EN

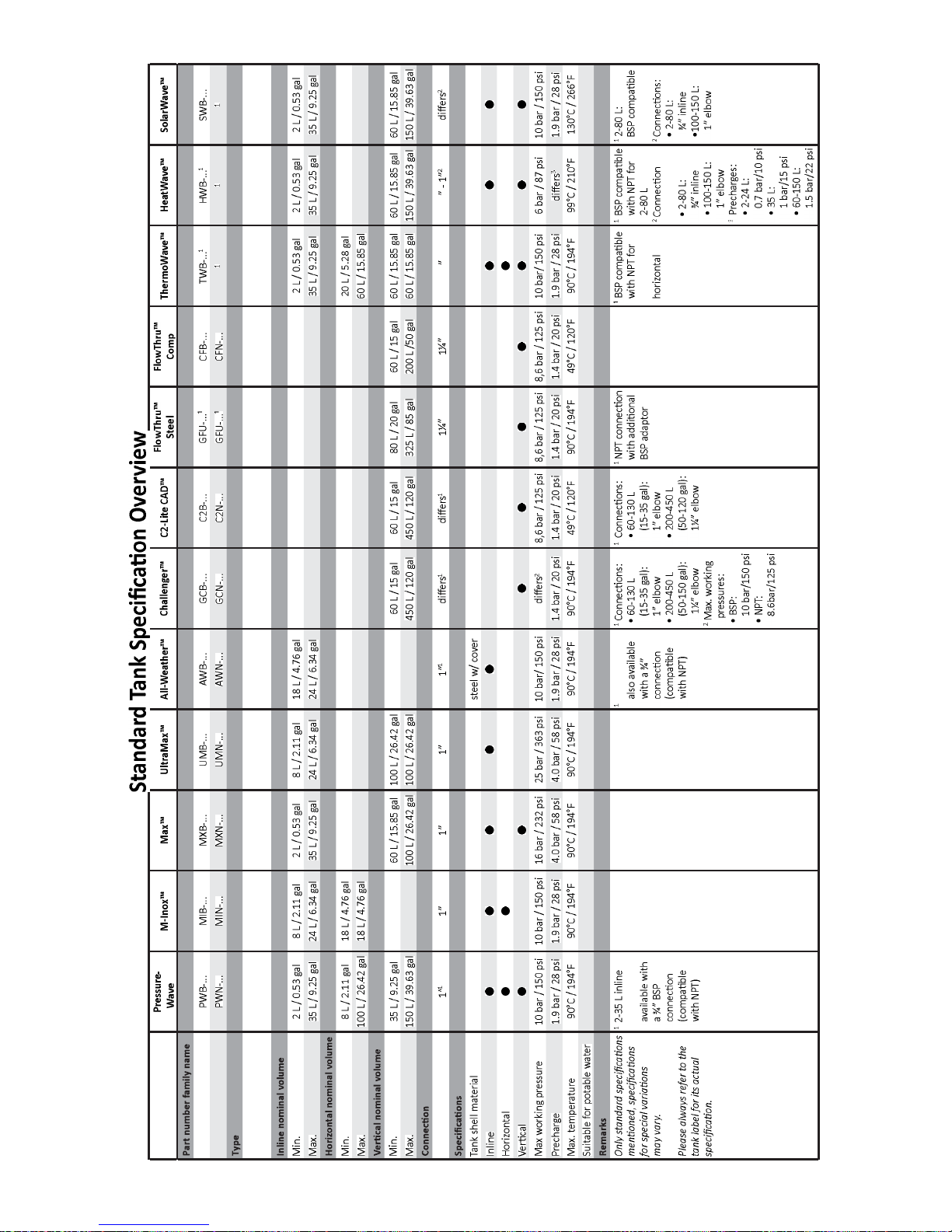

PressureWave™/ Max™/ UltraMax™/ M-Inox™/ E-Wave™/ Challenger™/

C2-Lite CAD™/ FlowThru™/ All-Weather™/ HeatWave™/ SolarWave™/

ThermoWave™Series

CAUTION: To prevent personal injury, ensure all water

pressure is released from the pressure system prior to work

being performed. Ensure pumps are disconnected and / or

electrically isolated.

WARNING: It is strongly recommended that the system is

protected by a suitable pressure relief valve set at or below

the maximum tank pressure rating. Failure to install a relief

valve may result in tank explosion in the event of a system

malfunction or over pressurization, resulting in property

damage, serious personal injury or death.

WARNING: If the pressure tank leaks or shows signs of

corrosion or damage do not use it.

Installed on __________ by ________________

W

These instructions have been prepared to acquaint you with the

correct method of installing and operating your GWS pressure

tank. We urge you to study this document carefully and follow all

the need for further advice, you should contact the dealer from

PressureWave™, Max™, UltraMax™, M-Inox™, E-Wave™,

All-Weather™, Challenger™, C2-Lite CAD™, and

FlowThru™Series tanks are designed for use in well water or

potable water booster systems. Refer to Sec. 1 for installation

details.

HeatWave™and SolarWave™Series tanks are designed

for use in non-potable closed loop hydronic or solar water

heating systems. Refer to Sec. 2 for installation details.

ThermoWave™Series tanks are designed for use in open loop

potable water heating applications. PressureWave™, E-Wave™,

Challenger™and SuperFlow™Series may also be used in

open loop potable water heating applications. Refer to Sec. 2

for installation details.

See tank data label for maximum working pressure and

maximum temperature.

Be sure to protect tank, piping and all system components

from freezing temperatures.

The manufacturer is not responsible for any water damage in

connection with this diaphragm pressure tank.

Installation

In order to ensure your tank provides its maximum service

life it should always be installed in a covered, dry position. The

tank should not be allowed to rub against any surrounding hard

surfaces, such as walls etc.

Install the tank at a suitable location to prevent water damage

due to leaks. The tank should always be located downstream

from the pump. If the tank is located at a lower elevation than

the demand then a check valve should be installed. If the tank is

installed remotely from the pump then install the pressure switch

near the tank.The tank should be installed as close as possible to

adverse effects of added friction loss and differences in elevation

between the tank and / or the water mains’and the pressure

switch, transducer or sensor.

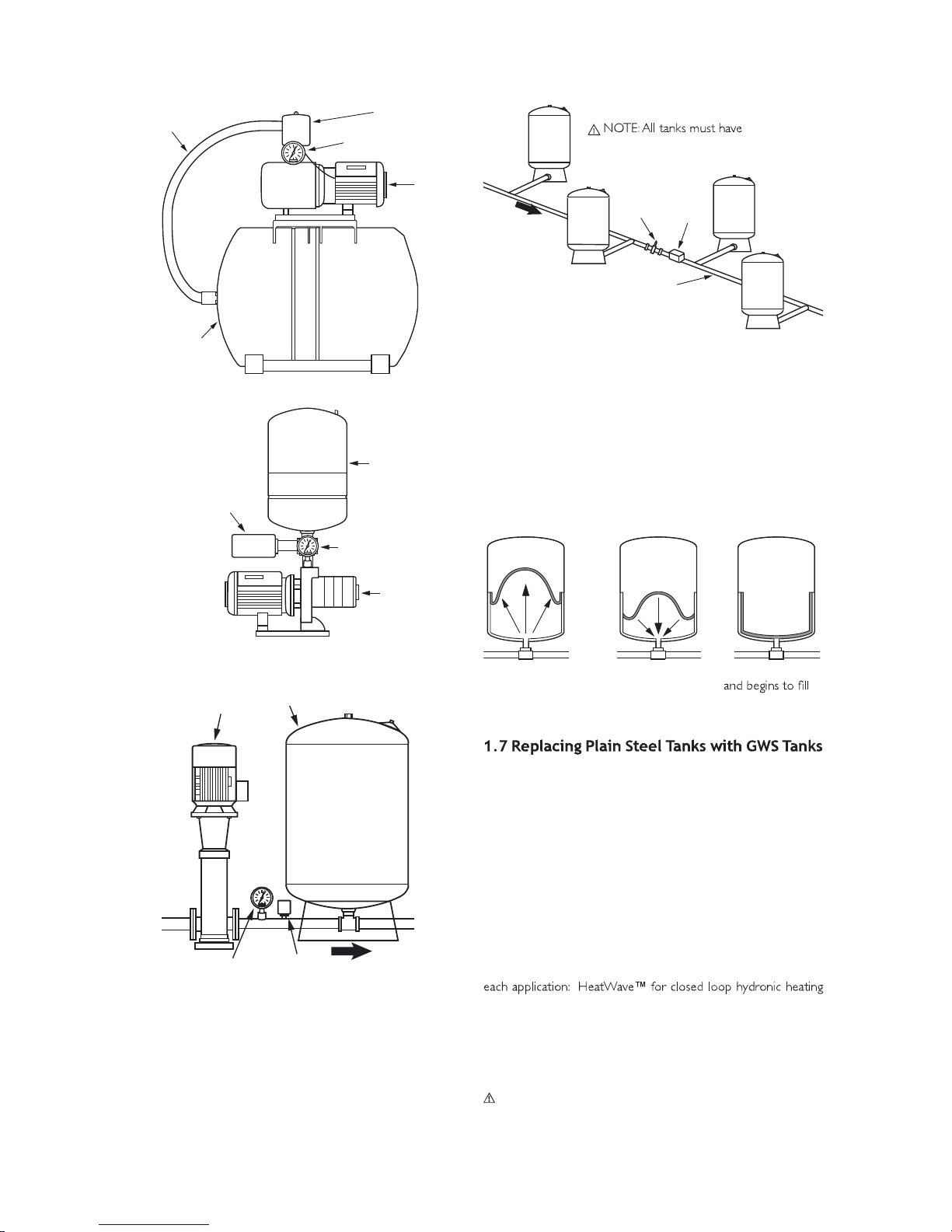

1.2 System Connection

1.

2. Level as necessary. All vertical and horizontal model tanks

in the vicinity the tank should be mounted on a resilient

mounting. Tanks with steel bases should be mounted using

supplied “L”brackets, while tanks with plastic bases should be

mounted through the holes in the base. For bases without

holes, holes should be drilled at four points equally distant

along the rim of the base and then mounted accordingly. Inline

tanks should be connected directly to the pump or to the

supply line using a “T”connection.

3. Connect the tank to the pump supply line with a short pipe to

eliminate unnecessary friction loss.

4. All piping should be in accordance with prevailing local codes

and standards.

5.

connections.

6. Tanks mounted on booster sets should be strapped down for

shipment.

1.3 Adjusting Precharge Pressure

Correct precharge is required for proper tank performance.

1. For tanks installed with a pressure switch controlled pump

with a differential pressure set up to 2 bar (30 psi), the

precharge should be set to 0.2 bar (2 psi) below the cut-in

pressure.

2. For tanks installed with a pump controlled by a pressure

switch with a pressure differential greater than 2 bar (30 psi),

electronic controls or variable speed controls, the precharge

should be set to 65% of the cut-out or maximum system

pressure.

3. For tanks installed on mains’pressure, the tank precharge

should be set equal to the mains’pressure. For mains’pressure

EN