Escorts FarmTrac 45 DT User manual

OPERATOR ’S

M A N U A L

OPERATOR ’S

M A N U A L

45 DT

2

CONTENTS

Page

LimitedWarranty ii

FederalEmission Warranty iii-iv

Introduction v

Safety Precautions vi-viii

UniversalSymbols ix

RoadSpeed Decal ix

Safety Decals x

CONTROLS,INSTRUMENTS AND OPERATION

Operator’s Seat, Seat Belt, Safety Frame or Roll Bar 2

Instrumentsand Controls 2

Starting the Engine 4

StoppingtheEngine 5

ParkingBrake 5

FootControls 6

Transmission 7

Power-Take-Off 7

Hydraulic System 9

ThreePoint Linkage 14

TrackAdjustment 17

TractorWeighing 20

Tire Inflation 22

LUBRICATIONANDMAINTENANCE

Lubricationand Maintenance Chart B/2

RoutineServicing B/4

GeneralMaintenance B/21

SPECIFICATIONS

INDEX

SECTION A

SECTION B

SECTION C

SECTION D

LIMITED WARRANTY

FARMTRACAGRICULTURALTRACTORS

ESCORTS LIMITED warrants to its overseas Authorized Dealers that each new Farmtrac Agricultural tractor sold

byitto theAuthorizedDealer willbefree, undernormalusage andservice,from defectsinmaterials andworkmanship

foraperiod of one (1) yearor one thousand (1000) hoursofoperation, whichever is earlier, fromthedate of sale to

thefirstoriginal retail purchaser. Escorts Limited’s obligationunderthis warranty is limited to repairing orreplacing

at its own, sole and absolute option in an Authorized Dealer’s place of business any part or parts that, within the

warrantyperiod,arereturnedtoitsAuthorizedDealerswithtransportationcharges prepaid.EscortsLimited’sinspection

mustshow that the returned partor parts were defectiveatthe time of manufacture.Parts replaced pursuant tothis

warranty shall be warranted only for the remainder of the warranty period applicable to the tractor.

This warranty is expressly limited to the repair or replacement of the defective parts as set forth herein and is the

only warranty given by Escorts Limited and is in lieu of any and every warranty of every kind either expressed or

implied, and this warranty cannot be changed, modified or added to except in writing by a duty elected officer of

Escorts Limited and no dealer, distributor, agent, salesman or representative has any right or authority to change,

modify or enlarge this warranty or to make any promise, stipulation and/or agreement inconsistent or in conflict

therewith.

This warranty does not apply if the tractor or any part thereof has been subjected to misuse or negligence on the

part of the owner or operator, or accident. This warranty does not extend to expendable and consumable items

including such items as brake discs, clutch discs, air filters, engine and hydraulic oil, oil filters, fan belts and light

bulbs. This warranty does not cover normal maintenance services such as engine tune-up, cleaning or minor

adjustments.This warranty also doesnot apply to tractorswhich have been fittedwith any part orparts which have

not been made or supplied by Escorts Limited.

IMPORTANT

No other warranty whether or merchantability, fitness or otherwise, expressed or implied, in fact

or by law, is given by Escorts Limited with respect to any new tractor or part and no other or

further obligation or liability shall be incurred by Escorts Limited by reason of the manufacture or

sale of any new tractor or part whether for breach of any warranty, negligence of manufacture or

otherwise.

Theobligations of EscortsLimitedset forthin the firstparagraph hereinaboveshallbe theexclusiveremedy forany

breachof warrantyhereunder. Inno eventshall EscortsLimited beliable forany general,consequential orincidental

damages including, without limitations, any damages for loss of use or loss of profits.

Farmtrac tractors sold through other than Authorized Dealers are not subject to standard warranty and service

policies of Escorts Limited.

EscortsLimited has a Companypolicy of continuousimprovementand development. EscortsLimitedreserves the

right to make changes or improvements at any time without incurring any obligations whatsoever to make such

changesonproducts sold previously.

Thiswarrantybecomes effectiveuponreceiptofa properlycompletedPre-Delivery InspectionReportbyitsOverseas

AuthorizedDealers or Distributors.

Escorts Limited makes no warranty with respect to proprietary articles such as tires, tubes batteries etc. which

maybe fittedinanoverseasterritorysincesuch productsare warrantedseparately bythe respectivemanufacturers.

This warranty shall not apply to any tractor or part there of that has been repaired or altered outside of Escorts

Limited’sfactoror anAuthorizedDealer’sShop.

SAFETY INSTRUCTIONS

ii

SAFETY INSTRUCTIONS

FEDERAL EMISSIONS WARRANTY

(Applicable only to Tractors sold in United States of America)

Escorts Limited warrants that each new 2002 and later non-road diesel engine fitted on your Farmtrac Agricultural

tractorwas designed, builtand equippped toconfirmto applicableU.S.Environment ProtectionAgencyregulations

for a period of five years of three thousand (3,000) hours of operation, whichever is earlier, from the date of sale to

thefirstoriginal retail purchaser.

Thenew model year,class ofdieselengine andemissionapplication determinationfor your engineare identified on

the emission control information label affixed to the top of your engine’s rocker arm cover (see on the next page).

This warranty is expressly limited to repair or replacement of any emission control system parts, which are proven

defectiveduringnormal use during the warranty period. Thewarrantyrepairs and service will be performed byany

Authorized Dealer of Escorts Limited at the Dealer’s place of business. Parts replaced pursuant to this warranty

shall be warranted only for the remainder of the warranty period applicable to the tractor. This emission control

system warranty applies to the following emission control parts:

Fuel Injection Pump Intake Manifold

Fuel Injectors Exhaust Manifold.

HighPressurePipes

As a tractor owne, your are responjsible for performing all the required engine maintenance listed in your Owner’s

Manual. Escorts Limited will not deny an emission warranty claim solely for lack of maintenance records with you.

However, a claim may be denied if your failure to perform maintenance resulted in the failure of a warranted part.

Receipts covering regular maintenance should be retained in the event of any clarifications required and these

receipts should be passed to each subsequent owner of the tractor.

Tomaintain the quality andperformance originally designed intoyouremission certified engine,itis recommended

that only replacement parts supplied by Escorts Limited be used for maintenance or repairs. The use of parts not

supplied by Escort Limited does not invalidate the warranty on other components unless the use of such parts

causesdamage towarrantedparts. Ifyou beliueve youhave not receivedthe serviceentitledto underthis warranty,

you should contact us for assistance at the following address:

Export Department

Agri.MachineryMarketing Division,

Escort Limited,

18/4MathuraRoad,

Faridabad- 121007,INDIA.

Phone- (91)(0129) 5283071

Fax - (91) (0129) 5284839

Please note that the Emission Warranty does not cover:

1. Systems and Parts that were not first installed on your tractor or engine as original equipment by Escorts

Limited.

2. Part malfunctions caused by abuse, misuse, improper adjustment, modification, alteration, tampering,

disconnection,improper, or inadequate maintenance,oruse of non-recommendedfuelsand lubricating oils.

3. Accident caused damage, acts of nature, or other events beyond Escorts Limited’s control.

4. Replacement of expendable items made in connetion with scheduled maintenance.

5. Partsrequiring replacement, inspectionor adjustment atregular maintenance intervalsforreasons otherthan

being defective.

iii

6. Parts which are not Escorts Limited’s Service Parts.

7. Loss of time, inconvenience, loss of use of equipment/engine or commercial loss.

8. Equipmentwith altered or disconnectedhourmeterwhere the hours cannotbe determined.

9. Equipment not sold by Escorts Limited in United States or normally operated outside the United States.

10. Non defective parts replaced by other that Escorts Limited’s Dealers.

This warranty becomes effective upon receipt of a properly completed Pre-Delivery Inspection Report by the

Authorized Dealers of Distributors of Escorts Limited.

SAFETY INSTRUCTIONS

EMISSION CONTROL INFORMATION LABELS

NOTE : The Model year shown on the Emission Control Information Lable changes as applicable.

IMPORTANTENGINE INFORMATION

EPA ENGINE FAMILY :XAELL 2.86 FTD TAPPET CLEARANCE-IN (COLD) :0.014-0.018 inch

ENGINE MODEL :F3.287 TAPPET CLEARANCE-EX (COLD) :0.017-0.021 inch

DISPLACEMENT :2.86 Lts. INJECTION TIMING (STATIC) :120BTDC

ADVERTISED POWER :29KW NET (ISO 2288) HIGH IDLING SPEED :2300-2400 RPM

RATED SPEED :2000 RPM LOW IDLING SPEED :600-700 RPM

•·THIS ENGINE CONFORMS TO 1999 U.S. EPA REGULATION FOR LARGE NON-ROAD COMPRESSION

IGNITION ENGINES.

•THIS ENGINE IS CERTIFIED TO OPERATE ON COMMERCIALLY AVAILABLE DIESEL FUEL

IMPORTANTENGINE INFORMATION

EPA ENGINE FAMILY :XAELL 3.14 FTD TAPPET CLEARANCE-IN (COLD) :0.014-0.018 inch

ENGINE MODEL :F3.315 TAPPET CLEARANCE-EX (COLD) :0.017-0.021 inch

DISPLACEMENT :2.86 Lts. INJECTION TIMING (STATIC) :120BTDC

ADVERTISED POWER:34.9KW NET (ISO 2288) HIGH IDLING SPEED :2300-2400 RPM

RATED SPEED :2000 RPM LOW IDLING SPEED :600-700 RPM

•THIS ENGINE CONFORMS TO 1999 U.S. EPA REGULATION FOR LARGE NON-ROAD COMPRESSION-

IGNITION ENGINES.

•THIS ENGINE IS CERTIFIED TO OPERATE ON COMMERCIALLY AVAILABLE DIESEL FUEL

(a)FARMTRAC45

(a)FARMTRAC60

iv

INTRODUCTION

ThankyouforpurchasingyournewFarmtractractor.

ThisManual has beenprepared toassistyou inthe correct procedurefor running-in, drivingand operating your new

tractor and to assist you in the correct method of maintenance to keep it in peak condition.

Your tractor has been designed and built to give maximum performance, economy and ease of operation undera

wide variety of operating conditions. Prior to delivery, the tractor was carefully inspected, both at the factory and

by yourAuthorizedDealer toensure that itreaches youin optimum condition.To maintainthiscondition andensure

trouble-free operation, it is important that the routine services, as specified in this manual, are carried out at the

recommendedintervals.

Pages vi to viii inclusive, list the precautions to be observed to ensure your safety and the safety of others. Read

the safety precautions and follow the advice offered before operating the tractor.

A vehicle identification plate is located under the tractor bonnet. The vehicle reference serial number are also

recordedonthepre-deliveryinspectionsheetthatwasprovidedtoyoubyyourAuthorizedDealerandshouldbequoted

to the Dealer should the tractor require service.

Read this Manual carefully and keep it at a convenient place for future reference. This manual must be considered

as an integral part of your tractor. If at any time you require service or advice concerning your tractor, do not

hesitate to contact your Authorized Dealer. He has trained personnel, genuine parts and the necessary equipment to

carry out all your service requirements.

Following these introductory pages, this manual is split into four sections. Section A describes the controls and

instrumentsand advises the correctmethod of operatingyournew tractor. SectionB details lubrication andmainte-

nanceprocedures and includes acomprehensive service chart.SectionC outlines thespecificationsof your tractor.

A comprehensive index is provided at the back of the Manual in Section D.

Escorts Limited has a Company policy of continuous improvement and development. Designs, materials and/or

specifications are subject to change without notice and without any liability whatsoever.

Alldata given inthis book issubjectto productionvariations.Dimensions and weightsare approximate onlyand the

illustrations do not necessarily show tractor in standard condition. Some of the equipment /accessories described

in the text may also not be fitted on your tractor. For exact information about any particular tractor, please consult

yourAuthorized Dealer.

SAFETY INSTRUCTIONS

v

SAFETY INSTRUCTIONS

SAFETY PRECAUTIONS

vi

THE TRACTOR

1. Read this Manual carefully and familiarize yourself

withallthecontrolsbeforeattemptingtooperatethe

tractor.Workingwith unfamiliarequipmentor lackof

operatingknowledge maylead toaccident.

2. Do not permit anyone to ride on the tractor with the

operator.

3. Use the foot steps and assist handles when getting

onoroffthetractor.Itisrecommendedthatyouface

thetractorwhenmountingordismounting.Keepsteps

and platform clear of mud and debris.

4. Replace any warning sign on the tractor that

becomes damaged or is painted over. Replace all

missing, illegible or damaged safety decals.

OPERATING THE TRACTOR

1. Neverstarttheenginewhilestandingbesidethetractor.

Alwayssitinthetractorseat,fastenseatbeltandensure

thattheRollOver Protective Structure (ROPS)/Cab is

in place before starting the engine.

2. Applytheparkingbrake,placetheP.T.O.leverinthe

“OFF” position, set the control levers in the down

position,theremotecontrolvalveleversintheneutral

position and the transmission in neutral before

starting the tractor.

3. Donotbypassthesafetystarterswitch.Consultyour

Authorized Dealer if your safety starter controls are

notoperatingcorrectly.

4. Stop the engine, disconnect P.T.O. and apply the

parkingbrakebefore dismounting.

5. Donotengage theparkingbrakewhilethetractoris

in motion.

6. Never get off the tractor while it is in motion.

7. Never park the tractor on a steep incline.

8. Toprovidemaximumlateralstability,addliquidballast

to tires, use cast iron wheel weights and set front

and rear wheels to maximum tread width

commensuratewiththeoperationbeingperformed.

9. Do not tie ropes, chains, or cables to the axle or

other parts of the chassis. Always hitch the load to

thetractor’sdrawbarinthelowestpossibleposition,

exceptwhenpullingimplementsspecificallydesigned

for and properly attached to the three point hitch.

10. Donotoperatethetractorwithalightfrontend.Ifthe

fronttendstorise withheavyimplementsattherear,

install front end or front wheel weights.

11. Ensurethatanimplementcoupledtothethree-point

linkage does not contact any part of the cab, if cab

is provided.

12. Neverleave equipment in theraisedposition.

13. If the engine or power steering ceases operating,

stop the tractor immediately.

14. Always engage ‘Position Control’ when attaching

equipment, transporting equipment and when no

equipment is attached. Be sure hydraulic couplers

are properly mounted and will disconnect safely in

case of accidental detachment of the implement.

15. Ensureany attachedequipment or accessoriesare

correctly installed, are approved for use with the

tractor,donot overloadthetractor andareoperated

and maintained in accordance with the instructions

issuedbytheequipmentoraccessorymanufacturer.

16. Rememberthatyour tractor,ifabused orincorrectly

used,canbedangerousandbecomeahazardboth

to the operator and to bystanders. Do not overload

oroperatewithattached equipmentwhichisunsafe,

not designed for a particular task or is poorly

maintained.

WARNING :Hearing protection must be worn

when operating this tractor if a safety cab is not

fitted.

CAUTION:YourFarmtractractorisnotequipped

withaSparkArrestor.Where thereis ariskoffire

to the crop or environs or local legislation so requires, a

suitable Spark Arrestor must be installed.

DRIVING THE TRACTOR

1. Always drive the tractor with care and at speeds

compatible with safety, especially when operating

overroughground,crossingditchesorslopesorwhen

turningto avoid overturning thetractor.

2. Never allow the tractor to over-run when going

downhill,particularlywithtrailedequipmentattached.

Keepthetractorinthesamegearwhengoingdownhill

asusedwhengoinguphill.Donotcoastorfree-wheel

down hills. Use extreme caution while operating on

steepslopes and usea low gearto maintain control

withminimum braking.

3. Lockthefootbrakespedalstogetherwhentravelling

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions to

prevent the possibility of injury or damage. The following precautions should be taken to help prevent accidents.

Readthem carefully before operatingyour new Farmtrac tractor.

SAFETY INSTRUCTIONS

vii

onthehighway.

4. Whenoperatingin thefieldunlockthebrakepedals.

5. Reducespeedbeforeturningorapplyingthebrakes.

Brakeboththewheelssimultaneouslywhenmaking

an emergency stop.

6. Do not engage the differential lock when turning

the tractor. When engaged, the lock will prevent

the tractor taking the turn and may result in

overturning of the tractor.

7. Ifthe tractordrivewheelsarestuck,shiftto reverse

gear and back out, to prevent from lifting the front

wheelsofftheroundand possiblyrolling thetractor

overbackwards.

8. Slowmoving vehicleson highwaysare dangerous.

Useaslow moving (SMV) sign inconjunctionwith

red lights, tail lights, and flashing warning lights.

9. Useextreme cautionand avoidhard applicationof

the tractor brakes when towing heavy loads. Any

towed vehicle whose total weight exceeds that of

the tractor must be equipped with brakes for safe

operation.

10. Watchwhere youare goingespecially atrowends,

on roads, around trees and any low hanging

obstacle.

11. Dip the tractor lights when meeting a vehicle at

night. Ensure the lights are adjusted to avoid

blinding the driver of an on coming vehicle

(applicable only twin beam Head lamps are fitted.

12. Alwayscheckoverheadclearance,especiallywhen

working in confined spaces.

13. Engage the clutch slowly when driving out of a

ditch, gully or up a steep hillside. Disengage the

clutch promptly if the front wheels rise off the

ground.

OPERATING THE P.T.O.

1. Ensure the P.T.O. guard is always installed and

replacethe P.T.O.shaftcapwhentheP.T.O.is not

beingused.

2. Shutoffthe engine and waitforthe P.T.O. shaft to

stopturningbeforegettingoff thetractor toconnect

ordisconnect P.T.O.drivenequipment.

3. Applytheparkingbrakeand blockthe rearwheels,

front and rear, when operating stationary P.T.O.

drivenequipment.

4. Toavoidinjuryneverclean,unclog,adjustorservice

P.T.O.driven equipmentwhile thetractor engineis

running.

5. NeverwearlooseclothingwhenoperatingtheP.T.O.

or when near equipment that is rotating.

6. Beforeoperating implements,study theimplement

manufacturer’s handbook. Certain implements

requirespecial operatingtechniques.

SERVICING THE TRACTOR

1. Keepthetractorandequipment, particularlybrakes

and steering, maintained in a reliable and

satisfactory condition to ensure your safety and

comply with legal requirements.

2. Stop the engine and disconnect battery terminals

beforeperformingany service on the tractor.

3. Topreventfireorexplosion,keepopenflamesaway

from the battery. To prevent sparks which could

cause explosion, use jumper cables according to

instructions.

4. The fuel oil in the injection system and fluid in the

hydraulicsystem are underhigh pressure andcan

penetrate the skin. Unqualified and unauthorized

persons should not remove or attempt to adjust a

pump, injector, nozzle or any other part of the fuel

injectionsystem.This also may beunlawfulunder

certain circumstances. Failure to follow these

instructions can result in serious injury.

5. DO NOT

lUse your hand to check for leaks. Use a piece

of cardboard or paper to search for leaks.

lStop the engine and relieve pressure before

connecting or disconnecting hydraulic or fuel

lines.

lTighten all connections before starting the

engineor pressurising lines.

lIf fluid is injected into the skin obtain medical

attentionimmediately or gangrene mayresult.

6. Thecoolingsystem operatesunderpressure which

iscontrolledby the radiator cap. Itisdangerous to

remove the cap while the system is hot. Allow the

engine to cool, then turn the cap slowly to the first

stop and allow the pressure to escape before

removingthe cap entirely.

7. Continuouslongterm contact with usedengineoil

may cause skin cancer. Avoid prolonged contact

withused engineoil. Washskin promptlywithsoap

andwater.

8. Some components on your tractor, such as

gasketsand frictionsurfaces (brake linings,clutch

linings, etc.), may contain asbestos. Breathing

asbestos dust is dangerous to your health. You

are, therefore, advised to have any maintenance

or repair operations on such components carried

out by an Authorised Dealer. If, however, service

operations are to be undertaken on parts that

contain asbestos, the following essential

precautions must be observed:

ATTENTION ! BECOME ALERT ! YOUR SAFETY IS INVOLVED !

lWork out of doors or in a well ventilated area.

lDustfoundonthe tractor or produced during

work on the tractor should be removed by

extraction and not by blowing.

lDust waste should be dampened, placed in a

sealed container and marked to ensure safe

disposal.

lIf any cutting, drilling etc., is attempted on

materialscontaining asbestos,the itemshould

bedampenedandonlyhand toolsor lowspeed

powertoolsused.

9. Do not run the tractor engine in a closed building

without adequate ventilation as exhaust fumes

may suffocate you.

10. Do not modify or alter or permit anyone else to

modifyor alterthetractor orany of itscomponents

orany tractorfunctionwithout firstconsulting your

AuthorisedDealer.

11. Tractorwheels are heavy. Handlethemwith care

and ensure that, when stored, they cannot topple

andcauseinjury.

DIESEL FUEL

1. Underno circumstancesshould gasoline,alcohol

or blended fuels be added to diesel fuel. These

combinations can create an increased fire or

explosive hazard. In a closed container, such as

afueltank, these blends aremoreexplosive than

pure gasoline. Do not use them blends.

2. Neverremovethefuelcap orrefuelwith theengine

runningorhot.

3. Donot smokeor allowan openflame nearthe fuel

tank or while refuelling the tractor. Wait for the

enginetocool before refuelling.

4. Maintaincontrol on thefuel filler pipenozzle when

filling the tank.

5. Do not fill the fuel tank to capacity. Allow room for

expansion.

6. Wipe up spilled fuel immediately.

7. Always tighten the fuel tank cap securely.

8. If the original fuel tank cap is lost, replace it with

anapproved cap.A non-approvedcap maynot be

safe.

9. Keepequipment cleanand properlymaintained.

10. Do not drive equipment near open fire.

11. Never use fuel for cleaning purpose.

12. Use diesel fuel with a minimum cetane rating of

40 (Diesel fuel no. 2) at ambient temperatures

above –700C(200F) or Diesel fuelno. 1 below this

temperature. At very low ambient temperatures

and/orat high attitude, a fuelwith a higher cetane

ratingis required.

13. Diesel fuel with a sulphur content above 1.3% is

notrecommended.

14. Precaution should be taken to ensure that stored

fuel is kept free of dirt, water, etc.

15. Fuel should be stored in black iron tanks, not

galvanised tanks, as the galvanised coating will

react with the fuel and form compounds that will

contaminate the injection pump and injectors.

16. Bulk storage tanks should be installed away from

directsunlight andangled slightlysothat theoutlet

pipe is at the higher end. In this way sediment in

the tank will settle away from the outlet pipe.

17. To facilitate moisture and sediment removal, a

drain plug should be provided at the lowest point

(at the opposite end to the outlet pipe). If there is

no filter on the outlet pipe, then a funnel with a

fine mesh screen should be used when filling the

tractor fuel tank.

18. Fuelpurchasesshouldbearrangedsothatsummer

grade fuels are not held over and used in winter

andvice-versa.

19. Refill the fuel tank via filler tube which is on the

rear left-hand side of the hood.

CAUTION :Thefuel oil in theinjection system

is pressurized and can penetrate human skin

withfatalresults.Adjustmentoffuelinjection equipment

should not be carried out by unqualified person.

SAFETY FRAME OR ROLL BAR (where fitted)

Yourtractor maybeequipped withasafety frameor roll

barwhichmustbemaintainedinaserviceablecondition.

Becareful whendriving throughdoorwaysor workingin

confinedspaceswith low headroom.

Under no circumstances:

i) modify, drill, weld or alter the safety frame or roll

barin anyway. Doingso couldrender youliable to

legal prosecution in some countries.

ii) attemptto straightenor weldany partofthe safety

frame, roll bar or retaining brackets which have

suffered damage. By doing so you may weaken

thestructure and endanger yoursafety.

iii) secureanyparts on the safetyframeor roll bar or

attach if with other than the special high tensile

bolts and nuts specified.

iv) attach chains or ropes to the safety frame or roll

barforpulling purpose.

v) take unnecessary risks even though your safety

frame or roll bar affords you the maximum

protectionpossible.

CAUTION : Ifthereisarisk fromfallingobjects

at your work environment, a Falling Objects

Protective Structure (FOPS) must be installed on your

tractor.

SAFETY INSTRUCTIONS

Whenever you see the symbol it means:

viii

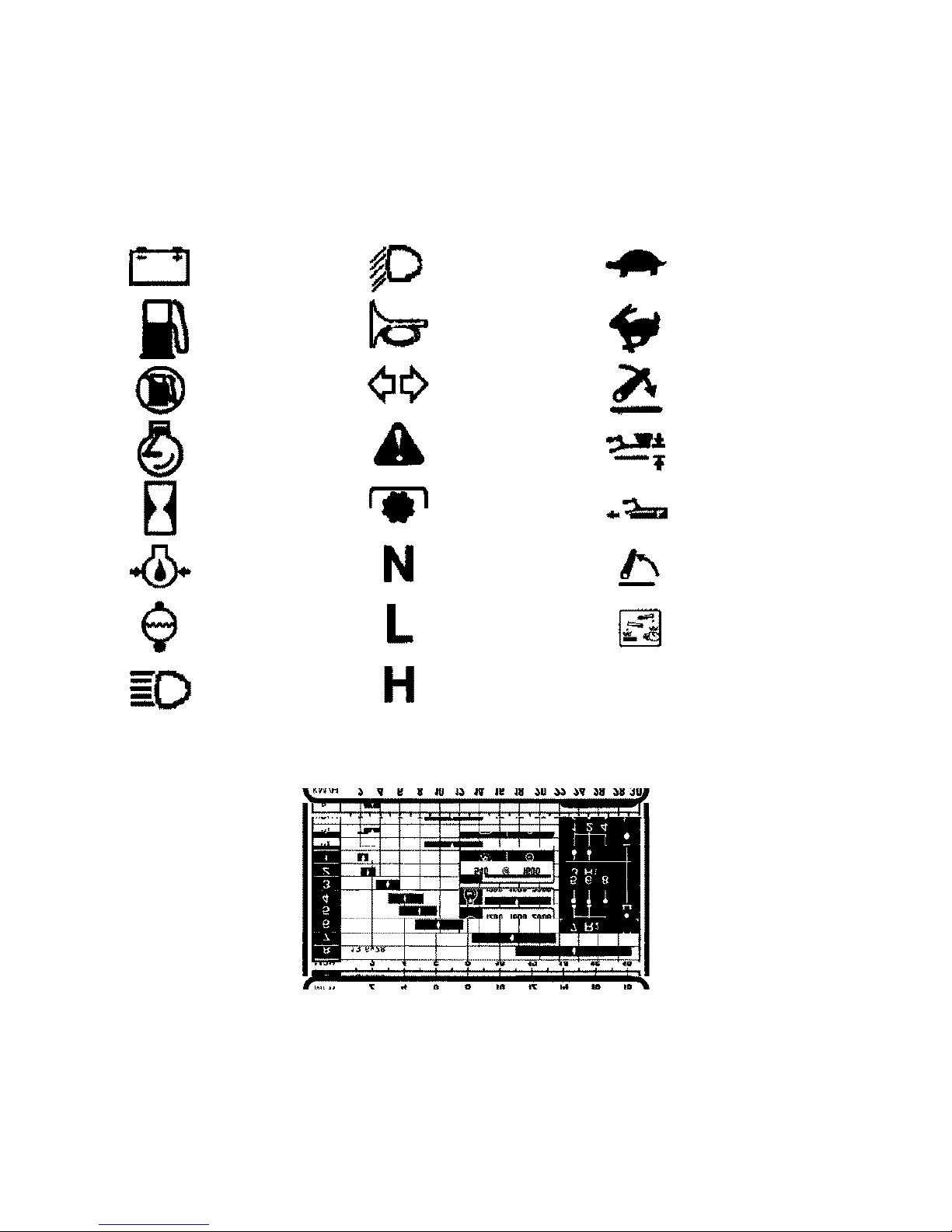

UNIVERSAL SYMBOLS

As a guide to the operation of your tractor, various universal symbols have been utilized on the instruments,

controls, switches and fuse box. The symbols are shown below with an indication of their meaning.

Alternator/Dynamo

Charge

Fuel level

Fuel shut-off

Enginespeed

(rev/min × 100)

Hoursrecorded

Engineoil pressure

Enginecoolant

temperature

Headlight

mainbeam

Headlightdipped

beam

Horn

TurnSignals

Warning!

P.T.O.

Transmissionin

neutral

Lowtransmission

range

Hightransmission

range

Slow or low setting

Fast or high setting

Linkagelower

PositionControl

DraftControl

Linkageraise

Warning!Corrosive

substance

Thedecal shown aboveissimilar to thatfitted next totheinstrument panel ofyour tractor andgraphically illustrates

the approximate tractor road speed at three alternative engine speeds. The decal also shows the engine speed at

which P.T.O. speed of 540 RPM is obtained. Accurate road speed charts are provided at the end of Section C.

ix

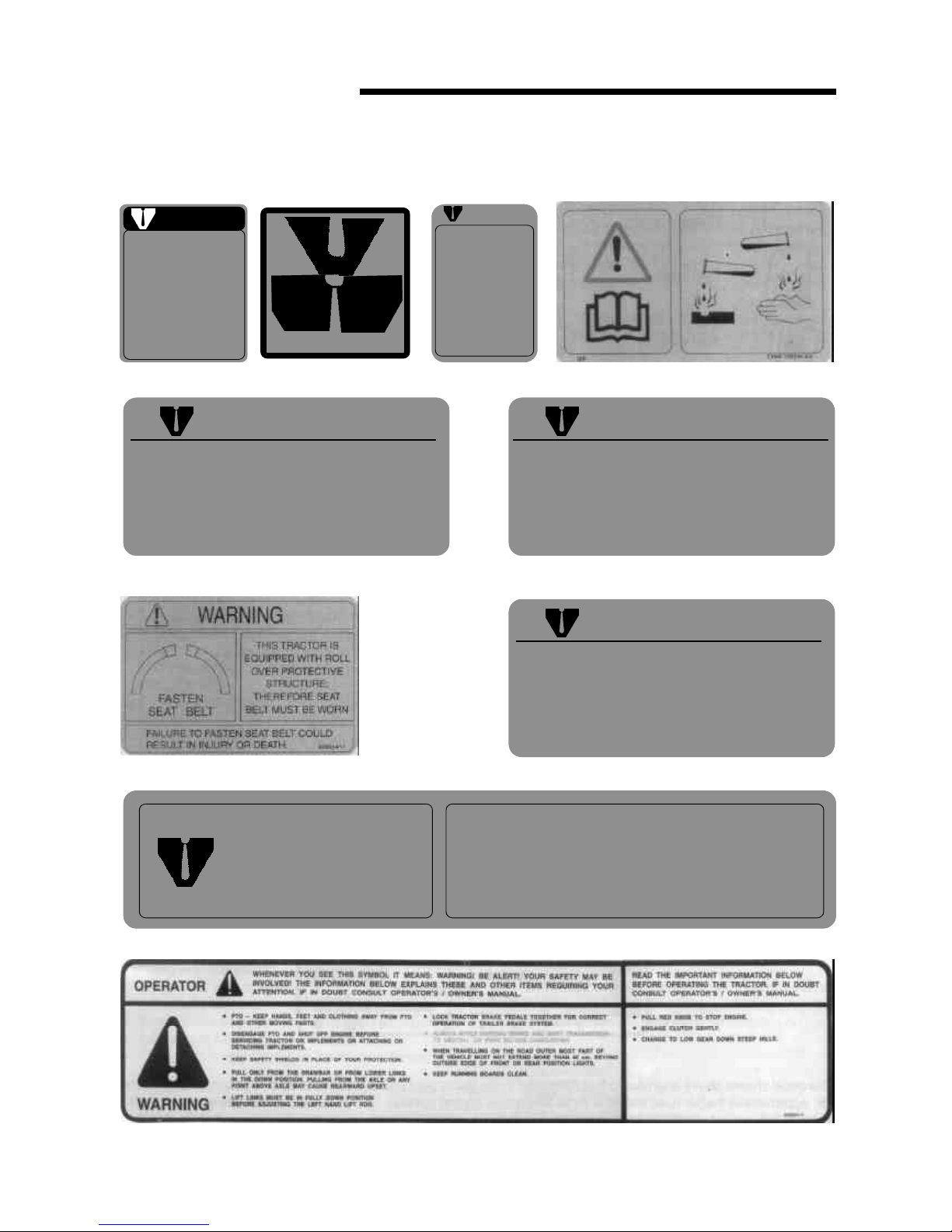

SAFETY SYMBOLS

x

CAUTION

DO NOT OPERATE

UNTILL YOU READ THE OWNERS MANUAL

IF YOU DID NOT RECEIVE A COPY ONE MAY BE OBTAINED FROM

YOUR AUTHORISED DEALER

l

Pull only from drawbar. Pulling

from other points can cause rear

overturn.

l

Do not operate with unshielded PTO.

l

Disangage PTO and stop engine before

servicing tractor or implements or

attaching and detaching implements.

l

Position drawbar at 14" from end of

PTO shaft to drawbar hole for 540 RPM.

l

When towing equipment use a safety

chain.

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS

ABOVE CAN CAUSE SERIOUS INJURY TO THE

OPERATOR OR OTHER PERSONS.

WARNING WARNING

AVOID POSSIBLE INJURY

OR DEATH FROM A

MACHINE RUNAWAY

1. Donotstartengine byshorting

across starter terminals.

Machinewill statrt ingear and

move if normal starting cir-

cuitry is bypassed.

2. Startengine only fromopera-

tors seat with transmission in

neutral or park.

NEVER start enigine while

standing on the ground.

CAUTION

AFTER FIRST HOUR OF OPERATION FRONT

AND REAR WHEEL LUG NUTS AND BOLTS

SHOULD BE CHECKED FOR PROPER

TORQUE - THERE AFTER CHECK DAILY.

82835415

WARNING

THE DIFFERENTIAL LOCK IS PRO-

VIDED FOR USE ON SLIPPERY SUR-

FACES, IT MUST NOT BE USED ON

THE ROAD.

WARNING TO AVOID INJURY, KEEP

THIS GUARD IN PLACE

SAFETY INSTRUCTIONS

E2NN-94000R86-AA

82835419

1178500AA

CONTROLS,

INSTRUMENTS

and OPERATION

Thefollowing pages in thissection detail thelocationand function ofthe various instruments, switchesand controls

on your tractor. Even if you operate other tractors, you should read through this section of the Manual and ensure

thatyouare thoroughly familiar withthe location and function ofall the features ofyournew tractor. Do notstartthe

engine or attempt to drive or operate the tractor until you are fully accustomed to all the controls. It is too late to

learn once the tractor is moving. If in doubt about any aspect of operation of the tractor, consult your Authorized

Dealer.Reference totractor modelsor equipmentnotavailable inyour territoryor tooptions oraccessoriesnot fitted

on your tractor should be ignored.

Particular attention should be paid to the recommendations for running-in to ensure that your tractor will give the

long and dependable service for which it was designed.

See Section B for the routine lubrication and maintenance requirements. The specification of your tractor will be

found in Section C.

SECTION A

1

OPERATOR’S SEAT

Before operating the tractor, it is important to adjust

theseatto the most comfortableposition. See Figure 1

for details.

To achieve the optimum suspension setting, sit in the

seat and turn the suspension adjuster knob until the

weight indicators on the seat frame align.

Press down the horizontal travel adjustment lever and

movetheseat forwardorbackward, asrequired.Further

seat travel is possible after loosening the two seat

mountingboltsthat secure the seatbase to the tractor.

Seat height is adjusted after loosening the two knobs

on both sides of the seat frame.

NOTE: Do not use solvents to clean the seat. Use

warm water with a little detergent added.

SEAT BELT, SAFETY FRAME OR ROLL BAR

(where fitted)

WARNING : Tractors equipped with a safety

frame or roll bar also have a seat belt fitted.

Always use the seat belt with a safety frame or roll-bar

installed. Do not use a seat belt if the tractor is not

equipped with a safety frame or roll bar.

To lengthen the belt, tip the buckle away from the belt

and pull on the buckle. With the belt fastened around

you, pull the free end of the belt until it is a snug fit.

The belt may be sponged with clean, soapy water. Do

1. Seat

1. Suspension adjuster knob

2. Weight indicators

3. Horizontal travel adjustment lever

4. Seat mounting bolts

5. Height adjustment knob

not use solvents, bleach or dye on the belt as a these

chemicals will weaken the webbing. Replace the belt

whenitshowssignsof fraying,damageor generalwear.

If your tractor is fitted with a safety frame or roll bar, it

must be maintained in a serviceable condition.

If your tractor is fitted with a front end loader, it is

recommended that a canopy be fitted to protect the

operator from objects that may fall from the loader

bucket.

WARNING: Do not attach chains or ropes to

thesafetyframeorrollbarforpullingpurposesince

thetractormaytipback-wards.Alwayspullfromthetractor

drawbar.Becareful whendrivingthrough dooropenings

or under low overhead objects. Make sure that there is

sufficientoverhead clearance fortheroll bar.

INSTRUMENTS AND CONTROLS

The following text describes the various gauges,

switches and warning lights installed on your tractor,

See Figure 2A and 2B.

Tachometer

Thetachometerindicatesenginerevolutions perminute.

Eachdivision on thescalerepresents 100 rev/min.-eg.

with the needle indicating ‘20’ the engine is running at

2000rev/min.

Theyellow mark on thetachometer scale indicates the

engine speed at which the standard P.T.O. speed of

540 rev/min is obtained.

Thetachometer also records thetotal number of hours

that the tractor has operated, based on an average

engine speed of 1600 rev/min. If the engine is run at a

speedlower than1600 rev/minthen thetachometerwill

accumulatehoursatarate slowerthan realtime.Higher

enginespeedswillcausethetachometerto accumulate

hours at a rate faster than real time.

The hours recorded should be used as a guide to

determine hours servicing intervals. (see Section B of

this Manual).

Engine Coolant Temperature Gauge

The gauge indicates the temperature of the engine

coolant. If the needle enters the red area of the gauge

while the engine is running, stop the engine and

investigate the cause.

NOTE :When the key-start switch is turned off, the

gauge needle will assume a random position.

CONTROL, INSTRUMENTS AND OPERATION

2

2A. Single Instrument Cluster

1. Tachometer

2. Engine coolant temperature gauge

3. Engine Oil Pressure Warning Light

4. Fuel Gauge

5. LH Turn Signal Indicator

6. RH Turn Signal Indicator

7. Battery Charging Indicator

8. Hazard Warning Light Switch

9. Air Restriction Warning Light

10. Engine Stop Control

11. Tractor Light Switch

12. Key Start Switch

13. Horn Switch

14. Hand Throttle

15. Turn Signal Indicator Switch

16. Plough Lamp Switch

EngineOilPressure Warning Light

The red warning light on the instrumentpanel indicates

lowengineoilpressureandshouldextinguishimmediately

after the engine is started, and is only operative with the

key start switch in the ‘ON’ position.

NOTE :If the light comes on while engine is running,

stop the engine immediately and investigate the cause.

Thelightindicateslowoilpressureandisnotanindication

of oil level. The engine oil level must still be checked

daily by means of the dipstick.

Hand Throttle

Withtheengine running, pull thethrottle lever rearwards

toprogressivelyincreaseenginespeed.Pushthethrottle

leverforwardtodecreasetheenginespeed.

Hazard Warning Light Switch

Press the switch to operate both turn signals

simultaneously. The switch, which is internally

illuminated, will flash in unison with the turn signals

and the turn signal indicator lights on the instrument

panel.

Indicator Ligthss

The upper indicator light of the pair will illuminate when

headlampmainbeamisselected.Wheneitheroftheturn

signal is operated, the lower indicator light will flash in

unison with the turn signals.

In some territories, where only single beam (dipped

beam) headlamps are fitted, the upper indicator light

will flash in unison with the turn signals when either of

the turn signal is operated. If, however, the tractor is

also equipped with a 7 pin rear trailer socket, the lower

indicator light will flash in unison with the turn signals

of the trailer when either of the turn signal is operated.

The turn signal indicator lights will also flash in unison

with the turn signals whenever the hazard switch is

operated.

NOTE : Please check with your Authorized Dealer on

which system is fitted on your Tractor.

Tractor Lights Switch

The lights switch is of the push-pull type and has three

positions:

Fully in :lights OFF

Midway :side, rear and instrument lights ‘ON’

Fully out :side,rear, instrument andheadlights‘ON’

Engine Stop Control

Pull the stop control knob fully out and hold it in that

position to cut off the fuel supply to the injectors and

stoptheengine.Theknobmustbe pushedfullyinbefore

restarting the engine.

SECTION A

3

2B. Instrument Panel

(Steering wheel removed)

4

7

5

39

2

6

1

10

11

12

13

14

15

16 8

4

Key-Start Switch

The key operated switch actuates the starting motor.

See ‘Starting The Engine’ for the correct operating

procedure.

Road Speed Decal

Thedecalwhichisalsoillustratedon PageIX,showsthe

approximatetractorspeedinallgearratios.Accurateroad

speed charts are provided at the end of section C.

Charging Indicator

Theredwarninglighton theinstrument clusterindicates

thatthe alternatorisnotchargingthebatteryand should

extinguish when the engine speed is increased above

idle.

Fuel Gauge

The gauge indicates the level of fuel in the tank and is

only operative with the key-start switch in the ‘ON’

position.

NOTE :When the key-start switch is turned off the

gaugeneedle may assumea random positionand may

indicatesa fuel levelgreater than thetrue level. Always

check the fuel level with the key-start switch on.

Air Restriction Warning Light (where fitted)

When this lamp lights up, clean or replace the outer

elementofdryaircleaner.Iflightcomes onduringtractor

operation when replacement of element is not

immediatelypossible,justcleantheelementandreduce

theenginespeed soontopreventthelampfromlighting.

Seven-Terminal Trailer Socket (where fitted)

Thissocketallowslights,turnsignalsandotherelectrical

equipment on a trailer or impliment to be connected.

This is fitted at the rear of driver’s seat.

Alwaysuseadditionallighting onthemountedimplement

if this conceals the turn signals and other lights at the

rear of the tractor.

CONTROL, INSTRUMENTS AND OPERATION

STARTING THE ENGINE

A five-position key-start switch is installed on all the

tractors. For starting in temperatures down to –180C

(00F) the thermostart option may also be installed,

Basically the thermostart consists of an electrically

heatedelement inthe air intaken manifoldwhich, when

operated, ignites a measure of diesel fuel and

introduces it into the combustion chamber. With the

thermostart installed, all the five positions of the

keystart switch are connected as shown in Figure 3.

However, if the automatic thermostart is not installed,

the starting motor operates at position (4) while as

position (5) is left unconnected (see Figure 3).

IMPORTANT : Never push or tow the tractor to start

the engine. Doing so may overstress the drive train.

NOTE: A safety start switch prevents operation of the

startingmotor unless the transmissionrange lever is in

theneutral(N) position.

Beforestartingthe engine,alwayscarry outthefollowing

procedure:

lSitinthedriver’sseatandensurethattheparkingbrake

latch is firmly applied.

lPush the stop control knob fully in.

lEnsure that both gearshift levers are in neutral and

thattheP.T.O.leverisinthedisengagedposition.

lMovebothhydrauliclift control levers fully forward.

lPlace the remote control valve levers in neutral.

WARNING:Startthetractoronlyfromthedriver’s

seat. If the key-start switch is bypassed, the

engine may start inadvertently with a gear selected and

cause sudden and unexpected movement of the tractor

or a tractor runaway. Wear eye protection when starting

thetractor with jumpleads or whencharging the battery.

For standard tractors (without automatic

thermostart)

lOpen the hand throttle halfway, depress the clutch

to ease the load on the starter motor and turn the

key-start switch fully clockwise to position (4) to

operate the starting motor. Crank the engine until it

startsbutdo notoperatethestartingmotorformore

than 40 seconds and then allow the key to return to

position(3).

lReturnthethrottletotheidleposition andcheckthat

allwarninglightsextinguishandgaugereadingsare

normal.

Connection WireColour

1. Ground Brown

2. ParkingRH Grey-Red

3. Turnsingal LH Black-White

4. Brake light Red-White

5. TurnsignalRH Black-Green

6. ParkingLH Grey-Red

3. Key-startSwitch

1. Electrical equipment ‘OFF’

2. Accessories ‘ON’

3. Warning lights and instruments ‘ON’

4. Thermostart heater ‘ON’ (where fitted), or

Starting motor operates (where thermostart is

not fitted).

5. Starting motor operates (where thermostart is

fitted), or

Unconnected (where thermostart is not fitted).

For tractors fitted with automatic

thermostart:

lInwarmweather,orwhentheengineishot,depress

theclutchandturnthekeystartswitchfullyclockwise

to position (5). Operate the starting motor until the

engine starts or for a maximum of 40 seconds and

then allow the key to return to position (3).

lIn cold weather with the engine cold, depress the

clutch and turn the key-start switch to position (4),

holdfor20-30secondsandthenturnfullyclockwise

to position (5). Operate the starter until the engine

starts or for a maximum of 30 seconds.

lReturn the throttle to the idle position and check

thatallwarninglightsextinguishandgaugereadings

arenormal.

NOTE : If the engine fails to start, repeat the procedure,

after waiting for 1-2 minutes. If the thermo-start is fitted,

thekeyshouldbeheldatposition(4)onlyfor7-10seconds

when attempting to restart the tractor.

STARTING THE TRACTOR WITH JUMP LEADS

If it is necessary to use jump leads (booster cables) to

start the tractor, proceed as follows:

lConnectoneend ofthered jumpleadtothetractor

battery positive (+) terminal and the other end to

the auxiliary battery positive (+) terminal.

lConnect one end of the black jump lead to the

auxiliary battery negative (-) terminal and the other

end to a suitable projection on the tractor engine

block. Follow the starting procedure previously

described.

lWhenthe enginestartsallow itto runatidle speed,

turn on all electrical equipment (Lights etc.) then,

disconnect the jump leads in the reverse order to

theconnectingprocedure.Thiswillhelpprotectthe

alternatorfrompossibledamageduetoextremeload

changes.

NOTE : When using an auxiliary battery to start the

engine,ensurethatthepolarityofthejumpleadsiscorrect

- positive to positive, negative to negative otherwise

thealternatormay bedamaged.

STOPPING THE ENGINE

Tostop theengine, carryoutthe followingprocedure:

lSit in the driver’s seat and close the throttle.

lEnsurethattheparkingbrakelatchisfirmlyapplied.

lEnsurethat both gearshiftlevers are inneutral and

thattheP.T.O.leveris inthe disengagedposition.

lPullthestop controlknob fullyoutand turnthekey-

start switch off.

lMovethehydraulicliftcontrolleversfullyforwardto

lowerall hydraulic equipmentto theground.

lMove the remote control valve levers fully forward

andthenfullyrearwardbeforeplacingtheminneutral

position.

WARNING :Check the area beneath the

equipmenttoensurethatnoinjuryordamagewill

becausedwhenequipmentislowered.

PARKING BRAKE

Toparkingbrakeconsistsofa latchthat isusedtosecure

the foot brakes in the applied position. (See Figure 4).

SECTION A

5

4. Parking Brake

1. T-handle

Tooperatethe parking brake, lockthe brakes together

(see the following text titled ‘Foot-brakes’). Apply the

footbrakes, pullup theT-handle androtate onequarter

turn.To free theparking brake, rotatethe T-handle one

quarterturn andrelease.Momentarily depressthe foot

brakestodisengage theratched.In Figure4,theparking

brake is shown in the applied position.

IMPORTANT : Ensure that the parking brake is fully

releasedbeforedriving off.

FOOT CONTROLS

For details of foot operated controls, refer to Figure 5

and the following text.

Foot Brakes

Thefoot brake pedals,Figure 5,activate therear wheel

brakes and may be operated independently, to aid

turning in confined spaces or together for normal

stopping.When operating in thefield, the brake pedals

may be unlocked. However, due to the close proximity

of the pedals to one another, it is still possible to apply

bothbrakestogether,whenrequired.

WARNING : For your safety, always lock the

brake pedals together when travelling at

transport speeds, or on a highway or if a trailer is

attached.To lockthe pedals together,slide thelatch (5)

across to engage in the hole in the underside of the

right-handpedal, as shown.

Foot Accelerator

The foot accelerator, Figure 5, may be used

independently of the hand throttle to control the speed

of the tractor. It is recommended that you use the foot

acceleratorwhen driving on thehighway.

NOTE :Whenit is requiredto use thefoot accelerator,

set the hand throttle to the idle position (fully forward).

Differential Lock

In field conditions including wheel slip, hold down the

differential lock pedal, Figure 5, until the lock is felt to

engage. The lock will automatically disengage when

traction at the rear wheels equalizes.

Ifconditionscausearear wheelto spinatspeed,reduce

theengine speedto idlebefore engagingthedifferential

lock.

WARNING :Neverengagethedifferentiallock

atspeedsabove5mph (8kmph) orwhenturning

the tractor. When engaged, the lock will prevent the

tractorfromturning.

Clutch

Whenthe clutch pedal,Figure5, is depressedthe drive

betweentheengineandtransmissionwillbedisengaged.

Usethe clutch pedaltotransfer engine powersmoothly

tothedriving wheels when movingoff from a standstill.

Alwaysdepresstheclutchpedaltoengageordisengage

a gear ratio or when operating transmission P.T.O. or

live P.T.O. (see Power Take Off in this section of the

Manual)

NOTE :Avoid resting your foot on the clutch pedal

whenoperating the tractor.Such actionwill leadto early

clutch failure.

5. FootControls

1. Brake pedals

2. Foot accelerator

3. Differential lock pedal

4. Clutch pedal

5. Locking latch

6

CONTROL, INSTRUMENTS AND OPERATION

TRANSMISSION

Thetransmissionis of theconstantmesh type andhas

eightforwardand two reverse speed ratios.

WARNING :To prevent inadvertent tractor

movement, avoid accidental contact with the

gearshift levers. Always stop the engine, firmly apply

the parking brake and place both gearshift levers in

neutral before dismounting from the tractor. A safety

switch prevent operation of the starting motor unless

the right-hand lever is in the neutral (N) position.

The gearshift levers protrude from the center of the

transmission,beneaththe steering wheel.

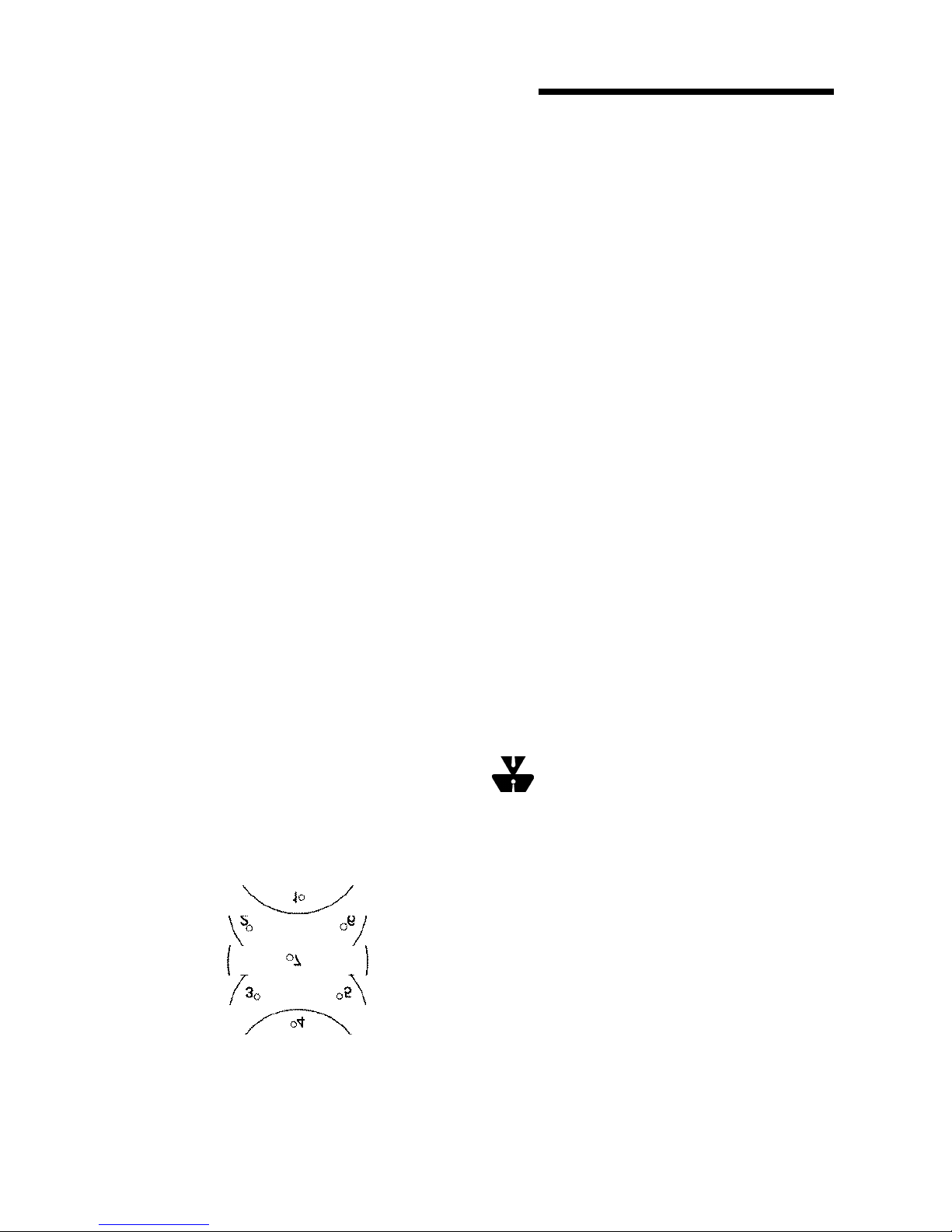

The left-hand gearshift lever (main) is used to select

any one of four forward or one reverse gear ratio. The

right-handlever (range) isused to selectthe high (H)or

low(L)rangewhichhastheeffectofdoublingthenumber

of available gear ratios. Stop the tractor and fully

depress the clutch before moving either of the gear

levers. See Figure 6 for the gear shift positions.

IMPORTANT : When towing the tractor, it is essential

that the transmission main (right-hand) lever is kept in

the neutral (N) position. Non compliance may result in

damage to transmission components.

Avoid overloading the engine. Operating in too high a

gear under heavy load may cause excessive engine

overloading. Overloading occurs when the engine will

not respond to a throttle increase.

Usethe lowergearratios whenpulling heavy loadsand

avoidcontinuousoperation at constant engine speeds.

Operating the tractor in too low a gear with a light load

andhigh enginespeed willwaste fuel.You willsave fuel

andminimize enginewear byselectingthe correctgear

ratio for each particular operation.

Checkthe instruments frequentlyandkeep the radiator

and various oil reservoirs filled to the recommended

levels.

POWER TAKE-OFF (P.T.O.)

The power take-off (P.T.O.) on your tractor transfers

engine power directly to mounted or trailed equipment

via a splined shaft at the rear of the tractor.

The P.T.O. shaft is a 6-spline, 1.375 in (34.9 mm)

diameter shaft designed for 540 rev/min operation, the

speed at which most P.T.O. actuated equipment are

designedto run.

Toobtain540 rev/minatthe P.T.O.,setthetractorengine

speed to 1600 rev/min if your tractor is equipped with

transmissionP.T.O.,or1800rev/minforlivePTOmodels.

FormostP.T.O.operationsthegroundspeedofthetractor

is controlled by selection of the appropriate gear ratio

whilemaintaining the correctP.T.O.speed by usingthe

throttle.

Attaching P.T.O. Driven Equipment

WARNING :Before attaching, detaching or

workingonP.T.O.drivenequipment,thefollowing

precautions must be taken :-

*Firmly apply the parking brake.

*Ensurethat bothgearshift leversare inneutral and

thattheP.T.O.leveris inthedisengagedposition.

*Stop the engine.

*Ensurethat the P.T.O. shaft hasstoppedturning.

6. Gear Shift Lever Positions

H = High Range

L = Low Range

N = Neutral

R = Reverse

SECTION A

Rangelever Main gear shift lever

RUNNING-IN-PROCEDURE

Yournewtractorwillprovidelonganddependableservice

ifgiven proper careduringthe first 50hours running-in-

period and if serviced at the recommended intervals.

Avoid prolonged operation at either high or low engine

speeds without a load on the engine.

7

ToconnectP.T.O.drivenequipment tothe P.T.O.shaft,

removethe guard (wherefitted) which issecured to the

rear axle center housing by a linch pin, as shown in

Figure7.Unscrewandremove theP.T.O.cap andstore

inthe toolbox. Attach theimplement to the P.T.O.shaft

andreinstallthe guard.

WARNING :The guard serves as a support

for drive line shields used with Pull-type P.T.O.

driven equipment and also provides you safety.

If P.T.O. driven equipment is attached to the drawbar

thenthe drawbarshould be setto theextended position

so that the horizontal distance between the end of the

P.T.O.shaftandthepin holein theend ofthedrawbaris

at least 14.9 in (378 mm.) See figure 8.

IMPORTANT :After attaching mounted equipment

carefully raise and lower them using Position Control

LeverandcheckclearancesandP.T.O.shaftsliderange

/articulation. Whenattaching trailed equipment,ensure

the drawbar is correctly set.

WARNING :Do not approach or work on the

P.T.O. shaft or equipment with the P.T.O. in

motion. Block all four wheels when carrying out

stationaryP.T.O. work.

OPERATING THE P.T.O.

Transmission P.T.O. (where fitted)

To operate transmission P.T.O., start the engine, fully

depress the clutch pedal and pull the P.T.O. selector

lever,Figure9,rearwards.Set theenginespeed to1600

rev/min. then release the clutch pedal.

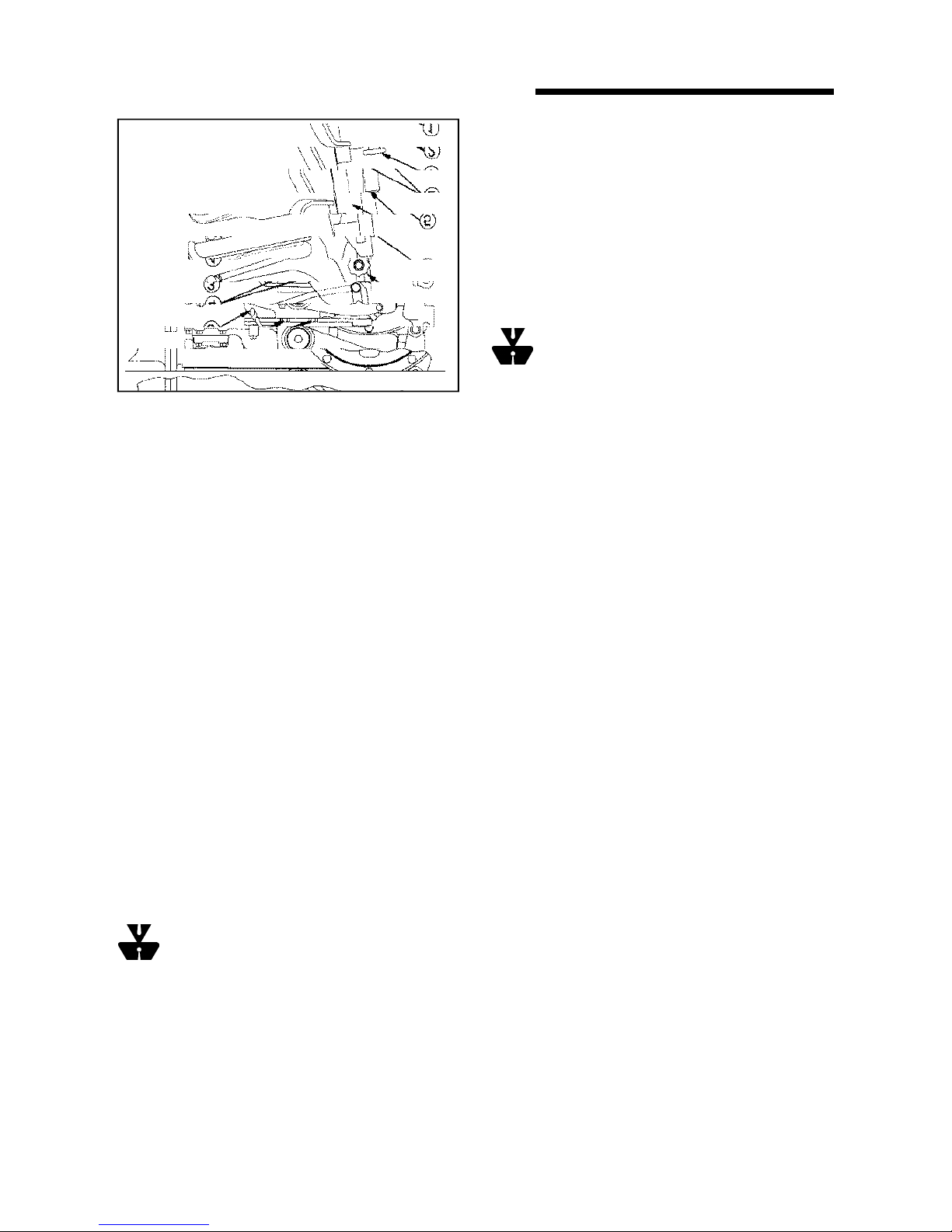

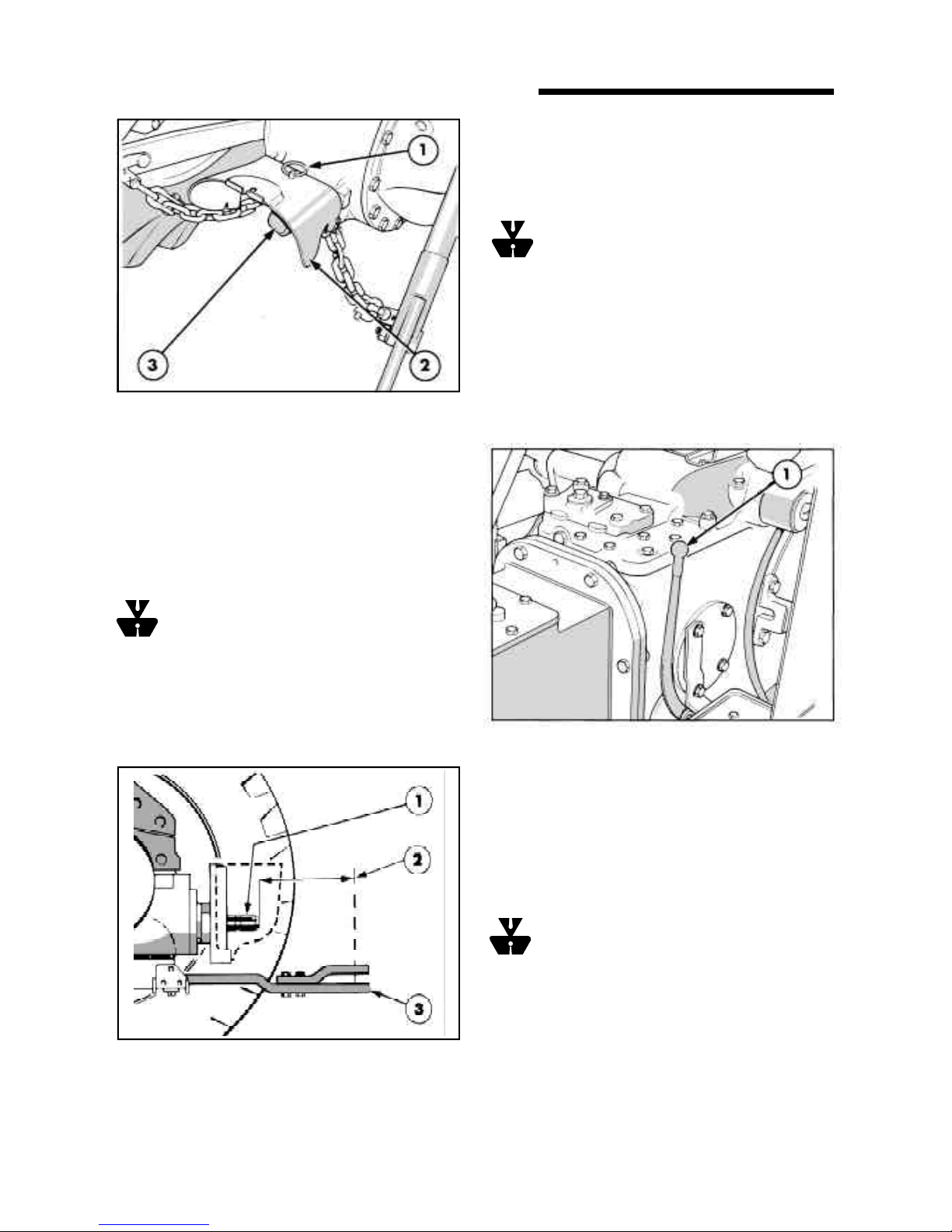

7. Power Take-Off

1. Linch pin

2. Guard

3. P.T.O.cap

8. Drawbar setting

1. P.T.O.outputshaft

2. Horizontal distance - shaft to hitch pin

3. Drawbar

9. P.T.O.Selector

1. P.T.O.selectorlever

Transmission P.T.O. may be engaged or disengaged

whether the tractor is moving or stationary. When

stoppingthe tractor, the actionof depressing the clutch

pedal will stop rotation of the P.T.O. output shaft.

IMPORTANT: Always depresstheclutchpedalbefore

engagingordis-engagingtheP.T.O. topreventdamage

toP.T.O.components.

WARNING :To avoid inadvertent movement

oftheimplement,disengage theP.T.O.aftereach

use.

Live PTO (where fitted)

LiveP.T.O.operatesinasimilarmannertoTransmission

P.T.O.exceptthatatwo stageclutch permitsthetractor

tobestoppedwhileallowing theP.T.O. shafttocontinue

turning. With the clutch pedal fully depressed neither

thetractor nor theP.T.O.shaft is operable.

8

CONTROL, INSTRUMENTS AND OPERATION

To operate Live P.T.O., start the engine, fully depress

the clutch and pull the P.T.O. selector lever, Figure 9,

rearwardstoengagetheP.T.O.

Set the engine speed at 1800 rev/min and release the

clutchpedaltothehalfway positiontoactuate theP.T.O.

output shaft.

With a gear selected, fully release the clutch pedal to

runthetractor.

Tostop thetractor,depress theclutchpedal tothe mid-

positionand tostop the P.T.O.output shaftdepress the

pedalfully.

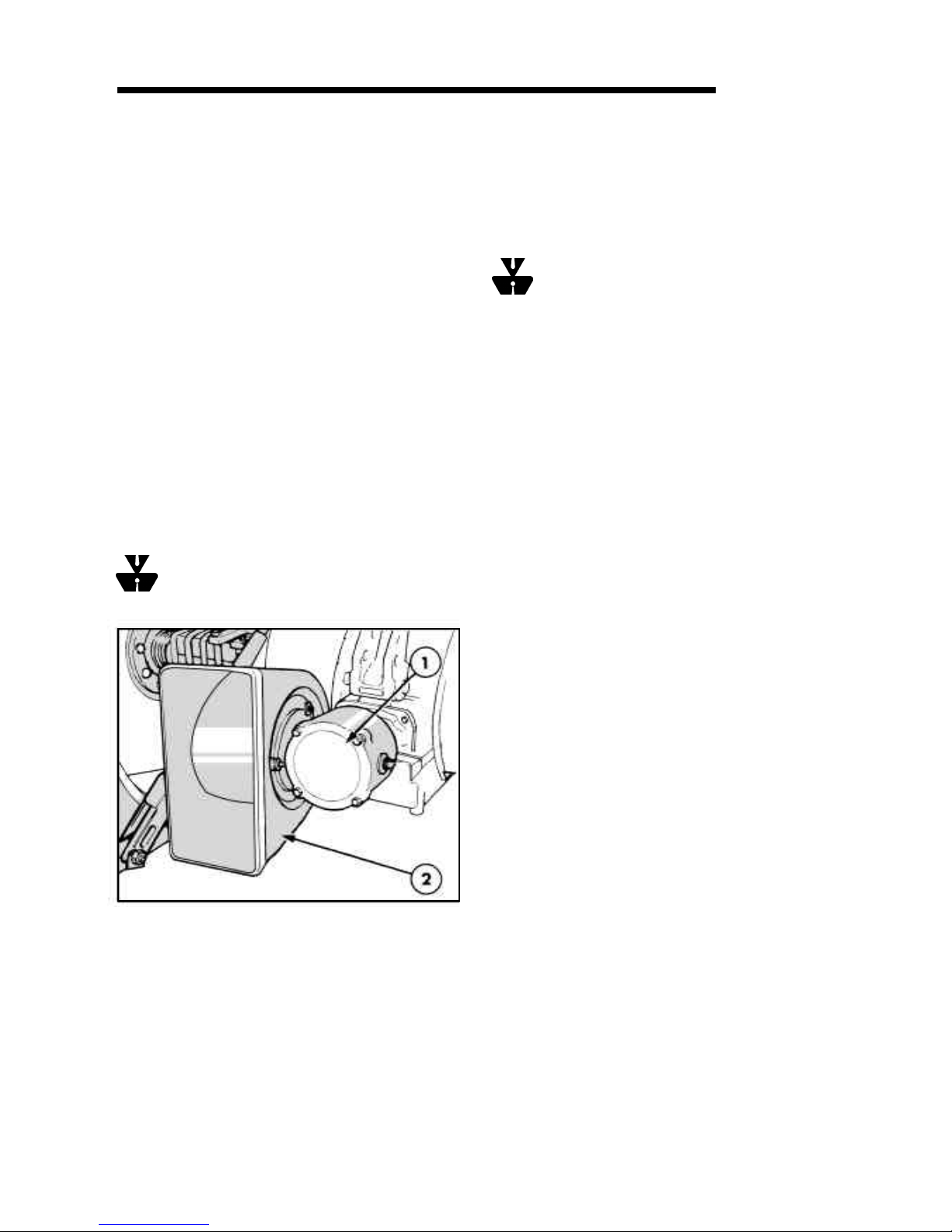

BELT PULLEY (where provided)

The belt pulley, which is driven by the P.T.O . output

shaft, should be installed as shown in Figure 10.

Prior to installation, remove the drawbar and drawbar

hangerto provide the maximumclearance for the drive

belt.

To install the belt pulley, remove the P.T.O. safety cap

and guard and the four bolts securing the check chain

bracketsto the rearaxle center housing.Install the belt

pulleyon the P.T.O.shaft using thefour bolts provided.

WARNING : Toavoid injury, alwaysuse abelt

guardwhenever using the beltpulley.

lHanga chainor leananiron baragainst thetractor

to earth static electricity.

lStart the engine and engage the P.T.O. The

recommended belt speed is 3000-3200 ft/min

(15.3-16.3 m/sec). To obtain this speed set the

engine speed at 2000 rev/min.

WARNING: Never attempt to re-fit or adjust a

belt in motion. Never approach a moving belt

when wearing loose clothing. Apply the parking brake,

place both gearshift levers in neutral and block all four

wheelsbefore operating thebeltpulley.

HYDRAULIC SYSTEM

Your tractor is equipped with a hydraulic system

providing accurate and sensitive control over a wide

rangeof operating conditions.

Twodistinctsystems are incorporated

1. UpperLink Draft Control.

2. PositionControl.

The type of control selected will depend on the type of

implement in use and the operating conditions.

Draft Control is most suitable for mounted

implements operating in the ground. Changes in the

workingdepth orsoil resistancecausethe draftloading

onthe implementto increaseordecrease. Thischange

in draft loading is sensed through the top link of the

three-pointlinkage and the hydraulicsystemresponds

byraising or loweringthe implement torestore the draft

loading. In this way a uniform draft load is maintained

on the implement. The system responds to both upper

link compression and tension loads and is, thus,

described as a double-acting system.

Position Control provides accurate and sensitive

controlofimplementssuchas sprayers,rakes,mowers,

etc., that operate above the ground. Position Control

would not normally be used with ground engaging

equipment unless it is essential to maintain a constant

depth regardless of the draft load.

Thetractorhasadualleversystem, i.e.,separatelevers

forDraft and Position Controlfunctions. See Figure 11.

TheDraftand Position Control levers areusedto raise

or lower the three-point linkage (and implement) to the

requiredheight orworking depth.

To Operate the Belt Pulley

lFully raiseand secure the lower links.

lAlignthetractorwiththeequipmentto obtainfullwidth

contactonbothpulleyswithoutthebeltcontactingany

otherpart of the tractororequipment.

lApplytheparkingbrakeandblockallwheelstoprevent

tractormovement due tovibration.

SECTION A

10. Belt Pulley

1. Belt pulley

2. Belt guard

9

Table of contents