ERS AK 6000 User manual

AK 6000

Maga

Wood Gasifying Boilers

Control System

User Manual

Elektronické riadiace systémy s.r.o. Polianky 18, 841 01 Bratislava www.ers.sk email: [email protected] Tel: 421 2 693 07 000

AK6000 - prevádzkový manuál

This document is intended for use with AK6000 –the electronic system for wood gasyfying

boilers control.

AK6000.X

The modular electronic control system for wood gasyfying heat-water or heat-air boilers. On

the basis of the choosed program effectively optimizes combustion procesess so the boiler is

able to generate appropriate medium in heating system. Indication .X means hardware

version of the AK6000 where X may be within 0 ÷ 3.

DUOLED

Double color light emitting diode used to show main state of the boiler.

Display

Grafic LCD display with 128x64 pixel, LED backlight.

Flash memory

Electrically Erasable Programmable Read Only Memory to preserve data even after

shutdown.

RWM

Read Write Memory is intended to save continuously processed data. They are erased after

shutdown.

AKBUS

System Bus connects modules of the AK3000 and provides powering and communication by

means of RS485 bus and other specialized signals.

Specification

Terminology

AK6000 - prevádzkový manuál

!

Warning - danger or risk of injury

!Important note or statement

Please read these instructions carefully before using the AK6000 control unit

Do not use the boiler until completely installed

When the boiler is ON you can not do the following

oremove enclosure from the electrical parts - for example electronic modules,

fans, sensors, thermostat etc.

oreplace the fuses

orepair damaged cables and modules etc.

Before removing the cover of the electrical parts or other apliances is important to

disconect the power cord from the AC outlet.

Do not operate the boiler unless all enclosure panels are properly in place

In case of failure detection or damaging any part is important

odo not touch any part of boiler

oimmediately disconect boiler out of the AC outlet

orefer all servicing to qualified service personnel

This appliance is not suitable for person which were not instructed by the responsible

operator for using the appliance or whose have physical and other disability which

prevents from the safe operation on the apliances

!

Improper connection of the equipment can result in risk of electric shock. Check with

qualified electrician or service representative if you are in doubt whether the boiler is properly

Safety Instructions

Important Symbols

AK6000 - prevádzkový manuál

This automatic system is intended to control the producing of heat-water or heat-air in wood gasyfying boilers. Basic principle of the

function is regulation of the water temperature by means of setting the amount primary air in combustion fireplace of boiler.

Supply of air is controlled by continous influence to the suction fan operating speed.

Two electronic modules create basic composition of the AK6000.0

AK6000D –Control Unit

AK5000S –Power Board

Grafic LCD display, 128x64 pixel, LED backligt

Two level power source 230VAC / 24 and 9 VDC

Five point touch-button

Two fan outputs - main fan and auxiliary fan

Duo LED ( red / green )

Water-pump output

20 pin connector to connect power board

Four temperature sensors T1..T4

! Two independent fuses F1,2/0,8A save system parts and fans in malfunction

Adjusting boiler by means of the LCD display, signal DuoLED and five

arrow button

Water temperature PID control in adjustable range 60 ÷ 85 °C by means

of the continuous regulation of the fan

Water pump switching in pulse mode provides suppresion of the low-

temperature corrosion

Two temperature sensors connection option: T1 (water sensor) and T2

(combustion sensor)

Emergency heat thermostat conecting option

It is possible to expand the basic configuration by Lambda-probe board or Ethernet board for remote control.

CONTROL SYSTEM CONFIGURATION

Basic Configuration AK6000.0

Basic Configuration Functions AK6000.0

AK6000 - prevádzkový manuál

- graphic display, 128 x 64 pixels, LED backlight for getting

information

- duoLED –total status OK ( green ) / Err ( red )

- button ▲- increasing adjusted value or switching depiction of

the measured values

button ◄- auxiliary fan power down or move the selection left

- button ►- choice back (ESC ) or move the selection right

- button ENTER

oshort pressing

power on the boiler, five arrow button depiction and subsequently you can power off boiler or

supply fuel ( suction fan goes to 100% )

fuel suply ending - after fuel suply is passed by

menu level or choice confirmation, data storage

olong ( 2 sec ) pressing –entrance to user operation settings

- button - decreasing adjusted value or switching depiction of the measured values

- current time

- boiler thermometer is installed

- power value of the boiler (16 –80kW)

- actual status of the boiler OFF/ON/END/boiler temp.

- combustion thermometer is installed

- water pump status –sign is flashing when water pump is ON

- boiler temperature –user depiction –it can be switched by ▲or button to next value

- boiler dealer

- current date

- combustion temperature

- instant speed of the main fan

GUIDE TO THE CONTROL UNIT

Operating Points AK6000.X

Operating Screen AK6000.X

AK3000 –User Manual

Boiler is OFF

Short pressing of the ENTER turns the boiler ON.

Long pressing of the ENTER gets the operator into the parameter settings

Start of the heating

Fan is working with 100% top speed

We can turn OFF the boiler by pressing ENTER and ◄subsequently

After the combustion temperature reaches value end+20°C in 30 minutes

long time interval the boiler is in combustion process otherwise the boiler turns off ( END status )

Water pump power ON

Water pump is working in pulse status first and then in permanent status

Boiler is prepared to fuel supply by means of the double pressing of the

ENTER( function ) –main fan goes to 100% top speed in suction

version or to 0% in blower version

Combustion

Continuous regulation of the fan keeps the boiler temperature on the acquired

value

Critical values of temperatures and thermostat automatic monitoring

Boiler maximal temperature overrun

Capture of the boiler max. temperature overrun ( T max = T requested + 10°C) or

at Tmax = 90°C

Fan power OFF. Back from MAX state gets boiler after decreasing under the

requested temperature.

Heating gets weaker

Top speed of the fan (100%) cannot reach requested temperature for long time

Combustion temperature falls despite the top speed (100%) of the fan for long

time

Fuel supply is necessary

Basic Modes AK6000.X

AK3000 –User Manual

Fuel supply

Double click of the button ENTER ( function ) prepares the boiler to fuel

supply–main fan goes to 100% top speed in suction version or to 0% in blower version

Door opening

Wait 10 seconds after door is depicted on the display - fan will absorb the

combustion

Open the door and make all required action

Short press the ENTER–boiler gets in original state again

End of the combustion

Combustion temperature decreases under the minimal value –boiler is

automatically turned OFF

Fuel supply and boiler turning ON is necessary

Water pump is OFF

Basic Characteristics AK6000.X

AK3000 –User Manual

Boiler is turned ON by connecting the power cord into the AC outlet. In 10 seconds will the basic view displayed

Basic view

Starting at basic view we must hold the button ENTER two seconds long:

Basic view goes to the frame 1 where we use short click on the ENTER and we are in the frame 1.1. Short click of the

ENTER and we can set required temperature by buttons ▲or in 70 –85 °C range. Short click of the ENTER

confirms choosed value and frame 1.1 we leave by double click of the ►( ESC ).

OPERATING

Starting AK6000.X

Required Boiler Temperature Setup AK6000.X

AK3000 –User Manual

Starting at basic view we must hold the button ENTER two seconds long:

Basic view goes to the frame 1 where we use button ▲till we get to the frame 2. Short click on the ENTER and we are in

the frame 2.1. One more time click on the ENTER and we get to the frame 2.1.1. Using buttons ▲or we can choose

required parameter:

Frame 2.1.1 we can leave by double click of the ►( ESC ).

Combustion upper temperature –increase over of this value limits speed of

the fan. It provides chimney protection.

130 - 280°C

Combustion lower temperature –decrease under of this value activates

boiler status END –fuel burnout. It keeps the embers waiting.

50 - 130°C

Main fan power change. For example: value -3 decreases fan speed in 30%

-3, -2, ... 2, 3

Fan minimal speed. This value is limit for speed decrease of the fan after

reaching requested boiler temperature.

0 –70%

LCD display brightness

0 - 128

Roling of the values in user depiction on the basic view of the display.

yes / no

Time to display help of five arrrov button in frame 2.1.1

0 –10 s

Ventilation in combustion chamber –this time interval of the 100%

fan speed is switched every 60 seconds after overrun the required

boiler temperature

0 –300 s

Time to reach END status after decreasing the combustion

temperature below end value

0 –60 min

Temperature scale set up.

°C ( Celsius ) / °F ( Fahrenheit )

Automatic change of winter and summer time.

yes / no

User Parameter Setup AK6000.X

AK3000 –User Manual

Starting at basic view we must hold the button ENTER two seconds long:

Basic view goes to the frame 1 where we double use button ▲till we get to the frame 3. Short click on the ENTER and we

are in the frame 3.1. Using buttons ▲or or ENTER we can make required parameter to flash. Using buttons ▲or we

set flashed value to required time or date. Choice is stored by the ENTER and so we move to next position we want to

change. Frame 3.1 we can leave by double click of the ►( ESC ).

All the connected accsesories are monitored by system. Common error status is displayed by red color of the LED. More exactly

is error message displayed on the LCD display in the failure frame 4.

Starting at basic view we must hold the button ENTER two seconds long. Triple click on the buttons ▲or will get us to the

frame 4. One click on the ENTER displays first failure, if any. Next failures we can display by the button▲.

Disconnecting of thermometers T1 ( boiler temperature ) or T2 ( combustion temperature ) is on the next views:

Frame 4.1 we can leave by double click of the ►( ESC ).

Current Time Setup AK6000.X

Error messages AK6000.X

AK3000 –User Manual

Sotware implemented in hardware modules we can verify in frame 6 „Info“. We can see a version and date with exact time of

software generation here.

Starting at basic view we must hold the button ENTER two seconds long. One click on the button will get us to the frame 6.

By means of the ENTER button we can enter into the version display:

.....

By means of the ENTER button we can display the current software version of the AK6000D module:

...

Frame 6.1.1 we can leave by triple click of the ►( ESC ).

We can use service parameter setup 1 to configurate basic properties of the connected components.

!

Improper setup of service parameters can result in risk of boiler incorrect behaviour

or damaging some amount of boiler. Just the qualified service representative can properly

act in this area.

You need to TURN OFF the boiler before setting in this area.

Starting at basic view we must hold the button ENTER two seconds long. One click on the button▲will get us to the frame2.

We can hold the ◄button for two seconds and more now. A frame with request for service PIN will be displayed:

Version of software AK6000.X

Service Parameter Setup 1 AK6000.X

AK3000 –User Manual

By means of the ▲or we can set the first flashing digit of the PIN xxxx and by ENTER button we confirm it. So we can

enter rest of the PIN. With ENTER button we can get to the frame 2.8.1.1. :

Using buttons ▲or we can choose required parameter then by means of ENTER button confirm and flashing parameter

is able to change by ▲or buttons:

......

Frame 2.8.1.1 we can leave by click of the ►( ESC ). Parameter is set now.

Boiler type. Numeric value represents power of the boiler and L character

is for Lambda module connected. Caution! Parameter setup can

change related parameters.

XY16, XY16L,....XY100,

XY100L etc.

Main fan is suction type. We can change it to the blower type.

or

Combustion thermometer is installed. Boiler reaches END status after

decreasing the combustion temperature below end value.

yes / no

Auxiliary fan is not connected.

yes / no

Boiler thermometer is installed with KTY type. You can change it to the Pt1000.

KTY / Pt1000

AK3000 –User Manual

We can use service parameter setup 2 to configurate chosen „hardware“ properties of control unit.

!

Improper setup of service parameters can result in risk of boiler incorrect behaviour

or damaging some amount of boiler. Just the qualified service can properly act in this area.

You need to TURN OFF the boiler before setting in this area.

Starting at basic view we must hold the button ENTER two seconds long. One click on the button▲will get us to the frame2.

We can hold the ◄button for two seconds and more now. A frame with request for service PIN will be displayed:

By means of the ▲or we can set the first flashing digit of the PIN yyyy and by ENTER button we confirm it. So we can

enter rest of the PIN. With ENTER button we can get to the frame 2.9.1. :

Using buttons ▲or we can choose required parameter then by means of ENTER button confirm and flashing parameter

is able to change by ▲or buttons:

......

Frame 2.9.1 we can leave by click of the ►( ESC ). Parameter is set now.

Secondary servodrive S1 valve in Lambda module. It means end position of close

movement.

0-100%

Min. switching value for triac of the main fan.

0,25 –0,99

Max. switching value for triac of the main fan.

0,25 –0,99

Display contrast

0 - 40

Service Parameter Setup 2 AK6000.X

AK3000 –User Manual

In this section we can manually activate connected components as fans or water pump for service purpose.

!

Improper setup of service parameters can result in risk of boiler incorrect behaviour

or damaging some amount of boiler. Just the qualified service can properly act in this area.

You need to TURN OFF the boiler before setting in this area.

Starting at basic view we must hold the button ENTER two seconds long. One click on the button▲will get us to the frame2.

By means of the ▲or we can set the first flashing digit of the PIN xxxx and by ENTER button we confirm it. So we can

enter rest of the PIN. With ENTER button we can get to the frame 2.8. Subsequently by means of the ▲and ENTER

button we can depict frame 2.8.15 with set of outputs:

Using buttons ▲or we can choose required output then by means of ENTER button to turn it ON or OFF:

Output –main fan is OFF

ON / OFF

Output –auxiliary fan is OFF

ON / OFF

Output –water pump is OFF

ON / OFF

Output –OPEN secondary servodrive is OFF

ON / OFF

Output –CLOSE secondary servodrive is OFF

ON / OFF

Inicialization secondary servodrive is OFF

ON / OFF

Output –expander relay 1 is OFF

ON / OFF

Output –expander relay 2 is OFF.

ON / OFF

Output –expander relay 3 is OFF

ON / OFF

Component Service Activation AK6000.X

AK6000D

Input voltage

7,5VDC

Input current

0,06A

Operating temperature

max 45°C

Case

IP20

Connection with AK5000S

20-pin conector PFL

AK5000S

Input voltage

230VAC, 50Hz ±10%

cord 3m, H05VV-F 3Gx0,75, PVC, temperature range -15 až +70°C

Full load

1,6A

Temperature range

max 45°C

Case

IP00

Component terminals

Fan / Pump : 0,75mm², T1-T4 : 0,5 mm²

Maximum number of inputs

3

Boiler thermometer

KTY ( PTC / polovodič, R=2kOhm/20°C )

Combustion thermometer

PT1000

Crash thermostat

Contact Normally Closed

Maximum number of outputs

3

Main fan

230VAC / 0,4 A

Auxiliary fan

230VAC / 0,4 A

Water pump

230VAC / 0,8 A

Fuse F1 –Main and auxiliary fan

0,8 A, T 5x20mm

Fuse F2 –Control unit and water pump

0,8 A, T 5x20mm

Electric Parameters AK6000.X

AK3000 –User Manual

BLOCK DIAGRAM AK6000.X

Table of contents

Popular Control System manuals by other brands

Elstat

Elstat ems25 Series product manual

ABB

ABB REC670 2.1 IEC Product guide

ONEFINITY

ONEFINITY Elite Series Installation and operation instruction

Extron electronics

Extron electronics TouchLink TLC Pro 526M Series user guide

Toshiba

Toshiba TOSDIC-CIE DS Installation and wiring manual

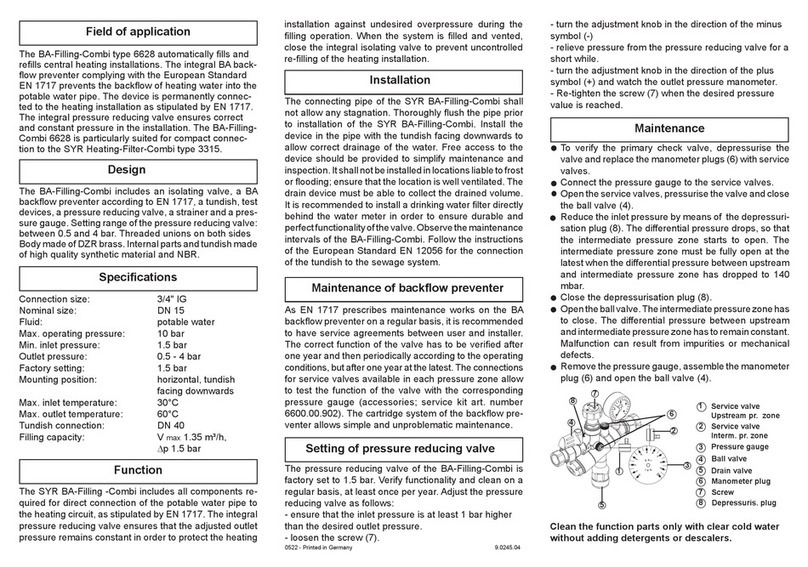

SYR

SYR BA-Filling-Combi 6628 Instructions for use and installation