra ion-S ar inpu se ing menu 26

5.6.2.4. Rese inpu se ing menu 26

5.7. Controller setting menu 27

5.7.1. Tc se ings menu 27

5.7.1.1. Variable Tc se ings menu 27

5.7.2. Tempera ure se ings menu 27

5.7.3. Time se ings menu 27

5.7.4. Calibra ion se ings menu 28

5.7.5. Se value se ings menu 28

5.8. Display settings menu 28

5.8.1. Se ings menu for lang. and brigh ness 28

5.8.2. Hold Mode menu 29

5.8.3. Opera ing menu 29

5.8.4. Releases menu 29

5.9. Save menu 30

5.9.1. Parame er se s menu 30

5.9.2. Fac ory Se ings menu 30

5.10. Informations-Menü 30

6. Installation and commissioning 31

6.1. Installation 31

6.2. Configuring the settings 31

6.3. Connection of the PIREG-D2 31

6.4. Control inputs 31

6.5. Connecting to the mains voltage 31

6.6. Burning in the heating conductor 32

6.7. When the contr.r does not work corr. 32

6.8. Current Transformer 32

7. The heating conductor 32

8. Technical data 33

8.1. Controller 33

8.2. Current transformer 35

8.3. Sealing transformer 35

8.4. External thermometer DTM3000 36

8.5. Ordering codes 36

8.6. Housing 37

8.6.1. PIREG-D2 housing 37

8.6.2. Curren ransformer housing 37

8.7. Spare parts 37

9. Connection diagrams 38

9.1. PIREG-D2 with ext. solid-state relay 38

9.2. PIREG-D2 with internal thyristors 38

9.3. RS232 / RS485 connection - interface 38

10. Application note 39

10.1. Application instructions 39

11. Disposal 39

1. General, safety and warning instructions

1.1. ote on the device description

The purpose of his device descrip ion is o ensure op imum ins alla ion, commissioning, opera ion and

main enance of he PIREG-D2 and mus be read prior o carrying ou any of he ac ions described. Keep

he device descrip ion handy and accessible o all users for possible referencing. Pass his manual on o

fu ure users of he PIREG-D2.

All necessary se ings are described in his device descrip ion. Should difficul ies never heless arise dur-

ing commissioning or opera ion, please do no carry ou any unau horised manipula ions. You could pu

yourself and o hers a risk as well as jeopardize your warran y claim. In such cases, please con ac us

immedia ely:

GmbH & Co. KG Phone: +49 (0) 64 08 - 90 91 - 0

-Verpackungssys eme- Fax: +49 (0) 64 08 - 43 55

Danziger S raße 15 E-mail: info@ oss-gmbh.de

D-35418 Al en-Buseck In erne : www. oss-gmbh.de

1.2. Icons and symbols

Danger

(EN)

:

Indica es a hazard ha could resul in personal injury. Whenever his symbol is

used, he device descrip ion mus be consul ed and he accompanying ins ruc ions mus be

observed and followed in order o avoid hazards.

Danger (FR): Indique un danger pouva

n en rainer des a ein es à la san é des personnes.

Lorsque ce symbole es u ilisé, la descrip ion de l’appareil doi ê re consul ée e les indica ions

doiven ê re observées e respec ées afin d’évi er ou e mise en danger.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

4

Danger

(EN)

:

Indica es a hazard due o elec rical curren . Failure o observe he safe y ins ruc-

ions may resul in serious or fa al injuries.

Danger (FR): Indique un danger d’élec rocu ion. Un non-

respec de ces indica ions de sécuri é

en raine un danger de blessures graves, voire mor elles.

Danger

(EN)

:

Indica es a hazard due o ho surfaces or burn up ha could resul in personal

injury.

Danger (FR): Indique un danger dû aux surfaces brûlan es, voire rougeoyan es pouvan en-

rainer des a ein es à la san é des personnes.

ote

(EN)

:

Indica es par icularly impor an informa ion which, if ignored, can lead o ma erial

damage, for example.

Indications (FR):

Indique une informa ion par iculièremen impor an e pouvan en rainer des

dégâ s ma ériels en cas de non-respec .

1.3. General safety instructions

E :

The safe y ins ruc ions and warnings given in his descrip ion mus be followed o guaran-

ee safe opera ion of he equipmen . The equipmen can be opera ed wi hou impairing he op-

era ional reliabili y if he condi ions s a ed in he echnical specifica ions are observed.

The equipmen may only be ins alled and s ar ed-up by sui ably rained personnel.

Ma

in enance and repair of he equipmen may only be carried ou by rained personnel, who are

familiar wi h he dangers and guaran ee condi ions.

FR:

Les indica ions e mises en garde con enues dans ce e descrip ion doiven ê re respec ées

afin de garan ir

un fonc ionnemen sûr. Si les consignes de sécuri é de fonc ionnemen son

respec ées, l’appareil peu ê re exploi é aux condi ions men ionnées dans les données ech-

niques.

Ce appareil ne peu ê re ins allé e mis en service que par un personnel qualifié

en echnique

élec ronique !

Les ravaux d’en re ien e de répara ion ne peuven ê re effec ués que par des personnes

formées e spécialis es familiarisées avec les dangers liés à l’appareil e les condi ions de gar-

an ie.

1.4. Application

E :

The PIREG-D

2 resis ance empera ure con roller may only be used for he hea ing and

empera ure con rol of hea ing conduc ors as specified via isola ing ransformers in accordance

wi h he regula ions, no es and warnings con ained in his descrip ion.

Non-

observance of he ins ruc ions or incorrec use of he equipmen can resul in impairmen of

he safe y or overhea ing of he hea ing conduc or, he elec rical wiring or he ransformer.

FR: Le régula eur de empéra ure à résis ance PIREG-D2 ne doi ê re u ilisé que pour le chauf-

fage e la régula ion de empéra ure de conduc eurs de chaleur expressémen conçus à ce

effe par l'in ermédiaire de ransforma eurs de sépara ion conformémen aux prescrip ions, indi-

ca ions e mises en garde men ionnés dans ce e descrip ion.

Le non-respec ou l'u ilisa ion non conforme peu comprome re la sécuri é ou en rainer le sur-

chauffe des conduc eurs de chaleur, des câbles élec riques, du ransforma eur, e c.

1.5. ote on the heating conductor

A basic precondi ion for he func ion and safe opera ion of he comple e hea ing sys em is he applica ion

of sui able hea ing conduc ors.

The posi ive empera ure coefficien of he hea ing conduc or used mus be equal or grea er han he

posi ive empera ure coefficien se a he PIREG-D2. The appropria e empera ure coefficien of he hea -

ing conduc or mus be se on he display uni of he PIREG-D2 or via he in erface. The empera ure coef-

ficien of he hea ing conduc or mus be posi ive over he en ire empera ure range.

Cau

tion

(EN)

:

Using hea ing conduc ors wi h oo low a empera ure coefficien , or adjus ing he

con roller o a empera ure coefficien ha is oo high, can resul in uncon rolled overhea ing or

melting of he hea ing conduc or.

Attention (FR):

Si un conduc eur de chaleur es u ilisé avec un pe i coefficien de empéra ure

ou qu’un coefficien de empéra ure rop grand es réglé sur le régula eur, les conduc eurs de

chaleur von chauffer de manière incon rôlée e peuven aller jusqu’à fondre.

Tempera ure regula ion of hea ing conduc ors connec ed in parallel mus be more precise han of hea ing

conduc ors connec ed in series. However, he wiring mus be s ric ly symme rical and performed in such a

way ha no overcurren arises when wo hea ing conduc ors on opposi e sides con ac each o her.

If series-connec ed hea ing conduc ors have o be used, he effec on he overcurren reac ion should be

aken in o considera ion if wo opposi e sealing bands ouch each o her.

1.6. ote on the sealing transformer

The sealing ransformer mus be configured according o EN 61558 (VDE 0570) resp. UL 5085 (isola ing

ransformer wi h reinforced isola ion) and in a single-chamber design. All ypes and designs ha comply

wi h he s andards can be used as sealing ransformers. The induc ion in he ransformer's iron core mus

no be reduced as is normally he case wi h primary side hyris or opera ion. A ransformer wi h low losses

are disrup ed less on he secondary side han wi h ransformers ha have low energizing curren s. Thus

in applica ions wi h shor hea ing and sealing imes, s iff and generally larger ransformers should be

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

5

used. Where a grea deal of sealing is o be performed, a ransformer wi h a primary vol age of 400 V is

advan ageous, because his way, he swi ching capaci y of he PIREG-D2's in ernal ac ua or is more likely

o be sufficien and an ex ernal ac ua or wi h solid-s a e relay will no have o be used.

Caution

(EN)

:

There mus be sufficien pro ec ion agains acciden al con ac if he ransformer

is ins alled in a machine frame. Fur hermore, ensure ha wa er, cleaning liquids or conduc ing

liquids do no come in o con ac wi h he ransformer. The conduc or wiring c

ross sec ions

should be designed o ma ch he ac ual curren s. Non-

observance of hese no es may resul in

impairmen of he elec rical safe y.

Attention (FR):

Si le ransforma eur es placé dans le corps de la machine, une pro ec ion

suffisan e con re les

con ac s acciden els doi ê re prévue. De plus, il convien d’empêcher l'eau,

les solu ions de ne oyage ou les liquides conduc eurs d’en rer en con ac avec le ransfo

r-

ma eur. Les sec ions des câbles doiven ê re conçues en fonc ion des couran s réels. Le non

-

respec de ces ins ruc ions comprome la sécuri é élec rique.

For bes resul s, he ransformer's performance and he secondary vol age mus be sui ed o he hea ing

conduc or. A shor hea -up period is reached wi h of a high ransformer ou pu vol age. However, he vol -

age selec ed should no be oo large so ha no less han 12 con roller measuremen s are needed for a

arge empera ure increase of 300°C when hea ing up (hea -up period 240 ms). For smaller hea -up

curves, correspondingly fewer measuremen s are necessary. (The PIREG-D2 akes a measuremen eve-

ry 20 ms while hea ing).

The larger he ransformer's secondary vol age for a given hea ing conduc or, he more energy is fed in o

he hea ing conduc or, even in he OFF s a e. This is done by means of empera ure measuring impulses,

which he con roller regularly sends o he hea ing conduc or. Therefore, he higher he secondary vol age

of he ransformer he grea er is he difference be ween he res ing empera ure and he ambien empera-

ure in he OFF s a e.

1.7. ote on the current transformer

E :

The curren ransformer is an essen ial par of he con rol sys em. Only Toss curren rans-

formers may be used. The curren ransformer may only be opera ed wi h ballas resis ance.

The ballas resis ance is in egra ed in o he PIREG-D2. The curren ransformer mus be moun -

ed in such a way ha magne ic leakage fields from he sealing ransformer or o her leakage

fields do no affec he measuremen .

FR: Le ransforma eur de couran fai par ie du sys ème de régula ion. Seuls les ransfor-

ma eurs de couran Toss peuven ê re u ilisés. Le ransforma eur de couran ne doi ê re u ilisé

qu'avec une résis ance ohmique apparen e. La résis ance ohmique apparen e es in égrée dans

le PIREG-D2. Le ransforma eur de couran doi ê re mon é de elle sor e que les champs mag-

né iques de dispersion du ransforma eur de soudage ou d'au res champs de dispersion n'influ-

encen pas la mesure.

Caution

(EN)

:

The used cable o he hea ing conduc or can hea up he curren ransformer.

Attention (FR): Le condui u ilisé allan vers le conduc eur de chaleur peu chauffer le ransfor-

ma eur de couran .

1.8. General assembly instructions

The PIREG-D2 resis ance empera ure con roller is only sui ed for use in a swi ch cabine . Open opera-

ion is no permi ed.

The con roller is designed for ins alla ion in o he swi ch panel and he curren ransformer is fi ed on a 35

mm moun ing rail according o EN 60715 (EN 50022). When ins alling he con roller in he swi ch panel,

here mus be a dis ance of a leas 20 mm from he neighbouring device. Hea dissipa ion from neigh-

bouring devices mus be aken in o accoun (no e he ambien empera ure specifica ions).

1.9. Maintenance

The PIREG-D2 resis ance empera ure con roller does no require any special main enance. However, an

occasional check or igh ening of he connec ion erminals is recommended. Dus deposi s on he con rol-

ler can be removed wi h dry compressed air once he power has been swi ched off.

1.10. Validity

The firs device version (v.vv) shipped was he version 1.00 wi h program versions 1.13 for he display

uni (d.dd), 1.16 for he elec rically isola ed side (g.gg) and 1.10 for he ins rumen a ion side (m.mm).

Supplemen s in his descrip ion which are only valid from a la er version include he version, he no a ion

Vv.vv/d.dd/g.gg/m.mm, e.g. V1.00/1.13/1.16/1.10 from which hey are valid. The device and program

versions are read from he Informa ion menu or by a command (LVERS) via he in erface.

2. Short description

The PIREG-D2 resis ance empera ure-con roller is a empera ure con roller wi h a buil -in sequence con-

rol, which is used o con rol empera ures of hea conduc ors for hea pulse sealing of films and for con-

rolling film sealing machines.

The sealing ransformer is used by he PIREG-D2 on he primary side. The hea conduc or is fed from he

secondary side of he ransformer. The measuring signals are received direc ly a he hea conduc or and

are made available o he con roller.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

6

The PIREG–D2 empera ure con roller has four con rol inpu s and hree relay ou pu s o con rol he film

sealing machine. The PIREG-D2 empera ure con roller can con rol a film sealing machine independen ly

via he la er and he in egra ed sequence con rol. The hree relay ou pu s are divided in o one message

ou pu and wo con rol ou pu s wi h differen capaci ies. In addi ion, here is an alarm ou pu .

The empera ure coefficien of he hea conduc or mus be posi ive. I s resis ance increases when i is

hea ed. This effec is used for empera ure con rol. The empera ure con roller measure and regula es he

resis ance of he hea conduc or. The empera ure coefficien is a ma erial cons an ha depends on he

alloy used for he hea conduc or. The ac ual empera ure is de ermined by measuring he vol age and

curren .

The PIREG-D2 opera es as a propor ional con rol uni ha independen ly de ermines he P-fac or ( he

con rol amplifica ion) for he con rolled par of a process during calibra ion i self. The con rolled sys em

consis s of a sealing ransformer and a hea conduc or. The P-fac or de ec ed during he calibra ion pro-

cess may s ill be correc ed la er by he se ing in he display uni or by a command ( 5.2.5.). Wi h an

addi ional con rol-func ion he ypical offse a propor ional con roller will be minimized (from

V1.00/1.23/1.30/1.25).

The PIREG-D2 is opera ed ei her via he buil -in display uni ( 5.) by five bu ons ( 4.1.) or by he

RS232 or USB in erface which is fi ed o he PIREG-D2. Combina ions of bo h ypes of opera ion are

also possible. An OLED module wi h eigh lines wi h wen y-one digi s each is used as display.

The PIREG-D2 is adjus ed o he hea conduc or's empera ure coefficien s ( 5.7.1.). The PIREG-D2

can also de ermine a hea conduc or’s ac ual empera ure coefficien i self by means of a empera ure

coefficien correc ion ( 5.7.4.). Connec he PIREG-D2 via he RS232 in erface o an ex ernal hermom-

e er exTM, DTM3000 (from V1.00/2.08/1.33/1.26) or previous TM6, which measures he ac ual empera-

ure of he hea ing conduc or o simplify he empera ure coefficien correc ion. Depending on he se ing,

he PIREG-D2 can opera e up o a empera ure range of 500°C.

During calibra ion, he con roller se s i self o he secondary vol age of he ransformer and he curren

hrough he hea conduc or. he secondary vol age of he ransformer may be wi hin a range of 1...80 V.

The curren measured wi h a curren ransformer can range from 20 o 400A. The calibra ion values are

s ored in he PIREG-D2, so ha here is no need for renewed calibra ion and s ar -up ime af er swi ching

on he power, if condi ions have no changed.

The PIREG-D2 can s ore he calibra ion se ings for wo hea conduc ors (from V1.00/1.23/1.30/1.25). A

his wo calibra ions i is necessary o use he same empera ure coefficien s, he same empera ure

range, and he same o her calibra ion se ings ( 3.). For each hea conduc or a separa e empera ure

coefficien correc ion will be de ermined. The ac iva ion of he calibra ion swi ching and he change be-

ween his wo calibra ions will do by command or by con rol inpu s ( 5.6.2).

The PIREG-D2 performs he calibra ion process wi hin a variable room empera ure range of 0-50°C.

During he process, he ac ual reference empera ure mus be se in he con roller's display uni (

5.7.2.). Tha is advan ageous for cons an sealing empera ures wi h differing environmen al condi ions.

High quali y sealing ransformers, such as oroidal core ransformers, are connec ed by he PIREG-D2 on

he primary side, wi hou curren surges occurring. A smoo h swi ching procedure is employed ha com-

pensa es for he remanence of he sealing ransformer. An ini ialising remanence se ing is made au o-

ma ically af er swi ching on he power and following calibra ion,. Only a shor remanence se ing las ing

40 ms for eI core ransformers and 80 ms wi h oroidal core ransformers is needed before each sealing

process. If, wi h oroidal core ransformers, he pause be ween wo sealing processes is longer han 10

minu es, he remanence se ing akes 160 ms. The remanence is he residual magne iza ion in he rans-

former's iron core. During he ini ial remanence se ing procedure, he hea conduc or has o be hea ed

for a shor ime o approx. 40 °C – 70 °C. The PIREG-D2 i self uses a phase angle con roller o regula e

he empera ure.

The PIREG-D2 provides he func ion measuremen pause (from V1.00/1.23/1.30/1.25). A he measure-

men pause he PIREG-D2 s ops he sending of measuremen impulse o he sealing ransformer. There-

fore i is possibly o work a he head conduc or circui wi hou o genera e an error. The measuremen

pause is con rolled by con rol inpu s or by command ( 5.6.2.).

3. Functions

3.1. Control

Wi h he PIREG-D2, here are he following con rol se ings which mus be performed before calibra ion

s ar . The PIREG-D2 peforms he hea conduc or's adap a ion o he vol age Ur and he curren Ir and he

P-fac or (con rol amplifica ion) on i s own.

3.1.1. Heat-up ramp: A hea -up ramp is used o se he ime value in which he con roller increases he

ac ual empera ure value o he arge value wi h a linear ramp ( 5.7.3.). This allows he hea conduc or

o be hea ed gradually.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

7

3.1.2. Setting temperature coefficients: The hea conduc or's empera ure coefficien , which mus be

posi ive, mus be se on he PIREG-D2 ( 5.7.1.). The empera ure coefficien is a ma erial cons an ha

depends on he alloy used for he hea conduc or.

Caution

(EN)

:

Using hea ing conduc ors wi h oo low a empera ure coefficien , or adjus ing he

con roller o a empera ure coefficien ha is oo high, can resul in uncon rolled overhea ing or

melting of he hea ing conduc or.

Attention (FR): Si un conduc eur de cha

leur es u ilisé avec un pe i coefficien de empéra ure

ou qu’un coefficien de empéra ure rop grand es réglé sur le régula eur, les conduc eurs de

chaleur von chauffer de manière incon rôlée e peuven aller jusqu’à fondre.

The ac ual value canno hen reach he arge value and he con roller con inues o hea up. For hea

conduc ors which have a empera ure coefficien devia ing from he four possible ones, he variable em-

pera ure coefficien se ing mus be used.

3.1.3. Calibration reference time: In he calibra ion process ( 3.2.), he hea conduc or's resis ance is

de ermined a reference empera ure. To ensure ha he reference resis ance value de ermined is cor-

rec , he resis ance of he hea conduc or is measured again af er he calibra ion reference ime has ex-

pired, and compared o he de ermined reference resis ance measured previously. If he difference be-

ween he wo measuremen s is grea er han 1.2%, a new calibra ion process is s ar ed. This preven s

calibra ion from aking place on a hea conduc or which is s ill cooling. The grea er he calibra ion refer-

ence ime selec ed, he sooner resis ance changes in he hea conduc or, caused by cooling during cali-

bra ion, are de ec ed .

3.1.4. Temperature range: The PIREG-D2 offers a choice be ween he four fixed empera ure ranges of

200, 300, 400 and 500°C and a variable empera ure range wi h an adjus men range of 100°C-500°C.

The over empera ure (ra ed value +20%) and under empera ures (-10°C) apply accordingly.

3.1.5. Calibration mode:

- ew calibration: If he calibra ion mode “new-calibra ion“ is chosen, he PIREG-D2 performs a calibra-

ion af er every power-on or he signal “Rese ”. The calibra ion values are no saved. Calibra ion can also

be s ar ed in he Off- or error s a e wi h he signal “Calibra ion S ar ”.

- Save calibration: Calibra ion is only s ar ed wi h he signal “Calibra ion S ar ”. The signal “Calibra ion

S ar ” can be applied in he Off- or error s a e or before power-on. The calibra ion values are s ored in a

non-vola ile memory and canno be dele ed by a power on or he signal “Rese ”. This means ha a new

calibra ion mus be performed af er he hea ing conduc or configura ion was changed or modifica ions

were carried ou on he ransformer. The saved values are hen overwri en wi h he newly de ermined

values.

3.1.6. Transformer type: The PIREG-D2 mus be adap ed o he ype of sealing ransformer, EI or oroi-

dal core. The nex ime he power is swi ched on, he ransformer is charged wi h mul iple unipolar phase

angles and he remanence is aken o a specified posi ion in he ransformer's iron core. The phase an-

gle's curren conduc ion angle for se ing he remanence is adap ed o he ype of ransformer, during he

process. The rapid swi ch-on process is used for every sealing procedure wi h he ransformer being

charged by only a small number of remanence se ing pulses before being swi ched on comple ely. Wi h

oroidal core ransformers, if he pause be ween he wo sealing procedures is longer han 10 minu es,

he number of rapid swi ch-on process pulses is doubled. The sof swi ch-on procedure is used for swi ch-

ing on high-quali y ransformers wi hou power surges occurring.

3.1.7. Reference temperature: The reference empera ure is he environmen al empera ure a which he

hea conduc or resis ance, called reference resis ance (Rref) is de ermined during he calibra ion process.

Wi h he PIREG-D2, he reference empera ure may be se be ween 0 and 50°C.

3.1.8. Temperature coefficient correction: The PIREG-D2 provides wo empera ure coefficien correc-

ions, wi h which sca ering of he hea conduc or ma erials, caused by alloys, can be correc ed.

- Temperature coefficient correction: In normal empera ure coefficien correc ion, he hea conduc or

is hea ed up in eigh empera ure s eps. A each s ep here is a comparison wi h he ac ual hea conduc-

or empera ure and an ac ual value correc ion depending on he devia ion. The normal empera ure coef-

ficien correc ion is par of he calibra ion process ( 3.2.) and also occurs as par of i .

- Single-point temperature coefficient correction: In he case of he single-poin empera ure coeffi-

cien correc ion, correc ion occurs for one opera ing poin . The single-poin empera ure coefficien correc-

ion is carried ou ou side of he calibra ion process and is s ar ed from he Off s a e.

3.2. Calibration

During calibra ion, he PIREG-D2 independen ly adap s o he combina ion of sealing ransformer and

hea conduc or. A he same ime, he vol age Ur a he hea conduc or and he curren Ir hrough he hea

conduc or is measured every second. This s a us is indica ed by he corresponding opera ing s a us sym-

bols in he symbol field of he Working menu on he display uni ( 5.3.). If you make sui able adjus -

men s, a Calibra ion OK message, which is rese during calibra ion, may be issued by he PIREG-D2's

hree relay ou pu s. Addi ional informa ion on he progress of he individual calibra ion s eps is shown by

he ac ual value display or ou pu . The ac ual value is upda ed every second.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

8

The calibration process runs through the following steps:

3.2.1. Initialisation: During he ini ialisa ion s age, he PIREG-D2 iden ifies he da a necessary for cali-

bra ion. In addi ion, i checks he selec ed empera ure coefficien for dynamics and con inui y wi hin he

selec ed empera ure range. Should he dynamics and con inui y exceed he permi ed limi s, he

PIREG-D2 will s op he calibra ion procedure wi h Error 133 (parame er error).

3.2.2. Calibrate input amplifier: The inpu amplifiers for Ur and Ir are adjus ed in s eps o he vol age

and curren a he hea ing conduc or. In he firs s ep, he required modula ion reserve for he sealing

ransformer/hea ing conduc or combina ion is de ermined au oma ically (from V1.00/1.23/1.30/1.25).

In his calibra ion s ep, he ac ual value display shows differen values every second and he ac ual value

ou pu is charged wi h differen vol ages every second. The measured curren or vol age value is dis-

played or issued al erna ely.

Wi h he ac ual value being shown on he display, he curren value is shown in he con roller's 0-50% se

empera ure range and he vol age value is shown in he 50-100% range. The zero poin of he displayed

values is se a 50 %. A he beginning of he calibra ion, he amplifiers (for Ur and Ir) are ini iallised wi h

minimum amplifica ion. A he end of he calibra ion procedure, if he adjus men has been made success-

fully, he range for he displayed curren value is from 16-33% and he range for he measured vol age

value is from 66–83%. The curren value is displayed accordingly in he 0-5V range a he ac ual value

ou pu and he vol age is displayed in he 5-10 V range. The measuremen s' zero poin is around 5V. The

amplifiers (for Ur and Ir) are ini ialised wi h minimum amplifica ion a he s ar of he calibra ion process.

A he end of he calibra ion procedure, if he adjus men has been made successfully, he range for he

displayed curren value is from 1.66 - 3.33 V and he range for he displayed vol age value is from 6.66 -

8.33 V.

3.2.3. Determining the phase shift: During his s ep, he phase shif s be ween Ur and Ir, caused by he

ransformer, are measured and correc ed. The con roller au oma ically se s he op imum scan imes for Ur

and Ir. The ac ual value display and he ac ual value ou pu show he phase shif . A display of approx.

50% of he con roller's se empera ure range or a signal of approx. 5V corresponds o he op imal value.

3.2.4. Determine reference resistance: The reference resis ance of he hea conduc or (Rref) is de er-

mined in his s ep. A reference empera ure of 0-50°C mus be se in he con roller ( 5.7.2.), for he cali-

bra ion process. During calibra ion, he hea conduc or mus be a he reference empera ure o ensure

ha regula ion is exac . By s andardizing he vol age signal (Ur) and he curren signal (Ir), he reference

resis ance for he differen empera ure coefficien s is always wi hin he same resis ance range. If 20 °C

has been selec ed as he reference empera ure, hen hea conduc or's R20 is direc ly de ermined as he

reference resis ance. If a hea conduc or empera ure o her han 20 °C has been selec ed for calibra ion,

hen he de ermined reference resis ance corresponds o he empera ure coefficien s above or below he

value for he R20. The reference resis ance is displayed for one second a calibra ion s age 4 as an ac u-

al value and a he ac ual value ou pu . A a reference empera ure of 20°C, 70%-80% of he se empera-

ure range is displayed as an ac ual value or he ac ual value ou pu vol age amoun s o 7-8V. For he

en ire range of he reference empera ure of 0-50°C he ac ual value display is wi hin a range of 60%-

100% and he vol age a he ac ual value ou pu is wi hin a range of 6-10V.

3.2.5. Temperature comparison time: ( 5.7.3.) The aim of he empera ure reference ime is o ensure

ha he reference resis ance can only be de emined when he hea conduc or has comple ely cooled

down. During he comparison period, he ac ual value display goes down o from 100% o 0% of he con-

roller's se empera ure range. During his reference ime, he signal a he ac ual value ou pu declines

from 10 V o 0 V. Times of 15 or 30 s can be chosen for he empera ure reference ime.

3.2.6. Check reference resistance: Here he reference resis ance is checked af er he empera ure

comparison period has expired. If calibra ion akes place on a hea conduc or ha has cooled down s ill

fur her during he course of he empera ure reference ime, he en ire calibra ion will be discarded and

he procedure au oma ically res ar ed. Once he reference resis ance has been successfully checked

from he se reference empera ure, he empera ure coefficien selec ed and he calcula ed reference

resis ance, he PIREG-D2 calcula es he hea conduc or’s R20 (resis ance a 20°C).

The reference resis ance measured is displayed for one second a he ac ual value ou pu . The same

vol age se a he ac ual value ou pu as when he reference resis ance was de ermined ( 3.2.4).

3.2.7. Determine the P-factor: The P-fac or of he sealing ransformer/hea conduc or combina ion is

de ermined by specific hea ing a a cons an ac ua ing variable. The hea conduc or is ei her warmed by a

maximum of approx. 60 K or charged for a maximum of 120 ne work periods wi h a defined con rol value.

The o al amplifica ion of he con rol sys em is calcula ed from he measuremen of he power fed in o he

hea conduc or and he measuremen of he empera ure increase of he hea conduc or. The P-fac or for

he PIREG-D2 is calcula ed from his.

In he case of highly adverse condi ions in he sealing ransformer and hea conduc or combina ions or

he mains supply, he PIREG-D2’s P-fac or can be correc ed manually wi hin a range of 30…250 % (

5.5.4.).

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

9

3.2.8. Set initialising remanence: The sof swi ch-on process is performed by se ing he ini ialising

remanence, in order o connec he sealing ransformer af er calibra ion, wi hou curren surges. The ini-

ialising remanence se ing las s 80 ms wi h EI ransformers and 300 ms wi h oroidal core ransformers

(a a mains frequency of 50Hz).

3.2.9. Temperature-coefficient correction: Tolerances in he empera ure coefficien s can be correc ed

by his fea ure. These resul from he dispersion of he me allurgical composi ion of he hea conduc ors.

In Calibra ion S ep 9, he hea conduc or is hea ed up in eigh empera ure s ages by he PIREG-D2. The

PIREG-D2 hen compares i s ac ual-value empera ure wi h he hea conduc or’s ac ual empera ure,

which is ransmi ed o i as a se value or direc ly as he value of he ex ernal hermome er exTM.

The leng h of he s eps is a resul of he selec ed empera ure range. The firs empera ure s ep is always

50°C. The empera ure of he eigh h empera ure s ep is 20% below he final value of he selec ed em-

pera ure range. The six o her empera ure s eps are equidis an be ween hese. For he 300 °C empera-

ure range, his gives he empera ures 50, 77, 104, 131, 159, 186, 213 and 240°C. For he 500 °C em-

pera ure range, his gives he empera ures 50, 100, 150, 200, 250, 300, 350 and 400°C.

The hea conduc or's ac ual empera ure mus be se as a se value in he display uni or direc ly repor ed

back o he PIREG-D2 as a measuremen by he ex ernal hermome er exTM via he RS232 in erface.

Devia ions of up o ±20 % be ween he calcula ed ac ual value empera ure and he ac ual empera ure of

he hea conduc or can be correc ed ( 5.7.4.). The correc ion process is con rolled by he “S ar ”/”Hea ”

selec ion poin on he Working menu, he “S ar ” sinal or by command. When he TK correc ion hea ing

period is se accordingly, he correc ion process can also run au oma ically.

The hree relay ou pu s of he PIREG-D2 can be programmed o provide a con rol message o open and

close he hea seal jaw bar, while he empera ure-coefficien correc ion is in process. When programmed,

he chosen relay is ac ua ed af er a delay of 250 ms and when he ac ual empera ure has exceeded 95%

of he desired empera ure. The chosen relay is released when he hea seal band's ac ual empera ure is

repor ed back o he PIREG-D2. The nex hea -up s age is approached using he Tc correc ion con rol

message wi h a delay of 250ms o allow he hea seal jaw o open before hea ing. (from

V1.00/1.07/1.29/1.23)

The empera ure coefficien correc ion can be saved, so ha i does no have o be performed again in he

case of a new calibra ion process, bu only when he hea conduc or is changed ( 5.2.5.).

Performing the temperature coefficient correction:

- manual operation: The hea conduc or's ac ual empera ure is repor ed back o he PIREG-D2 as a se

value. There is a swi ch o he nex empera ure hea ing s ep, wi h he rising edge of he “S ar ” signal.

Af er he hea conduc or has reached a uniform empera ure he empera ure se as he se value is aken

over as he ac ual empera ure of he hea conduc or wi h he falling edge of he “S ar ” signal. Opera ion

can also occur wi h he “S ar ”/”Hea ” selec ion poin in he working menu ( 5.2.).

Af er hea ing up o he nex empera ure s age, for he empera ure o be accep ed i is necessary o wai

un il he hea conduc or has ac ually accep ed he new empera ure. The ac ual value display and he

ac ual value ou pu show he PIREG-D2’s corresponding ac ual value empera ure, s ill uncorrec ed.

- manual operation with the external thermometer exTM: The empera ure coefficien correc ion is

also con rolled by he “S ar ” signal resp. he “S ar ”/”Hea ” selec ion poin in he working menu, as de-

scribed above. The hea conduc or's ac ual empera ure is measured wi h he hermome er exTM which is

connec ed o he PIREG-D2’s RS232 in erface. The PIREG-D2 au oma ically ries o es ablish a connec-

ion wi h he hermome er exTM a he beginning of he empera ure coefficien correc ion. As soon as a

connec ion o he hermome er exTM has been es ablished he measured value is displayed ( 5.2.).

If he hermome er DTM3000 is using as ex ernal hermome er exTM, he PIREG-D2 au oma ically se

empera ure uni o he selec ed empera ure uni of he display uni ( 5.8.). Ensure ha he same em-

pera ure uni is se on he TM6 hermome er and on he PIREG-D2 display uni ( 5.8.).

- automatic temperature coefficient correction: The ex ernal hermome er exTM mus be connec ed o

he PIREG-D2 for he au oma ic empera ure coefficien correc ion and he se value for he Tc correc ion

hea ing ime mus be grea er han zero. The hea ing ime is he period un il he hea conduc or has

reached a uniform empera ure a a empera ure s age. The hea ing ime is se in he display uni or by

command ( 5.7.3.). The PIREG-D2 runs hrough he au oma ic empera ure coefficien correc ion on i s

own and remains a each empera ure s age for he prese hea ing ime

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

10

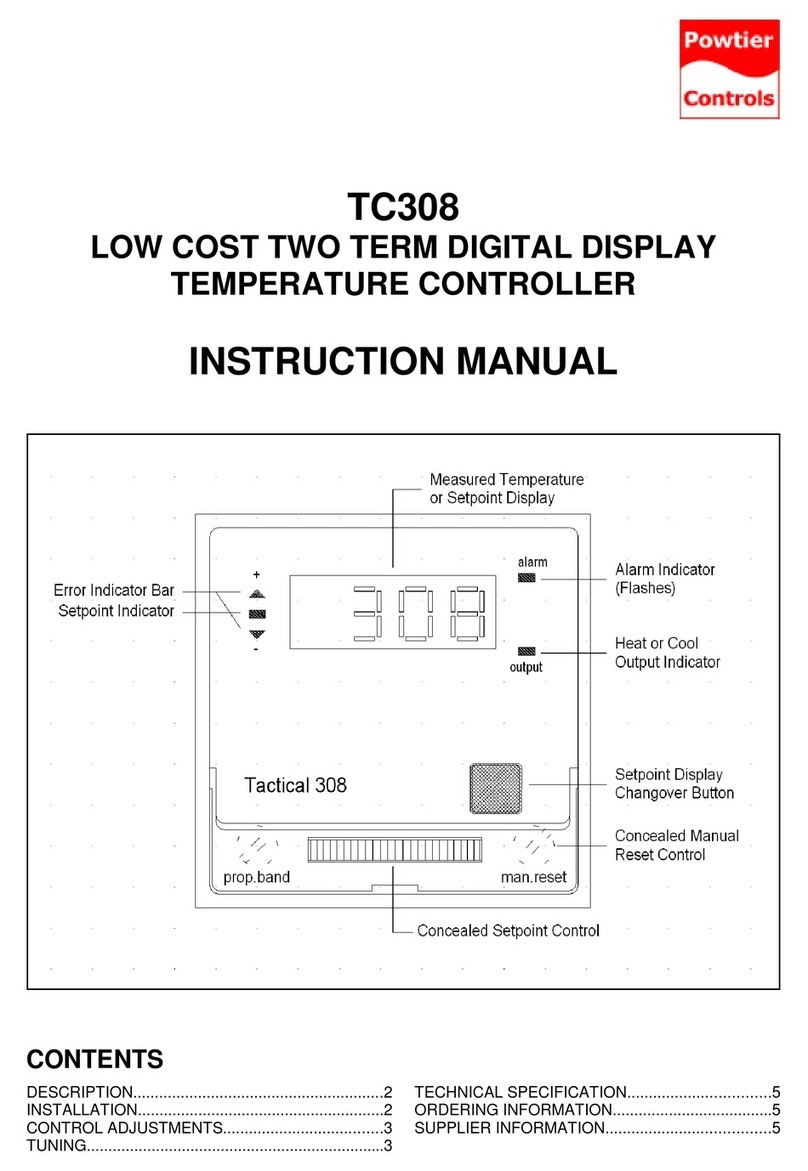

Figure 1: Calibration sequence

For each calibra ion, Calibra ion S eps 1 o 8 mus be comple ed by he con roller. S ep 9 is an op ional

calibra ion func ion ( 5.7.4.). If an error occurs during he individual calibra ion s eps, he PIREG-D2

s ops he calibra ion procedure and begins a new a emp . Af er he fif h a emp i abor s he calibra ion

process wi h an error message ( 3.7.).

Af er successful calibra ion, he PIREG-D2 re urns o he Off s a e.

So ha he hea conduc or's R20 reference resis ance is se correc ly, calibra ion mus be performed

when he hea conduc or is a he reference empera ure de ec ed. The ime required for a calibra ion

process is influenced by various fac ors. The vol age level on he hea conduc or, he curren passing

hrough i , he Ur and Ir phase shif and he P-fac or of he sealing ransformer-hea conduc or combina-

ion de ermine he dura ion of calibra ion. The con roller requires a maximum of 46 resp. 60 s for one

calibra ion process. (from V1.00/1.23/1.30/1.25)

If he calibra ion process is no successful, e.g. because he P-fac or has been de ermined incorrec ly, he

con roller makes ano her four a emp s before repor ing an error. In his case, he maximum calibra ion

ime can amoun o 230 resp. 305 s, depending on he empera ure reference ime.

If he calibra ion mode “ ew calibration” is chosen, he con roller always swi ches o calibra ion imme-

dia ely af er a power-on or af er a rese and carries ou a new calibra ion. Calibra ion can also be s ar ed

in he OFF or error s a e wi h he signal “Calibra ion S ar ” or from he Calibra ion selec ion menu of he

display uni .

If he calibra ion mode “Save” is chosen, he con roller swi ches o calibra ion when in an Off- or error

s a e or before power-on only when he “Calibra ion S ar ” signal is applied. Calibra ion can also be s ar -

ed in he Off- or error s a e from he Calibra ion selec ion menu on he display uni ( 5.2.5.). In his ype

of calibra ion, he calibra ion values are saved in a non-vola ile memory and are loaded immedia ely af er

a power-on or he “Rese " signal.

3.2.10. Single-point temperature coefficient correction: Wi h he single-poin empera ure coefficien

correc ion, he hea conduc or’s empera ure coefficien olerances can be correc ed for jus one opera ing

poin . For his opera ing poin he hea conduc or’s ac ual empera ure is repor ed back o he PIREG-D2

as a se value or direc ly as a measuremen of he hermome er exTM. The single-poin empera ure coef-

ficien correc ion is carried ou ou side he s andard calibra ion and is s ar ed from he Off-s a e. The sin-

gle-poin empera ure coefficien correc ion has one Off- and one On-s a e. Af er he single-poin empera-

ure coefficien correc ion has been s ar ed, he PIREG-D2 is in he Off s a e. When he PIREG-D2 is in

he On-s a e, he hea ing conduc or is hea ed o he empera ure which was se as he se value in he

Off-s a e. Af er hea ing he empera ure is only accep ed when he hea ing conduc or has defini ely

reached he empera ure. The ac ual value display or he ac ual value ou pu show he PIREG-D2’s ac ual

value empera ure, s ill uncorrec ed. The single-poin empera ure coefficien correc ion is ended upon

exi ing he On-s a e. The correc ion process is con rolled by he “S ar ”/”Hea ” selec ion poin in he work-

ing menu, he “S ar ” single or by command. When he TK correc ion hea ing period is se accordingly, he

one-poin empera ure coefficien correc ion process can also run au oma ically.

Devia ions of up o ±20 % be ween he calcula ed ac ual value empera ure and he ac ual empera ure of

he hea ing conduc or can be correc ed. The single-poin empera ure coefficien correc ion can only be

performed if he normal empera ure coefficien correc ion covering eigh poin s ( 3.2.9.) has no been

carried ou during calibra ion. The single-poin empera ure coefficien correc ion is rese a each calibra-

ion.

The empera ure coefficien correc ion can be saved, so ha i does no have o be performed again in he

case of a new calibra ion process, bu only when he hea conduc or is changed ( 5.2.5.)

Performing the single-point temperature coefficient correction:

- manual operation: Single-poin empera ure coefficien correc ion is s ar ed from he Calibra ion selec-

ion menu on he display uni ( 5.2.5.) of he PIREG-D2 or by command when he PIREG-D2 is in he

Off-s a e. The PIREG-D2 re ains he empera ure se as arge value as he empera ure of he opera ing

poin as long as a low-signal is applied as “S ar ” signal. When a high-signal is applied as “S ar ” signal

0

16

33

50

66

Ac . val.

display

83

100 %

0

1.66

3.33

5

6.66

Ac . val.

ou pu

8.33

10 V 1. Ini . 2. Calibra e

inpu amplifier

3. De ermine

phase shif

Calibra ion-

reference ime

4. De ermine reference resis ance

5. Calibra ion-

reference ime

6. Check reference resis ance

7. De ermine

P-fac or

S ar

Signal

8. Ini ialising remanence-se ing

1 2

50°C

9. Tempera ure coefficien correc ion

43 5 6 7 8

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

11

he PIREG-D2 hea s he hea ing conduc or o he empera ure of he opera ing poin . Now he ac ual

empera ure of he hea ing conduc or is se as arge value. When a low-signal is applied again as "S ar ”

signal, he PIREG-D2 calcula es he correc ion fac ors for he single-poin empera ure coefficien correc-

ion and saves hese values, if "Save" was selec ed as calibra ion mode. The single-poin empera ure

coefficien correc ion using he “S ar ”/”Hea ” op ion from he Working menu is con rolled as described

above. The s a us of he single-poin empera ure coefficien correc ion is indica ed by he corresponding

opera ing s a us symbols in he symbol field of he Working menu on he display uni ( 5.2.).

- manual operation with the external thermometer exTM: The single-poin empera ure coefficien

correc ion is s ar ed and con rolled as described above. The ac ual empera ure of he hea ing conduc or

is measured wi h he hermome er exTM which is connec ed o he RS232 in erface of he PIREG-D2.

The PIREG-D2 au oma ically ries o es ablish a connec ion wi h he hermome er exTM a he beginning

of he singlepoin empera ure coefficien correc ion. As soon as a connec ion o he hermome er exTM

has been es ablished he measured value is displayed ( 5.2.).

- automatic single-point temperature coefficient correction: The PIREG-D2 mus be connec ed o he

hermome er exTM and he se value for he Tc correc ion hea ing ime mus be grea er zero for he au-

oma ic single-poin empera ure coefficien correc ion. The hea ing ime is he period un il he hea ing

conduc or has reached a uniform empera ure in he On-s a e of he single-poin Tc correc ion. The hea -

ing ime is se in he display uni or by command ( 5.7.3.). Au oma ic single-poin empera ure coeffi-

cien correc ion is s ar ed as described above for manual opera ion. The PIREG-D2 undergoes he au o-

ma ic single-poin empera ure coefficien correc ion independen ly and remains in he On s a e for he

prese hea ing ime.

3.2.11. P-factor correction: The P-fac or correc ion is used o la er correc he calibra ed P-fac or manu-

ally ( 3.2.7.), in he case of he sealing ransformer-hea conduc or combina ion or he mains connec ion

being in highly adverse condi ions. The correc ion range is 30…250 %.

The P-fac or correc ion is se in he display uni or by command ( 5.2.5.). The P-fac or correc ion value

is no rese during a calibra ion process, since i is sys em-dependen .

3.3. Off-state

In he Off s a e, he PIREG-D2 con inually measures he hea conduc or's resis ance, calcula es i s em-

pera ure from ha and shows he la er in he display as an ac ual value or issues i as an ac ual value.

For his purpose, a posi ive and nega ive power line half-wave always of he same polari y wi h a fixed

curren conduc ion angle (1.8 ms a 50 Hz line frequency) is applied o he ransformer, for each meas-

uremen . The in ervals be ween he measuremen s depend on he hea conduc or empera ure. When he

hea conduc or has reached a empera ure of 20°C, he ime be ween measuremen s is 1.5 s. A a em-

pera ure of 300°C, he ime be ween measuremen s is only 100 ms.

Since power is in roduced o he hea conduc or for measuring he resis ance, i hea s up in he Off s a e,

depending on he hea conduc or vol age.

The con roller swi ches from he Off s a e o he On s a e as soon as he “S ar ” signal is applied. If he

“Calibra ion S ar ” signal is applied, he PIREG-D2 swi ches o calibra ion mode and re urns o he Off

s a e when calibra ion has been successful. The PIREG-D2 remains in he Off s a e, even when he “Cal-

ibra ion S ar ” signal is s ill presen (for evalua ing he rising edge). A corresponding con rol is also possi-

ble wi h he “S ar ”/”Hea ” selec ion poin in he Working menu ( 5.2.). Single-poin empera ure coeffi-

cien correc ion can be s ar ed from he Calibra ion selec ion menu of he display uni of he PIREG-D2

when in he Off-s a e ( 5.2.5.).

3.2.1. Measurement pulse-pause: In he off s a e, he measuremen pulse-pause can be swi ched on

and off per command or, if configured, via he con rol inpu s ( 5.6.2.). When measuremen pulse-pause

is ac iva ed, he PIREG-D2 s ops sending measuremen pulses o he sealing ransformer in order o de-

ermine he empera ure of he hea ing conduc or. (from V1.00/1.23/1.30/V1.25)

The ac ual value ou pu indica es he value de ermined las . Only he moni oring of he mains vol age and

he device func ion is s ill ac ive. All o her moni oring func ions ha rela e o he measuremen pulses are

disabled.

The measuremen pulse-pause is for applica ions in which he primary or secondary circui of he sealing

ransformer has o be in errup ed during opera ion wi hou he PIREG-D2 swi ching o he error s a e.

Wi h he s ar of a sealing process, a calibra ion or a rese , he measuremen pulse-pause is au oma ically

ermina ed.

3.2.2. Calibration switching: The PIREG-D2 offers he possibili y o save wo calibra ions and o swi ch

be ween hem (from V1.00/1.23/1.30/V1.25). The calibra ion swi ching is ac iva ed by command or by

configuring he con rol inpu s ( 5.6.2.). In he off s a e, a changeover be ween he wo calibra ions is

made by command or, if configured accordingly, via he con rol inpu s. For he calibra ion swi chover, a

delay ime can be se in which he PIREG-D2 execu es a correspondingly long measuring pulse-pause

during he swi chover.

The hea ing conduc ors of he wo calibra ions mus be he equal for he empera ure coefficien , empera-

ure range and he o her calibra ion se ings ( 3). A possible empera ure coefficien correc ion is per-

formed separa ely for each calibra ion. The PIREG-D2 performs i s own calibra ion for each hea conduc-

or, which is also s ored separa ely. The validi y of he calibra ion se ings is saved for each calibra ion. If

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

12

he se ings change, he validi y of bo h calibra ions will be rese and a new calibra ion will have o be

performed for bo h hea ing conduc ors, s ar ing wi h calibra ion 1.

3.4. On state

In he On-s a e, he PIREG-D2 con rols he empera ure of he hea ing conduc or in accordance wi h he

arge value. A phase angle con roller is used. The con roller re urns o he Off s a e when he “S ar ” sig-

nal is removed. A corresponding con rol is also possible wi h he “S ar ”/”Hea ” selec ion poin in he

Working menu ( 5.2.).

When sequence con rol is ac iva ed he On s a e addi ionally consis s of he S ar delay and he cooling

phase ( 5.4.).

3.5. Sequence control

The sequence con rol can be swi ched on and off ( 5.4.). If he sequence con rol is swi ched off, hen a

sealing process wi h he se desired empera ure is ac iva ed and deac iva ed af er he “S ar ” signal. If

he sequence con rol is swi ched on, a sealing cycle wi h subsequen s ar delay, sealing ime and cooling

ime will be s ar ed au oma ically af er he “S ar ” signal.

3.5.1. Preheating: Prehea ing is used o prehea he hea ing elemen during a pause in a sealing process

or a sealing cycle. Prehea ing is con rolled via he “Prehea ” signal. When he “Prehea ” signal is applied,

he PIREG-D2 adjus s he hea conduc or empera ure o he prese prehea ing empera ure. The pre-

hea ing empera ure can be se irrespec ive of he desired empera ure. Prehea ing is also possible when

he sequence con rol is swi ched off.

3.5.2. Start delay: S ar delay is he delay ime af er he “S ar ” signal has been applied and un il sealing

ime s ar s. During he s ar delay he hea conduc or is no hea ed by he PIREG-D2. If prehea ing has

been swi ched on, i con inues.

3.5.3. Sealing time: During he sealing ime he PIREG-D2 adjus s he he hea conduc or empera ure

according o he se arge value. Depending on he se ings he sealing ime s ar s when his sequence

phase is reached or af er he ac ual empera ure has exceeded 95% of he desired value.

3.5.4. Cooling phase: The sealing ime is followed by he cooling phase. Depending on he se ing he

hea ing conduc or is o cool down for a se ime or o he prese empera ure during he cooling phase.

The cooling empera ure can ei her be se as an absolu e value or as percen age of he desired value.

3.6. Monitoring

3.6.1. Temperature monitor: The empera ure moni or is a moni oring fea ure enabled and se in he

display uni ( 5.5.1) or by command. During he sealing process, he ac ual empera ure value is moni-

ored o ensure ha i is wi hin an empera ure ok range. If he ac ual value comes ou of he empera ure

ok range af er expiry of he s abilisa ion ime, he PIREG-D2 en ers he Faul s a e, displaying Error 83 or

84. The s abilisa ion period is res ar ed, in he case of a change in he se value by over 2°C.

3.6.2. Heating monitor: The hea ing moni or is a moni oring fea ure enabled and se in he display uni

( 5.5.2.) or by command. Wi h his fea ure, he empera ure rise is moni ored af er he “S ar " signal has

been applied. If he ac ual empera ure value does no reach he se empera ure ok range wi hin he se

hea ing period, he PIREG-D2 en ers he Faul s a e, displaying Error 85. If he se value increases by

more han 5°C, he hea ing moni or is res ar ed.

3.6.3. Start monitor: A sealing cycle can be abor ed by he “S ar ” moni or. The sealing cycle is in errup -

ed when he “S ar ” signal is no longer applied during he running sealing cycle. An Emergency S op func-

ion will hen be execu ed. ( 5.5.)

3.6.4. Communication monitor: The communica ion moni oring is an addi ional moni oring func ion for

he wo in erfaces of he con roller PIREG-D2, which only wi h one command is independen ly ac iva ed

and se for each in erface. The communica ion moni or is an addi ional moni oring fea ure for he PIREG-

D2 con roller’s wo in erfaces, which are au oma ically enabled and se wi h one single command. This

func ion moni ors he communica ion via he in erfaces. If communica ion via he in erface is in errup ed

for a longer ime han he se down ime, he PIREG-D2 en ers Faul s a e.

3.7. Error state

The error s a e is indica ed on he PIREG-D” only when an error occurs. The con roller moni ors he line

vol age, he empera ure of he hea ing conduc or, he values of he vol age and curren measuremen s a

he hea ing conduc or, he calibra ion parame ers and he moni oring func ions.

The Alarm ou pu and he Alarm LED are swi ched in he error s a e. The ac ual value ou pu is also cy-

cled in some error cases. The vol age a he ac ual value ou pu hen changes every second be ween he

vol ages applicable o he differen errors ( Table 1). The error s a e can only be cancelled by swi ching

off he power supply, he „Rese “ signal and „Calibra ion S ar “. Wi h errors 10…33 he error s a e canno

be cancelled wi h he “Calibra ion S ar ” signal.

In he error s a e he Error menu can be called from he display uni ( 5.2.4.). Here, he error number,

an error descrip ion and possible correc ive ac ions are displayed.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

13

3.7.1. Possible errors: Table 1

o.

Error

Actual

value

output

Corrective action

10 Device error 4.66 / 0 V perform rese

21 in ernal error 4.00 V perform rese

22 read-wri e error in he non-vola . Memory

31 mains vol age oo low 3.33 V check mains connec ion and

perform rese

32 mains vol age oo high

33 mains frequency error

40 curren signal Ir and vol age signal Ur

oo

low

2.00 V perform calibra ion and

check hea ing circui

50 vol age signal Ur oo low 1.33 V perform connec ion o vol age measure-

men Ur and calibra ion

60 curren signal Ir oo low 0.66 V check connec ion o curren measuremen

Ir and perform calibra ion

71 curren signal Ir oo high 5.33<>10 V

check hea conduc or and

perform calibra ion

72 vol age signal Ur oo high check connec ion o vol age measure-

men Ur and perform calibra ion

73 curren sig. Ir and vol age sig. Ur oo high perform calibra ion

81 hea conduc or empera ure oo high 2.66 V check hea conduc or and

perform calibra ion

82 hea conduc or empera ure oo low

83 empera ure moni or ( 3.6.1.) empera-

ure oo high

check se ing,

check hea conduc or and

perform calibra ion

84 empera ure moni or ( 3.6.1.) empera-

ure oo low

85 hea ing moni or ( 3.6.2.)

87 empera ure s ep down

(from V1.00/1.07/1.29/1.23)

loose con ac ,

check hea ing circui

88 empera ure s ep up

(from V1.00/1.07/1.29/1.23)

90 da a error -

saved calibra ion values do

no ma ch se ing

6.00<>10 V

perform calibra ion

91 communica ion

moni or RS232 in erface

( 3.6.4)

check RS232 in erface connec ion

92 in ernal communica ion moni or 1 perform rese

93 communica ion moni or USB in erface (

3.6.4)

check USB in erface connec ion

94 in ernal communica ion moni or 2 perform rese

95

communica ion moni or RS232 in erface

for exTM hermome er

check RS232 in erface connec ion

and exTM hermome er

Calibration error:

101

curren signal Ir and vol age signal Ur oo

high

8.00<>10 V

check dimensioning

102

curren signal Ir and

vol age signal Ur oo

low

check hea conduc or connec ion and

dimensioning

103

curren signal Ir oo low and vol age signal

Ur oo high

check dimensioning

104

curren signal Ir oo high and vol age sig-

nal Ur oo low

105

R20 canno be de ec ed

106

P-fac or unable o be de ermined

111

vol age signal Ur oo low 7.33<>10 V

check connec ion o vol age measure-

men Ur and dimensioning

112

vol age signal Ur oo high check connec ion o vol age measure-

men Ur, hea conduc or and

dimensioning

113

vol age signal Ur uns able

(from V1.00/1.01/1.19/1.18)

check connec ion o vol age measure-

men Ur

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

14

121

curren signal Ir oo low 6.66<>10 V

check curren measuremen Ir connec ion

and dimensioning

122

curren signal Ir oo high check hea conduc or and

dimensioning

123

curren signal Ir uns able

(from V1.00/1.01/1.19/1.18).

check curren measuremen Ir

connec ion

131

reference empera ure selec ed oo high 8.66<>10 V

correc se ing

132

range of empera ure coefficien correc-

ion exceeded

repea calibra ion

133

parame er error - cons ancy and dynam-

ics of he selec ed empera ure coeffi-

cien s are below he empera ure range

change se ings

3.8. Relay functions

The following same func ions can be se independen ly for each of he message and he wo con rol relay

ou pu s.

3.8.1. Temperature function: The relay is ac ua ed if he ac ual empera ure is in he “Tempera ure ok”

range. A delay during which he ac ual empera ure has s abilized can be se wi h he s abiliza ion ime.

The holding func ion is an addi ional func ion during which he relay remains ac iva ed af er he welding

cycle and un il s ar of he following welding cycle.

3.8.2. Sequence function: This relay func ion is used o se he condi ions when he relay is ac ua ed:

- Active upon “Start” signal: The relay is ac ua ed as soon as he “S ar ” signal is applied and is re-

leased when he cooling ime has elapsed.

- Active when temperature is reached: The relay is ac ua ed when he ac ual empera ure has exceed-

ed 95% of he desired value and is released when he cooling ime has elapsed.

- Active during heating phase: The relay is ac ua ed while he welding ime is running off.

- Active during cooling phase: The relay is ac ua ed during he cooling phase.

- Calibration Ok: The relay is no ac ua ed during calibra ion. I is ac ua ed again af er a successful cali-

bra ion. End of calibra ion is indica ed wi h he “Calibra ion Ok” func ion.

- Active while Alarm: The Relay is ac ua ed while he error s a e.

- Active as Temperature-coefficient correction control message: The relay is used as con rol mes-

sage o open and close he welding bar while he empera ure-coefficien correc ion (8- poin ). The relay

is ac ua ed af er a delay of 250 ms and when he ac ual empera ure has exceeded 95% of he desired

value. The relay is released when he hea conduc or's ac ual empera ure is repor ed back o he PIREG-

D2. (from V1.00/1.07/1.29/1.23)

3.8.3. Time pulse function: The following swi ching pulses can be genera ed wi h he relays using he

“Time pulse” func ion:

- Heating phase: The relay is ac ua ed for he se pulse ime when he sealing ime s ar s, i.e. during

hea ing of he hea ing conduc or.

- Cooling phase: The relay is ac ua ed for he se pulse ime a he s ar of he cooling phase.

- Pulse end: The relay is ac ua ed for 500 ms a he end of he cooling phase.

3.9. Display functions

3.9.1. Languages: The following languages can be se for he PIREG-D2 display uni :

German English French I alian Du ch Russian

3.9.2. Brightness: The brigh ness of he background ligh ing is se as a percen age value in a range of

30…100 % in 5%-s eps.

3.9.3. Hold mode: If he “Hold” mode is ac iva ed he ac ual empera ure value which was measured a

he end of he welding process or he welding ime will also displayed. You can selec whe her he meas-

ured ac ual value is only displayed for 2 seconds or un il he following welding process or welding cycle is

s ar ed.

3.9.4. Cycle counter: The PIREG-DIS display uni has a cycle coun er (0…9999999) for coun ing he

welding cycles. Der Zyklen-Zähler kann zurückgese z werden. Bei einem Überlauf beginn der Zähler

wieder bei Null.

In addi ion he PIREG-DIS display uni has a o al cycle coun er (0…999999999) which is used as „ser-

vice life coun er“, bu canno be rese .

3.9.5. Saving: Wi h he display uni se ings can be saved and res ored. One dis inguishes be ween pa-

rame er se s ( 5.9.1.) and fac ory se ings ( 5.9.2.). The se ings for differen applica ions of he weld-

ing machine are saved using he five parame er se s so ha he machine can be adjus ed quickly when

he applica ion was changed. One basic se ing of he machine can be saved and res ored wi h he fac o-

ry se ings. In addi ion he PIREG-DIS display uni can be rese o i s fac ory se ings.

3.9.6. Releases: The display uni has hree release levels ( 5.8.4.) wi h which differen user-dependen

opera ing levels can be realized. Each release level has i s own release number. All release numbers are

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

15

fac ory-se o “0000”. This means ha all release levels are ac iva ed af er he display uni was swi ched

on and he display uni can be adjus ed. The following se ings are assigned o he individual release lev-

els.

- Level 0: Con rol via he inpu s and bu ons of he display uni (unpro ec ed).

- Level 1: - Se ing of level 0

- Targe value

- Welding ime and cooling ime

- Reference empera ure for calibra ion

- Reading parame er se s 1…5

- Level 2: - Se ing of level 1

- all con roller se ings

(se ings of he TC empera ure, ime, calibra ion and arge value)

- Saving parame er se s 1…5

- Level 3: - Se ing of level 2

- all se ings of he PIREG-D2

3.9.7. Temperature unit: Wi h he display uni he empera ure values can be indica ed in [°C] or [°F] (

5.8.). The empera ure uni is only used for display of he empera ure values. The display uni con inues

o opera e in ernally wi h he uni [°C] even when [°F] is displayed which resul s in empera ure leaps of 2

°F when he uni [°F] is se as empera ure value.

If he hermome er DTM3000 is using as ex ernal hermome er exTM, he PIREG-D2 au oma ically se

empera ure uni o he selec ed empera ure uni of he display uni . When working wi h he TM6 her-

mome er he same empera ure uni mus be se on he hermome er and on he PIREG-D2 display uni .

4. Operation

4.1. Keys

The following five keys are used for opera ing he PIREG-D2 display uni :

Up

Down

Righ

Lef

Accep

Ok

4.1.1. Cursor: The cursor

is moved o he possible se ing i ems using he arrow keys in he display.

There are numerical values which can be se , op ions which can be selec ed and menu i ems for calling

ano her menu. An emp y riangle

is used as symbol for he cursor. The cursor remains on he menu

i em which was selec ed las af er he menu was changed.

4.1.2. Setting numerical values: Move he cursor

o he numerical value o be se and confirm wi h he

Ok

bu on. As soon as he value is changed using he bu ons

and

he value s ar s flashing a a fre-

quency of 1 Hz indica ing ha he value was changed. The value is accep ed af er he

Ok

bu on was

pressed and s ops flashing. Press he

key o cancel he changes and o res ore he original value.

If he

and

bu ons are pressed for more han 1 second he numerical value s ar s o run a a ra e of

change of 10 dig/sec.. If he bu on is pressed more han 3 seconds he ra e of change increases o 100

dig/sec..

4.1.3. Selecting functions: Move he cursor

o he i em o be selec ed. Press he

Ok

bu on o selec

he i em. A filled riangle

is used as selec ion cursor. If he cursor

and he selec ion cursor

are on

he same func ion, he display changes be ween he selec ion cursor and he cursor a a frequency of

1Hz.

4.1.4. Acceptance of the settings: The se numerical values are accep ed by pressing he

Ok

bu on. If

he se ing is no accep ed wi hin 3 seconds af er i was changed wi h he Ok bu on, hen he se ing will

be discarded and he old value will be fur her used.

The numerical values can also be accep ed au oma ically, i.e. he se ing will be accep ed if i was no

changed for more han 3 seconds. The au oma ic accep ance is ac iva ed and deac iva ed in he “Opera -

ing” menu ( 5.8.3.).

4.1.5. Menu change: Move he cursor

o he menu i em if you wan o change he menu. If he menu

i em is also a op ion, you should use he bu on

o change he menu. Press he

Ok

bu on if i is a mere

menu i em. Exi he menu wi h he bu on

.

Swi ch o he las changed se ing in a menu by pressing he

+

simul aneously in he Working menu.

4.1.6. Menu return: If no changes were made, he program will re urn from all menus o he Working

menu af er 20 seconds a he la es . Press he key combina ion

+

o jump o he posi ion in he menu

where he program re urned o he Working menu. The menu re urn can be ac iva ed and deac iva ed in

he Opera ing menu ( 5.8.3.).

4.1.7. Locking: A locking which preven s unin en ional changes of he se ings is provided which can be

ac iva ed and deac iva ed by pressing he key combina ion

+

+

Ok

. Firs , however, he locking mus

be ac iva ed in he Display Se ings menu ( 5.8.).

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

16

4.1.8. Execution prevention: If a se ing or menu change is no possible, he cursor

changes o a di-

agonal cross for one second o indica e his condi ion.

No e: During calibra ion and On s a e, mos se ings on he PIREG-D2 can no be changed.

4.2. Leuchtdioden

4.2.1.

Power

:

The green LED “Power” indica es ha he mains vol age is applied o he

PIREG-D2.

4.2.2.

Heat

:

The yellow LED “Hea ” indica es ha a welding cycle is execu ed if he se-

quence con rol is swi ched on. If he sequence con rol is swi ched off, his

LED only signalizes he welding process i self.

4.2.

3

. Alarm

:

The red LED “Alarm” indica es ha an error is presen and ha he PIREG-

D2

is in he faul condi ion. The faul i self is shown in plain ex in he Error

menu (5.2.4.).

4.3. Inputs

4.3.1. Start inputs: The PIREG-D2 has wo S ar inpu s. On he one hand, here is he S ar inpu (3) in

which he con rol opera es wi h an ex ernal vol age. On he o her hand, here is he S ar -Con ac inpu (7)

wi h con rol occurring by he inpu , for example, being connec ed o AGND (2) by a swi ch.

By applying he high signal o he S ar inpu (3) or applying he connec ion of he S ar -Con ac inpu (7)

o AGND (2), a sealing process or a sealing cycle is s ar ed. If he sequence con rol is swi ched on and

he “S ar ” moni oring func ion is deac iva ed, a sealing cycle will only be s ar ed wi h rising edge.

If he normal empera ure coefficien correc ion is selec ed during calibra ion via eigh poin s, he correc-

ion process is also con rolled by he S ar inpu s, during manual opera ion. The single-poin empera ure

coefficien correc ion is also con rolled by he s ar inpu s.

4.3.2. Preheat inputs: The PIREG-D2 has wo prehea inpu s. On he one hand, here is he Prehea

inpu (22) in which he con rol opera es wi h an ex ernal vol age. On he o her hand, here is he Prehea -

Con ac inpu (19) wi h con rol occurring by he inpu , for example, being connec ed o AGND (2) by a

swi ch.

If here is a high signal applied o he Prehea inpu (22) be ween wo sealing processes or wo sealing

cycles or he Prehea -Con ac inpu (19) is connec ed o AGND (2), he PIREG-D2 regula es he hea

conduc or empera ure o he se prehea empera ure ( 5.4.1.).

4.3.3. Calibration Start Input: Wi h a high signal a he Calibra ion S ar inpu (25) in he Off and Faul

s a es, he PIREG-D2 swi ches o he calibra ion s a e. Here, he con roller is adap ed o he combina ion

of hea conduc or and sealing ransformer. During he con roller's calibra ion func ion, he signal can re-

descend o low.

4.3.4. Reset Input: Wi h a high signal a he Rese inpu (26), he PIREG-D2 is rese o he Power On

s a e in he even of a faul even wi hou swi ching off a he mains.

The following wo inpu func ions can be configured independen ly for each of he four inpu s of he

PIREG-D2 ins ead of he above basic func ion ( 5.6.2):

4.3.5. Measurement pause: Wi h a high signal a he correspondingly configured inpu in he Off s a e

he PIREG-D2 s ops sending he measuremen impulse o he sealing ransformer. Therefore i is possi-

bly o work a he head conduc or circui wi hou o genera e an error. (from V1.00/1.23/1.30/1.25)

4.3.6. Calibration switching: Wi h a high signal a he correspondingly configured inpu in he Off s a e

he PIREG-D2 change from calibra ion 1 o he calibra ion 2. Wi h a low signal he PIREG-D2 change

back o he calibra ion 1. (from V1.00/1.23/1.30/1.25)

4.3.8. Set value input: A he se value inpu (23) he empera ure se value may also be se , as an al er-

na ive o se ing he se value in he PIREG-D2's display uni . An analogue vol age is used for he se ing

a he se value inpu . The selec ion regarding which se ing possibili y should be used for he empera ure

se value is made in he display uni ( 5.7.5.) or by command.

- Internal: The se value is se in he PIREG-D2's display uni ( 5.2.)

- U set value: Se he empera ure se value wi h an analogue vol age. The vol age se value range is 0-

10V. The only selec ed empera ure range is linearly imaged o he maximum se -value vol age , i.e. 10V

a he se value inpu corresponds o 300°C, if he selec ed empera ure range is 300°C.

- R set value: The empera ure se value is se by a po en iome er. in he case of he po en iome er, he

cu er is linked o he se -value inpu (23), he CW connec ion o he ac ual value ou pu (24) and he

CCW connec ion o he GND connec ion (20). In his se ing, he ac ual value ou pu opera es as a refer-

ence vol age source wi h an ou pu vol age of 10V. Pay a en ion o he direc ion of ro a ion when con-

nec ing he po en iome er. In he case of clockwise ro a ion on he po en iome er, he vol age should in-

crease a he se value inpu . The chosen empera ure range is imaged o he se value vol age, as de-

scribed above.

© 2019 TOSS GmbH & Co. KG -Verpackungssys eme- Alle Rech e vorbehal en! Nachdruck, auch auszugsweise, ohne unsere schrif liche Genehmigung nich ges a e !

17

4.4. Outputs

4.4.1. Actual Value Output: The ac ual value ou pu (24) supplies a vol age in he range 0-10V, propor-

ional o he hea conduc or’s empera ure. The vol age range rela es o he selec ed empera ure range,

i.e. 10V a he ac ual value ou pu corresponds o 300°C, if he selec ed empera ure range is 300°C. The

ac ual value ou pu can supply a maximum curren of 5 mA.

While he se value ou pu is being used wi h a po en iome er (“R se value” se ing) he ac ual value ou -

pu ac s as a cons an vol age source wi h an ou pu vol age of 10V.

4.4.2. Message relay output: Message relay ou pu 1 (21) provides a NO con ac , which works agains

he GND con ac (20). I can be se whe her he con ac is open or closed when he relay is ac ua ed. The

swi ching capaci y of he relay con ac is only designed for message func ions. The relay con ac has

been fac ory-se in such a way ha he relay con ac is closed when he relay is pressed.

4.4.3. Control relay outputs: The con rol relay ou pu s 1 (16/17/18) and 2 (27/28/29) each provide a

change-over con ac . The swi ching capaci y is only designed for con rol func ions.