I.lntroduction.

1.

Brief

Descripfion

2

The DXY-800

and

DXY-101

~re

compact, lightweight, high

speed

X-V plotters

with

exchangeable

pens

(DXY-800 only)

and

realize excellent cost performance. By connecting a computer,

letters, figures

and

graphs

can

be

drawn easily.

These

plotters

permit much clearer and more accurate drawing

of

pictorial

output

than

is

possible

with

an

ordinary printer.

Some

of

the many outstanding features

of

the

DXY-800

and

DXY-101

are

as

follows.

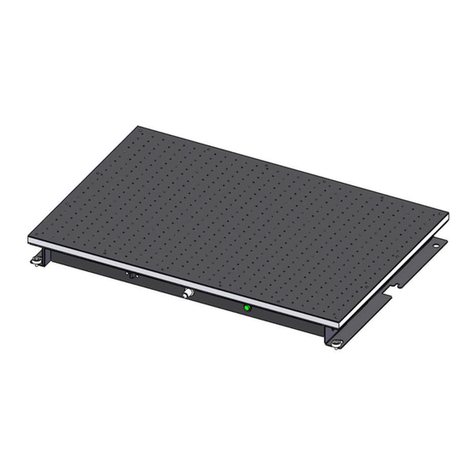

1.

Compact

and

lightweight.

Can

be

installed vertically (60°).

A more compact, lightweight design

has

been

realized over

conventional models,

with

a

width

of

496mm,

a depth

of

435mm, a height

of

77mm

and

a weight

of

4.1

kg

(DXY-

800

unit

only).

In addition, vertical installation

is

possible

by using the accessory stand. This allows the

unit

to

be

freely installed

in

any location.

2.

An

abundance

of

functions

are

provided

and

control

commands

are

simple.

A wide variety

of

command functions

such

as

vectors,

characters

and

graphics are available, along

with

replaceable

pens,

as

standard features. In addition,

such

items

as

circles,

arcs

and

hatching

can

be

drawn just

as

you desire.

What

is

more, control commands

are

simple using BASIC.

3.

Pen

movement permits drawing in

0.1

mm steps and paper

up

to

420 mm by 297 mm

can

be

used.

Since

pen

movement

is

in

0.1

mm steps, coordinate designa-

tion

or

calculation in the program

are

simple. In addition,

recording papers smaller than 420mm x297mm

can

be

used.

4. Felt

tip

pens

can

be

used.

In addition

to

eight special color pens, by using the

acces-

sory

pen

holder,

felt

tip

pens

can

be

used. Depending on

the condition

of

the

pen

used, drawing

speed

can

be

switched between

two

settings (180mm/sec and 90mm/sec).

5.

Easy

to

connect

to

a computer.

Simple connection

is

possible

for

a computer which

'is

connectable

to

a printer having standard Centronics specifi-

cations. In addition, RS-232C specifications interface

is

available.

6. AC adapter system power supply

Equipment stability and safety

have

been

improved

by

separating the

DC

pack power supply system

from

the

unit.

A hook hole

is

provided

to

allow the pack

to

be

hung on a

wall.