UNITED Static Control Products Inc. Telephone: 719 676 3928 Page 2of 3

Installation

NOTE: This unit is not for use in explosive environments or around flammable liquids or vapors. The

HDG-600 depends on clean, dry, oil and particulate free compressed air for its outstanding performance.

Should the compressed air become compromised or if the hand held blower is allowed to come into

contact with liquids the unit may become permanently damaged. Although the power supply is protected

with a fuse, a high voltage failure detect circuit is not incorporated into the power supply. Hence, the high

voltage output is not interrupted even in some abnormal conditions. Abnormal conditions include water in

the air supply, getting the gun assembly wet, dropping the unit in water or a short circuit or sparking

caused by insulation degradation. Regular inspection and keeping the gun assembly away from liquids is

essential for efficient and problem free operation of ALL hand held ionizers. The HDG-600 should be

used by trained personnel only.

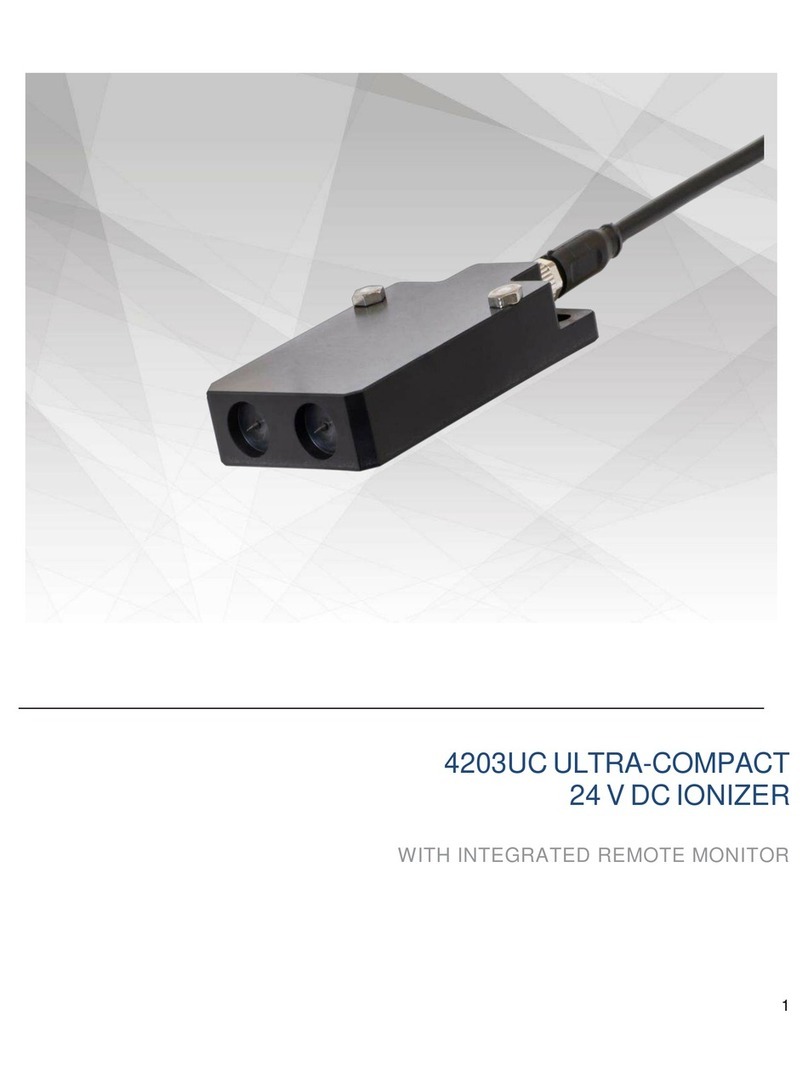

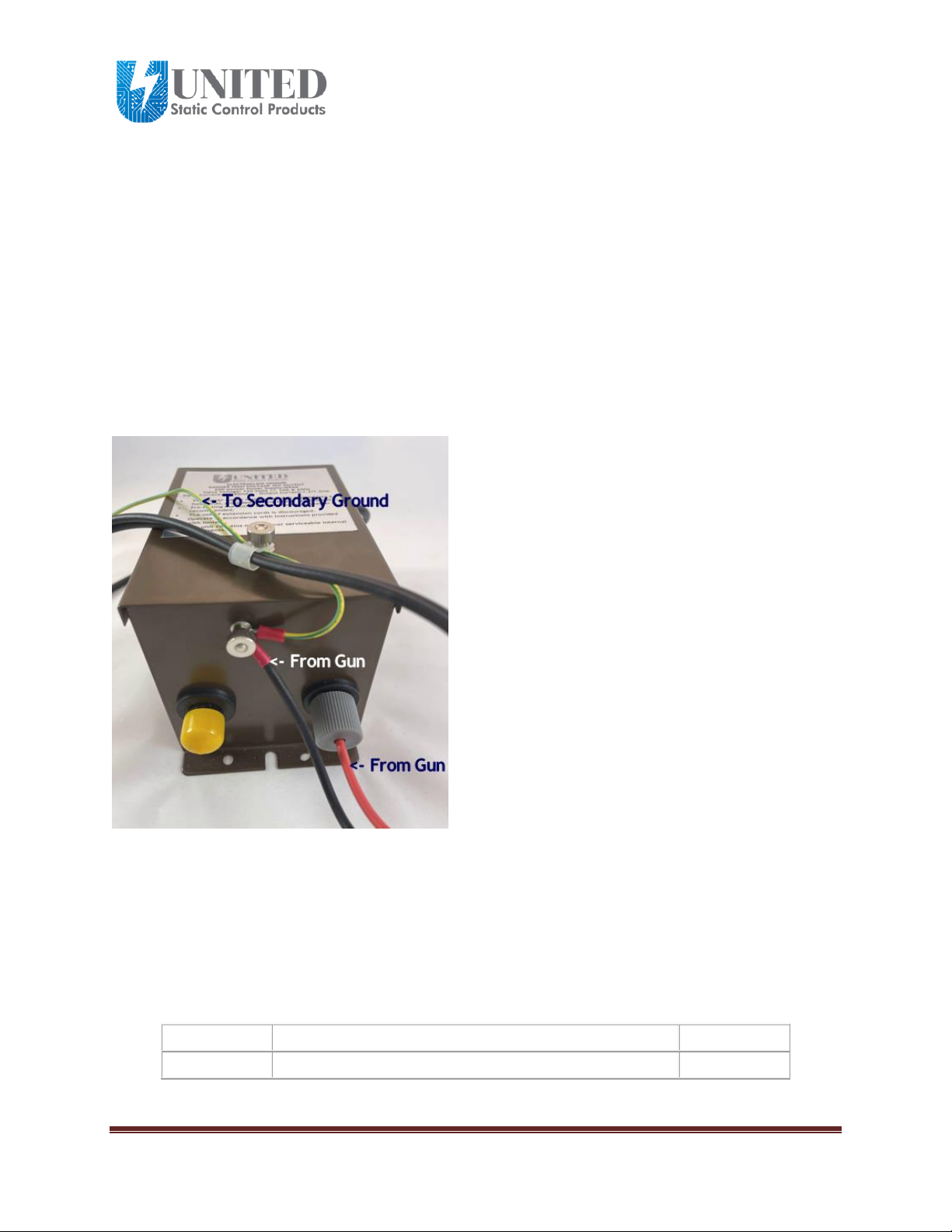

POWER SUPPLY: Mount the power supply /

transformer to a sturdy structure close to a reliable

grounded AC Power outlet. Do not attach the Power

cord to the outlet at this time.

ATTACH SECONDARY GROUND WIRE: Attach the

yellow and green ground wire to the front post of the

transformer as is shown in figure 2. Tighten in place

using knurled steel nut. Attach opposite end of yellow

/ green ground wire to a reliable AC Electrical ground

such as the center screw of an AC faceplate cover, a

grounded machine tool or a ground point designated

by your electrician.

ATTACH HIGH VOLTAGE CABLE: Red and black

high voltage cables have been preinstalled into the

handle of the HDG 600. The black wire is terminated

in a ring eyelet. Attach this ring eyelet to the ground

post located on the front of the power supply as

shown in figure 2. Remove one of the 2 yellow

protective covers and screw the red power supply

coupling onto the threaded male connector (see

figure 2).

ATTACHMENT TO COMPRESSED AIR: Attach the

clear airline (included with your order) to the gun

handle by pressing the clear airline firmly into the air inlet located on the handle. It will lock into place.

Example. Attach the opposite end of the air supply hose to filtered, compressed, and regulated air. Note:

Two of the most popular couplings are included with your order. However, due to the variety of couplings

this part may need to be replaced with what is used in your facility. Note: For best results use an air

drying and cleansing regulator with 5 to 10 micron filtration.

OPERATION: Plug power supply into AC electrical. Adjust the air pressure using an air regulator (not

included with your order) from 15 to 100 PSI. NOTE: Maintain the air pressure at 15 PSI minimum at all

times. The instrument is now ready for operation.

WHAT'S INCLUDED WITH YOUR ORDER:

The HDG-600 includes the hand held air gun,

power supply, 6 foot high voltage cable, 6 foot

clear airline, hose barbs, a yellow ground wire

and manual.