8

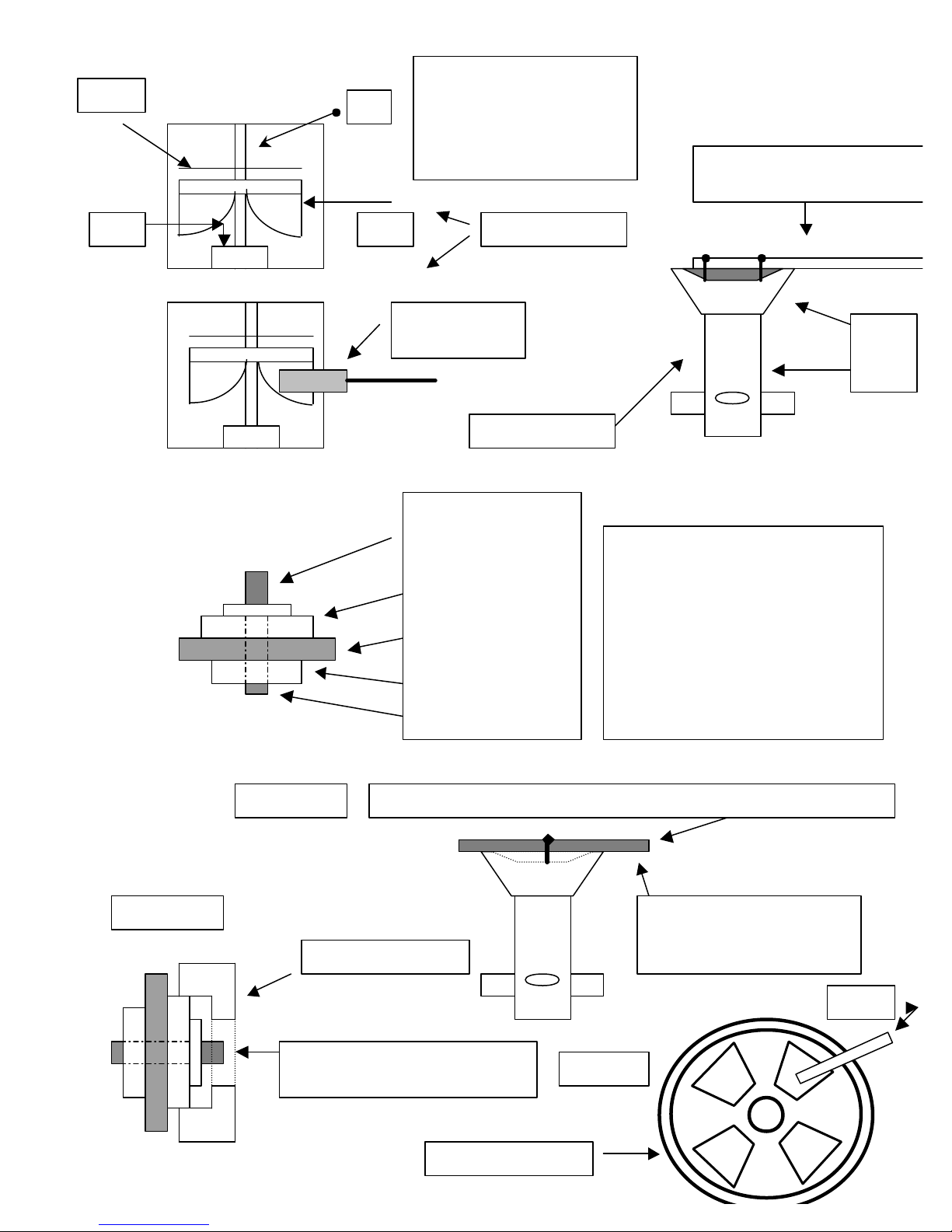

b) C7-41 (6202) Located on the bottom of the armature, You must take the edger apart &

remove the armature to replace this bearing.

i) Remove disc pad (See #1)

ii) Remove the disc guard ring (C7-65), and disc guard (C7-67) (5 screws)

iii) Remove the 6 flat head screws holding the gear housing cover (C7-3) in place.

iv) Using the gear housing cover remover (C7-85) pull the jackshaft, gears and gear housing

cover out of the machine. (Fig. C) Remove the gear housing remover and tap the

jackshaft out of the gear housing cover. (Fig. D)

v) Clean the grease from the base to avoid a mess.

vi) Turn the machine upright.

vii) Remove cover (C7-4) and load spring (C7-12a) (4 screws). Be careful to see how the load

spring comes out of the machine so you can put it back in the proper position.

viii)Mark the top of the Bearing plate (C7-12) with a magic marker to show which side is top.

Remove the bearing plate with a set of pullers.

ix) Remove four housing screws (C7-48) that hold the motor frame (C7-1) to the gear

housing (C7-2).

x) Hold the motor frame on your hip with the lamp shield C7-5) facing out. Gently tap the

gear housing away from the motor frame using a rubber mallet; rotate the housing as

you hit it. The bearing at the base of the armature (C7-41) is seated in the gear

housing, holding the armature in place.

xi) Once the base is remove, flip the motor frame upside down and remove four screws (C7-

47) holding the baffle plate to the motor frame. Pull the armature out of the frame.

xii) Remove the LH nut (C7-45) on the end of the armature. Note the shoulder of this nut

has been machined, the small end face towards the gear. Remove the small gear (C7-11),

spacer (C7-26) and finally the bearing C7-41, (6202).

xiii)Replace the defective bearing and rebuild the armature.

xiv)Reinstall the armature into the motor frame and secure with the four bolts (C7-47).

xv) Line up the bearing (C7-41) with the bearing seat located in the gear housing (C7-2), tap

the top bearing (C7-40) straight down so the bearing is lowered into the seat. Line up

the holes in the motor frame and gear housing and reattach with the bolts (C7-48).

xvi)Turn the unit upside down, and grease the gear housing, small gear and large gear.

xvii) Line the jackshaft up with the gear housing and mesh the large and small gear teeth.

Gently tap the jackshaft back into the gear housing, allowing bearing #3 (C7-61) to be

inserted into its seat. The jackshaft will be install to the correct depth when the teeth

of the two gears are at the same height.

xviii) Line up the gear housing cover with the gear housing and bearing #4 (C7-71) and tap

it back in place. You may want to use a bolt to keep the cover lined up with the holes.

Screw the bolts back into the cover.

xix) Flip the machine over and reinstall the bearing plate, load spring and Cover.

xx) Flip the machine over again, resting on the cover (C7-4) and reinstall the disc guard, disc

guard retainer and disc pad.

c) C7-61 (6203) & C7-71 (6204) Located on the jackshaft.

i) Repeats steps 1-4 for replacing C7-41.

ii) Remove the LH nut from the jackshaft.

iii) Gently tap or press the jackshaft through C7-61 (6203) bearing.

iv) Remove large gear (C7-10) and key. Clean gear and check for wear.