ES manufacturing G830 User manual

Model G830 Gel Coat Touch-up Spray Gun

Documentation & Warranty Packet

Documentación y Pa uete de Garantía

Thank you for purchasing the G830 Gel Coat Touch-up gun. If properly maintained, this sprayer will

pro ide years of trouble free ser ice.

Gracias por comprar la Pistola de retroque G830. Si se mantiene apropiadamente, “ESTA” le pro eerá

muchos anos de ser icio sin problemas.

WARRANTY/GARANTIA

This modelo G830 Spray Gun is warranted against defects for a period of 60 days. Keep your original

sales receipt for proof of purchase. ES Manufacturing, Inc. will replace or repair any defecti e part, either

direct, or through the distributor, at the option of ES Manufacturing. ES Manufacturing reser es the right

to inspect the merchandise at our facility. Transportation to and from the ser ice center is the

responsibility of the purchaser. ES Manufacturing, Inc. doesn’t warrant uninterrupted or error-free

operation of the products, and is not responsible for damage, loss, lost production or any other expenses

due to the failure of this product. The supplied listing of nozzle suggestions is based on use comments

and are no way guaranteed. This warranty in no way guarantees the suitability of this equipment for use

with any material. No other warranty is expressed or implied.

El modelo G830 (Pistola Rociadora) esta garantizada por defectos por 60 dias. Guarde el original de su

recibo como prueba de compra. ES MFG., Inc. le remplaza o repara alguna parte que enga defectuosa

al momento de su compra. Si bien directamente o a tra és de nuestro Distribuidor. (Es la opción de ES

Manufacturing, Inc.) ES Manufacturing se reser a el derecho de inspeccionar la mercancía de uelta en

nuestras Oficinas. La transportación de la mercancía de uelta es responsabilidad única del comprador.

ES Manufacturing, Inc. no garantiza interrupciones o algún error en la operación de este producto,

tampoco es responsable por danos, perdidas o cualquier otro gasto debido al fallo de este producto. La

lista que le pro eemos con sugerencias para el uso de las boquillas están basados en comentarios de

los usuarios y no hay forma que puedan ser garantizadas. Esta garantía no garantiza de ninguna

manera el uso de este equipo con ningún material. Ninguna otra garantía es expresada o implicada.

Important! Important! Important!

Enclosed warranty sheet must be returned with a copy of your original bill of sale

to ES Manufacturing for any service or returns!

¡Importante! ¡ Importante! ¡ Importante!

Adjunto el Formulario de arantía que debe ser retornada con una copia del

recibo original al momento de la compra a ES Manufacturing para cualquier tipo

de servicio o devolución.

Copyright 2005

ES Manufacturing, Inc.

2647 24th Street North

St. Petersburg, Fl 33713

US/Canada: 800-55ES-MFG, Local/International: 727-323-4040, Fax: 727-327-9872,

Website: www.esmfg.com Email Address: [email protected]

Model G830 2.0 HVLP Spray

Contents:

u Technical Data

u Important Safety Instruction

u Operating Instructions

u Adjustment

u Maintenance

u Caution

u Troubleshooting

u Parts List

Read this Instruction Manual caref lly and nderstand it completely, basic preca tion sho ld be strictly

followed to prevent the damage to the tool and inj ry to the operator. Retain this man al for f rther reference.

And yo sho ld pay more attention to the Technical Data.

Feed Type: Gravity

Standard Dia of Nozzle: φ2.0mm

Optional Dia of Nozzle: φ0.5-1.2mm

Recommended air press re: 4.5 – 6.0 bar (40-60 PSI)

Material Capacity: 120cc (250cc w/optional al m. c p)

Air Cons mption: 3.5-6.0cfm

u Important Safety Instructions

1.For toxic vapors prod ced by spraying certain materials can create intoxication and

serio s damage to health. Always wear safety glasses, gloves and respirator to

prevent the toxic vapor hazard, solvent and gelcoat coming into contact yo r eyes

or skin. (see fig 1)

2.Never se oxygen, comb stible or any other bottle gas as a power so rce or wo ld

ca se explosion and serio s personal inj ry. (see fig 2)

3.Fl id and solvent can be highly flammable or comb stible. Use in well-ventilated

spray booth and avoid any ignition so rces, s ch as smoking, open flames and

decrial hazard. (see fig 3)

4.Disconnect tool from air s pply when not in se or maintaining also a sh t off valve.

As an emergency stop is recommend.

5.Use clean, dry and reg late compressed air rated at 4.5-6.0 bar, (40-60PSI) never

exceed maxim m permissive operating press re (see fig 4)

6.Never se homogenate hydrocarbon solvent, which can chemically react with

al min m and zinc parts and chemically compatible with al min m and zinc parts.

7.Never point g n at yo and others at any time.

8.Before operating the tool, make s re all the screws & caps are sec rely tightened in

case of leaking;

9. Before spraying, be s re trigger and related parts operate smoothlyl.

10.Never modify this tool for any applications. Only se parts, nozzles and accessories recommended and

accessories recommended by ES Man fact ring, Inc.

tOperating Instructions

Ø

ØØ

Ø This tool applies to operate on clean, dry and compressed air at reg lated press re at 4.5-6.0 bar. Too

low or too high press re will adversely affect the g n and the q ality of spray.

Ø

ØØ

Ø Check and replace any damaged or worn parts on the too. Make s re the trigger and nozzle can operate

well.

Ø

ØØ

Ø Connect the g n to air s pply. Be s re fl id cap, container and air hose sho ld be connected tightly with

spray g n.

Ø

ØØ

Ø When spraying, hold the g n perpendic lar with spraying area then move it parallel for several times.

The trigger sho ld be locked before the stroke ended. Keep the appropriate distance of 6-10 inches

between g n and s rface area, according the atomization press re and spraying conditions. See Fig 5.

Fig 5

u Adjustment

The desired pattern, vol me of fl id o tp t and fine atomization can easily be obtained by reg lating the

Pattern Adj sting Knob, Fl id Adj sting Knob and Air Adj sting Knob.

Adjusting pattern T rning Pattern Adj sting Knob to the right ntil tight will make spray pattern ro nd, or

t rning it left, will make spray pattern ellipse.

Adjusting volume of fluid output T rn the Fl id Adj sting Knob, clockwise will red ce the vol me of fl id

o tp t and co nter-clockwise will increase fl id o tp t.

Adjusting air volume T rning the Air Adj sting valve clockwise will red ce the air vol me. And

co nter-clockwise will increase the air vol me.

u Maintenance

Po r remaining material into a separate container and then clean material passage and air cap. Spray a small

amo nt of acetone to clean passage. Incomplete cleaning will ca se adverse material pattern sharp and

particles. Clean other sections with attached br sh,, and acetone soaked cloth.

u Caution

Never se the wire or other hard thing to clean nozzle or fl id needle. This will ca se damage to them. Never

immerse spray g n completely in acetone or solvent. D ring reassembly, always clean and dry parts to prevent

the sticking of d st.

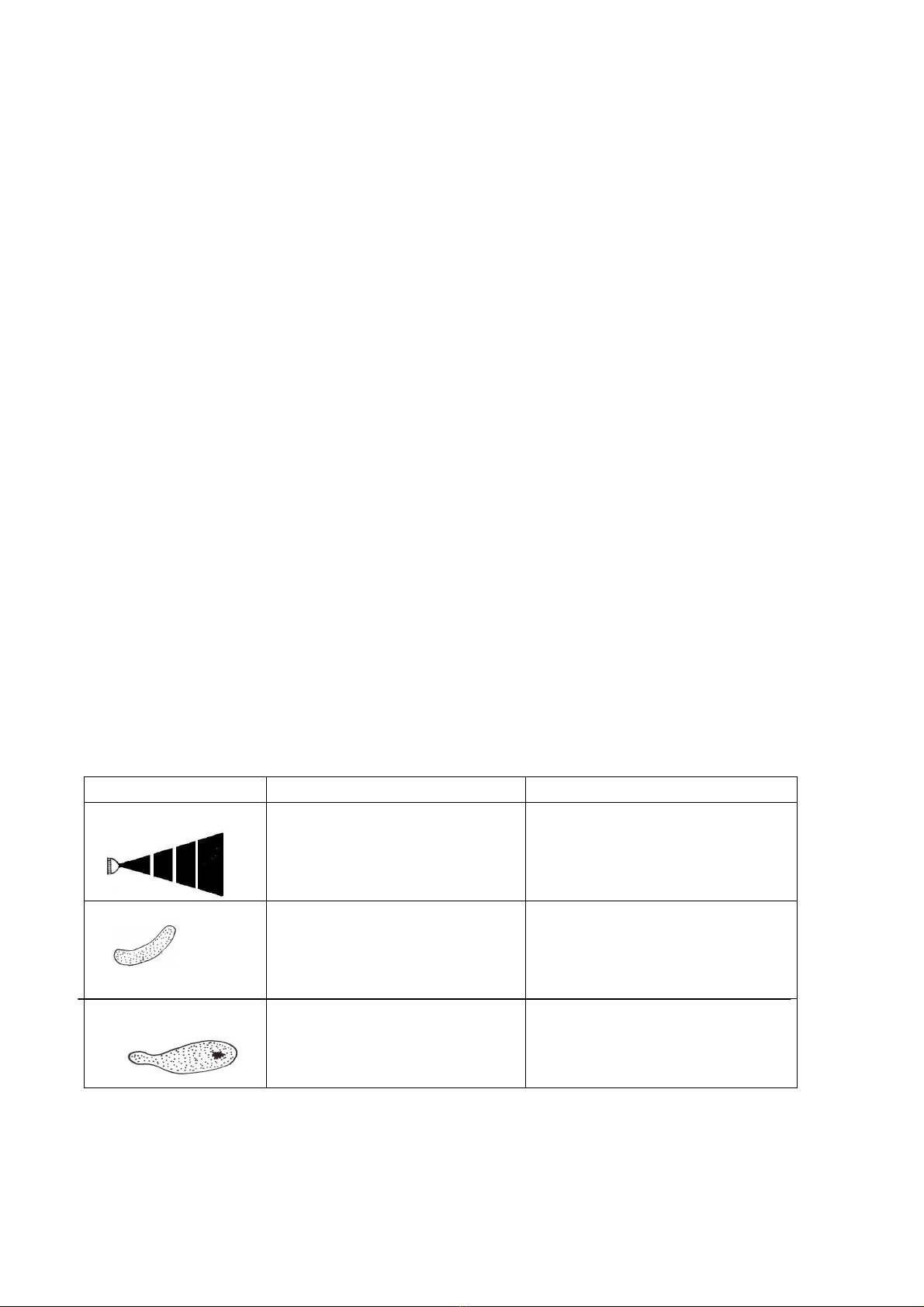

u Troubleshooting

Symptom Problems Solution

Fl ttering or spitting

1. Material in container is low.

2. Dry or worn Needle packing set.

3. Fl id nozzle loose or worn

1. Add material into container.

2. L bricate or replace Needle

packing set.

3. Tighten or replace Fl id nozzle.

Pattern is arc.

1. Worn or loose Fl id nozzle.

2. Material b ild p on Air cap.

1. Tighten or replace Fl id nozzle.

2. Remove obstr ctions from holes,

b t don’t se metal objects to

clean it.

Pattern is not

Evenly spread.

1. Material b ild p on Air cap.

2. Fl id nozzle dirty or worn.

1. Clean or replace Air cap.

2. Clean or replace Fl id nozzle.

Model G830 2.0 Parts List

No Description No Description No Description

1 Air Adj Screw 21 Trigger Lever 37 O-Ring

2 Air Adj N t 22 Trigger Lever II 38 O-Ring

3 O-ring 23 Trigger 39 Snap Retainer

4 Washer 24 Snap Retainer 40 Pattern Adj stment Joint

5 Air Valve Spring 25 Snap Retainer 41 O-Ring

6 Air Inlet Valve 27A Al m C p Assy. (.25L) 42 Air Inlet Joint

7 Switch Spring 27P Plastic C p Assy. (.12L) NK20 2.0mm Nozzle Kit

8 Air Inlet Valve Assly 28 Filter NK12 1.2mm Nozzle Kit

9 Switch Knob 29 Fl id Inlet Joint NK10 1.0mm Nozzle Kit

10 Switch Washer 2 (Req.) 30 Fl id Needle NK08 0.8mm Nozzle Kit

11 Lock Screw 31 Fl id Inlet Spring

13 Air Cap O-Ring 32 Mat. Adj. Stop

17 Fl id Nozzle Washer 33 Mat. Adj. Knob

18 Bolt 34 Phillips Screw

19 Needle Washser 35 Pattern Adj. Knob

20 Compressed Spring 36 Pattern Adj. Screw

.

www.esmfg.com

ES Manufacturing, Inc.

PO Box 11692

St. Petersburg, FL 33733-1692 G830 2.0

USA

Fold Here

______________________________________________________________________

Date of Purchase____/____/_____

Your Company’s Name __________________________________________________

Mailing Address __________________________________________________

__________________________________________________

City / State / Postal Code__________________________________________________

Phone #___________________________ Fax #_______________________________

Web Site__________________________ Email _______________________________

Primary Lines of Business_________________________________________________

_________________________________________________

How many employees at this location 1-10 11-20 21-100 100 or more

Primary use for this Spray Gun (Circle one) Gelcoat Resin Gypsum Other

If “Other” please describe: ________________________________________________

Is this your first ES Touch-up Gun? Yes No

Is this your first ES Mfg. product? Yes No

Name of distributor this unit was purchased ___________________________________

What was your purchase price?_ ___________________________________________

Did you purchase additional nozzles? Yes No

If so what size? 0.8mm 1.0mm 1.2mm

Which was more important to your purchase? Simplicity Effectiveness Price

Would you like us to send you a free catalog? Yes No

Comments_____________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

Important Notice: You should copy this sheet and keep it and you original sales

receipt. Return this form with a copy of your sales invoice. Failing to return this form

will void you warranty.

Note: Visit our website for duplicate copies of parts diagrams or instructions.

Table of contents

Other ES manufacturing Paint Sprayer manuals