Escea TFS Series Mounting instructions

Installation Instructions

and User Guide

TFS650 & TFS1000

FREE-STANDING SOLID FUEL BURNER

630592_1

WARRANTY REPAIR AND ANNUAL SERVICING

Please contact Escea if you require warranty work. Warranty repair work must be carried

out by a recognised Escea woodfire installer. It is recommended that recognised Escea

Wood Fire Installers are also used to carry out annual servicing requirements (particularly

during the warranty period). For contact details of recognised Escea Wood Fire Technicians

in your area, or for replacement parts, please contact the retailer from whom the appliance

was purchased from, or visit our website.

All installation work must comply to AS/NZS 2918:2018 Domestic solid fuel burning

appliances- Installation AND these installation instructions. Any work undertaken that

does not comply to AS/NZS 2918:2018 AND these installation instructions will not

qualify for the Escea warranty. Escea will not be accountable for any unsafe installation

that does not comply to AS/NZS 2918:2018.

Manufactured by: Escea Ltd, PO Box 5277 Dunedin NZ, Ph: +64 3 478 8220

For contact details of your local Escea distributor or dealer, please visit www.escea.com,

From Australia, please visit www.escea.com.au, call AU: 1800 460 832 or WA: 1800 730

CONTENTS

A Safety Information 4

B Product Details 6

C Installation Process 10

D Woodfire Operation 34

E Maintenance & Servicing 41

F Troubleshooting 55

G General Warranty Terms & Conditions 56

H Service History & Data Plate 59

4

AA SAFETY INFORMATION

ͳThe appliance should be allowed to cool

ͳDo not operate without fully assembling all

ͳ

ͳDo not operate appliance before reading and

55

A

ͳ

ͳ

ͳ

be carefully supervised when they are in the

individuals out of the room and away from hot

ͳ

ͳ

ͳ

ͳ

ͳ

children and dispose of the material in a safe

ͳ

ͳ

ͳThis appliance is designed to burn natural

ͳ

ͳ

ͳ

ͳ

ͳDo not let the appliance become hot enough

ͳ

ͳ

ͳ

maintained when building a mantel or shelves

on the wall or in the air above the appliance

ͳThe appliance must be installed using only

the building materials as approved by the

ͳ

within 1 meter of the product that is

6

B

B PRODUCT DETAILS

B1 Product Description

The TFS series is a free-standing wood fire.

B2 Product Dimensions

The TFS series consists of the TFS650 and TFS1000 fireplace. Plinths are available for

purchase to go along with the free-standing woodfire.

GRC plinths (Glassfibre-Reinforced Concrete) are available for both TFS650 and

TFS1000 products. The TFS1000 and 1500mm GRC Plinths can be used for both

TFS650 and TFS1000 products. The sheetmetal plinth is only available for the TFS650

product.

Dimensions for each fireplace and plinth options are available in the following pages.

For more detail, view architectural drawings at www.escea.com

TFS650 Fire Dimensions:

606mm

483mm

605mm

200mm

150mm

650mm

291mm

TOP VIEW

689mm

ISOMETRIC VIEW

FRONT VIEW

SIDE VIEW

FLUE PIPE

COMBUSTION

AIR INLET PIPE

506mm

77

B

TFS1000 Fire Dimensions:

Sheetmetal Base 650W Dimensions:

940mm

459mm

988mm

200mm

150mm

506mm

494

240mm

606mm

566mm

83mm

609mm

TOP VIEW

FRONT VIEW SIDE VIEW

FLUE PIPE

COMBUSTION

AIR INLET PIPE

ISOMETRIC VIEW

302mm

292mm

648mm

506mm

106mm

656mm

TOP VIEW

FRONT VIEW

8

8

B

Plinth 650W Dimensions:

Plinth 1000W Dimensions:

540

245mm 506mm

650mm

300mm

FRONT VIEW

TOP VIEW

884mm

320mm 506mm

994mm

FRONT VIEW

TOP VIEW

375mm

99

B

Plinth 1500W Dimensions:

B2 Specifications Table

TFS650:

Fuel Type Hardwood

Average Particulate Emission (g/kg) 0.97

Overall Average Eciency (%) 68.63

Maximum Average Heat Output (kW) 6.75

TFS1000:

Fuel Type Hardwood

Average Particulate Emission (g/kg) 1.00

Overall Average Eciency (%) 61.88

Maximum Average Heat Output (kW) 8.77

225mm

1350mm

1500mm

506mm

375mm

FRONT VIEW

TOP VIEW

10

C

C INSTALL ATION PROCESS

C1 Installation - General

ͳ

ͳ

of fuel and burn the appliance with the air

control fully open for an hour as the appliance

moisture is being drawn from the appliance

and it will be necessary to build several hot

1111

C

C2 Safety Clearance Minimum Dimensions

If there is combustible flooring within 500mm of the appliance, a floor protector must be

installed.

If there is combustible flooring directly in front of the appliance, the appliance must be

installed on one of Escea’s plinths/ bases, or another heat resistant structure of minimum

height H (as detailed below). Additionally, a floor protector of any suitable heat resistant

material (eg. steel, glass etc) must be installed to prevent any ash contacting the floor. The

floor protector must extend not less than 300mm from the front of the appliance and not

less than 200mm from each side of the appliance.

Dimension H can be reduced if the product is installed over an insulating, heat resistant

floor complying with the requirements of AS/NZS 2918:2018 section 3.3.3.

TFS650 Clearances:

A

(Back)

(mm)

B

(Side)

(mm)

C

(Floor

Protector

Front)

(mm)

D

(Floor

Protector

Side)

(mm)

E

(Flue

Centre

to Side)

(mm)

F

(Flue

Centre

to Back)

(mm)

G

(Top to

Ceiling)

(mm)

H

(Oset

height

from floor)

(mm)

Parallel

Position

200 320 300 200 645 415 1495 300

Corner

Position

100 100 300 200 490 490 1495 300

TFS1000 Clearances:

A

(Back)

(mm)

B

(Side)

(mm)

C

(Floor

Protector

Front)

(mm)

D

(Floor

Protector

Side)

(mm)

E

(Flue

Centre

to Side)

(mm)

F

(Flue

Centre

to Back)

(mm)

G

(Top to

Ceiling)

(mm)

H

(Oset

height

from floor)

(mm)

Parallel

Position

200 370 300 200 864 440 1420 375

12

12

C

Parallel Position

Corner Position

F

E

B

A C

D

A

B

D

C

E

F

1313

C

Height Clearances

Flue Clearances

At the ceiling and roof penetrations, it is permitted to have a combustible material hard

up against the 250mm dia galvanised liner. However the material must be no thicker than

20mm. At all other points, a minimum clearance of 25mm between the 250mm liner

and any combustible material must be maintained. Note: the Escea ceiling plate must be

installed to comply.

G

250mm GALVANISED LINER

25mm

Ceiling

Bottom of 250mm dia liner

flush with bottom of ceiling 200mm PAINTED FLUE

14

14

C

C3 Appliance Installation

Place the floor protector on the floor. Ensure that the floor protector is properly

centred to the location of the flue exit hole on the ceiling. Place the plinth or base on

the floor protector once the location of floor protector is set.

*Note: Safety clearance requirements for the woodfire must be taken into account

when setting the floor protector location.

Secure the plinth/ base and floor protector to the floor. Use 4x suitable bolts (M6

minimum) through the pre-drilled holes on the plinth and floor protector (circled

below). For concrete floors, concrete screws or dynabolts must be used.

1515

C

If installing onto one of the Escea Plinths, drill holes for mounting the fire, as per the

schematics below. If installing onto the Escea base, this will not be necessary as the

base already has mounting holes in the sheetmetal.

Note: if installing onto the 1500W Plinth, drill the same holes for the product, but

oset to where the fire is being positioned on the plinth.

DRILL HOLES THROUGH

GRC PLINTH TO SECURE

THE WOODFIRE PRODUCT

TO THE PLINTH

16

16

C

Place the appliance on top of the plinth and secure it to the plinth. Use the supplied 4x

M8x50 Hex bolts and 4x M8 x 32 washers to bolt through the plinth to the appliance.

*Note: Before placing the fire on the plinth, pre-drill 3x 3.3mm dia flue fixing holes on

both the fireplace Ø150mm and Ø200mm spigots.

USE M8 x 32 WASHER AND

M8 x 50 BOLT HEX BOLT FOR

EACH HOLE

2x HOLES ON EACH SIDE

Connect 3x pieces of the 1219mm long, Ø150mm flue pipe together to create a long

flue pipe. Drill through flue pipes and use a minimum of 3x SS rivets to connect flue

pipes together.

Place Ø150mm flue spiders around each of the Ø150mm flue pipe. Tighten the screws

and nuts to secure the spiders to the flue pipes. Drill through spider and flue pipes and

use a minimum of 3x SS rivets to further secure the spiders to flue.

Connect 3x pieces of the 1219mm long, Ø200mm flue pipe together to create a long

flue pipe. Drill through flue pipes and use the provided rivets to connect flue pipes

together.

Place Ø200mm flue spiders around each of the Ø200mm flue pipe. Tighten the

screws and nuts to secure the spiders to the flue pipes. Drill through spider and flue

pipes and use a minimum of 3x SS rivets to further secure the spiders to flue.

*Note: For more information regarding flue installation and minimum requirements,

please refer to section C5.

1717

C

Place the Escea ceiling plate over the spigots on the fire (folds pointing upwards). The

ceiling plate is supplied with the Escea Freestanding Flue Kit.

Position the long Ø150mm flue pipe (with the crimped end pointing downwards) into

the inner spigot. Use a minimum of 3x rivets to fasten the Ø150mm flue pipe through

pre-drilled holes on the Ø150mm spigot.

Position the long Ø200mm flue pipe (with the crimped end pointing downwards) into

the outer spigot. Use a minimum of 3x rivets to fasten the 200mm flue pipe through

pre-drilled holes on the outer spigot.

*Note: For more information regarding flue installation, please refer to section C4.

150

PLACE 150mm SPACER HERE

200

MINIMUM 1600mm

PLACE 200mm SPACER HERE

18

18

C

Secure the ceiling plate on to the ceiling. Use the 4x supplied machine pozi screws and

4x 12mm ceramic spacer.

Cut one of the Ø250mm galvanised liners from a length of 1219mm length to match

the required liner length. Then connect the 2 pieces of the Ø250mm liners together to

create a long liner pipe. Use a minimum of 3x SS rivets to connect flue pipes together.

Position the Ø250mm flue liners above the ceiling plate (with the crimped end

pointing upwards). Align the Ø250mm liner so that the end is flush with the ceiling

and attach the flue liner to ceiling and roof beams using appropriate fasteners. Note:

above the ceiling penetration and below the roof penetration, a 25mm clearance to any

combustible material must be maintained.

For more information regarding flue installation, please refer to section C4.

1919

C

Install the back vermiculite panel by tilting the panel and placing the bottom edge of

the back panel above the ember air plenum. Carefully push the top of the back panel

towards the back wall of the firebox.

*Note: Please hold the back panel in place while placing the side panels in place to

prevent it from tipping over.

*Note: Please refer to the diagram below for the correct orientation of the back

vermiculite panel during installation to the firebox. The door has been removed for

clarity.

THIS SURFACE IS VISIBLE

FROM THE FRONT

ISOMETRIC VIEW

BACK SURFACE OF THE

VERMICULITE PANEL

FRONT SURFACE

OF THE

VERMICULITE PANEL

BACK SURFACE

OF THE

VERMICULITE PANEL

THIS CHAMFER IS

NOT VISIBLE

SIDE VIEW

20

20

C

Install the left and right side vermiculite panels next by placing the panels on the sides

above the firebox base. Carefully push the top of the side panels towards the side walls

of the firebox.

*Note: Please refer to the diagram below for the correct orientation of the side

vermiculite panels during installation to the firebox. The door has been removed for

clarity.

THIS SURFACE IS VISIBLE

FROM THE TOP

ISOMETRIC VIEW

CHAMFERS ON THE

BOTTOM EDGE

BACK SURFACE OF THE

VERMICULITE PANEL

THIS CHAMFER IS

NOT VISIBLE

THIS CHAMFER IS

NOT VISIBLE

FRONT SURFACE OF THE

VERMICULITE PANEL

TOP VIEW

This manual suits for next models

2

Table of contents

Popular Wood Stove manuals by other brands

Blaze King

Blaze King SIROCCO 20 manual

Osburn

Osburn 2300 owner's manual

Vermont Castings

Vermont Castings The Aspen 1920 Installation & operating manual

Drolet

Drolet HERITAGE owner's manual

Blaze King

Blaze King BOXER 24 Operation & installation manual

Jøtul

Jøtul F 100 Nordic Installation instructions with technical data

Vermont Castings

Vermont Castings Challenger VSW40 owner's manual

CARBEL

CARBEL ARES Manual for use and maintenance

Enerzone

Enerzone EB00060 Installation and operation manual

Regency

Regency F1100S Owners & installation manual

Blaze King

Blaze King ASHFORD AF20.2 Operation & installation manual

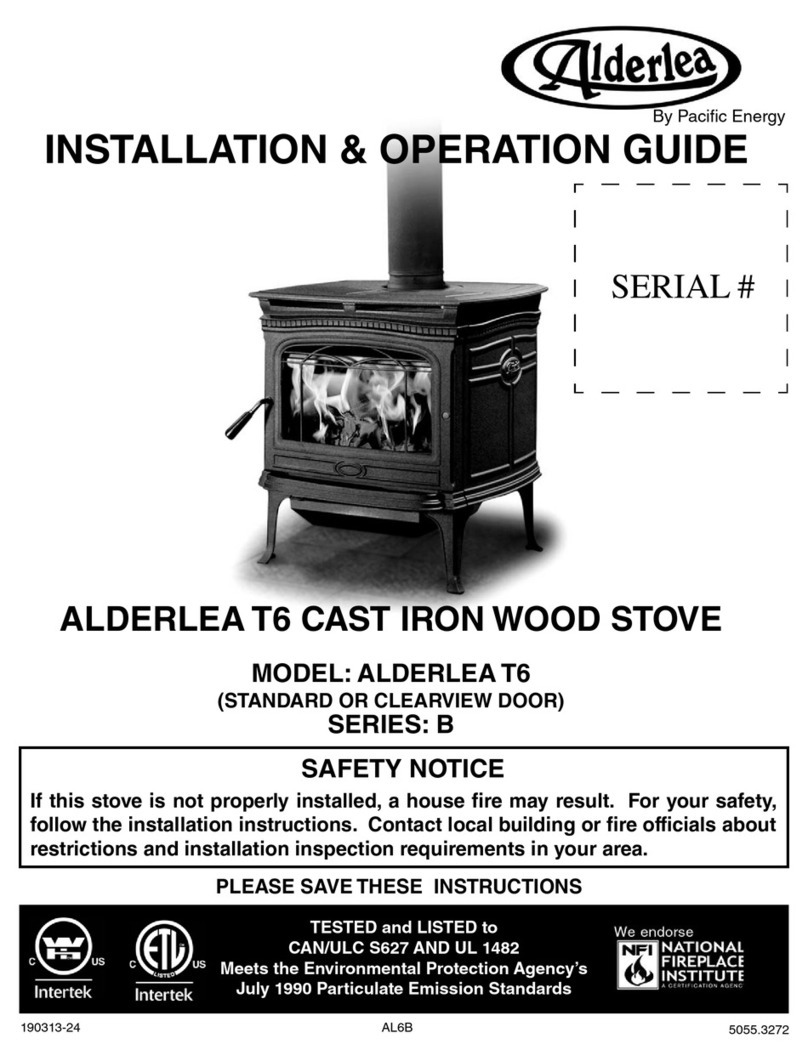

Alderlea

Alderlea T6 Installation & operation guide