ES manufacturing G9601L2.5 User manual

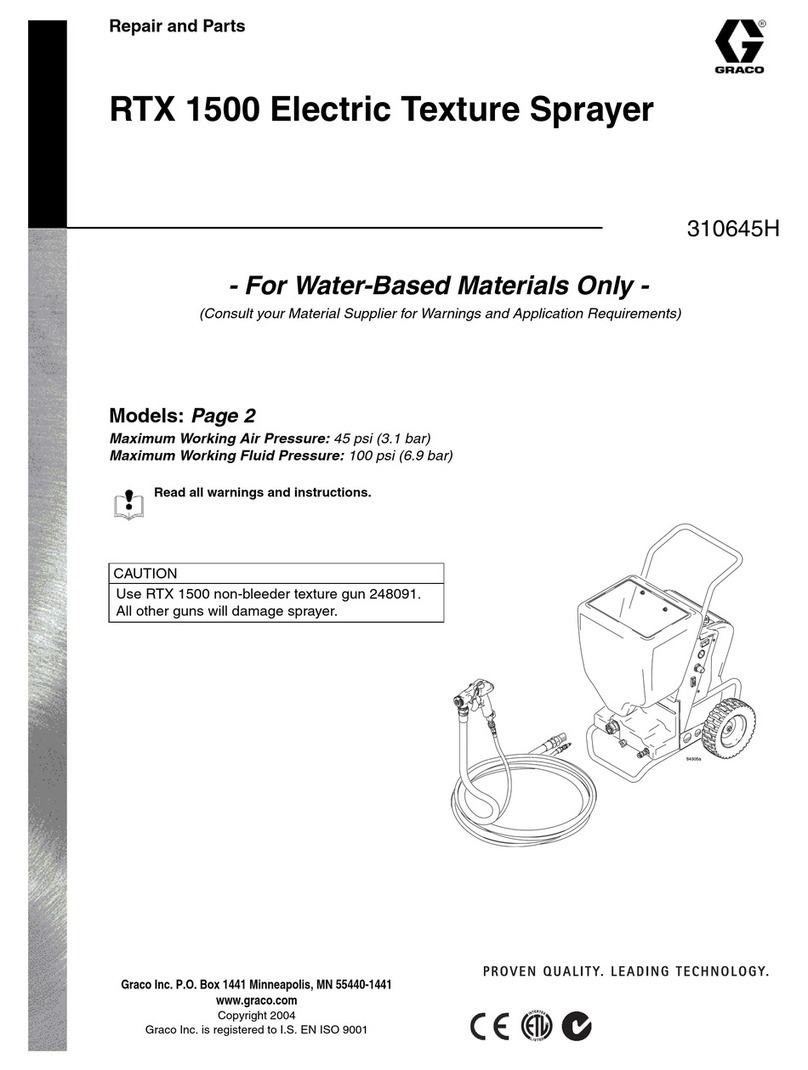

G960-2.5 w/2 liter High Pressure Spray Gun

Pistola de alta Presión (G9602L2.5)

Includes:

1 G960 Spray Gun w/ 2.5mm Nozzle

1 PT20 2 Liter Pressure Tank

1 AH15 Orange Air Hose 1.5m

1 MH15 Blacke Material Hose 1.5mm

1 PT20-012 Plated Steel Handle w/Nut

1 PT20-005 Tank Lid Seal (EP)

1 Tool Kit, (Stamped Wrench & Hex Key)

Safety Warnings & Precautions:

1. Keep work area clean.

2. Keep children away from this equipment and your work area.

3. Do not operate this equipment under the influence of alcohol or drugs.

4. Do not operate this equipment near open flames or other heat sources.

5. Read all safety information for material to be sprayed.

6. Read all safety information for cleaning materials to be used.

7. Check all seals before connectiing to air supply. Make sure lid is fully attached to the cup,

retaining is screwed past the first thread, air pressure plug is fully tightened and air supply is

sealed and firmly attached.

8. Use eye protection at all times.

9. Wear properly fitting protective clothing at all times.

10. Replace any component that looks warn or damaged immediately.

11. Use only approved ES Manufacturing components.

12. Follow all company saftey policies, and contact your supervisor with any questions.

Air

Connection

G960 Spray Gun

w/2.5mm Nozzle PT20

MH15

PT20

AH15

Air

Inlet

PT20

012

Assembly

Reference Figure 1

1. Connect black material hose (PT20-MH15) to the

material outlet as shown, using the supplied wrench.

2. Connect the other end of the black hose to the both of

the G960 spray gun head, just below the air cap, using

the supplied wrench.

3. Connect the orange air hose (PT20-AH15) toe the air

connection point on the regulator assembly as shown.

4. Connect the other end of the orange hose to the bottom

of the G960 spray gun, at the bottom of the handle as

shown. Using teflon sealing tape on these connection

will reduce the chance for air leaks.

Material

Outlet

Figure 1

Assembly

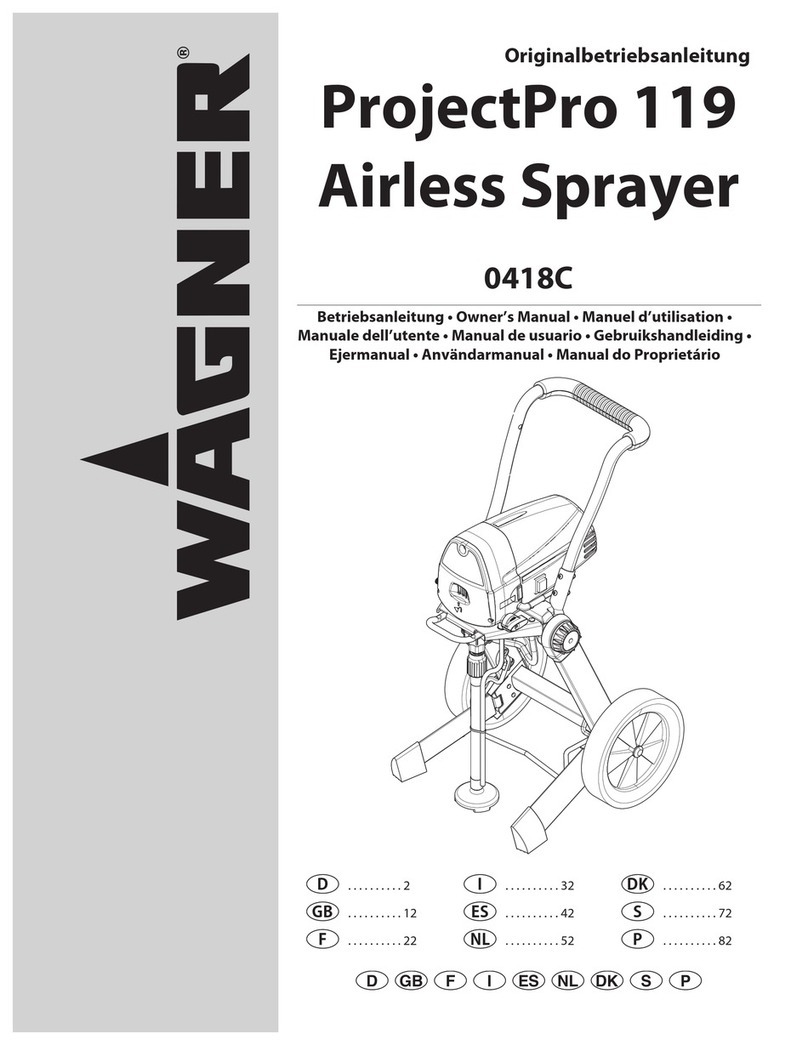

Reference Figure 2

1. Connect plated steel handle (PT20-012) to the

top of the centerpost assemble as seen is Figure 1.

2. Lock the supplied plated steel hex nut (PT20-013) to

secure steel handle

3. Close the air adjustment cap on the regulator assembly

by turning it clockwise.

4. Connect the air hose from your compressor to the air

connection point using a 1/4" NPT coupling and a

minimum 3/8" hose barb. It is not recommended to use

“quick-connect” style fittings, as they will restrict air flow to

the tank & gun.

5. Regulate air source to approximately 50 P.S.I.

PT20-013

PT20-012

Air

Adjustment

Cap

Coupling /

Hose Nipple

(Sold Seperately

)

Figure 2

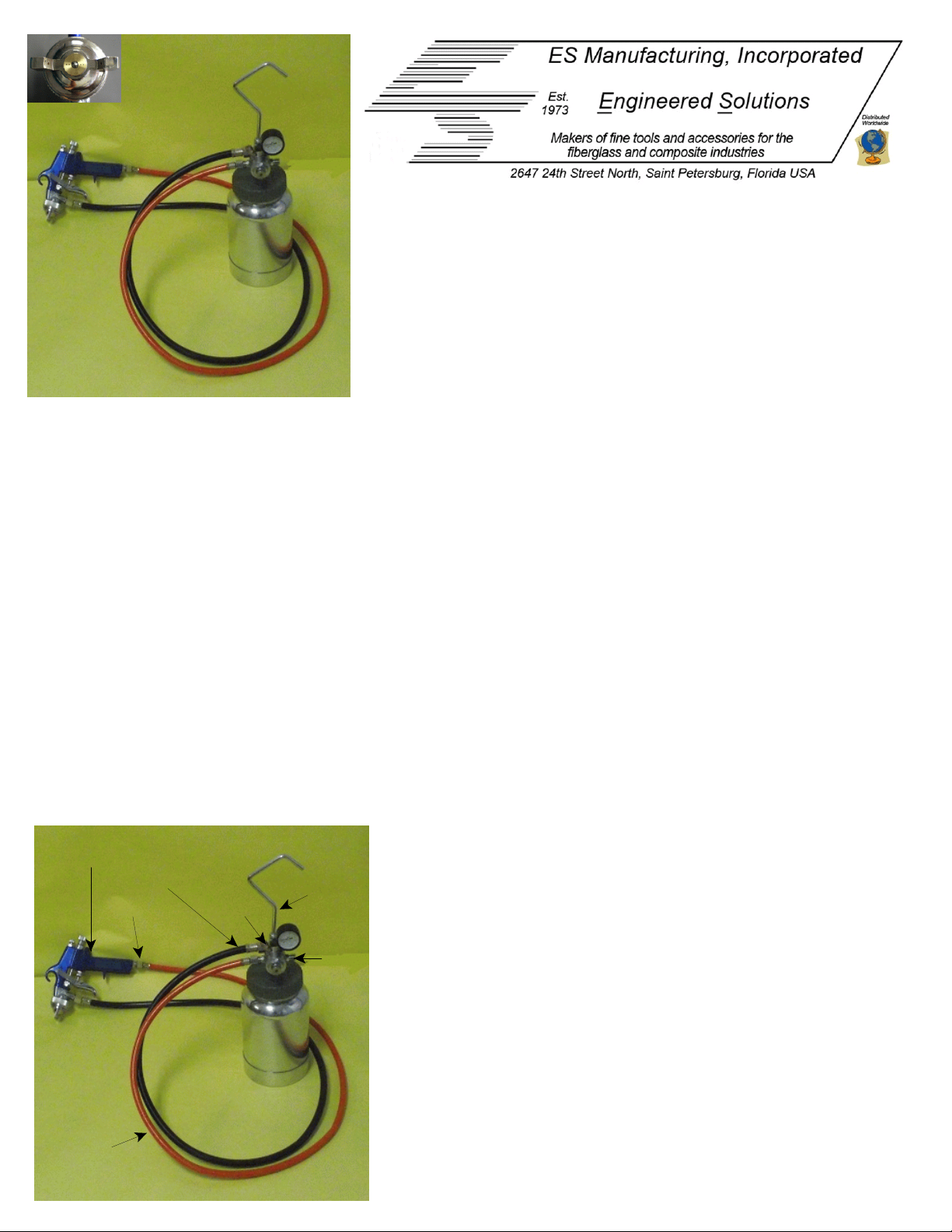

Operation

Reference Figure 3

1. Unscrew and remove tank cover assembly from the

aluminum cup.

2. Premix gel coat or resin in cup per manufacturers

instructions. Bag liner is optional.

3. Close the air adjustment cap on the regulator assembly

by turning it clockwise.

4. Fill cup to 3/4 full mark shown in Figure 4.

5. Lower and assemble tank cover to aluminum cup.

6. Set compressors regulator to the correct setting.

7. Connect the regulators iar connection to the your air

source hose. Inspect for leaks and re-seal if neccessary.

Figure 3

Tank Cover

Assembly

2 Liter

Aluminum

Cup

Caution:

When the cup contains material, always keep the spray gun upright. This will keep material

from conaminating portions of the spray gun it was not intended to go. Never leave catalyzed

gel coat or resin to remain in the aluminum cup.

Caution:

For thorough cleaning, the cup may be fully immeersed in solvent. Do not leave the cup in

solvent for more than 24 hours. Never immerse your spray gun in solvent. When cleaning, only

brush solvent onto exterior parts only.

100%

50%

8

"

For Most uses, e.g. painting walls benches.

Wehicles. Etc., the best results are obtained by

spraying thin, even coats of paint. Let the layers

dry in between coats.

As with any manual process, practice leads to

perfection. Th followint are a few general rules

that may be of help in perfecting your process:

* Use the lowest pressure setting recomended

by the paint manufacturer.

*Keep the gun perpendicular.

*Maintain a distance of about 8" from the work

ad shown in Figure 6.

*Make smooth, thin and even strokes across the

work. Overlap each stroke by about 50%. (See

Figure 7)

*Let each coat dry before re-coating.

Spraying Techniques

Figure7-Overlapping strokes

Figure 6-Distance from wall

Maintenance

General Maintenance:

Checking & Replacing the Needle

Needle wear is expected and inspection during cleaning will ensure the

continued top performance of your Air Paint Sprayer. If needle tip wear is

noted:

Step 1. Unscrew and remove the adjusting Screw

Step 2. Using a Pair of pliers or other suitable device, carefully pull and twist

the Needle until it has been removed.

Step 3. Purchase an identical replacement Needle from ESMFG.

Step 4. By hand, carefully insert the Needle into the Housing and push until the

tip has exited the hole in the NK Air Cap nozzle.

Step 5. Insert the Needle and insert it into the Housing.

Step 6. Replace the adjusting Screw and readjust its settings to the position it

was in before removed (refer to Step 1).

Caution:

Always keep the Cove (g960001)

tight when connected to air source

Cleaning:

Step 1. Depressurize the Cup (g960001) and disconnected the house.

Step 2. Remove the Cover Assembly from the Cup as Described in OPERATION.

Step 3. Empty the paint or coating from the Cup.Dipose of properly.

Step 4. Pour a small amount of clean solvent ( as Specified by the paint

manufacturer) in the Cup. See Saftey Warnings and Caustions #5.

Step 5. Place the Cover Assembly into the Cup and tighten until the assembly is

sealed.

Step 6. Reconnect the air hose to the Regulator and pressurize the cup.

Step 7. Clean the Air Paint Sprayer by Shaking continuously and spraying the solvent

though the gun.

Step 8. Repeat steps 1 through 7 until the sprayed solvent appears clean and clear.

Step 9. After depressurizing disconnect the regulator from the air supply.

Step 10.Remove the Cover Assembly From the Cup and dispose of the surplus

solvent.

Step 11. Wipe the Cup clean with a dry, lint-free cloth.

Warning:

Always dispose of paints, coating and other chemicals in a proper and

responsible fashion. If you have questions regarding the propper disposal of any

chemical, contact the chemical manufacturer for instructions.

Caution:

For thorough cleaning, the CUP may be fully immersed in solvent. DO

NOT LEAVE SOLVENT FOR MORE THAN 24HOURS as damage may occur.

NEVER IMMERSE THE AIR PAINT SPRAYER IN SOLVENT. When cleaning,

brush solvent onto extiorior parts only.

Lubrication:

Before and after each use of a G960-2L, perform the following lubrication process,

using a non-silicon, spray gun lubricant:

Step 1. Put 2 or 3 drops of lubircant on the Part of NK, infront of the

Trigger(g960015). Tip the gun backward and allow the lubricant to drip into the front

of the gun housing.

Step 2. Put 2 or 3 drops of lubircant on the Air Valve (g960024). Tip the gun

backward and allow the lubricant to drip into the front of the gun housing.

Step 3. Put 2 or 3 drops of lubircant on the Fan Adjuster(g960014). Tip the gun

backward and allow the lubricant to drip into the front of the gun housing.

Step 4. Put 1 drops of lubercant on the Trigger Stud (g960016) and another on the

Trigger Screw (g960017). Work the Trigger to allow the lubricant to coat the parts.

Step 6. Put 1 drops of lubercant on the regulator Adjusting Cap(g960009). Tip it

sideways and allow the lubricant to drip into the Air Cap.

Step 1 Step 4

Step 5

Step 2

Figure 8 - Lubricating the G960-2L

Step 3

.

www.esmfg.com

ES Manufacturing, Inc.

PO Box 11692

St. Petersburg, FL 33733-1692

USA

Fold Here G9601L2.5 G9602L2.5 G9609L2.5

______________________________________________________________________

Date of Purchase____/____/_____

Your email address______________________________________________________

Your Company’s Name __________________________________________________

Mailing Address __________________________________________________

__________________________________________________

City / State / Postal Code__________________________________________________

Phone #___________________________ Fax #_______________________________

Web Site__________________________ Email _______________________________

Primary Lines of Business_________________________________________________

_________________________________________________

How many employees at this location 1-10 11-20 21-100 100 or more

Primary use for this Spray Gun (Circle one) Gelcoat Resin

If “Other” please describe: ________________________________________________

Is this your first G960 Gun? Yes No

Is this your first ES Mfg. product? Yes No

Name of distributor this unit was purchased ___________________________________

What was your purchase price?_ ___________________________________________

Did you purchase additional nozzles? Yes No

If so what size? ________________________________________________________

Which was more important to your purchase? Simplicity Effectiveness Price

Would you like us to send you a free catalog? Yes No

Comments_____________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

Important Notice: You should copy this sheet and keep it and your original sales

receipt. Return this form with a copy of your sales invoice. Failing to return this form

will void your warranty.

Note: Visit our website for duplicate copies of parts diagrams or instructions.

This manual suits for next models

2

Table of contents

Other ES manufacturing Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Multi-Clean

Multi-Clean E-Spray Hand Held quick start guide

Collomix

Collomix VIBA X.30 instructions

POLINS

POLINS GARDEN PRO 12 Original instructions

Nordson

Nordson Encore HD Customer product manual

CountyLine

CountyLine TS30G-CL Operation instructions manual & user guide

California Air Tools

California Air Tools CAT-33000 owner's manual