Mahindra Jivo 365 DI User manual

Other Mahindra Tractor manuals

Mahindra

Mahindra '15' Series 2015 4WD User manual

Mahindra

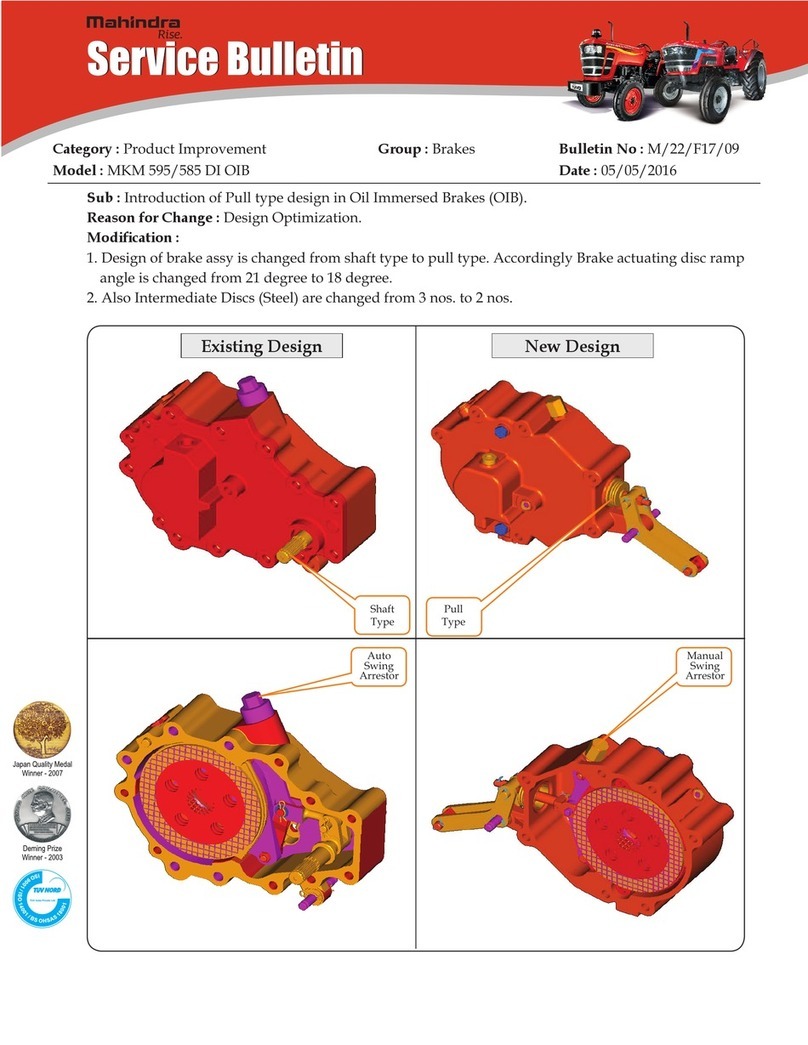

Mahindra MKM 595 Reference manual

Mahindra

Mahindra 60 Series User manual

Mahindra

Mahindra 10 Cab Series 4510C User manual

Mahindra

Mahindra JINMA-200 User manual

Mahindra

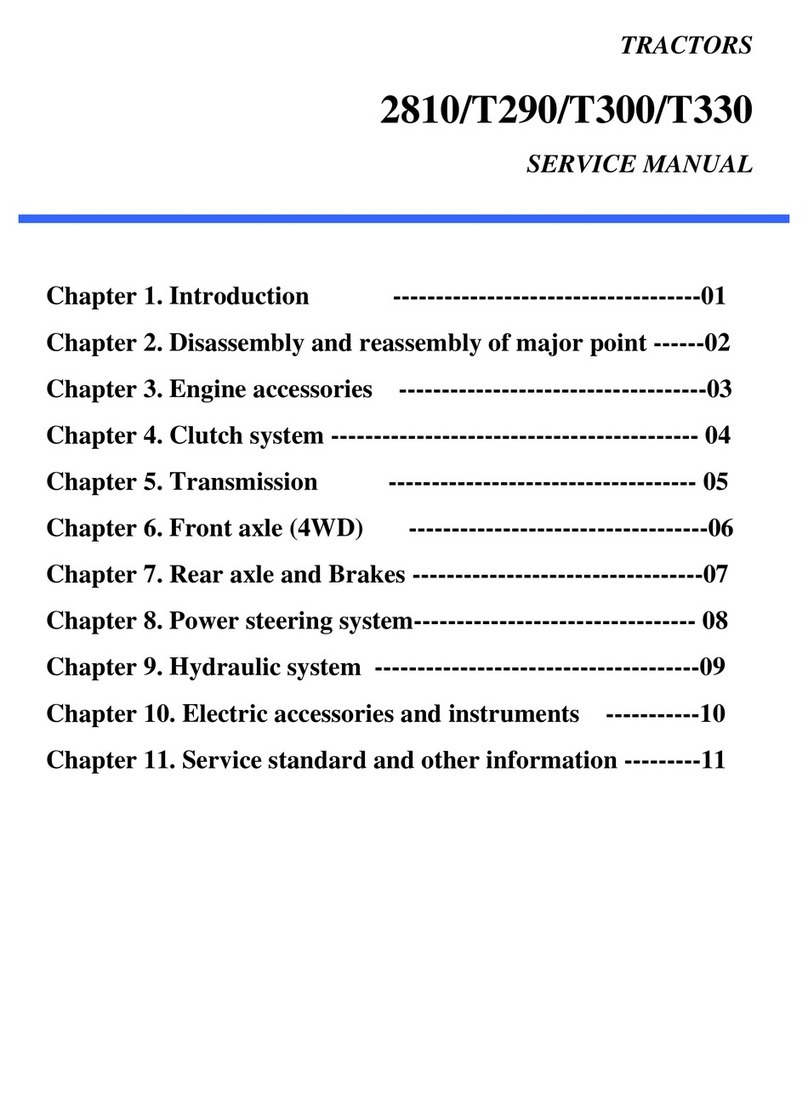

Mahindra 2810 User manual

Mahindra

Mahindra 35 Series User manual

Mahindra

Mahindra YUVRAJ 215 User manual

Mahindra

Mahindra ML170 series User manual

Mahindra

Mahindra 10 Series User manual