2

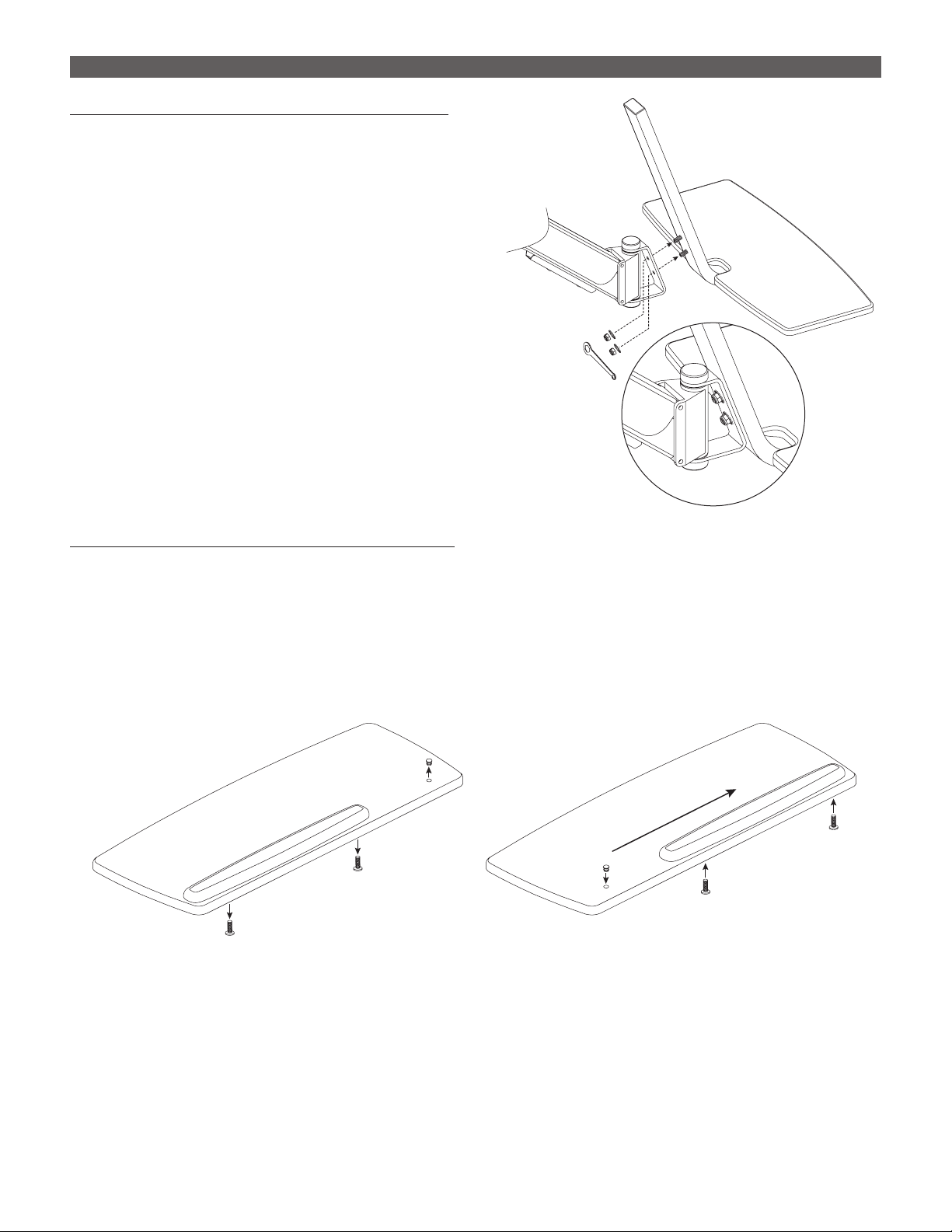

Clamp Base and Column Assembly to Work Surface

The base clamp requires 4" of clearance under the work surface for attachment. The clamp

accommodates work surface thicknesses from .75" to 3.3" (20mm to 80mm).

Adjust Clamp, If Necessary

• The clamp as shipped can be attached to work surfaces from

1¾" to 3.3" thick.

• For thinner work surface thicknesses, the three screws on the

clamp portion may be removed and the clamp re-attached

in one of the other three sets of holes. Each set of holes is

approximately 1" apart.

Attach Clamp

• Position the clamp at the desired location, with the back

of the clamp ush against the back of the work surface.

• Use the provided 5/8" wrench to tighten the clamp bolts.

IMPORTANT: Be sure the clamp is securely tightened.

Adjust Height of Main Assembly Arm

TIP: It is benecial to have a helper to support the main

assembly arm when making this adjustment.

• Use the 3mm Allen key to loosen the two set screws in the

locking ring.

• Move the locking ring up or down to set the height of the

main assembly arm. The main assembly arm rests on top of

the locking ring.

• Tighten the two set screws to secure the locking ring/main

assembly arm in the desired position.

— This adjustment can be ne-tuned at any time. It is

especially important to have a helper hold the main

assembly arm after the monitor, keyboard, etc. are in

position.

WARNING: Do not engage the paddle until after

assembly is complete. With no load on it, the main

assembly arm could raise quickly and suddenly.

ASSEMBLY CLIMB1

Remove Screws

to Adjust Clamp

.75"

3.3"

Tighten

Securely!

Work Surface

5

/8" Wrench

Locking

Ring

3mm

Allen Key