Mounting to a Tractor

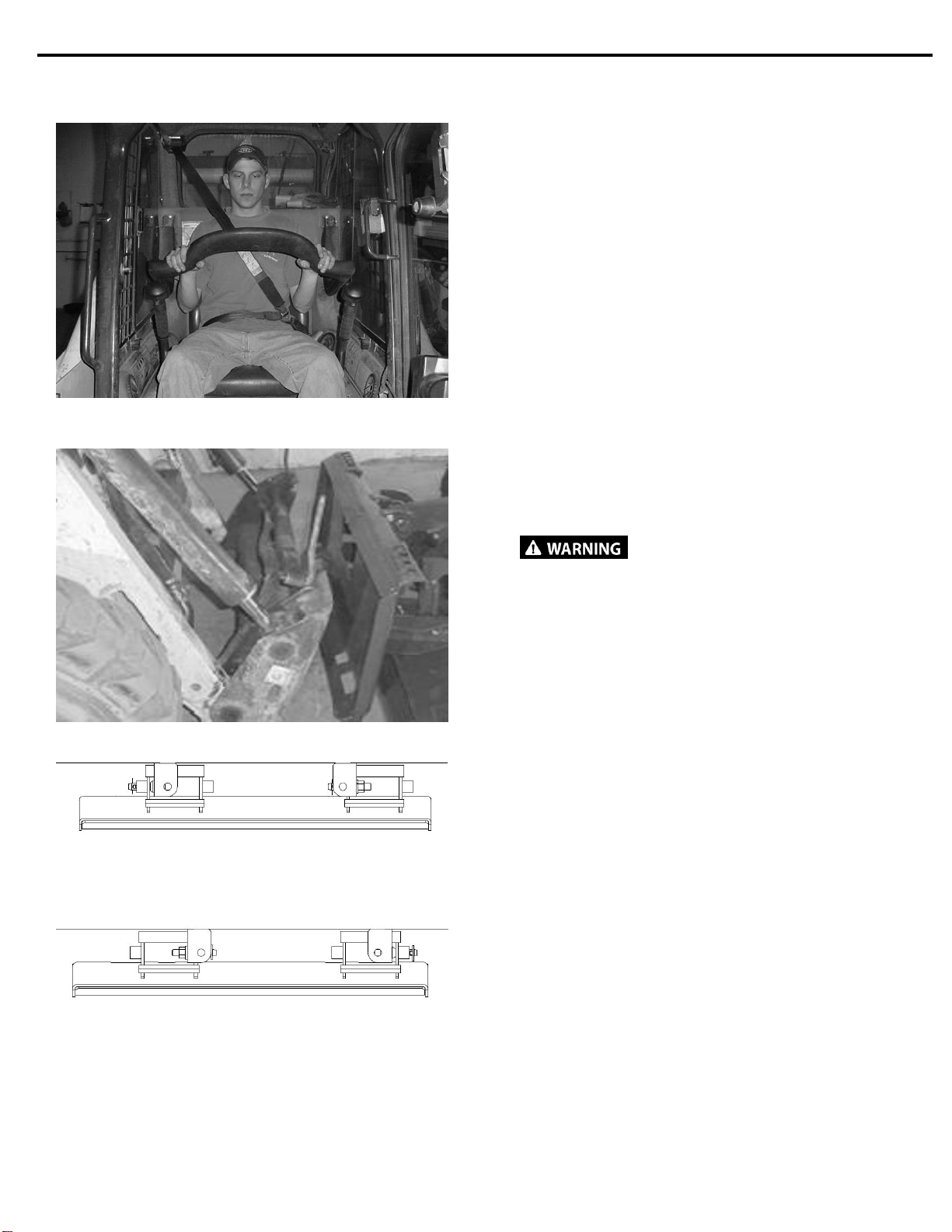

1. Use the step, safety treads, and grab handles to

get on and off the tractor.

2. Sitting in the operator’s seat, fasten the seat belt

(if so equipped).

3. Drive the tractor to the front of the attachment.

Align the tractor 3-point arms with the attachment

mounting pins.

4. Stop the engine and engage the park brake.

5. Have a second person connect all 3-point links to

the attachment using the pins provided.

All appropriate hitch pins and

locking pins must be locked into place. Failure

to secure pins can allow the attachment to

disconnect from the tractor and cause injury

or death.

6. Adjust the 3-point top link so that the attachment

is level while resting on the ground (see tractor’s

operator’s manual for top link adjustment

instructions).

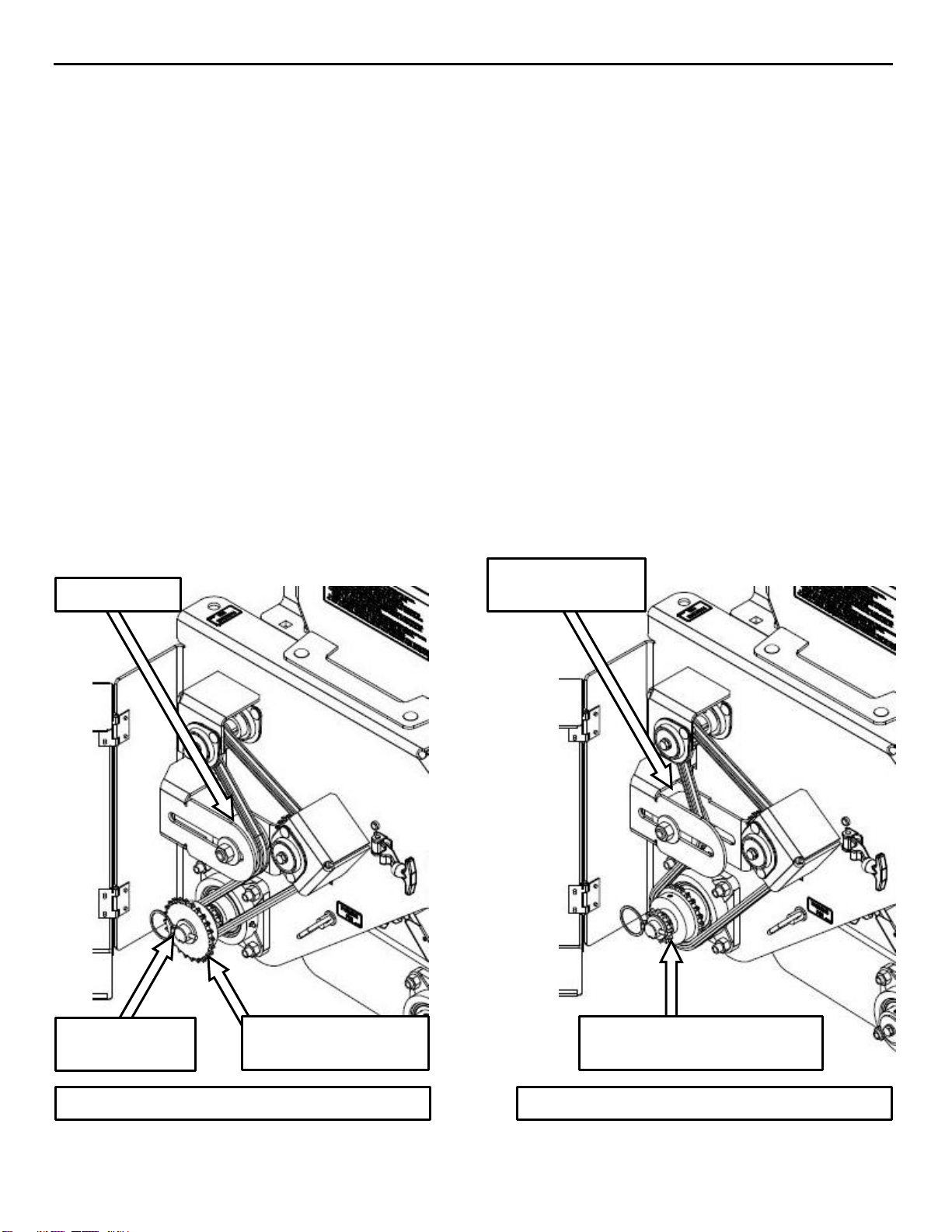

Wheel Track Remover Adjustment

1. Raise the attachment 6” to 12” off of the ground

and block in position.

To avoid being crushed, never

work on raised attachment without using

additional support blocks or jack stands.

2. Remove the 1/2" nut and lock washer from the

carriage bolt that holds the spring mount in place,

and move it to the desired depth.

3. Reinstall the nut and lock washer once the spring

mount is in place. Tighten hardware to the proper

torque (see “Bolt Torque Information” on page 29).

NOTE: Softer soil requires the wheel track

remover springs to be set deeper.