Elstat ems25 Series User manual

This manual suits for next models

2

Table of contents

Other Elstat Control System manuals

Popular Control System manuals by other brands

ZETRON

ZETRON 4000 Series Installation

Next Wave CNC

Next Wave CNC SHARK HD500 owner's manual

Vicon

Vicon PILOT PLUS V1544 Installation and operation manual

IN-COMMAND

IN-COMMAND NCSP35CM Installation and operation manual

Carrier

Carrier i-Vu CCN Pro 4.2 installation guide

Siemens

Siemens Albatros2 RVS46 Series user manual

ProMinent

ProMinent DULCOMARIN 3 Compact Assembly and operating instructions

DSE

DSE DSE6110 MKII Operator's manual

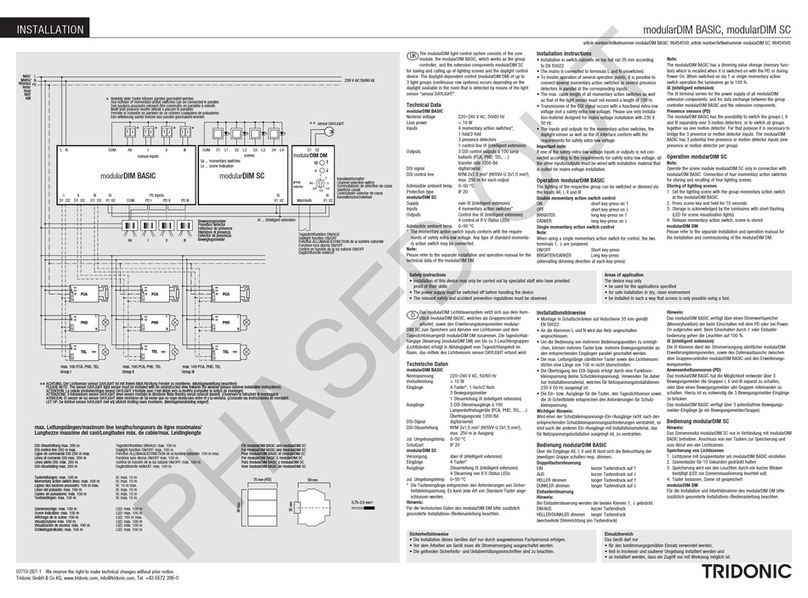

Tridonic

Tridonic modularDIM BASIC installation instructions

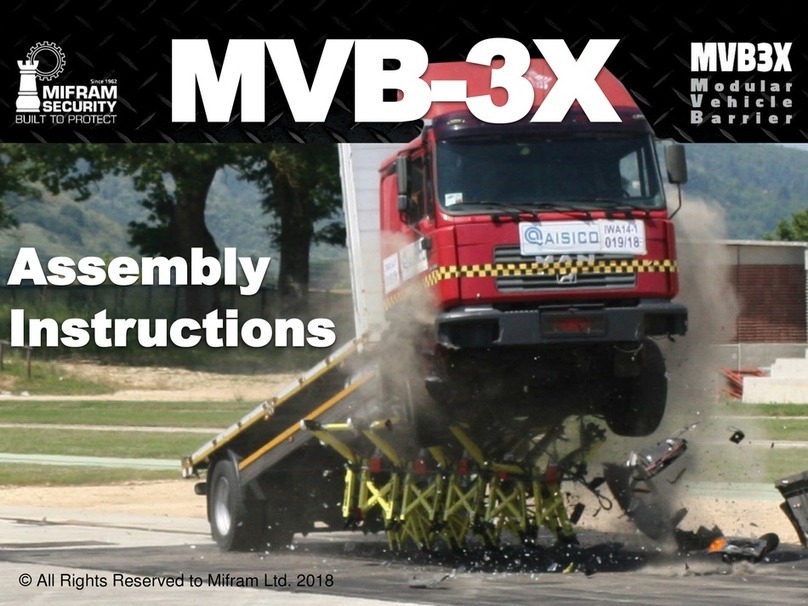

MIFRAM SECURITY

MIFRAM SECURITY MVB-3X Assembly instructions

Will Burt

Will Burt NIGHT SCAN Operator's manual

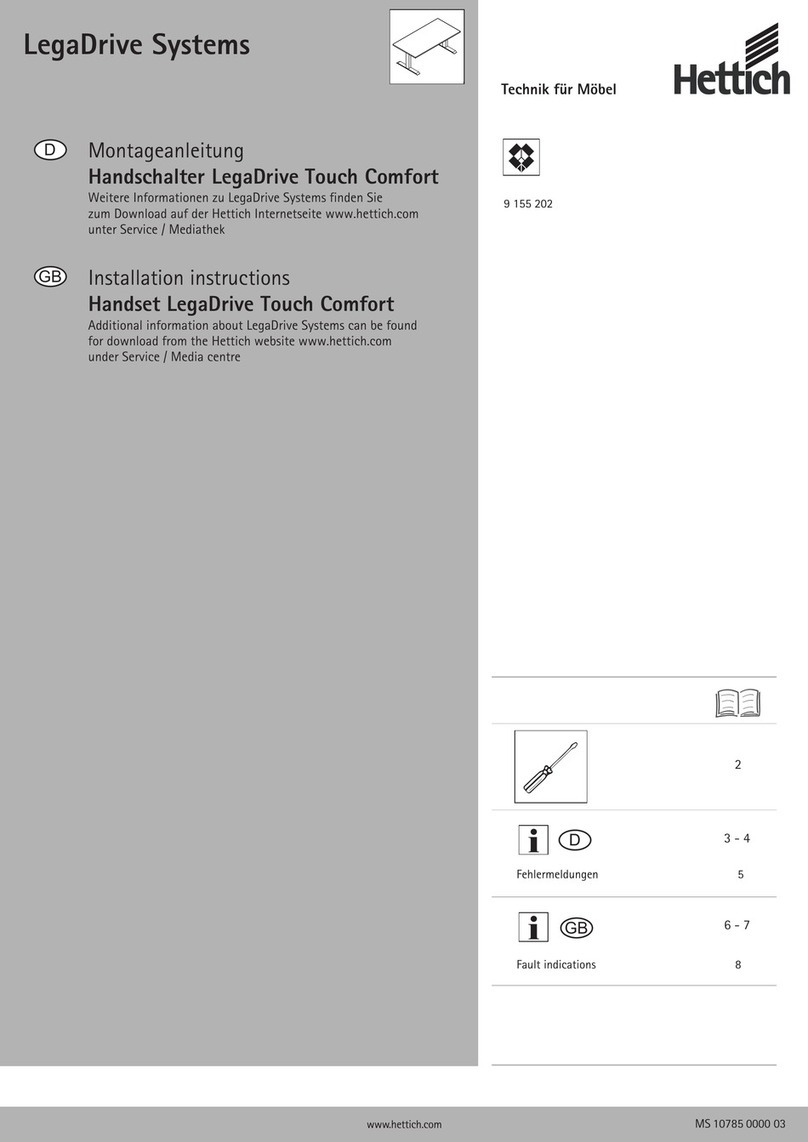

Hettich

Hettich LegaDrive installation instructions

Stagnoli

Stagnoli DAPHNE 4 manual

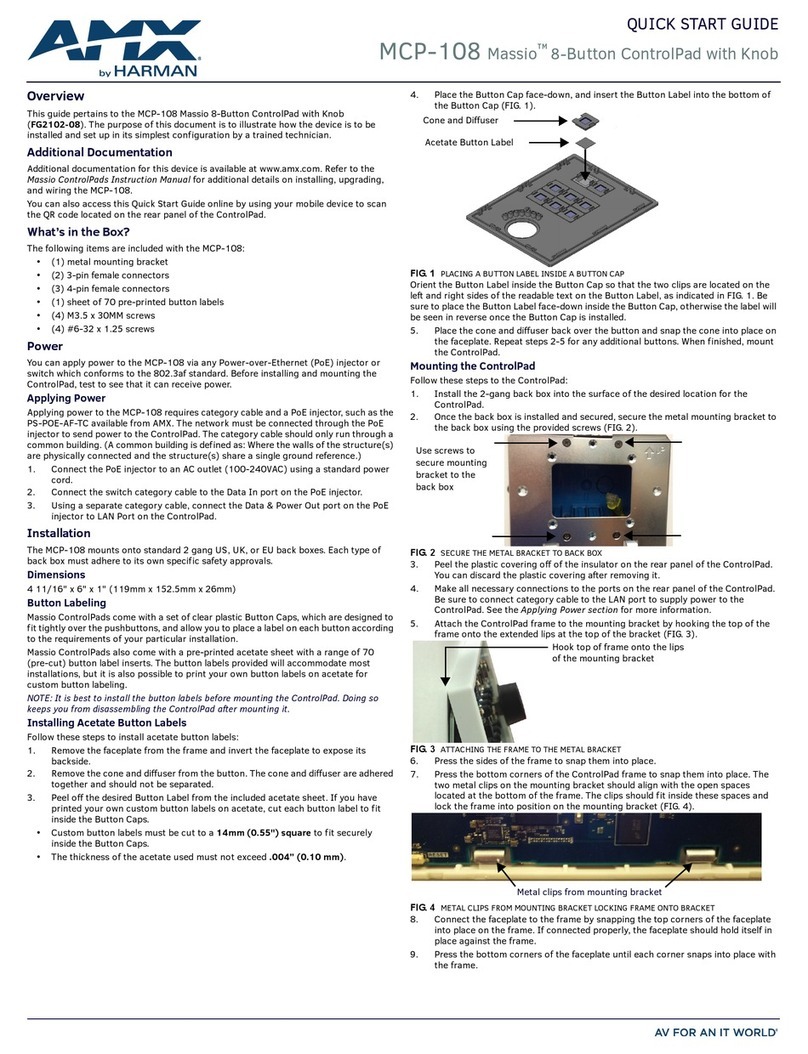

AMX

AMX Massio MCP-108 quick start guide

Veeder-Root

Veeder-Root TLS-350R Install, Setup, & Operation Manual

Intermatic

Intermatic PJB2175 Installation, operation & service manual

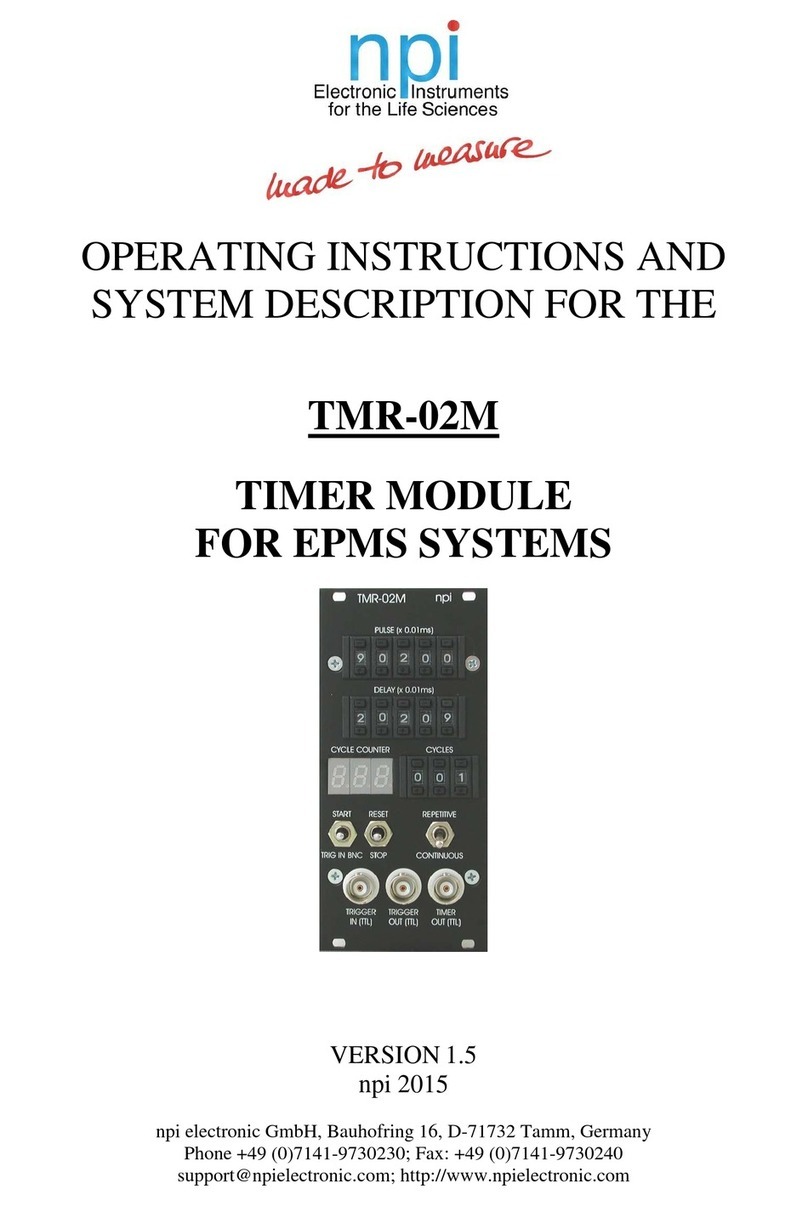

NPI

NPI TMR-02M Operating instructions and system description

Varifan

Varifan DIP-1C Installation & user guide