When there is no wind, it consumes the electricity from the battery group. Therefore, after

discharging, the batteries should be recharged soon, especially for lead-acid batteries. If

the batteries cannot be recharged quickly after over discharging, the working life of the

batteries will be reduced. The users should regulate the consumption of electricity

according to local wind conditions and the output of the wind generator, or have alternative

charging methods available.

5.1.3 After passing full wave bridge rectification, the 3-phase AC electricity generated by the

wind generator will output in DC24V, 36V, 48V, or 120V DC to charge the battery group.

The voltage of the battery group should be equal to the DC voltage of the wind generator

(after rectification), so the system works at its full efficiency. The input DC voltage of a

matched inverter should be equal to the working voltage of the wind turbine.

5.1.4 The input DC voltage of the matched inverter should be equal with working voltage of the

wind generator (after rectification).

5.2 Safety Notes

5.2.1 Do not run the wind generator without any load, or run at a very high rotating speed for

long periods of time.

5.2.2 Check the tower condition regularly. If there are any loose components, they should be

tightened immediately, to prevent the wind turbine falling down.

5.2.3 When running speed of the rotor is high, people should not stay under the wind turbine.

5.2.4 When wind speed is more than 24 m/s, the wind turbine should be stopped manually.

5.2.5 When vibration or strange noise is heard while the turbine is working, stop the wind turbine

and find the reason to prevent damage.

5.2.6 The power supply line of the wind generator should be run independently. It can not be

mixed used with other power supply lines. DC power supply is safer and more efficient for

lights. For home electric appliances, an AC power supply line (from an inverter) should

be used. It is suggested that the connector of a refrigerator should be inserted in a special

plug with a timer to control its usage.

5.2.7. When connecting the wires of the wind generating system, the battery lines must be

connected to the controller & inverter box first, then connect the three lines from the

generator to the controller. When disconnecting the wire from the wind generating

system, the three generator lines must be first disconnected from the controller, then

disconnect the two lines of the battery group from the controller & inverter box.

5.2.8 The “RUN & STOP” switch on the controller & inverter box should keep at the “RUN”

position under normal conditions. Only toggle the switch to the “STOP” position when the

batteries have been fully charged or to protect the system against storm winds,. It is not

recommended to move the switch when wind is strong and rotor is rotating at high speed.

Only change the switch to the “STOP” position when rotor is rotating slowly.

5.2.9. The batteries should be installed in a place that is far from fire and heat sources. The gas

generated from the charging and discharging process should be vented from the room.

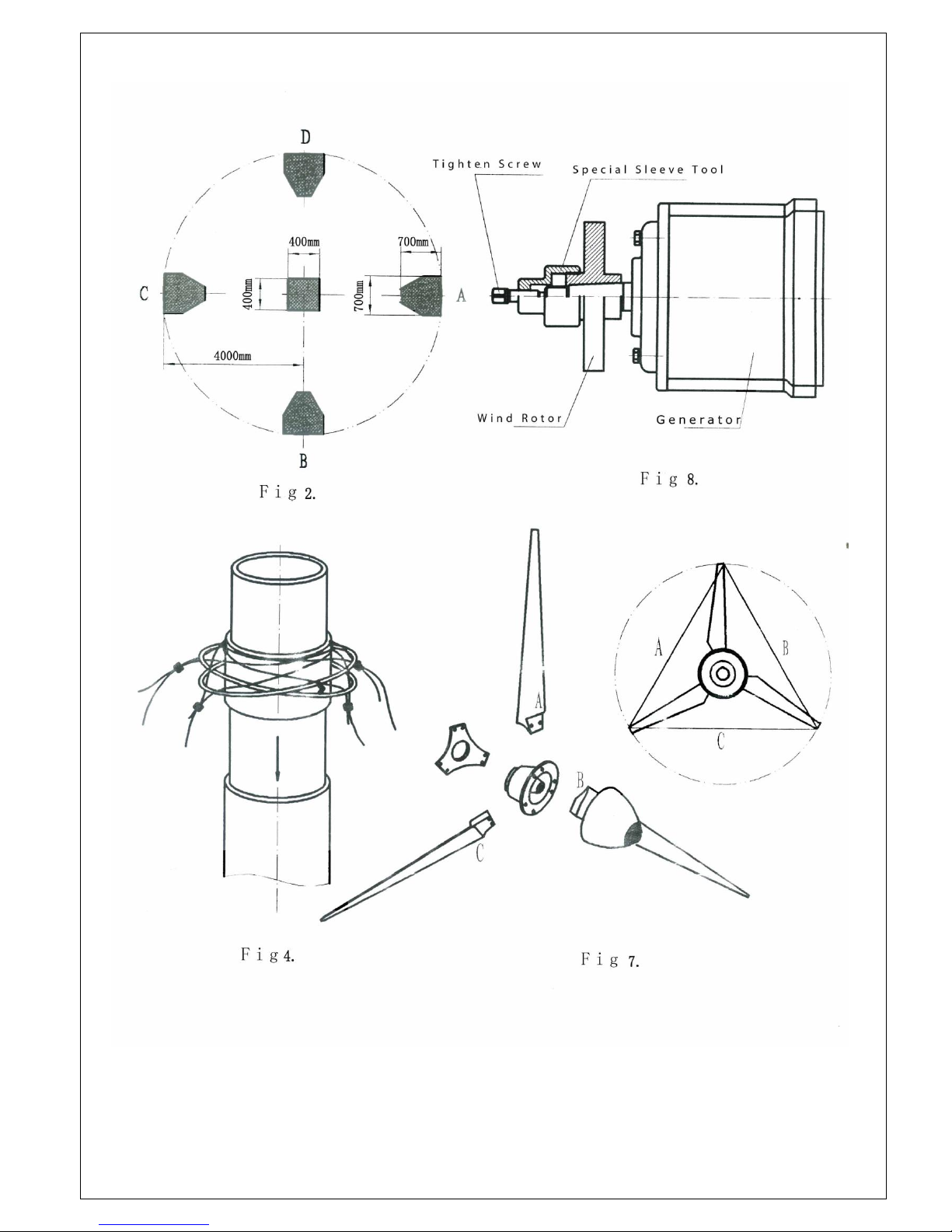

5.3.Keep the rotor balanced, eliminate vibrations

If the blades lose balance due to outside damage and create strong vibrations, the wind

generator must be stopped until the trouble is eliminated. The attached special tools should

be used for disassembling the rotor. Remove the nut and washer from the axes end of

generator first, screw the special sleeve onto the hub firmly, then drive the M16×30 screw