esera DS18S20 User manual

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11119 V2.0 R1.0 Manual Page 1 of 4

Art. No. 11119

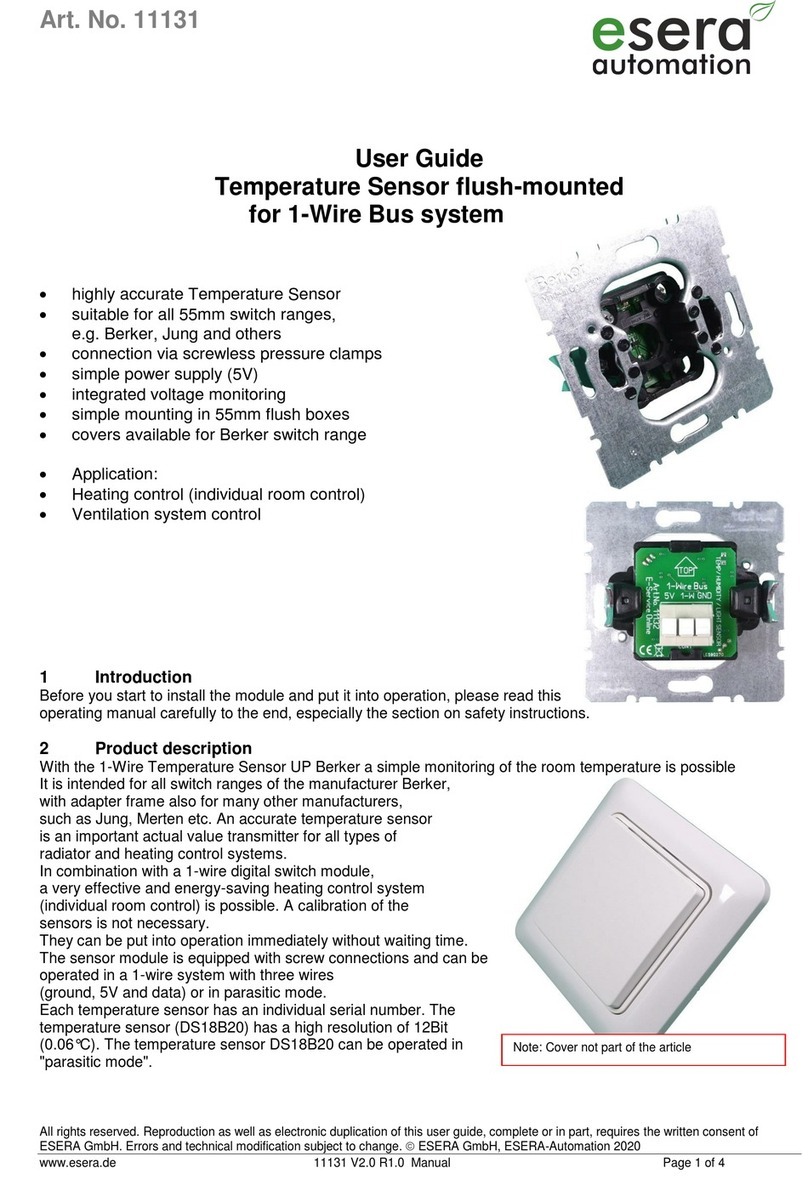

User Guide

1-Wire Temperature Sensor

Pressure-resistant 1/8 inch screw-in sensor

SEMOFLEX cable and RJ12 connector

1 Product description

The pressure-resistant temperature sensor with PUR connecting cable and 1/8" stainless steel sensor tube is

pressure-tight, chemically resistant and may be immersed in liquids that do not attack stainless steel (1.4571) in

the area of the sensor tube. The temperature sensor is ideally suited for high-quality applications in industry,

heating and measuring technology.

Individual 1-Wire sensors can be operated via adapter cable on a 1-Wire Adapter or 1-Wire bus coupler. For a

larger number we recommend using our 1-Wire Hub III and IV.

Sensor:

The sensor module can be integrated into a 1-Wire network via RJ12 plug connection. No calibration of the

temperature sensors is necessary. Each temperature sensor has an individual serial number.

Connection cable:

High-quality, shielded connection cable for industrial applications, available in three-pole design. Cable with

conductor cross-section 0.14 mm2, high-quality insulation made of extremely temperature and chemical resistant

TPE (neoprene). Colour coding of the cores according to DIN 47100, RoHS compliant.

The cable was specially developed for our temperature sensors to cover a wide temperature range with maximum

resistance to environmental influences.

Performance features

Temperature Sensor with screw-in thread 1/8 inch

High quality, Semoflex connection cable 2m

Wide temperature range from -40 to 125°C

Largely chemically resistant

Waterproof grouted

Resistant to alkalis and acids

(low concentrations)

Thermally formable for spiral

Typical areas of application

Industrial applications

Compressed air and hydraulic technology

Temperature sensor for heating systems

laboratory equipment, scientific equipment

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11119 V2.0 R1.0 Manual Page 2 of 4

2 Technical data Sensor

1-Wire module: DS18S20

Accuracy: +/- 0,5°C in the range of -10°C to 85°C

Resolution: 9 Bit, 0,5°C to 0,0625°C/Bit depending on readout method

Operating voltage: 5 V= (+/-5%)

Power consumption: approx..1mA

Connection cable: 2m

Mechanics: thread 1/8 inch

Dimensions: Immersion sleeve in front of thread: 20mm,

Thread height: 8mm

Wrench size: 14mm

Total length: 35mm (without cable)

bend relief: 47mm

ambient conditions (cable): Operation: moving -10 ... +60 °C, unmoved -40 ... +80 °C, briefly 100 °C

3 Auto-E-Connect® Support

The ESERA Auto-E-Connect® 1-Wire Plug and Play system will be used for the

1-Wire Bus supported. This enables fully automatic configurations of 1-Wire sensors

and actuators on the 1-Wire bus. It is optimized for industrial applications and

enables significant added value beyond the sensor and chip data.

The Auto-E-Connect function automatically recognizes ESERA chips, sensors and actuators, starts suitable

libraries and outputs fully formatted data.

The Auto-E-Connect functionality will be available from mid-2020 via 1-Wire Controllers, 1-Wire Gateways and

1-Wire ECO from ESERA available.

Further information on ESERA Auto-E-Connect can be found on the ESERA website, ESERA Config-Tool 3, or in

the download area for this article in the ESERA Webshop.

4 Pin assignment

The Western connector is assigned as follows (view of the cable, i.e. the contact surfaces of the connector):

Note, the sensor cannot be connected directly to the 1-Wire adapter because of different pin assignments!

Note: Basic information and tips on the 1-Wire Bus system can be found on the ESERA website at:

https://www.esera.de/1-wire-grundlagen/

5 1-Wire Network

For short connection lengths, no special requirements are placed on the cable used. With unshielded cable, a

longer connection length can be achieved in an undisturbed environment, since the capacitive bus load is lower.

A total length of 60 m and more can be achieved without additional measures.

In a disturbed environment, the cable should be shielded to improve the interference sensitivity of the system.

Due to the higher capacitive load, the maximum possible connection length is reduced.

The special feature of the wiring of the sensors is the "BUS technology": All sensors are operated in parallel on a

three-core cable, via which both the power supply and the data communication take place.

Increase the connection length:

The sum of all connecting cables should be less than approx. 60m to ensure safe operation. By connecting an

additional pull-up resistor with 4.7 ... 10 kOhm (line DATA against +5 V) the cable length can be increased, but

with a slight deterioration of the measuring accuracy due to the higher self-heating of the sensor.

1 Shielding or unoccupied

2 Ground

3 Dallas Data or unoccupied

4 Dallas Data

5 +5 V

6 +5 V or unoccupied

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11119 V2.0 R1.0 Manual Page 3 of 4

Art. No. 11119

6 Measuring Accuracy

The sensors are calibrated during manufacture and have a typical measuring accuracy of ±0.5 °K at

23 °C operating temperature. The accuracy deteriorates towards the upper and lower measuring range limits.

Further information can be found in the data sheet of the module on the homepage of the manufacturer.

As with all temperature measurements, however, the physical background must be taken into account to avoid

measurement errors, which have a significant influence on the precision of the measurement setup:

6.1 Thermal contact resistance of the target sensor

This measurement error occurs mainly with surface measurements. Good thermal contact can be remedied by

mounting in a bore hole, by using heat-conducting paste or by using heat-conducting adhesive.

6.2 Thermal Heat Dissipation Sensor Ambient Temperature

For surface measurements, the measurement setup should be thermally insulated from the environment, for

example with foam or mineral wool.

6.3 Thermal Heat Dissipation Sensor Connection Wires

This measurement error can be minimized, for example, by making the connecting cable as thin as possible and

made of material with poor thermal conductivity or by tempering the connecting cable with the measurement

object.

In principle, the highest measurement accuracy can be achieved by immersion in liquids or in a mounting hole.

On the other hand, an additional measurement error should be taken into account when measuring on surfaces.

7 Operating conditions

The sensor is designed for temperature measurement of gases or solids.

The temperature sensors are semiconductor sensors. The unhoused sensors are designed for temperature

measurements in the range from -55 ... +125 °C. These temperature values are limit data and must not be

exceeded or undercut, otherwise the component may be damaged.

8 Disposal information

Do not dispose of the device in household waste! Electronic devices must be disposed of in

accordance with the Directive on Waste Electrical and Electronic Equipment on local

Dispose of at collection points for old electronic equipment!

9 Safety instructions

When using products that come into contact with electrical voltage, the valid VDE regulations must be

observed, especially VDE 0100, VDE 0550/0551, VDE 0700, VDE 0711 and VDE 0860

All final or wiring work must be carried out with the power turned off.

Before opening the device, always unplug or make sure that the unit is disconnected from the mains.

Components, modules or devices may only be put into service if they are mounted in a contact proof housing.

During installation they must not have power applied.

Tools may only be used on devices, components or assemblies when it is certain that the devices are disconnected

from the power supply and electrical charges stored in the components inside the device have been discharged.

Live cables or wires to which the device or an assembly is connected, must always be tested for insulation faults or

breaks.

If an error is detected in the supply line, the device must be immediately taken out of operation until the faulty cable

has been replaced.

When using components or modules it is absolutely necessary to comply with the requirements set out in the

accompanying description specifications for electrical quantities.

If the available description is not clear to the non-commercial end-user what the applicable electrical characteristics

for a part or assembly are, how to connect an external circuit, which external components or additional devices can

be connected or which values these external components may have, a qualified electrician must be consulted.

It must be examined generally before the commissioning of a device, whether this device or module is basically

suitable for the application in which it is to be used.

In case of doubt, consultation with experts or the manufacturer of the components used is absolutely necessary.

For operational and connection errors outside of our control, we assume no liability of any kind for any resulting

damage.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11119 V2.0 R1.0 Manual Page 4 of 4

Kits should be returned without their housing when not functional with an exact error description and the

accompanying instructions. Without an error description it is not possible to repair. For time-consuming assembly or

disassembly of cases charges will be invoiced.

During installation and handling of components which later have mains potential on their parts, the relevant VDE

regulations must be observed.

Devices that are to be operated at a voltage greater than 35 VDC / 12mA, may only be connected by a qualified

electrician and put into operation.

Commissioning may only be realized if the circuit is built into a contact proof housing.

If measurements with an open housing are unavoidable, for safety reasons an isolating transformer must be

installed upstream or a suitable power supply can be used.

After installing the required tests according to DGUV / regulation 3 (German statutory accident insurance

https://en.wikipedia.org/wiki/German_Statutory_Accident_Insurance) must be carried out.

10 Warranty

ESERA GmbH guarantees that the goods sold at the time of transfer of risk to be free from material and workmanship

defects and have the contractually assured characteristics. The statutory warranty period of two years begins from date of

invoice. The warranty does not extend to the normal operational wear and normal wear and tear. Customer claims for

damages, for example, for non-performance, fault in contracting, breach of secondary contractual obligations,

consequential damages, damages resulting from unauthorized usage and other legal grounds are excluded. Excepting to

this, ESERA GmbH accepts liability for the absence of a guaranteed quality resulting from intent or gross negligence.

Claims made under the Product Liability Act are not affected.

If defects occur for which the ESERA GmbH is responsible, and in the case of replacement goods, the replacement is

faulty, the buyer has the right to have the original purchase price refunded or a reduction of the purchase price.

ESERA GmbH accepts liability neither for the constant and uninterrupted availability of the ESERA GmbH or for technical

or electronic errors in the online offer.

We are constantly developing our products further and reserve the right to make changes and improvements to any of the

products described in this documentation without prior notice. Should you require documents or information on older

11 Trademarks

All mentioned designations, logos, names and trademarks (including those which are not explicitly marked) are

trademarks, registered trademarks or other copyright or trademarks or titles or legally protected designations of their

respective owners and are hereby expressly recognized as such by us. The mention of these designations, logos, names

and trademarks is made for identification purposes only and does not represent a claim of any kind on the part of ESERA

GmbH on these designations, logos, names and trademarks. Moreover, from their appearance on ESERA GmbH

webpages it cannot be concluded that designations, logos, names and trademarks are free of commercial property rights.

ESERA and Auto-E-Connect are registered trademarks of ESERA GmbH.

12 Contact

ESERA GmbH

Adelindastrasse 20

D-87600 Kaufbeuren

GERMANY

Tel.: +49 (0) 8341 999 80-0

Fax: +49 (0) 8341 999 80-10

www.esera.de

WEEE-Number: DE30249510

Table of contents

Other esera Accessories manuals

Popular Accessories manuals by other brands

Thermo Scientific

Thermo Scientific 310 Series manual

Applied Physics Systems

Applied Physics Systems 751 user manual

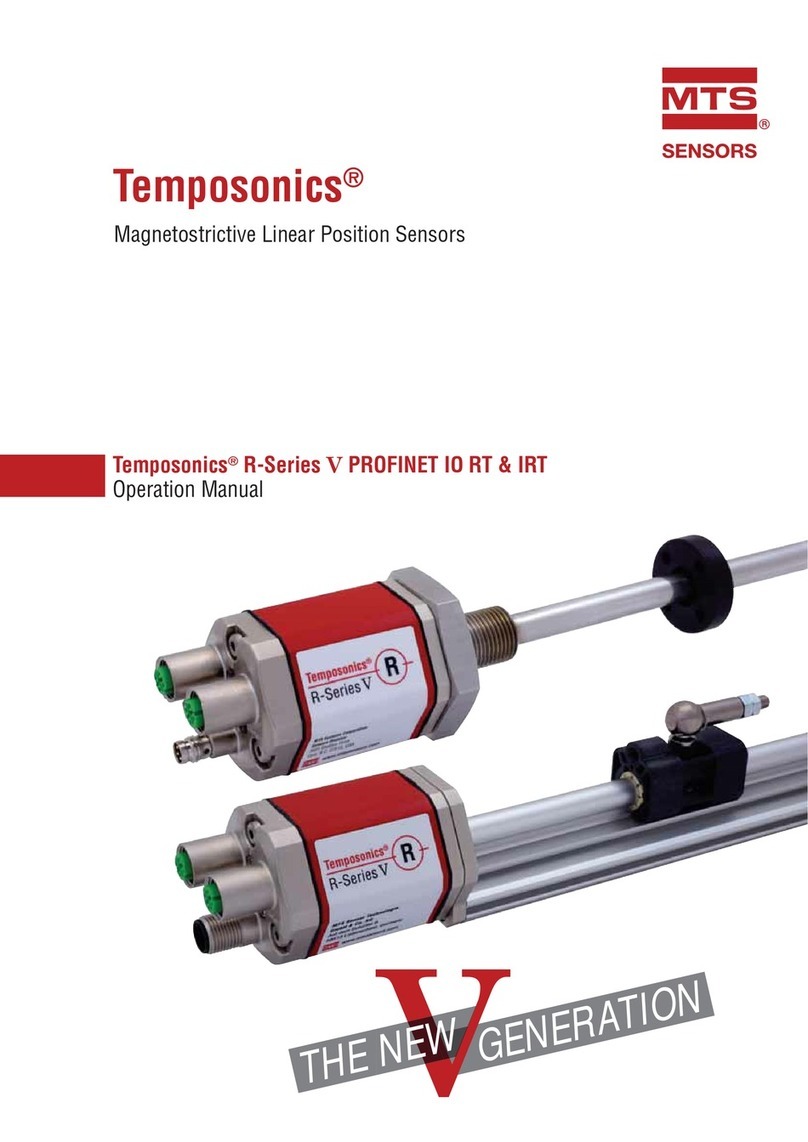

MTS Sensors

MTS Sensors Level Plus M Series Replacement guide

Ohmeda

Ohmeda Ohio Care Plus Operation and maintenance manual

JUGS

JUGS Jr. owner's manual

Yamato

Yamato IN602CS instruction manual