Kongsberg XE

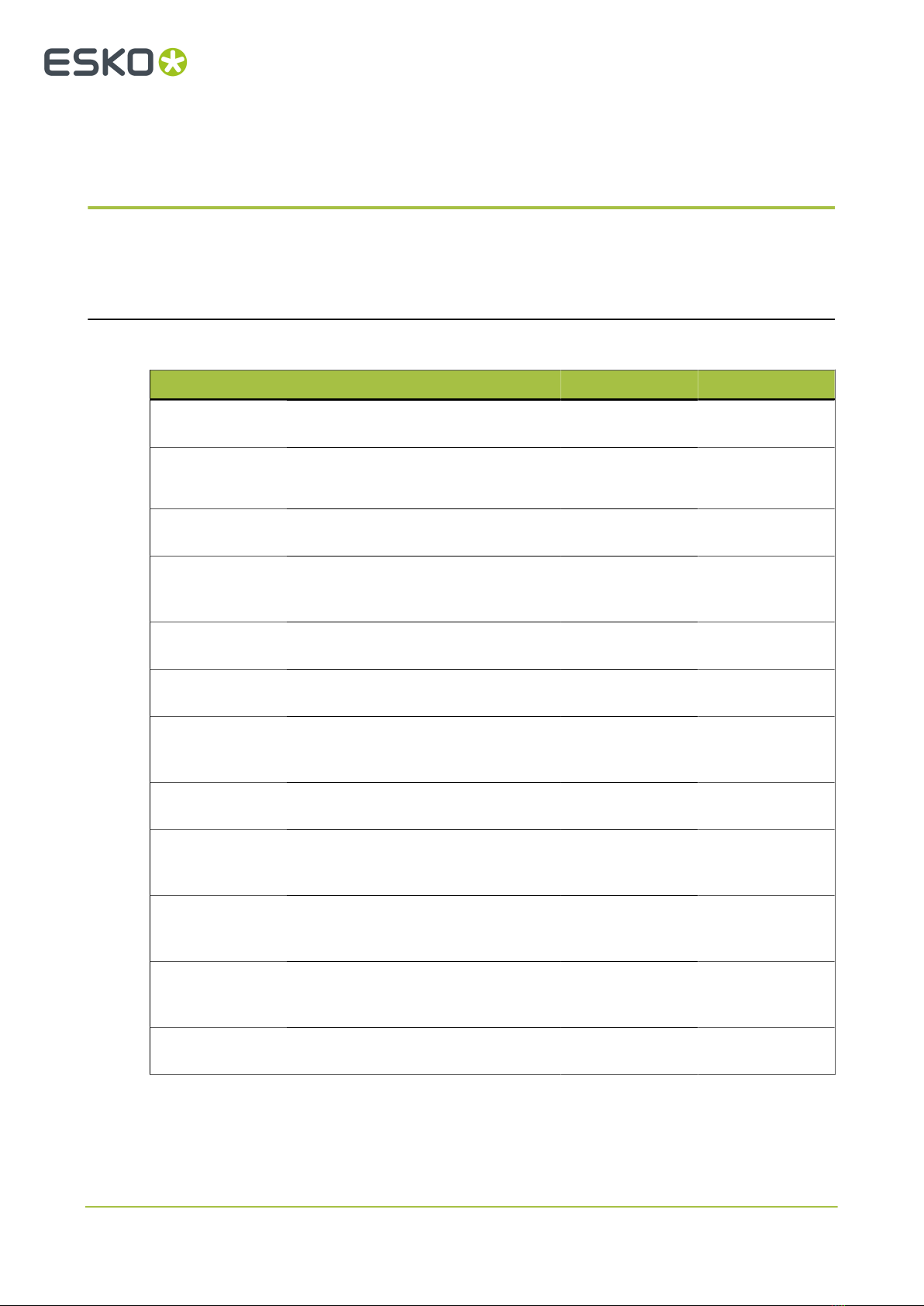

Contents

1. Preface............................................................................................................................................................3

2. Change record............................................................................................................................................... 5

3. Introduction................................................................................................................................................... 6

3.1. Welcome................................................................................................................................................6

3.2. System Label........................................................................................................................................ 6

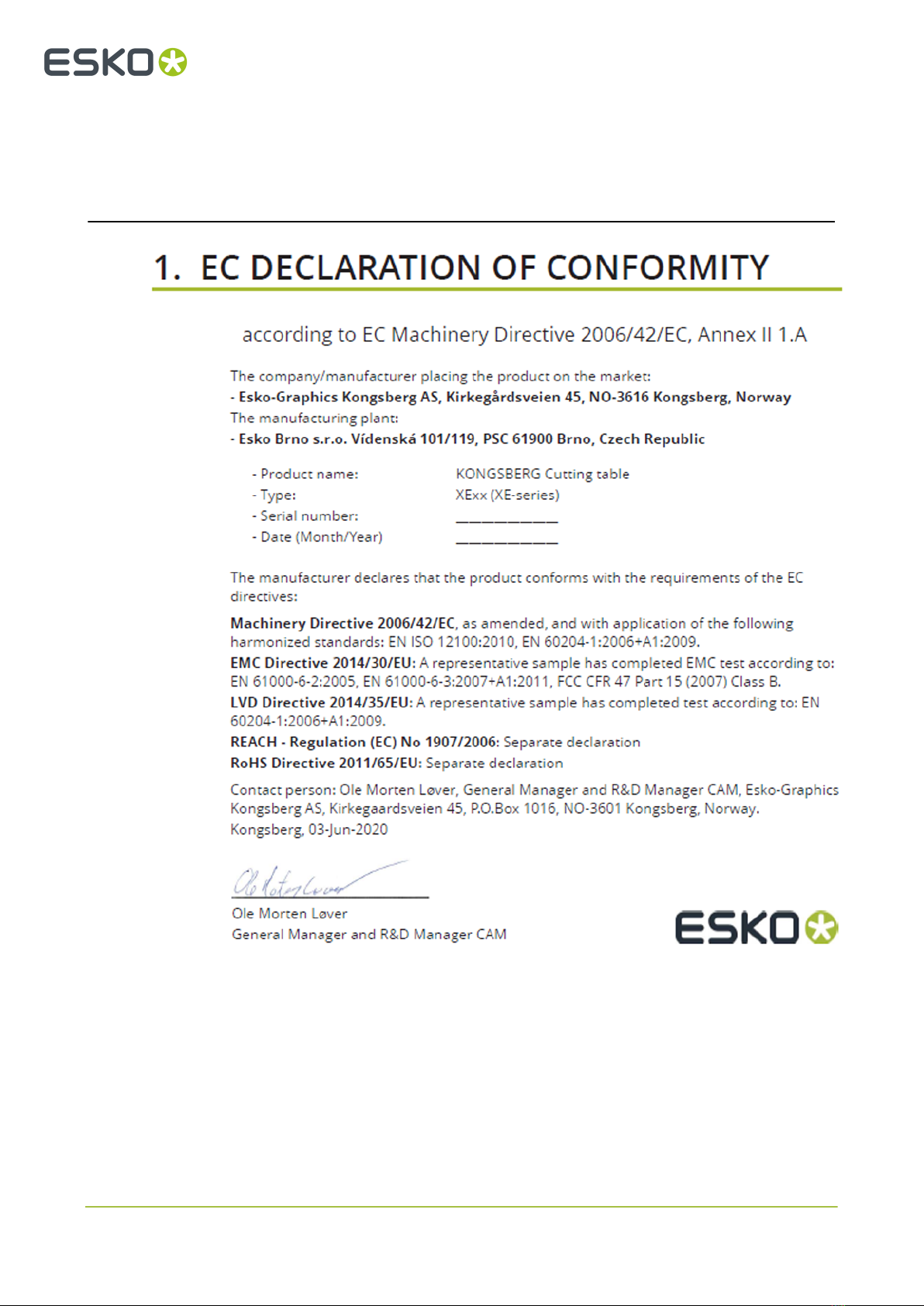

3.3. EC Declaration of Conformity............................................................................................................... 7

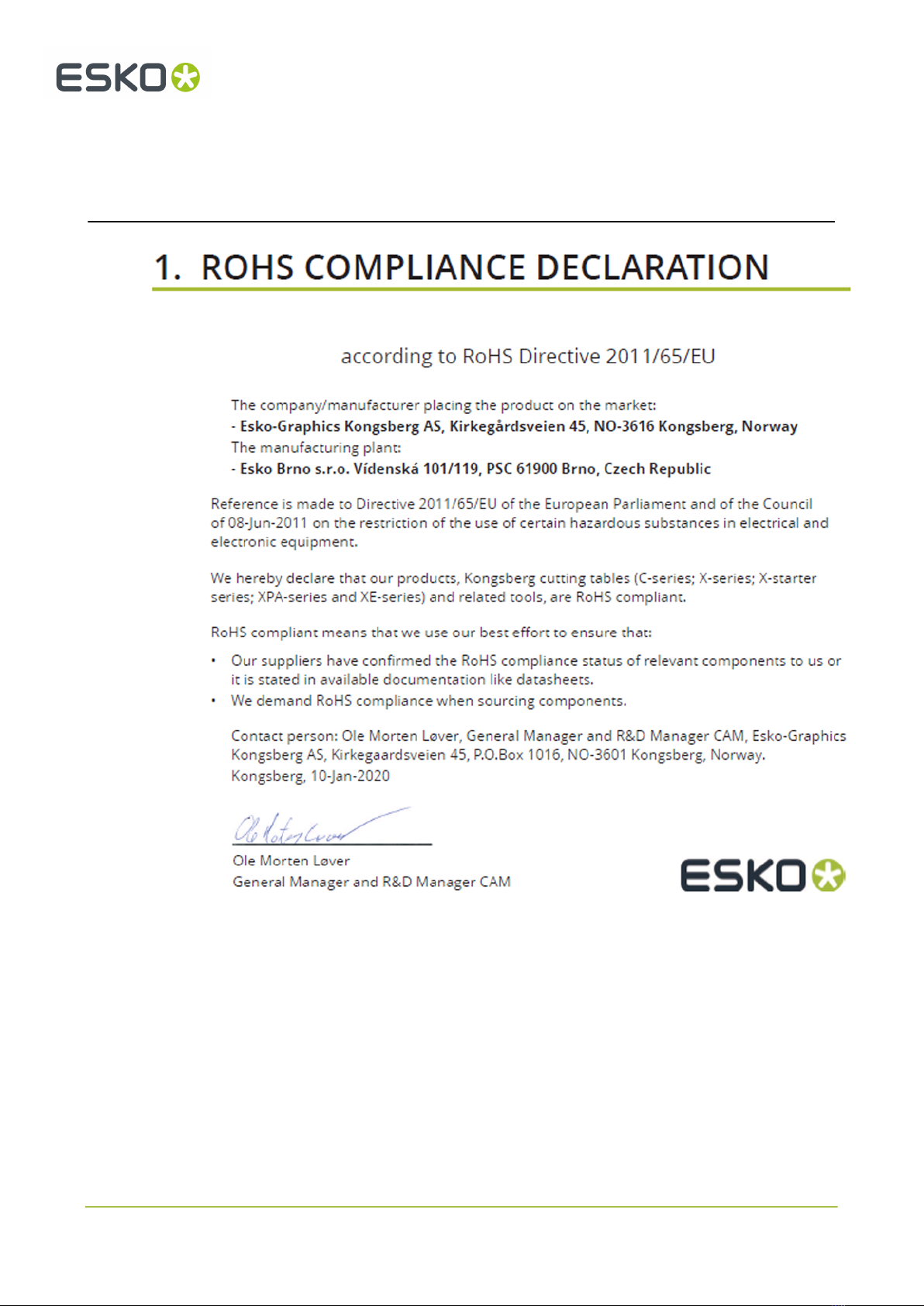

3.4. RoHS Compliance Declaration.............................................................................................................. 8

4. General Information.......................................................................................................................................9

4.1. Where to find information..................................................................................................................... 9

4.2. Site preparation.................................................................................................................................. 10

4.3. User manuals...................................................................................................................................... 10

4.3.1. User manual for cutting table....................................................................................................10

4.3.2. User manual for iPC.................................................................................................................. 10

4.3.3. Get the best out of iPC.............................................................................................................. 11

4.4. Installation........................................................................................................................................... 11

4.4.1. What is received........................................................................................................................ 11

4.4.2. Unpack Equipment.................................................................................................................... 11

4.5. Table Operation....................................................................................................................................11

4.5.1. Power On Sequence................................................................................................................... 11

4.5.2. Reset Safety System................................................................................................................. 12

4.5.3. Power Off Sequence..................................................................................................................13

4.5.4. Continue after Safety Break......................................................................................................13

4.6. Software updates................................................................................................................................14

4.7. Maintenance........................................................................................................................................ 14

5. Safety Issues................................................................................................................................................ 15

5.1. What can the system be used for.........................................................................................................15

5.2. Who are allowed to use the system.....................................................................................................16

ii